Professional Documents

Culture Documents

1-AVC See-Thru Air Vent: Inlet Alternate Inlet Outlet

Uploaded by

alexander ferraoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-AVC See-Thru Air Vent: Inlet Alternate Inlet Outlet

Uploaded by

alexander ferraoCopyright:

Available Formats

1-AVC See-Thru Air Vent

For Pressures to 150 psig (7 bar) or Specific Gravity Down to 0.80

A See-Thru Body—So You’ll Know When It’s Working

Now, you can literally see what you’ve been missing—the

early warning signs of a system problem. Since you’ll know

the operating condition of the air vent, you won’t have

to waste time and money scheduling maintenance that

isn’t needed. In other words, you will be able to react to a

condition before it becomes a problem.

A simple ball float mechanism requiring no electricity to

operate, the new Armstrong 1-AVC discharges automatically

only when air/gas are present. That means no liquid loss as

with manual venting.

An Inside Look

See-thru body means you can observe changing conditions

as they occur. See a problem in the making—instead of

having to deal with it after the fact.

A

Efficient Operation Alternate

Simple ball float mechanism discharges only when air is Inlet Outlet

present so it doesn’t waste liquid. (vent) 3

2

Positive Seating

Free-floating valve mechanism assures positive seating so B

C

it prevents liquid loss. There are no fixed pivots to wear or

create friction, and wear points are heavily reinforced for

long life.

Reduced Maintenance Inlet

Stainless steel internals mean corrosion resistance and 1-AVC 1

reduced maintenance.

How to Order

Corrosion Resistance Inlet Alternate Inlet Outlet

Long-lasting polysulfone body and reinforced nylon cap

resist corrosion and provide long, trouble-free service life.

3/4” 1/2” 1/2”

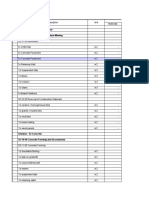

List of Materials

Name of Part Material

1/2” 1/2”

Cap Reinforced Nylon* or or 1/2”

Body Polysulfone 3/4” 3/4”

O-Rings (Body Cap and Fitting) Nitrile Elastomer Compound

Float Lever and Screws Stainless Steel NOTE: The Armstrong 1-AVC should not be used in an

Air Vents

Valve & Seat Stainless Steel environment where there are high levels of ketones or

Fitting & Pipe Plug Reinforced Nylon chlorinated or aromatic hydrocarbons.

Retainer Ring Zinc Plated Steel

*UV sensitive. For a fully detailed certified drawing, refer to CD #1031.

Physical Data Model 1-AVC Capacity

in mm Differential Pressure

Orifice Size scfm m3/hr

Inlet Connection 1/2, 3/4 15, 20 psig bar

Outlet Connection 1/2 15 15 1.0 4.3 7.3

“A” Face-to-Face 3-1/2 89 30 2.0 6.5 11.0

“B” Height 6-3/4 171 50 3.5 9.5 16.1

“C” Bottom to CL 61 52 75 5.0 1/8" 13.1 22.2

Maximum Allowable Pressure (Vessel 150 psig @ 150°F 100 7.0 16.9 28.7

Design) (10 bar @ 65°C) 125 8.5 20.5 34.8

Maximum Operating Pressure 150 psi (10 bar) 150 10.5 24.2 41.3

Specific Gravity Range 1.00 to 0.80 NOTE: Discharge of air through an orifice in scfm (standard cubic feet of free air per

Weight, lb (kg) 1 (.45) minute) at a standard atmospheric pressure of 14.7 psi (1 bar) and 70°F (21°C).

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com for up-to-date information.

454

North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstronginternational.com

Next

You might also like

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- See-thru air vent technical specificationsDocument1 pageSee-thru air vent technical specificationsdavidbejuNo ratings yet

- HBE Anti FlashDocument3 pagesHBE Anti Flashinsult2injuryNo ratings yet

- Rnp Actuator Metso NewDocument11 pagesRnp Actuator Metso NewOGPE-AMC1No ratings yet

- Related Products: Auto Drain Valve: PrecautionsDocument10 pagesRelated Products: Auto Drain Valve: Precautionsteknik otomotifNo ratings yet

- CH 10 Additional ProductsDocument47 pagesCH 10 Additional Productssaddam khanNo ratings yet

- AquaJet 2015 Singlepages WebDocument6 pagesAquaJet 2015 Singlepages WebestyNo ratings yet

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosNo ratings yet

- SERIES 7000/8000: 3 Piece Full Port " - 12"Document8 pagesSERIES 7000/8000: 3 Piece Full Port " - 12"ErickNo ratings yet

- The Axial Flow Valve: Class 300/600Document12 pagesThe Axial Flow Valve: Class 300/600julio cesar ramirez gonzalezNo ratings yet

- BRAY_7500_7700Document4 pagesBRAY_7500_7700omorales.cyvsaNo ratings yet

- Condensed Product CatalogueDocument20 pagesCondensed Product CatalogueMateo Jaramillo EcheverriNo ratings yet

- Catalogue Armacon-Valve 20190522Document26 pagesCatalogue Armacon-Valve 20190522Scipp ZengNo ratings yet

- 2011CDocument4 pages2011CbhaskarbabaiNo ratings yet

- Tomoe Valve-ManualDocument2 pagesTomoe Valve-Manualphuc nguyenNo ratings yet

- L&T Ball Valves: 3-Piece DesignDocument8 pagesL&T Ball Valves: 3-Piece DesignmahaveenNo ratings yet

- Catálogo Conectores PDFDocument16 pagesCatálogo Conectores PDFJulioNo ratings yet

- Valtek Maxflo: Control ValvesDocument11 pagesValtek Maxflo: Control Valvessaroat moongwattanaNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- Seriestvs 4000Document4 pagesSeriestvs 4000Jimit ShahNo ratings yet

- 53VML 30MV Ball Float Vent ValvesDocument2 pages53VML 30MV Ball Float Vent ValvesJose DevilzeusNo ratings yet

- CHOKE Valve - Acv12Document2 pagesCHOKE Valve - Acv12limaeronNo ratings yet

- Ball Valve (Maxflow)Document16 pagesBall Valve (Maxflow)vishnuNo ratings yet

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- Control+Valve Ecotrol Catalog V1R2+19Jan15 Rev2.CompressedDocument20 pagesControl+Valve Ecotrol Catalog V1R2+19Jan15 Rev2.CompressedLionell LogeshNo ratings yet

- 8290 SERIES: Angle Body Piston ValvesDocument12 pages8290 SERIES: Angle Body Piston ValvesCarlos Giovanni Camperos GaitanNo ratings yet

- Fire HydrantsDocument22 pagesFire HydrantsRaduNo ratings yet

- ULT Plug Valves - FMC TechnologiesDocument8 pagesULT Plug Valves - FMC TechnologiesManh TranNo ratings yet

- BRAY F15 Ball ValveDocument12 pagesBRAY F15 Ball ValveRicardoNo ratings yet

- AVK Check Valve BrochureDocument12 pagesAVK Check Valve BrochureDunia AnakNo ratings yet

- Flygt Submersible Pumps for Water & Wastewater ApplicationsDocument7 pagesFlygt Submersible Pumps for Water & Wastewater ApplicationsFredy NoalcaNo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- Tamperproof High-Shock Manual Reset Valves: FeaturesDocument2 pagesTamperproof High-Shock Manual Reset Valves: FeaturesDio MaseraNo ratings yet

- Tom Wheatley Piston Check Valves BrochureDocument8 pagesTom Wheatley Piston Check Valves BrochureRandiRahmansyahNo ratings yet

- Instruments Valve ManifoldDocument7 pagesInstruments Valve ManifoldkicsnerNo ratings yet

- CVS 1000L Electro-Pneumatic Linear Positioner: Product ManualDocument12 pagesCVS 1000L Electro-Pneumatic Linear Positioner: Product Manualmhidayat108No ratings yet

- Flowserve Mark OneDocument20 pagesFlowserve Mark OnetinozasableNo ratings yet

- Design RSS Lined Globe ValveDocument12 pagesDesign RSS Lined Globe Valveyenifer garciaNo ratings yet

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDocument8 pagesW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999No ratings yet

- VST - Axial Flow Catalog - 2021.R010Document6 pagesVST - Axial Flow Catalog - 2021.R010Jaydeep PanchalNo ratings yet

- Auslite Iii Gate Valves-Iso Mount: Resilient Seated - DN 80 To DN 400Document3 pagesAuslite Iii Gate Valves-Iso Mount: Resilient Seated - DN 80 To DN 400Akshat JainNo ratings yet

- KennedyDocument18 pagesKennedyHimat KhimaniNo ratings yet

- Guardian K81D Hydrant Meets AWWA and UL/FM StandardsDocument18 pagesGuardian K81D Hydrant Meets AWWA and UL/FM Standardsvicvic34No ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- BushingDocument24 pagesBushingElliza IshakNo ratings yet

- Pressure SwitchesDocument4 pagesPressure SwitcheshaggNo ratings yet

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- TOO Catalog File 2022 - 30.10.22Document6 pagesTOO Catalog File 2022 - 30.10.22Hen BenjaminNo ratings yet

- Bypass Blow Valve: Reliable TightDocument2 pagesBypass Blow Valve: Reliable TightAlejo ObregonNo ratings yet

- Check Valves Complete Catalog-2012Document6 pagesCheck Valves Complete Catalog-2012FAUSTO LEINESNo ratings yet

- Auslite Iii Gate Valves-Handwheel: Resilient Seated - DN 80 To DN 400Document3 pagesAuslite Iii Gate Valves-Handwheel: Resilient Seated - DN 80 To DN 400Akshat JainNo ratings yet

- AVK Gate Valve Maintenance-Free Design ConceptDocument8 pagesAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNo ratings yet

- Butterfly Valves: EngineeringDocument12 pagesButterfly Valves: EngineeringKarla RamirezNo ratings yet

- Double Offset High Performance Butterfly Valves: DescriptionDocument16 pagesDouble Offset High Performance Butterfly Valves: Descriptionmanmohansingh1999No ratings yet

- Jet Butterfly ValveDocument12 pagesJet Butterfly Valvesin67438No ratings yet

- ASME Safety Relief Valves for Boilers & Pressure VesselsDocument9 pagesASME Safety Relief Valves for Boilers & Pressure VesselsscribpenumakaNo ratings yet

- TT OpEXL Eccentric Plug Rotary Valve BrochureDocument16 pagesTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezNo ratings yet

- Tyco Valves & Controls CatalogDocument6 pagesTyco Valves & Controls CatalogHasanNo ratings yet

- Bfe API 6a ValvesDocument32 pagesBfe API 6a ValvesAldo P WicaksanaNo ratings yet

- R&D AXIAL FLOW CONTROL VALVESDocument2 pagesR&D AXIAL FLOW CONTROL VALVESnandkishorNo ratings yet

- Inna Phos Diammonium Phosphate MSDSDocument9 pagesInna Phos Diammonium Phosphate MSDSjosephNo ratings yet

- 01 The-Mckinsey-Edge-Hattori-En-26154Document5 pages01 The-Mckinsey-Edge-Hattori-En-26154Waqar AhmedNo ratings yet

- Cebuano LanguageDocument15 pagesCebuano LanguageIsla PageNo ratings yet

- If Sentences Type 1 First Type Conditionals Grammar Drills - 119169Document2 pagesIf Sentences Type 1 First Type Conditionals Grammar Drills - 119169Ivanciu DanNo ratings yet

- Deutsche BankDocument4 pagesDeutsche BankMukesh KumarNo ratings yet

- The Joint Force Commander's Guide To Cyberspace Operations: by Brett T. WilliamsDocument8 pagesThe Joint Force Commander's Guide To Cyberspace Operations: by Brett T. Williamsأريزا لويسNo ratings yet

- 2019 Implementasie-SamsatdiBaliDocument10 pages2019 Implementasie-SamsatdiBaliDiannita SusantiNo ratings yet

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- Bahasa Inggris Kelas XIIDocument2 pagesBahasa Inggris Kelas XIIMuhammad ImadudinNo ratings yet

- Climate Change Survivor GameDocument22 pagesClimate Change Survivor Game许凉发No ratings yet

- GSAA HET 2005-15, Tranche B2 / BSABS 2005-TC2, Tranche M6 Shown As An Asset of Maiden LaneDocument122 pagesGSAA HET 2005-15, Tranche B2 / BSABS 2005-TC2, Tranche M6 Shown As An Asset of Maiden LaneTim BryantNo ratings yet

- Wolfgang KohlerDocument16 pagesWolfgang KohlerMaureen JavierNo ratings yet

- Tax1 Course Syllabus BreakdownDocument15 pagesTax1 Course Syllabus BreakdownnayhrbNo ratings yet

- School of Education, Arts and Sciences General Education Area 1 SEMESTER S.Y 2021-2022Document4 pagesSchool of Education, Arts and Sciences General Education Area 1 SEMESTER S.Y 2021-2022JaylordPalattaoNo ratings yet

- COR2-03 Admist The Mists and Coldest Frost PDFDocument16 pagesCOR2-03 Admist The Mists and Coldest Frost PDFLouis BachNo ratings yet

- Analects of A.T. Still-Nature Quotes-UnboundedDocument8 pagesAnalects of A.T. Still-Nature Quotes-UnboundedBruno OliveiraNo ratings yet

- CARP Law NotesDocument5 pagesCARP Law NotesJustisia KaunlaranNo ratings yet

- Theory and Practice of Crown and Bridge Prosthodontics 4nbsped CompressDocument1,076 pagesTheory and Practice of Crown and Bridge Prosthodontics 4nbsped CompressYuganya SriNo ratings yet

- Hunk 150Document2 pagesHunk 150Brayan Torres04No ratings yet

- RTR Piping Inspection GuideDocument17 pagesRTR Piping Inspection GuideFlorante NoblezaNo ratings yet

- Psych 1xx3 Quiz AnswersDocument55 pagesPsych 1xx3 Quiz Answerscutinhawayne100% (4)

- AlternatorDocument3 pagesAlternatorVatsal PatelNo ratings yet

- 1.1 Enterprise AssessmentDocument1 page1.1 Enterprise AssessmentGermanRobertoFongNo ratings yet

- Shooting ScriptDocument12 pagesShooting Scriptapi-544851273No ratings yet

- Medication Calculation Examination Study Guide: IV CalculationsDocument2 pagesMedication Calculation Examination Study Guide: IV Calculationswaqas_xsNo ratings yet

- Technical Information System Overview Prosafe-Com 3.00 Prosafe-ComDocument49 pagesTechnical Information System Overview Prosafe-Com 3.00 Prosafe-Comshekoofe danaNo ratings yet

- Api RP 2a WSD 1pdf - CompressDocument1 pageApi RP 2a WSD 1pdf - CompressRamesh SelvarajNo ratings yet

- Lodha GroupDocument2 pagesLodha Groupmanish_ggiNo ratings yet

- ECE SAR OldDocument168 pagesECE SAR OldNagaraja RaoNo ratings yet

- LETTER OF AUTHORIZATION CREDO INVEST DownloadDocument1 pageLETTER OF AUTHORIZATION CREDO INVEST DownloadEsteban Enrique Posan BalcazarNo ratings yet