Professional Documents

Culture Documents

GSS-SWI-002-0005 Reserval Gas Analyser Function Test V2!2!6476903 - 01

Uploaded by

alfonzitoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GSS-SWI-002-0005 Reserval Gas Analyser Function Test V2!2!6476903 - 01

Uploaded by

alfonzitoCopyright:

Available Formats

RESERVAL GAS ANALYSER FUNCTION TEST

PPE Required:

OPERATIONAL STEPS

Introduction: this procedure validates the general function of the Reserval gas

analyzer. Use this procedure when starting up a Reserval at a new location, or

to re-validate the Reserval installation at an existing location.

1. Verify that the compressor air intake is located in uncontaminated air.

2. Verify that the Reserval lines from gas exhaust 1 and 2 are installed and

terminate outside the mud logging cabin.

3. Verify the air compressor regulator output pressure (min. 3 bars).

4. Verify the H2 Generator output pressure (0.5 bars).

5. Switch the Reserval ON, and wait for ignition of the FID flames.

6. Turn on the pump(s).

7. On the Reserval, verify on the screen that the pressures are within the

working range: air pressure 2 bar, H2 Pressure 0.5 bar, Gas OUT / Gas IN:

1.0 bar +/- 0.1 bar).

Continued on next page

GSS-SWI-002-0005 Schlumberger Private Page 1 of 5

RESERVAL GAS ANALYSER FUNCTION TEST

8. Verify on the Reserval screen that the flow rates are within the working range

(450 cc/min +/- 20 cc/min or 500 cc/min +/- 20 cc/min if Isotope Analyser is in

use).

9. Verify on the Reserval screen the FID Cell and column oven temperatures

are within the required operating range (FID: 150 deg. C +/- 2 deg. C,

Column oven: 50 deg. C +/- 0.5 deg C).

10. Wait for the baseline to become stable.

11. When the baseline is stable, carry out a full calibration check with

reference gases prior to commencing operations.

END OF OPERATIONAL STEPS

GSS-SWI-002-0005 Schlumberger Private Page 2 of 5

RESERVAL GAS ANALYSER FUNCTION TEST

DETAILED PROCEDURE

Step Action Figures/comments

1. Verify that the compressor air intake is The preferred location is inside the mud logging unit,

located in uncontaminated air. at or near the air inlet of the pressurization system.

Intake from outside the unit is generally not

desirable, due to potentially high humidity and

day/night or seasonal temperature variations.

2 Verify that the lines from gas exhaust 1 and 2 CAUTION: exhaust inside the cabin can result in

are installed and terminate outside the mud accumulation of toxic and/or flammable gases.

logging cabin.

3. Verify the air compressor regulator output Minimum pressure 3 bar.

pressure.

4. Verify the H2 Generator output pressure. Output pressure 0.50 bar.

Continued on next page

GSS-SWI-002-0005 Schlumberger Private Page 3 of 5

RESERVAL GAS ANALYSER FUNCTION TEST

Step Action Figures/comments

5. Switch the Reserval ON, and wait for ignition

of the FID flames.

6. Turn on the pump(s). Pump OUT if only gas OUT is being measured; Pump

OUT and Pump IN if Gas OUT-Gas IN measurement.

7. Verify that the pressures are within the Air pressure: 2 bar

working range. H2 Pressure 0.5 bar

Gas OUT: 1.0 bar +/- 0.1 bar

Gas IN (if used): 1.0 bar +/- 0.1 bar

8. Verify that the flow rates are within the Flow OUT if only gas OUT is being measured; Flow

working range. OUT and Flow IN if Gas OUT-Gas IN measurement.

Flow rate 450 cc/min +/- 20 cc/min or 500 cc/min +/-

20 cc/min if Isotope analyser is in use.

9. Verify the FID Cell and column oven FID: 150 deg. C +/- 2 deg. C:

temperatures are within the required Column oven: 50 deg. C +/- 0.5 deg C

operating range.

Continued on next page

GSS-SWI-002-0005 Schlumberger Private Page 4 of 5

RESERVAL GAS ANALYSER FUNCTION TEST

Step Action Figures/comments

10. Wait for the baseline to become stable. 10 mV, +/- 1 mV

11. When the baseline is stable, carry out a full

calibration check with reference gases prior

to commencing operations (See Reserval V2

Manual, InTouch 5664343, sections 6-3 and

6-4, for procedure). Measured Gas concentration must fall within

required tolerance:

PPM C1 C2 C3 iC4 nC4 iC5 nC5

Injection #1 100 25 25 25 25 25 25

Injection #2 1000 250 250 250 250 250 250

Injection #3 10000 2500 2500 2500 2500 2500 2500

Injection #4 50000 12500 12500 12500 12500 5000 5000

Injection #5 100000 25000 25000 25000 25000 10000 10000

5% error acceptable 10% error acceptable

If calibration check results do not fall within the acceptable range, perform another calibration, followed by a

new calibration check.

END OF PROCEDURE

Sub Segment Date Version Developed by: Reviewed by: Validated by: Approved by:

GSS 20 Nov. 2014 2.2 G. Haines P. Laz P. Laz/ D. Kumar

G. Haines

GSS-SWI-002-0005 Schlumberger Private Page 5 of 5

You might also like

- FHP011 03Document10 pagesFHP011 03Omonigho SapeleNo ratings yet

- Pipesim 2006.1 Fundamentals GasliftDocument13 pagesPipesim 2006.1 Fundamentals GasliftamulyanaNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Modulus II PlusDocument10 pagesModulus II PlusMiguelNo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- BOOK 09 - MaintananceDocument15 pagesBOOK 09 - MaintananceShau WilliamNo ratings yet

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- UOP Method 603-97 CO and CO2 в Газах Хро&#Document6 pagesUOP Method 603-97 CO and CO2 в Газах Хро&#Khalida MuddasserNo ratings yet

- Leak Standard LS-20B-instruction-manualDocument20 pagesLeak Standard LS-20B-instruction-manualVadim RiabovNo ratings yet

- Valvula de Gas HoneyWell VS820 - VS821Document16 pagesValvula de Gas HoneyWell VS820 - VS821John Carmona100% (1)

- Troubleshooting in Syngas PlantDocument91 pagesTroubleshooting in Syngas Plantprasada raoNo ratings yet

- 4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The ComplexDocument5 pages4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The Complexkirandevi1981No ratings yet

- A2 1 KMACS 5 Annual Inspection Maintenance Checklist 220909001Document7 pagesA2 1 KMACS 5 Annual Inspection Maintenance Checklist 220909001evayoscar98No ratings yet

- Proceso de Mantenimiento Maquina AnestesiaDocument20 pagesProceso de Mantenimiento Maquina AnestesiaSHIRLEY GIRALDONo ratings yet

- Process Description GCS-1Document23 pagesProcess Description GCS-1seeker4earth0% (1)

- RWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Document2 pagesRWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Antonio TorresNo ratings yet

- Gas Reference Package: This Document Is Free To Download and Copy From WWW - Gb-Gas - Co.ukDocument29 pagesGas Reference Package: This Document Is Free To Download and Copy From WWW - Gb-Gas - Co.ukQco MyNo ratings yet

- SOP - ID FanDocument2 pagesSOP - ID Fanarvidkumar87060No ratings yet

- Batu Pig Valve Brochure v4Document16 pagesBatu Pig Valve Brochure v4Tariq NbsNo ratings yet

- RWRG0051 - Splitter Complaint - Fault Code 42: Pre-Authorized Warranty Repair Guideline RWRG0051Document2 pagesRWRG0051 - Splitter Complaint - Fault Code 42: Pre-Authorized Warranty Repair Guideline RWRG0051Z MuvingiNo ratings yet

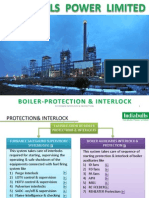

- Indiabulls Power Limited: SOP/OPNS/10 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/10 Operations DepartmentAmit SoniNo ratings yet

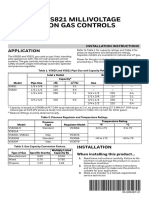

- VR8304 Intermittent Pilot Combination Gas Control: ApplicationDocument8 pagesVR8304 Intermittent Pilot Combination Gas Control: ApplicationGregorio Mata MartínezNo ratings yet

- Alarms and Action List of Turbine Oil SystemDocument6 pagesAlarms and Action List of Turbine Oil SystemMuhammad Junaid KhanNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- n25 ManualDocument12 pagesn25 ManualRikshita Agarwal100% (1)

- 1 RC Feeder Interlock & ProtectionDocument76 pages1 RC Feeder Interlock & Protectionarvidkumar87060No ratings yet

- 7800 - Relay Cleaver BroksDocument20 pages7800 - Relay Cleaver Broksrubl770622No ratings yet

- 03.SOP For Air CompressorDocument4 pages03.SOP For Air CompressorThangella Vijayaramaraju100% (2)

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- Bump Test Procedure For Single Gas DetectorDocument1 pageBump Test Procedure For Single Gas Detectorwilson dsouzaNo ratings yet

- Macurco CM6-FCK UserManualDocument4 pagesMacurco CM6-FCK UserManualTrí NguyễnNo ratings yet

- Sop For BFPDocument2 pagesSop For BFPSUBHASISH MUKHERJEENo ratings yet

- 5LB - SO2 - InstructionsDocument1 page5LB - SO2 - InstructionsAtul SharmaNo ratings yet

- A-4000 OElindikator GBDocument4 pagesA-4000 OElindikator GBmadiNo ratings yet

- Medical Air-Oxygen Blender Instruction ManualDocument22 pagesMedical Air-Oxygen Blender Instruction ManualHendra PurnamaNo ratings yet

- Diagnostic Information and Procedures: Special ToolsDocument249 pagesDiagnostic Information and Procedures: Special Toolsjosecuellar69No ratings yet

- Indiabulls Power Limited: SOP/OPNS/09 Operations DepartmentDocument3 pagesIndiabulls Power Limited: SOP/OPNS/09 Operations DepartmentAmit Soni100% (1)

- Procedure For Burner Handover and TakeoverDocument7 pagesProcedure For Burner Handover and TakeoverArjun Shantaram ZopeNo ratings yet

- Pka-Rp60Kal - TH Pka-Rp71Kal - TH PKA-RP100KAL - TH: Service ManualDocument32 pagesPka-Rp60Kal - TH Pka-Rp71Kal - TH PKA-RP100KAL - TH: Service ManualВладимир НаумычNo ratings yet

- Testing and Adjusting Bomba Hidraulica d6n - AlyDocument5 pagesTesting and Adjusting Bomba Hidraulica d6n - AlyElibey Cuadros BerbesiNo ratings yet

- Standard Operating Procedures: Prepared By: Approved By: Date: Department: Page NoDocument2 pagesStandard Operating Procedures: Prepared By: Approved By: Date: Department: Page NovictorNo ratings yet

- CalibrationDocument8 pagesCalibrationJefford Klein GogoNo ratings yet

- Functional Performance Test: FT: 15990-2 Item: Calibration and Leak-By Test Procedures ID: Area ServedDocument4 pagesFunctional Performance Test: FT: 15990-2 Item: Calibration and Leak-By Test Procedures ID: Area Servedvin ssNo ratings yet

- Gas Reference Package: This Document Is Free To Download and Copy From WWW - Gb-Gas - Co.ukDocument29 pagesGas Reference Package: This Document Is Free To Download and Copy From WWW - Gb-Gas - Co.ukPaul HorriganNo ratings yet

- OPERATIONAL QUALIFICATION OF AIR COMPRESSOR - Pharmaceutical GuidanceDocument8 pagesOPERATIONAL QUALIFICATION OF AIR COMPRESSOR - Pharmaceutical GuidanceWilliams Lucky Elvis100% (1)

- Dichtheitspruefung - 300 S 9010595 enDocument7 pagesDichtheitspruefung - 300 S 9010595 enSam WildNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument3 pagesSteam Power Plant Standard Operating ProceduresganimechNo ratings yet

- Series PEAD R407C/R410A: Split-Type, Heat Pump Air ConditionersDocument34 pagesSeries PEAD R407C/R410A: Split-Type, Heat Pump Air ConditionersGiovani RodriguesNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- SOP On Operation, Cleaning and Monitoring of Laminar Air Flow.Document3 pagesSOP On Operation, Cleaning and Monitoring of Laminar Air Flow.RainMan75100% (2)

- Group 4 Tests and Adjustments Group 4 Tests and AdjustmentsDocument10 pagesGroup 4 Tests and Adjustments Group 4 Tests and AdjustmentsSaidi JalelNo ratings yet

- WC Daily Checklist Procedure - v1.1 - MH-1Document13 pagesWC Daily Checklist Procedure - v1.1 - MH-1Hatem RmNo ratings yet

- Power Plant Emergency InsructionDocument14 pagesPower Plant Emergency InsructionbatporaNo ratings yet

- Airtester HP-3-GB D3188001 03Document7 pagesAirtester HP-3-GB D3188001 03federalulNo ratings yet

- Reguladores de Presion para LPGDocument4 pagesReguladores de Presion para LPGNelson VargasNo ratings yet

- Steam Power Plant Standard Operating ProceduresDocument4 pagesSteam Power Plant Standard Operating Proceduresarvidkumar8706050% (4)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- GSS-SWI-009-0010C Autocalcimeter Preparing Samples Final 6691901 01Document1 pageGSS-SWI-009-0010C Autocalcimeter Preparing Samples Final 6691901 01alfonzitoNo ratings yet

- GSS-CHL-009-0710 Before ACC TOC Measurement Final 6683043 01Document1 pageGSS-CHL-009-0710 Before ACC TOC Measurement Final 6683043 01alfonzitoNo ratings yet

- GSS-SWI-006-0701 ACC XRF Exporting Data Final 6682068 01Document7 pagesGSS-SWI-006-0701 ACC XRF Exporting Data Final 6682068 01alfonzitoNo ratings yet

- GSS-CHL-009-0710 Before ACC TOC Measurement Final 6683043 01Document1 pageGSS-CHL-009-0710 Before ACC TOC Measurement Final 6683043 01alfonzitoNo ratings yet

- GSS-CHL-009-0702 - Before Operation ACC - HRDM - Final - 6656642 - 01 - 6592525 - 01Document1 pageGSS-CHL-009-0702 - Before Operation ACC - HRDM - Final - 6656642 - 01 - 6592525 - 01alfonzitoNo ratings yet

- GSS-CHL-009-0705 Before Preparing Pellet For ACC XRF Final 6656710 01 6595755 01Document1 pageGSS-CHL-009-0705 Before Preparing Pellet For ACC XRF Final 6656710 01 6595755 01alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'Document1 pageHIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 pageHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'Document1 pageHIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 pageHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 pageHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 pageHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoNo ratings yet

- HIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'Document1 pageHIDRAULICA MPJ9-08 19 - 11 - 17 - Hoyo 8.5'' at 511'alfonzitoNo ratings yet

- Archie Hingle PickettDocument24 pagesArchie Hingle PickettVedarini Saraswati0% (1)

- Akg-A/Akgs-A: Gate ValvesDocument6 pagesAkg-A/Akgs-A: Gate Valvesedark2009No ratings yet

- OrificeDocument7 pagesOrificeVarsha GaikwadNo ratings yet

- Orifice PlateDocument2 pagesOrifice Platevijay kumar honnaliNo ratings yet

- Gas chlorinator-MTP1Document2 pagesGas chlorinator-MTP1Achira Chanaka PeirisNo ratings yet

- Multiport Valve Brochures SinglePage enDocument12 pagesMultiport Valve Brochures SinglePage enTrung Van BaNo ratings yet

- TemplateDocument10 pagesTemplateAudrey LaiNo ratings yet

- (Chapter 6) Examples PDFDocument6 pages(Chapter 6) Examples PDFKarwan GoodNo ratings yet

- CH 3Document5 pagesCH 3Amaterasu Susanoo Tsukuyomi100% (3)

- Example of Diffuser Calculation ReportDocument6 pagesExample of Diffuser Calculation ReportigarneroNo ratings yet

- HSV1 TB02 Table of ContentsDocument13 pagesHSV1 TB02 Table of Contentsعبدالرحمن احمد سيد ابوسريعNo ratings yet

- Flow Sheet Eh-500fk 1000-030-9846Document1 pageFlow Sheet Eh-500fk 1000-030-9846thanh thien nguyenNo ratings yet

- Introduction To Gas Turbine: 1. Operating PrincipleDocument6 pagesIntroduction To Gas Turbine: 1. Operating PrincipleMuhammad Ridhwan100% (2)

- ACU - 07 Air Compressor Atlas Copco XAMS.355Md Cap. 750 CFMDocument68 pagesACU - 07 Air Compressor Atlas Copco XAMS.355Md Cap. 750 CFMGanda SaputraNo ratings yet

- DOPAK - Closed - LPG - S32-LG Expansion Chamber & Bypass Purge F5Document2 pagesDOPAK - Closed - LPG - S32-LG Expansion Chamber & Bypass Purge F5Chia Sze KiatNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument9 pagesPVM (X) Series: Vertical Multistage PumpsDiego MorenoNo ratings yet

- REFRIGERATIONDocument5 pagesREFRIGERATIONRonnieNo ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- Ppe Steam CondenserDocument27 pagesPpe Steam CondenserNilesh SinghNo ratings yet

- INSTALACION Valvula Reguladora de PresionDocument2 pagesINSTALACION Valvula Reguladora de Presionfabian cardenasNo ratings yet

- How To Use This Catalog: Eearo-Orones 1soso0oDocument46 pagesHow To Use This Catalog: Eearo-Orones 1soso0omk saravananNo ratings yet

- Aircraft Hydraulic SystemDocument23 pagesAircraft Hydraulic SystemmaruliNo ratings yet

- Design of Hydraulic and Pneumatic SystemsDocument11 pagesDesign of Hydraulic and Pneumatic SystemsBoopathi Kalai100% (1)

- Hydraulic: Alphabetical Table of ContentsDocument34 pagesHydraulic: Alphabetical Table of ContentsRica RdoNo ratings yet

- 0 Basic Principle of Pneumatic CircuitsDocument76 pages0 Basic Principle of Pneumatic CircuitsBayu RafliNo ratings yet

- Robinair ACM 3000Document31 pagesRobinair ACM 3000cica1234100% (1)

- Water Hammer KSB PumpsDocument34 pagesWater Hammer KSB Pumpsfuji6500100% (12)

- Hydraulic Pressure Control Valves - OOVAL - Product CatalogDocument16 pagesHydraulic Pressure Control Valves - OOVAL - Product CatalogIsrael Exporter100% (2)

- 17421-2019-Winter-Question-Paper (Msbte Study Resources)Document4 pages17421-2019-Winter-Question-Paper (Msbte Study Resources)Pranay ManwarNo ratings yet

- Air Vent Valve Air Vent Valve With Vacuum BreakerDocument28 pagesAir Vent Valve Air Vent Valve With Vacuum BreakerDidik HariantoNo ratings yet

- 2-Page Leaflet KWP - Pump For Solids-Laden FluidsDocument2 pages2-Page Leaflet KWP - Pump For Solids-Laden FluidsGino Chavez ValenciaNo ratings yet