Professional Documents

Culture Documents

Hydraulic System Reservoir-Maintenance Practices 1. General

Uploaded by

Antonio CorteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic System Reservoir-Maintenance Practices 1. General

Uploaded by

Antonio CorteCopyright:

Available Formats

Print Date: Thu Aug 06 07:53:09 CEST 2009 MODEL 550 Bravo MAINTENANCE MANUAL (Rev 22)

29-11-01 (Rev 17)

HYDRAULIC SYSTEM RESERVOIR- MAINTENANCE PRACTICES

1. General

A. Maintenance of the hydraulic reservoir is mainly removal, installation, inspection and replacing

hydraulic low-fluid warning switch. If internal leakage or leaking of the reservoir case is apparent,

the reservoir requires replacement. Special tools are required to successfully disassemble

and assemble the reservoir. Observe phosphate ester base hydraulic fluid precautions during

maintenance of the reservoir. Refer to Main Hydraulic System - Maintenance Practices.

2. Description

A. The reservoir is self-pressurizing with hydraulic system pressure up to 1500 PSI (10342.4 kPa)

pushing on a small diameter piston that is connected to a large diameter surface in the fluid reservoir.

The area of the large surface (34.17 square inches) is approximately 120 times the area of the

small piston (0.285 square inch), to maintain 15 to 16 PSI (103.42 to110.31 kPa) on the fluid in the

reservoir. The large surface is also spring- loaded to maintain 2.7 to 4.0 PSI (18.61 to 27.57 kPa)

on the fluid reservoir and the hydraulic system when the engine-driven pumps are not operating.

B. A pressure relief valve is installed in the low-pressure area of the fluid reservoir. The valve starts

to open at 40 PSI (275.79 kPa) and is fully open at 60 PSI (413.69 kPa). When the fluid reservoir

is filled to capacity (150 cubic inches (2.458 l)), the relief valve is opened mechanically to drain

excess fluid. The relief valve may be operated manually to bleed off air and relieve pressure prior

to working on the hydraulic system. Entrapped air is the first to be expelled.

C. The large surface of the fluid reservoir is connected to an indicator for visual indication of fluid level.

A switch (S90) is included to illuminate a warning light on the annunciator panel when the fluid is

at minimum operating volume.

3. Hydraulic System Reservoir Removal/Installation

A. Remove the Hydraulic System Reservoir. Refer to Figure 201, Sheet 1, for Airplanes -1055 and

On. Refer to Figure 201, Sheet 2, for Airplanes -0801 thru -1054.

(1) Disengage circuit breaker (CB71) on the LH circuit breaker panel.

(2) Depressurize and drain the reservoir. Refer to Main Hydraulic System - Maintenance

Practices.

(3) Disconnect the electrical leads to the hydraulic low-fluid warning switch (S90) at the splices.

(4) Disconnect the relief line assembly, vent line assembly, right and left suction line assemblies,

and the drain line assemblies.

(5) On Airplanes -1055 and On, disconnect the main hydraulic return line assembly and the

landing gear hydraulic return line assembly. Refer to Figure 201, Sheet 1.

(6) On Airplanes -0801 thru -1054, disconnect the hydraulic return line assembly. Refer to Figure

201, Sheet 2.

(7) Disconnect the pressure line assembly.

(8) Put a cap on all of the line assemblies to prevent foreign object debris in the the hydraulic

system.

(9) Remove the bolts and washers that hold the reservoir in position.

(10) Remove the reservoir from the airplane.

(11) If you install a new or replacement reservoir, remove the hardware, fittings, and packings as

needed. Keep the hardware and fittings for reassembly and discard the packings.

B. Install the Hydraulic System Reservoir. Refer to Figure 201, Sheet 1, for Airplanes -1055 and On.

Refer to Figure 201, Sheet 2, for Airplanes -0801 thru -1054.

(1) Use new packings, fittings, and hardware when you install a new or replacement reservoir.

(2) Install the reservoir in the airplane with new hardware as needed.

(3) Connect the relief line assembly, vent line assembly, right and left suction line assemblies,

drain line assembly, and the pressure line assembly.

(a) On Airplanes -1055 and On, connect the main hydraulic return line assembly and

the landing gear hydraulic return line assembly. Refer to Chapter 20, Torque Data

- Maintenance Practices.

(b) On Airplanes -0801 thru -1054, connect the hydraulic return line assembly. Refer to

Chapter 20, Torque Data - Maintenance Practices.

© 2009 Cessna Aircraft Company

Retain printed data for historical reference only. For future maintenance, use only current data. Page 1

Print Date: Thu Aug 06 07:53:09 CEST 2009 MODEL 550 Bravo MAINTENANCE MANUAL (Rev 22)

29-11-01 (Rev 17)

(4) Connect the electrical leads to the hydraulic low-fluid warning switch (S90) at the splices.

(5) Engage circuit breaker (CB71) on the LH circuit breaker panel.

(6) Service hydraulic reservoir; refer to Chapter 12, Hydraulic Power System - Servicing. Check

lines and fittings for leaks.

(7) Cycle speed brakes three to four times and recheck for leaks.

(8) Disconnect and remove hydraulic service unit and install dust caps; close hydraulic service

door.

4. Manual Pressure Relief Valve Assembly Removal/Installation

A. Remove the Manual Pressure Relief Valve Assembly. Refer to Figure 201.

(1) Drain hydraulic reservoir, refer to Main Hydraulic System - Maintenance Practices.

(2) Cut safety wire and remove bolt securing manual pressure relief valve assembly to reservoir.

(3) Disconnect and cap relief line assembly.

(4) Remove manual pressure relief valve assembly from reservoir by pulling horizontally along

the axis of the reservoir.

NOTE: Use caution not to damage sight gage when removing relief valve assembly.

(5) Remove packing (O-ring) from manual pressure relief valve assembly.

B. Install the Manual Pressure Relief Valve Assembly. Refer to Figure 201.

(1) Install new packing in manual pressure relief valve assembly.

(2) Install manual pressure relief valve assembly on reservoir. Secure with bolt and safety wire.

Refer to Chapter 20, Torque Data - Maintenance Practices, and Safetying - Maintenance

Practices.

NOTE: Use caution to prevent sight gage from pinching or cutting packing as sight gage slips

into manual pressure relief valve assembly.

(3) Connect relief line assembly to manual pressure relief valve assembly.

(4) Service hydraulic reservoir, refer to Chapter 12, Hydraulic Power System - Servicing.

(5) Operate hydraulic system and check operation and for leaks.

5. Inspection/Check

A. Visual Inspection.

(1) Visually inspect attaching lines and fittings for hydraulic leaks. If a leak occurred, check area

where hydraulic fluid landed and/or collected.

(2) Check hydraulic low-fluid warning switch (S90) for security and damage.

(3) Inspect reservoir mounting bolts for tightness.

(4) Inspect reservoir for damage (dents, corrosion, etc.).

© 2009 Cessna Aircraft Company

Retain printed data for historical reference only. For future maintenance, use only current data. Page 2

Print Date: Thu Aug 06 07:53:09 CEST 2009 MODEL 550 Bravo MAINTENANCE MANUAL (Rev 22)

29-11-01 (Rev 17)

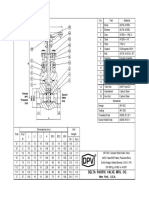

Figure 201. Hydraulic Reservoir Installation

A63188

RELIEF LINE

ASSEMBLY

ELBOW

NUT

MANUAL

PRESSURE RELIEF

VALVE ASSEMBLY

PACKING

PACKING

HYDRAULIC LOW#

SIGHT GAGE FLUID WARNING

PACKING SWITCH

UNION

PRESSURE LINE

VENT LINE

ASSEMBLY

ASSEMBLY

UNION

PACKING

PACKING

UNION

TEE

HYDRAULIC

RESERVOIR

REDUCER

RETURN LINE PACKING

ASSEMBLY NUT

LANDING GEAR RETURN LINE

TEE RIGHT SUCTION LINE

ASSEMBLY

LEFT SUCTION LINE

ASSEMBLY

PACKING

REDUCER

DRAIN LINE ASSEMBLY

DETAIL A 6517T1006A

AIRPLANES #1055 AND ON A6517T1013A

Sheet 1 of 3

© 2009 Cessna Aircraft Company

Retain printed data for historical reference only. For future maintenance, use only current data. Page 3

Print Date: Thu Aug 06 07:53:09 CEST 2009 MODEL 550 Bravo MAINTENANCE MANUAL (Rev 22)

29-11-01 (Rev 17)

A23540

RELIEF LINE

ASSEMBLY

ELBOW

NUT

MANUAL

PRESSURE RELIEF

VALVE ASSEMBLY

PACKING

PACKING HYDRAULIC LOW#

FLUID WARNING

SIGHT GAGE SWITCH

PACKING

UNION

PRESSURE LINE VENT LINE

ASSEMBLY ASSEMBLY

UNION

PACKING

PACKING

UNION

HYDRAULIC

RESERVOIR

REDUCER

RETURN LINE

ASSEMBLY PACKING

NUT

TEE RIGHT SUCTION LINE

ASSEMBLY

LEFT SUCTION LINE

ASSEMBLY

PACKING

REDUCER

DRAIN LINE ASSEMBLY

DETAIL A 6517T1006

AIRPLANES #0801 THRU #1054 A6517T1013

Sheet 2 of 3

© 2009 Cessna Aircraft Company

Retain printed data for historical reference only. For future maintenance, use only current data. Page 4

Print Date: Thu Aug 06 07:53:09 CEST 2009 MODEL 550 Bravo MAINTENANCE MANUAL (Rev 22)

29-11-01 (Rev 17)

A23541

PACKING

MANUAL PRESSURE

RELIEF VALVE

ASSEMBLY

DETAIL B

3 3 3 3

VIEW A#A B5517R1014

AA6517T1014

Sheet 3 of 3

© 2009 Cessna Aircraft Company

Retain printed data for historical reference only. For future maintenance, use only current data. Page 5

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Prop Control R 00Document32 pagesProp Control R 00Antonio CorteNo ratings yet

- CAUTION: Extreme Care Should Be Exercised During Maintenance Not To TwistDocument5 pagesCAUTION: Extreme Care Should Be Exercised During Maintenance Not To TwistAntonio CorteNo ratings yet

- Engine Removal 710102 - 4Document8 pagesEngine Removal 710102 - 4Antonio CorteNo ratings yet

- Powerplants Attachment 1 P&W Materials & Process Engineering Metallurgical Investigation Final Report Metallurgical InvestigatioDocument53 pagesPowerplants Attachment 1 P&W Materials & Process Engineering Metallurgical Investigation Final Report Metallurgical InvestigatioAntonio CorteNo ratings yet

- © 2009 Cessna Aircraft CompanyDocument4 pages© 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- CAUTION: If The Primary Outflow Valve Is To Be Installed Again, Make An Index MarkDocument25 pagesCAUTION: If The Primary Outflow Valve Is To Be Installed Again, Make An Index MarkAntonio CorteNo ratings yet

- Detection System-Description and Operation 1. General: © 2009 Cessna Aircraft CompanyDocument2 pagesDetection System-Description and Operation 1. General: © 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- Dimensions and Areas-Description and Operation 1. General: Airplane (Overall)Document4 pagesDimensions and Areas-Description and Operation 1. General: Airplane (Overall)Antonio CorteNo ratings yet

- Detection System-Inspection/Check 1. Inspect Fire Detection SystemDocument1 pageDetection System-Inspection/Check 1. Inspect Fire Detection SystemAntonio CorteNo ratings yet

- CAUTION: You Must Remove The Piccolo Tube and Put A Cap On The BarometricDocument10 pagesCAUTION: You Must Remove The Piccolo Tube and Put A Cap On The BarometricAntonio CorteNo ratings yet

- CH 74Document5 pagesCH 74Antonio CorteNo ratings yet

- CH 79Document5 pagesCH 79Antonio CorteNo ratings yet

- CH 78Document31 pagesCH 78Antonio CorteNo ratings yet

- CH 31Document33 pagesCH 31Antonio CorteNo ratings yet

- CH 33Document73 pagesCH 33Antonio CorteNo ratings yet

- Dimensions and Areas-General 1. Scope: © 2009 Cessna Aircraft CompanyDocument3 pagesDimensions and Areas-General 1. Scope: © 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- CH 30Document41 pagesCH 30Antonio CorteNo ratings yet

- © 2009 Cessna Aircraft CompanyDocument23 pages© 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- Main Hydraulic System-Maintenance Practices 1. General: © 2009 Cessna Aircraft CompanyDocument4 pagesMain Hydraulic System-Maintenance Practices 1. General: © 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- © 2009 Cessna Aircraft CompanyDocument15 pages© 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- Ata 23 I-Aea1Document51 pagesAta 23 I-Aea1Antonio CorteNo ratings yet

- Ata 34 I-Aea1Document163 pagesAta 34 I-Aea1Antonio CorteNo ratings yet

- Ata 76 I-Aea1Document43 pagesAta 76 I-Aea1Antonio CorteNo ratings yet

- CAUTION: Make Sure That The Airplane Ground Suction Source Quick Connect FittingDocument3 pagesCAUTION: Make Sure That The Airplane Ground Suction Source Quick Connect FittingAntonio CorteNo ratings yet

- Main Hydraulic System-Description and Operation 1. General: © 2009 Cessna Aircraft CompanyDocument5 pagesMain Hydraulic System-Description and Operation 1. General: © 2009 Cessna Aircraft CompanyAntonio CorteNo ratings yet

- Ata 22 I-Aea1Document9 pagesAta 22 I-Aea1Antonio CorteNo ratings yet

- Ata 80 I-Aea1Document7 pagesAta 80 I-Aea1Antonio CorteNo ratings yet

- Ata 35 I-Aea1Document45 pagesAta 35 I-Aea1Antonio CorteNo ratings yet

- Ata 78 I-Aea1Document29 pagesAta 78 I-Aea1Antonio CorteNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bendix Generators - Overhaul InstructionsDocument38 pagesBendix Generators - Overhaul InstructionsReydale Cacho100% (1)

- Mohamed Elsayed Hamido: Scientific DegreeDocument6 pagesMohamed Elsayed Hamido: Scientific DegreeAbidNo ratings yet

- 27100-C Air PadsDocument16 pages27100-C Air PadsJason MaNo ratings yet

- Rebar EstimateDocument2 pagesRebar EstimateJim Harold ALfarasNo ratings yet

- Nuts and Bolts Author(s) : Frederick E. Graves Source: Scientific American, Vol. 250, No. 6 (June 1984), Pp. 136-145 Published By: Scientific American, A Division of Nature America, IncDocument11 pagesNuts and Bolts Author(s) : Frederick E. Graves Source: Scientific American, Vol. 250, No. 6 (June 1984), Pp. 136-145 Published By: Scientific American, A Division of Nature America, IncFatima MEHDAOUINo ratings yet

- PB 16013 083Document6 pagesPB 16013 083Henriques Vasco MequeNo ratings yet

- Newcon Suggested Specifications Rev 100715Document1 pageNewcon Suggested Specifications Rev 100715saroat moongwattanaNo ratings yet

- Spare Parts Manual: Solidc PumpDocument12 pagesSpare Parts Manual: Solidc PumpDaniel FernándezNo ratings yet

- Dokumen - Tips - Planmed Sophie Part2 ServicemanualDocument37 pagesDokumen - Tips - Planmed Sophie Part2 ServicemanualMohammed BenzaidiNo ratings yet

- The Evolution of Chamfer Cutting: Cover StoryDocument2 pagesThe Evolution of Chamfer Cutting: Cover StorythisisjineshNo ratings yet

- Sir AquinoDocument529 pagesSir AquinoJat Bacsafra0% (2)

- Brake System in Tractor: Presented byDocument27 pagesBrake System in Tractor: Presented byDomnic KibetNo ratings yet

- Automata Standardized PartsDocument36 pagesAutomata Standardized Partsapi-23533765475% (4)

- Hot Rolled Steel Door 2Document1 pageHot Rolled Steel Door 2dolar buhaNo ratings yet

- Delta Pacific Valve Mfg. Co.: New York, U.S.ADocument1 pageDelta Pacific Valve Mfg. Co.: New York, U.S.ALê Tuấn AnhNo ratings yet

- Trial PLB-88 SequenceDocument8 pagesTrial PLB-88 SequenceFahmy FlipNo ratings yet

- Spreader Bar CalculationDocument5 pagesSpreader Bar CalculationMUHAMMAD NABULA RIFQYNo ratings yet

- Chapter 5.2 PIPE DRAFTINGDocument29 pagesChapter 5.2 PIPE DRAFTINGJack SantosNo ratings yet

- CE637A-Yield ConditionDocument24 pagesCE637A-Yield ConditionSanchita PaulNo ratings yet

- Helical Milling 2Document5 pagesHelical Milling 2macoolet dollenteNo ratings yet

- Cartridge Filters: Technical Manual MT 080Document30 pagesCartridge Filters: Technical Manual MT 080abessiNo ratings yet

- Splicing of Wire Rope 2Document27 pagesSplicing of Wire Rope 2Денис ХортюкNo ratings yet

- SL NO Observation Responsibility Tentative Date of Closure Status (Open/Closed)Document10 pagesSL NO Observation Responsibility Tentative Date of Closure Status (Open/Closed)shyam singh rajpurohitNo ratings yet

- Ensunchadora AH-114 - SignodeDocument4 pagesEnsunchadora AH-114 - SignodeTanSoloUnMinutoNo ratings yet

- BB831 Xa03xen E1 PDFDocument62 pagesBB831 Xa03xen E1 PDFDaniel RamirezNo ratings yet

- Massey Ferguson 8400 Workshop Service ManualDocument20 pagesMassey Ferguson 8400 Workshop Service ManualRita98% (59)

- Design and Fabrication of Pepper Separator MachineDocument5 pagesDesign and Fabrication of Pepper Separator MachineYohannes Mengistu AbebeNo ratings yet

- Nominal Pipe Size - Wikipedia PDFDocument4 pagesNominal Pipe Size - Wikipedia PDFmecano1No ratings yet

- Design of Vertical Pressure Vessel Using Pvelite Software: March 2013Document9 pagesDesign of Vertical Pressure Vessel Using Pvelite Software: March 2013moryNo ratings yet

- Final XDocument60 pagesFinal XSergio Roa PerezNo ratings yet