Professional Documents

Culture Documents

HACCP

Uploaded by

cherrymae balueta0 ratings0% found this document useful (0 votes)

8 views3 pagesReviewer in FDRSKMNGMNT (FINALS)

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentReviewer in FDRSKMNGMNT (FINALS)

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesHACCP

Uploaded by

cherrymae baluetaReviewer in FDRSKMNGMNT (FINALS)

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

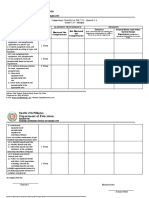

Reviewer in FDRSKMNGMNT (FINALS) The 7 HACCP Principles

From HANDOUTS Conduct a Hazard Analysis

Determine the CCP

Establish Critical Limit

The HACCP SYTEM Establish Monitoring Procedures

Take Corrective Action

- Innovative system that was

developed by Pillsbury Company for Verify that the System Works

NASA space program. (1960) Record Keeping and

Documentation

HACCP

Food safety system designed to keep

food safe through its flow of Principle #1

establishment. - The process of Identifying and

Based on the idea if the physical, evaluating potential hazard

biological, chemical hazards are associated w/ foods to determine

identifies at a specific points. which must be addressed in a

Dynamic Process HACCP Plan.

Principle #2

Proper food handling process

Monitoring techniques - Last step where you can intervene to

Record Keeping prevent, control, or eliminate

microorganisms in food before

Pre-requisite programs also called

service.

(Standard Operating Procedures)

Principle #3

Proper personal hygiene

Proper Facility Design - Minimum or Maximum limit that the

Choose good supplier and develop CCP must meet to prevent/eliminate

supplier specifications hazard to acceptable limit.

Proper cleaning and sanitation

Principle #4

Appropriate equipment

maintenance - The process of Analyzing where

critical limit are being met.

THE HACCP PLAN must be specific to

facility’s Principle #5

Menu - Predetermined step taken when

Equipment food does not meet a critical limit

Process - Last opportunity to ensure the

Operations safety of food.

-

Principle #6 - Sausage

- Cheese omelet

- Process of determining if HACCP

- Egg beaters

system is working according to plan

- Last step where you verify or double FACTORS THAT INFLUENCE RISK

check that the CCP and CL are

Type of customers served

appropriate.

Type of food on the menu

Principle #7 Nature of the organism

Past outbreaks

- Recording how food is handled as it

flows through the establishment. Size and type of food production

operation

Hazards can occur in Prepare: Extent employee training.

Potentially Adverse Conditions PREVENTIVE MEASURES

*Thawing at room temperature Controlling the temperature of the

*One Prep table for all foods food

Cross contamination control

*Hand contact with product. Good personal hygiene practices

Biological Hazards Other procedures that can prevent,

eliminate, minimize and identifies

- Form of bacteria, viruses, fungi, and health hazards.

parasites.

Typically CCP

Chemical Hazards

- Cooking

- Substances that are either naturally - Cooling

present/added to food during - Holding

production.

Establishing Critical limits keep in minds

Physical Hazards that they must be

- Physical contaminants that can - Measurable (time, temperature)

cause injury to the guest. - Based on scientific data such (FDA

Potentially hazardous food (Breakfast) FOOD CODE)

- Clear and Easy to follow

- Oatmeal

- Scrambled eggs CRITICAL LIMIT FOR COOKING CHICKEN

- French toast Receive – 41 F and below

- Cream of wheat

- Bacon Store - 32F – 41F

- Sausage gravy Prepare - 45F within (2 hrs.)

- Breakfast burrito

Cook - 165F – 212F for (15 sec)

IN MONITORING BE SPECIFIC ABOUT: safety problems that have been

noted.

How the CCP will be monitored

When an How often to monitor

Who will monitor

Principle 1,2,3 – Helps to design your

Equipment and tools needed to

system

monitor

Principle 4,5 - Implement it

CORRECTIVE ACTIONS MIGHT INCLUDE THE

FOLLOWING: Principle 6,7 - Maintain your system and

help you to verify its effectiveness.

Continuing to cook the food the

required minimum internal

temperature.

Throwing food away after a

specifies amount of time Goodluck!

Rejecting a shipment that is not

received at the temperature

specified.

VERIFICATION HELPS YOU DETERMIN IF

CCPs and Critical limits are

appropriate

Monitoring alerts you to hazards

Corrective actions are adequate

Employees are following

procedures

Critical limits are frequently not

being met.

Receive a foodborne illness

complaint

Your menu, equipment,

processes, suppliers or products

change.

PROPER RECORDS ALLOWS YOU:

- To document that you are

continuously preparing and serving

safe food

- Identify when your procedures

should be modified due to food

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- New Mayo ClinicDocument2 pagesNew Mayo ClinicRuth AbanadorNo ratings yet

- Self Awareness and Values DelopmentDocument32 pagesSelf Awareness and Values Delopmentcherrymae baluetaNo ratings yet

- Do You in Favor of Enactment of Law As A Means To Settle The Controversy of The Place Where The First Mass in The Philippines Was HeldDocument1 pageDo You in Favor of Enactment of Law As A Means To Settle The Controversy of The Place Where The First Mass in The Philippines Was Heldcherrymae balueta60% (5)

- Basic Concept of Hazard and Its ExampleDocument1 pageBasic Concept of Hazard and Its Examplecherrymae baluetaNo ratings yet

- Do You Think Jose Rizal Made RetractionDocument1 pageDo You Think Jose Rizal Made Retractioncherrymae balueta100% (1)

- Gymnastics Powerpoint VideoDocument9 pagesGymnastics Powerpoint Videocherrymae baluetaNo ratings yet

- CONTINUATION FROM PRELIM (Number Patterns in Mathematics)Document3 pagesCONTINUATION FROM PRELIM (Number Patterns in Mathematics)cherrymae baluetaNo ratings yet

- Reviewer in Food Risk Mngmnt. (GTHRSKMT)Document6 pagesReviewer in Food Risk Mngmnt. (GTHRSKMT)cherrymae baluetaNo ratings yet

- About: GymnasticsDocument11 pagesAbout: Gymnasticscherrymae baluetaNo ratings yet

- Physical Chemical and Biological HazardsDocument2 pagesPhysical Chemical and Biological Hazardscherrymae baluetaNo ratings yet

- Agriculture and Forestry University (Afu)Document67 pagesAgriculture and Forestry University (Afu)Blister CountNo ratings yet

- Roots Reviewer PDFDocument4 pagesRoots Reviewer PDFGAILE MEIZTY MOSADANo ratings yet

- 2.0 Strengths and Weakness NestleDocument17 pages2.0 Strengths and Weakness NestleMaizurah AbdullahNo ratings yet

- CoChe - TLE 7-8 - Q1Document34 pagesCoChe - TLE 7-8 - Q1KEICHIE QUIMCONo ratings yet

- Digital Marketing - Zomato - Group 5Document15 pagesDigital Marketing - Zomato - Group 5ARPAN DHARNo ratings yet

- English Question Bank Class VDocument24 pagesEnglish Question Bank Class Vsujatha ramkiNo ratings yet

- Degree of Comparison TestDocument7 pagesDegree of Comparison TestWahyu WidanaNo ratings yet

- Old Dog Tom PDFDocument2 pagesOld Dog Tom PDFAmit Kumar RanoNo ratings yet

- Wawin Vegan Menu Nov 2020 EditionDocument4 pagesWawin Vegan Menu Nov 2020 EditionpljgfrtcNo ratings yet

- 135-Article Text-773-1-10-20210712Document13 pages135-Article Text-773-1-10-20210712chessa saptaNo ratings yet

- Grammar Practice Bare Infinitive (Cheng Yung Lam 4M02)Document4 pagesGrammar Practice Bare Infinitive (Cheng Yung Lam 4M02)Cheng YunneyNo ratings yet

- Remind Me To SmileDocument143 pagesRemind Me To SmileVika RaikovskaNo ratings yet

- Edible LandscapingDocument32 pagesEdible LandscapingVic Ryan Julius Ong100% (1)

- Learning Outcome 3 Present Vegetable DishesDocument9 pagesLearning Outcome 3 Present Vegetable DishesMeldin May Perez100% (2)

- Jpav Sweet PalitawDocument11 pagesJpav Sweet PalitawJeth Vigilla NangcaNo ratings yet

- JAPAN - r01 - ADocument100 pagesJAPAN - r01 - ACheryl BrigitaNo ratings yet

- Animal HousingDocument4 pagesAnimal HousingGie MacandogNo ratings yet

- TCDA Seating Arrangement QsDocument12 pagesTCDA Seating Arrangement QsMuralidharan RamamurthyNo ratings yet

- QuestionsDocument4 pagesQuestionsSeller CoinsNo ratings yet

- Pearson Square: Crude Protein Requirement of GoatsDocument7 pagesPearson Square: Crude Protein Requirement of GoatsRoxlee Joy AcorinNo ratings yet

- Talking About Daily Routines (Using Simple Present)Document25 pagesTalking About Daily Routines (Using Simple Present)EGX ConsultoresNo ratings yet

- Feeding Proposal SubmittedDocument6 pagesFeeding Proposal SubmittedNoreen M. Semilla100% (1)

- PARDI Self 14 V.2.1 Oct 2020Document32 pagesPARDI Self 14 V.2.1 Oct 2020Marlon Chacon CamachoNo ratings yet

- Workshop There Is - There AreDocument5 pagesWorkshop There Is - There AreJavier Rincon QuevedoNo ratings yet

- Megaloblastic AnaemiaDocument14 pagesMegaloblastic AnaemiaDaniel OnyenucheyaNo ratings yet

- Scheme of Work - FBDocument5 pagesScheme of Work - FBPaul AtariNo ratings yet

- 180 1 PDFDocument52 pages180 1 PDFVladimir RusaliychevNo ratings yet

- Latihan Soal Dek Aimar Descriptive, Narrative, Procedural, Recount, AdvertisementDocument17 pagesLatihan Soal Dek Aimar Descriptive, Narrative, Procedural, Recount, AdvertisementAryandaNo ratings yet

- Feasibility Study Group 2. AbmDocument62 pagesFeasibility Study Group 2. AbmJustine Marie BalderasNo ratings yet