Professional Documents

Culture Documents

SQM10 SQM20

Uploaded by

jose cOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SQM10 SQM20

Uploaded by

jose cCopyright:

Available Formats

7 812

ISO 9001

Actuators SQM1...

for air dampers and control valves of oil burners

SQM2...

Reversible electromotoric actuators

• Torques: - SQM1... up to 10 Nm

- SQM2... up to 20 Nm

• Run times: - SQM1... 14...100 s

- SQM2... 29...66 s

• Versions: - Clockwise or counterclockwise rotation

The SQM... and this Data Sheet are intended for use by OEMs which integrate the

actuators in their products!

Use

The reversible actuators of the SQM... range are for use in connection with controllers

or switching devices equipped with changeover contacts.

CC1N7812en Siemens Building Technologies

17.03.2003 HVAC Products

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes should be observed!

Only qualified staff may open, interfere with or modify the actuators!

• Before performing any wiring changes in the connection area of the actuator, com-

pletely isolate the equipment from the mains supply (all-polar disconnection)

• Ensure protection against electric shock hazard by providing adequate protection

for the terminals

• Check to ensure that wiring is in an orderly state

• Fall or shock can adversely affect the safety functions. Such units may not be put

into operation, even if they do not exhibit any damage

Mounting notes

• Ensure that the relevant national safety regulations are complied with

• When mounting actuator and damper linkage, the geartrain can be disengaged

with a lever, thus allowing the actuator’s drive shaft to be easily adjusted in either

direction of rotation

Installation notes

• Installation work must be carried out by qualified staff

Commissioning notes

• Commissioning work must be carried out by qualified staff

• Prior to commissioning, ensure that wiring is in an orderly state

Norms and standards

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity) 89 / 336 EEC

- Low-voltage directive 73 / 23 EEC

Service notes

• Maintenance work must be carried out by qualified staff

• Each time a unit has been replaced, check to ensure that wiring is in an orderly

state

Disposal notes

The actuator contains electrical and electronic components and may not be disposed of

together with household waste.

Local and currently valid legislation must be observed.

2/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

Mechanical design

Housing - The actuator’s cover is made of impact-proof and heat-resistant plastic.

Color: Dark-grey

- The housing of the geartrain in made of die-cast aluminium and has 4 threaded holes

for cable glands Pg11

Actuator - Reversible, locking-proof synchronous motor

Adjustment of - With adjustable cams

switching points - Setting scales beside the cams give the switching point’s angular position

- The other cams can be adjusted manually, either with the enclosed hook spanner or

tool

Position indicator - Internally:

Scale at the beginning of the cam stack on the geartrain side

- Only SQM21...:

Equipped with position indicator visible from outside (also refer to «Dimens ions»)

Electrical connections - Screw terminals

Geartrain - The reduction gearing has self-lubricating sinter-bronze bearings and requires no

maintenance

Drive shaft - Ready fitted to the front of the geartrain

Mounting and fixing - Geartrain front is used as the mounting surface

- Fixing by means of 3 threaded holes M5

3/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

Type code

SQM 1 0 . 1 5 5 0 2 x x Serie 03

Voltage / frequency:

1 AC 110 V / 50...60 Hz

2 AC 220...240 V / 50 Hz bzw. AC 220 V / 60 Hz

A87 DC 24 V / 60 Hz

Connection diagram:

0 H 4 318 1521 0 Nr. 1 (refer to "Internal diagram")

3 H 4 318 1521 0 Nr. 1 (refer to "Internal diagram")

6 H 4 318 1522 0 Nr. 2 (refer to "Internal diagram")

Number of auxiliary switches:

5 5 auxiliary switches

1 1 auxiliary switch

Run time:

90°- 130°-angular rotation

5 14 s 20 s

6 29 s 42 s

7 70 s 100 s

8 45 s 66 s

Motor

Direction of rotation (facing the drive shaft):

0 Counterclockwise

1 Clockwise

7812t01e/0303

Torque:

1 Standard 10 Nm

2 Heavy duty 20 Nm

Type summary

Run time ³) Direction of rotation Number of Nominal Start- Hold- For For AC 110 V

50 Hz ¹) for when facing the auxiliary torque ²) ing ing AC 220...240 V 50 Hz or

angular rotation drive shaft and with switches torque torque 50 Hz or AC 110 V 60 Hz

control voltage AC 220 V (on request) 4)

applied to 60 Hz 4)

terminal 1

90° 130° Type reference Type reference

Standard version, diameter of drive shaft 10 mm

14 s 20 s 1 Counterclockwise 5 10 Nm 10 Nm 4 Nm SQM10.15502 ---

14 s 20 s 2 Counterclockwise 5 10 Nm 10 Nm 4 Nm SQM10.15562 SQM10.15561

29 s 42 s 1 Counterclockwise 1 10 Nm 15 Nm 7 Nm SQM10.16102 ---

29 s 42 s 1 Counterclockwise 5 10 Nm 15 Nm 7 Nm SQM10.16502 ---

29 s 42 s 1 Counterclockwise 5 10 Nm 15 Nm 7 Nm SQM10.16532 ---

29 s 42 s 2 Counterclockwise 5 10 Nm 15 Nm 7 Nm SQM10.16562 SQM10.16561

70 s 100 s 1 Counterclockwise 5 10 Nm 15 Nm 15 Nm SQM10.17502 ---

29 s 42 s 1 Clockwise 5 10 Nm 15 Nm 7 Nm SQM11.16502 ---

Heavy duty version

Diameter of drive shaft 12 mm

Geartrain shafts made of hardened steel, gearwheels nitrated

Type SQM21... with external position indication (refer to «Dimensions»)

29 s 42 s 1 Counterclockwise 5 20 Nm 20 Nm 12 Nm SQM20.16502 ---

45 s 66 s 1 Counterclockwise 5 20 Nm 20 Nm 12 Nm SQM20.18502 ---

29 s 42 s 1 Clockwise 5 20 Nm 20 Nm 12 Nm SQM21.16502 ---

45 s 66 s 1 Clockwise 5 20 Nm 20 Nm 12 Nm SQM21.18502 SQM21.18501

¹) At 60 Hz, run times are about 17 % shorter

²) Based on 150,000 position changes

³) Wiring according to diagram no.

4) Additional types on request

4/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

Ordering

When ordering, please give type references of actuator and accessories according to

«Type summary».

In addition to the actuator, the following item is to be ordered separately; it is also supplied

separately:

• Changeover relay ASZ50.5

Accessories

Changeover relay ASZ50.5

– For single-wire control of SQM10... / SQM20...

Potentiometer ASZ... Refer to Data Sheet 7921

- For integration on site

5/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

Technical data

General actuator data Operating voltage

- At 50 Hz ±6 % AC 220 V –15 %...AC 240 V +10 %

- At 60 Hz ±6 % AC 220 V –15 % / +10 %

(AC 110 V versions on request)

Switching capacity of end 10 (3) A, AC 24...250 V

and auxiliary switches

Positioning angle up to 160° (scale range)

Mounting position optional

Safety class I

Degree of protection IP 54, DIN 40050 (provided cable entry is

adequate and holes not used are closed

off)

Cable entry M16 and M20 for

2 x M16 x 1.5 and

2 x M20 x 1.5

Weight approx. 1.7 kg

Type of motor synchronous motor

Power consumption 9 VA

Environmental Transport DIN EN 60 721-3-2

conditions Climatic conditions class 2K2

Mechanical conditions class 2M2

Temperature range -50...+60 °C

Humidity < 95 % r.h.

Operation DIN EN 60 721-3-3

Climatic conditions class 3K5

Mechanical conditions class 3M2

Temperature range (switch on ratio < 0.5) -20...+60 °C

Humidity < 95 % r.h.

Condensation, formation of ice and ingress of water are not permitted!

Function

The synchronous motor drives the shaft via the geartrain. Attached to the drive shaft is

a cam stack which actuates the end and auxiliary switches. The switching position of

each end and auxiliary switch can be adjusted within the operating range with the help

of the relevant cams.

The control section includes 2 end switches and a maximum of 5 auxiliary switches. In

addition, a potentiometer can be integrated (as a feedback potentiometer for P-control,

or as a setting unit for slave control, or for remote position indication).

6/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

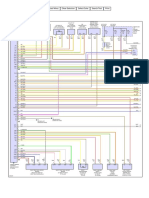

Internal diagrams

SQM... Diagram no. 1 (H 4 318 1521 0)

I II III IV V VI VII ASZ...

N 1 2 3 4 5 6 7 a b c

11 21 12 22 13 23 14 24 15 25 16 26 17 27

SQM...

7812a01/1097

Diagram no. 2 (H 4 318 1522 0)

I II III IV V VI VII ASZ...

N 1 2 3 4 5 6 7 a b c

11 21 12 22 13 23 14 24 15 25 16 26 17 27

130° 0° 30° 40° 60° 44° 50°

SQM...

7812a02/1097

ASZ50.5

N R 36 32 31 N 1 2

11 21 12 22

ASZ 50.5

SQM...

7812a03/1097

7/8

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

Dimensions

Dimensions in mm

M20 x 1.5 M16 x 1.5

26 164

*

130min.

120

ø10 DIN 6888

2.5

12.3

SQM 21 M20 x 1.5

b M5

120

82

50

a

M16 x 1.5

16

c

90

°

30

e

°

Woodruff

key 3 x 3.7 mm 7812m01e/0303

6 to DIN 6888 1 25 24

34.4 77.5

* Clearance required to remove the cover

Type reference a b c d e

SQM1... 10h8 3N9 4 20 6

SQM2... 12h8 3N9 4 21.5 4.5

The groove on the actuator’s drive shaft is in the position shown when the cam stack is

in the 0° position (as supplied).

2003 Siemens Building Technologies

8/8 Subject to change!

Siemens Building Technologies CC1N7812en

HVAC Products 17.03.2003

You might also like

- Controlado QuemadorDocument19 pagesControlado QuemadorDaniel SrkNo ratings yet

- Rmo RMG PDFDocument21 pagesRmo RMG PDFTiago LigabueeNo ratings yet

- Weishaupt WG10 and WG20 Gas Burners LN (Low No) VersionDocument8 pagesWeishaupt WG10 and WG20 Gas Burners LN (Low No) VersionAndrija MaticNo ratings yet

- RU 07 Norms 02 EN81-71Document13 pagesRU 07 Norms 02 EN81-71boubressNo ratings yet

- VFD of ETD Drives YantaiDocument125 pagesVFD of ETD Drives Yantaivb_scribd1234100% (1)

- Toshiba Vfp7-4370pDocument250 pagesToshiba Vfp7-4370pLucas Lopes LemosNo ratings yet

- External Control Electronics For The SYDFE Control of A0VSO Axial Piston Pumps Analogue Amplifier, ConfigurableDocument8 pagesExternal Control Electronics For The SYDFE Control of A0VSO Axial Piston Pumps Analogue Amplifier, ConfigurableRidha Abbassi100% (1)

- EC Wiring Diagrams: M3G074 Motor (Single Phase) M3G084 Motor (Single Phase)Document1 pageEC Wiring Diagrams: M3G074 Motor (Single Phase) M3G084 Motor (Single Phase)EduRoiNo ratings yet

- Crane AC Drive Technical ManualDocument71 pagesCrane AC Drive Technical ManualKavinda GehanNo ratings yet

- N100-Hyundai Brochure 2Document28 pagesN100-Hyundai Brochure 2herororoNo ratings yet

- Digimon TFT Console English Rev1Document16 pagesDigimon TFT Console English Rev1Dario Fernando Flores CottoNo ratings yet

- MIG250C Inverter DC GMAW Welding Machine Operating ManualDocument25 pagesMIG250C Inverter DC GMAW Welding Machine Operating Manualmaverick kitaroNo ratings yet

- 13s11 Combustion PDFDocument36 pages13s11 Combustion PDFAnonymous otUd3TzINo ratings yet

- ControlMaster Select Service ManualDocument46 pagesControlMaster Select Service ManualJoss Maykol Mundaca VasquezNo ratings yet

- DSE335 Operators ManualDocument2 pagesDSE335 Operators ManualArc HieNo ratings yet

- PLC SMART RELAY AR2 SYMBOLS AND SPECIFICATIONSDocument4 pagesPLC SMART RELAY AR2 SYMBOLS AND SPECIFICATIONSMohammed Hamza AhmedNo ratings yet

- OTM +1000 Manual 440VDocument1 pageOTM +1000 Manual 440VhumbertoNo ratings yet

- Tsurumi Vertical Multistage Pump PDFDocument13 pagesTsurumi Vertical Multistage Pump PDFjambrong88No ratings yet

- RS-485 MEMOBUS/Modbus Interface: Technical ManualDocument30 pagesRS-485 MEMOBUS/Modbus Interface: Technical ManualRobert AguilarNo ratings yet

- LFI7 GasBControlDocument7 pagesLFI7 GasBControlsanduzNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- Why Does The ATS46 or ATS48 Unit Get A Phase Fault PHF When Attempting To StartDocument2 pagesWhy Does The ATS46 or ATS48 Unit Get A Phase Fault PHF When Attempting To StartThức VõNo ratings yet

- EN Manuel MB DLE 405 412 PDFDocument6 pagesEN Manuel MB DLE 405 412 PDF754812No ratings yet

- Burner Control LGB21Document22 pagesBurner Control LGB21douglasNo ratings yet

- DRV Masterdrives MC Catalog Da 65 3Document224 pagesDRV Masterdrives MC Catalog Da 65 3bajricaNo ratings yet

- Danfoss VLT FC300 VLT Automation Drive DKDPB13C102Document16 pagesDanfoss VLT FC300 VLT Automation Drive DKDPB13C102hoor24332No ratings yet

- MDS 4100-Service InformationDocument113 pagesMDS 4100-Service Informationg_pargade100% (1)

- Arabic CatalogueDocument28 pagesArabic Cataloguekarim zoubiriNo ratings yet

- Diodes GP4504MTR G1Document15 pagesDiodes GP4504MTR G1Jose Luis ValduezaNo ratings yet

- Allen Bradley 700 hk32z24Document6 pagesAllen Bradley 700 hk32z24Fabro CoronelNo ratings yet

- Pe734e2-Ha Alternator StamfordDocument7 pagesPe734e2-Ha Alternator Stamfordgustavo amayaNo ratings yet

- Alba SP LIST For DAE 16 & DAE 16 LDocument26 pagesAlba SP LIST For DAE 16 & DAE 16 Ldrmasster100% (3)

- NE200 & NE300: High Performance Vector Control DriveDocument20 pagesNE200 & NE300: High Performance Vector Control DriveVũ Duy HảiNo ratings yet

- FB900 Digital Controller - ManualDocument400 pagesFB900 Digital Controller - ManualRenzoNo ratings yet

- G380 ACS880-01 FeaturesDocument8 pagesG380 ACS880-01 FeaturesMohsin Rafique100% (1)

- Páginas Extraídas de Manual - MX2Document8 pagesPáginas Extraídas de Manual - MX2Anonymous 97JlpvN4No ratings yet

- D81-1 2008 English Chap00 PDFDocument140 pagesD81-1 2008 English Chap00 PDFSellappan MuthusamyNo ratings yet

- Diagnosis Twin-3 Without PC-GINADocument5 pagesDiagnosis Twin-3 Without PC-GINAJasonNo ratings yet

- Weishaupt WM-G30Document28 pagesWeishaupt WM-G30RinnoNo ratings yet

- Fire Pump Controller GuideDocument14 pagesFire Pump Controller Guidek0nqueror50% (2)

- General Walk-In Freezer Cálculo de Carga De: Temperatura Interna Temperatura ExternaDocument5 pagesGeneral Walk-In Freezer Cálculo de Carga De: Temperatura Interna Temperatura ExternaJair Cuesta GomezNo ratings yet

- VACON NC1131-3 Engineering: File: 1 03/29/21/KHDocument11 pagesVACON NC1131-3 Engineering: File: 1 03/29/21/KHEugenNo ratings yet

- Jockey Pump Controller Wiring SchematicDocument2 pagesJockey Pump Controller Wiring SchematicUmair BaBer100% (1)

- 2cr Klixon 6Document2 pages2cr Klixon 6AlejandroCoila100% (1)

- Kemppi K2 - Operating - Manual - MIG - 500Document21 pagesKemppi K2 - Operating - Manual - MIG - 500NAM LÊNo ratings yet

- Actuators With Integral ControlDocument32 pagesActuators With Integral Controlgvnks90100% (1)

- Bromma Manual Electrical Circuit DiagramDocument45 pagesBromma Manual Electrical Circuit DiagramMalindaNo ratings yet

- 01 - Cms502-Esquema de Conexion PDFDocument35 pages01 - Cms502-Esquema de Conexion PDFJonas Mendibil PazNo ratings yet

- NXG Control Manual V4.0 - 08 - 2009 - A1AD19001588V4.0 PDFDocument408 pagesNXG Control Manual V4.0 - 08 - 2009 - A1AD19001588V4.0 PDFRaul quispe quispeNo ratings yet

- Inverter FMZ Main Motor & Roll BelakangDocument1 pageInverter FMZ Main Motor & Roll Belakangsteve yamamotoNo ratings yet

- FXSQ-A2VEB - Technical Data PDFDocument35 pagesFXSQ-A2VEB - Technical Data PDFMatthewNo ratings yet

- AT1 User Manual PDFDocument16 pagesAT1 User Manual PDFjoapmeNo ratings yet

- Gear Pump MKU-MKF-MKL Assembly InstructionsDocument102 pagesGear Pump MKU-MKF-MKL Assembly InstructionssunhuynhNo ratings yet

- 00f5semka01 PDFDocument28 pages00f5semka01 PDFKrittaphak HacheyramNo ratings yet

- Siemens Building Technologies: HVAC ProductsDocument10 pagesSiemens Building Technologies: HVAC ProductskevinNo ratings yet

- Siemens SQN3x SQN4xDocument17 pagesSiemens SQN3x SQN4xclauNo ratings yet

- SQNDocument22 pagesSQNare_reeNo ratings yet

- SQN 90 Dumper ActuarorDocument9 pagesSQN 90 Dumper ActuarorRomica CiorneiNo ratings yet

- Manual SQN7 Servomotor SiemensDocument22 pagesManual SQN7 Servomotor SiemensJehison EscobarNo ratings yet

- Actuador Caldera SQN31.401 A 2760Document15 pagesActuador Caldera SQN31.401 A 2760Cesar OmarNo ratings yet

- Man - Yuyao Gongyi - Xmt908 - EngDocument4 pagesMan - Yuyao Gongyi - Xmt908 - EngCsaba VargaNo ratings yet

- M8 and M12 Connectivity For Industrial ApplicationsDocument56 pagesM8 and M12 Connectivity For Industrial Applicationsjose cNo ratings yet

- Multifunctional Safety Switching Device Modular Electronic Safety System With CodingDocument76 pagesMultifunctional Safety Switching Device Modular Electronic Safety System With Codingjose cNo ratings yet

- Multifunctional Safety Switching Device Modular Electronic Safety System With CodingDocument76 pagesMultifunctional Safety Switching Device Modular Electronic Safety System With Codingjose cNo ratings yet

- 54-RE-46-E Instructions For Use 110207 PDFDocument52 pages54-RE-46-E Instructions For Use 110207 PDFanhdungro1986No ratings yet

- USB Frequency Counter and Voltmeter ProjectDocument63 pagesUSB Frequency Counter and Voltmeter ProjectGarra Crema StoneNo ratings yet

- B737-800 PneumaticsDocument5 pagesB737-800 PneumaticsReynaldo100% (1)

- Spring BalancerDocument3 pagesSpring BalancerAdeelNo ratings yet

- City Engineer / Engineering Office Inventory 2019Document2 pagesCity Engineer / Engineering Office Inventory 2019Garry Jay M. SantosNo ratings yet

- Opf Pto 1 DDocument2 pagesOpf Pto 1 DDiego Cárdenas VelásquezNo ratings yet

- Factory Automation - Sensing Your Needs: Pmi Inductive Positioning Measuring SystemsDocument8 pagesFactory Automation - Sensing Your Needs: Pmi Inductive Positioning Measuring SystemsticojfsNo ratings yet

- Elna 6004 Service ManualDocument32 pagesElna 6004 Service ManualGinny RossNo ratings yet

- MSA5T0726A161948 Power Window System PDFDocument4 pagesMSA5T0726A161948 Power Window System PDFMishu MishuNo ratings yet

- Valve Interview Questions and AnswersDocument7 pagesValve Interview Questions and AnswersQasim Iqbal100% (1)

- ISG1-08 - 1A9 PPE v5 090514Document6 pagesISG1-08 - 1A9 PPE v5 090514Samet AslanNo ratings yet

- Model 6300L Automated Pitot Static Tester 1Document2 pagesModel 6300L Automated Pitot Static Tester 1CARLOS GUILLERMO ORNELAS MACIASNo ratings yet

- Guide: Daily ReferenceDocument8 pagesGuide: Daily ReferenceAndreea VarzescuNo ratings yet

- Washing Machine: Service ManualDocument41 pagesWashing Machine: Service Manualimagex5No ratings yet

- Hydraulic Diagram, Basic Machine: E:4 E Schematics - Common HydraulicsDocument8 pagesHydraulic Diagram, Basic Machine: E:4 E Schematics - Common HydraulicsNguyễn Văn HùngNo ratings yet

- Media Converter BasicsDocument9 pagesMedia Converter BasicsmitaNo ratings yet

- User's Manual Vacuum PumpDocument28 pagesUser's Manual Vacuum Pumpdorin stoicuNo ratings yet

- DT800 Sdi12Document2 pagesDT800 Sdi12David ShermanNo ratings yet

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix VelasquezNo ratings yet

- HBC EN EcoDocument29 pagesHBC EN EcoRichard MarcolinNo ratings yet

- H - Disc Valves PDFDocument4 pagesH - Disc Valves PDFMIDHUN RAJNo ratings yet

- InferiorDocument3 pagesInferiorCHEMA BASANNo ratings yet

- KITZ F Series Pneumatic Actuator E-357-07Document12 pagesKITZ F Series Pneumatic Actuator E-357-07Wintoro RicalNo ratings yet

- Ups InverterDocument32 pagesUps InverterSuheil AjeebNo ratings yet

- Carefusion CannulasDocument8 pagesCarefusion Cannulasrubenr25No ratings yet

- IC-9 FCU Box With Cooling-ReheatDocument2 pagesIC-9 FCU Box With Cooling-ReheatShaik Bepari JakeerNo ratings yet

- A100K11750 CTB Technical ManualDocument82 pagesA100K11750 CTB Technical ManualMurat AltparmakNo ratings yet

- Cargo Gear Inspection and MaintenanceDocument47 pagesCargo Gear Inspection and MaintenanceSamar DasNo ratings yet

- EC P6130cdn-P6035cdn-P7040cdnENSMR4-ASSCDocument566 pagesEC P6130cdn-P6035cdn-P7040cdnENSMR4-ASSCFred SantosNo ratings yet

- Castel 3132 - 7 16Document5 pagesCastel 3132 - 7 16Zvonimir PalacNo ratings yet

- IQ Procedure & Report ALP AutoclaveDocument9 pagesIQ Procedure & Report ALP AutoclavePhong LeNo ratings yet

- Fire Panel Req.Document1 pageFire Panel Req.Amit SharmaNo ratings yet