Professional Documents

Culture Documents

For Stromboli Oven-Sample Changer: Preventive Maintenance Checklist

Uploaded by

Fernando Chacmana LinaresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Stromboli Oven-Sample Changer: Preventive Maintenance Checklist

Uploaded by

Fernando Chacmana LinaresCopyright:

Available Formats

Maintenance

Preventive Maintenance Checklist

for Stromboli oven-sample changer

Checklist

Instrument Stromboli oven-sample changer Date

Serial number Location

Visual checks and cleaning

Components Check Clean Replace n/a OK

Preventive Maintenance

Tower

Housing (no cracks and damages) • • {

Cover sheet • •

Preventive

Connection tubing • •

Rinsing unit • •

Pump connector •

Power connector • {

TTL I/O connector •

Power switch •

Connection cable to titrator • {

Rack housing

Sample rack • •

Housing • •

Oven

Self-test •

Display (no cracks and damages) • •

Air pump

Pump delivery •

Technical checks on opened instrument

Components Check Adjust/clean Replace n/a OK

Drive housing

Toothed rim •

Position board •

Fan •

Drive band •

• Standard (mandatory)

{ Optional (if necessary)

METTLER TOLEDO 1/2 Stromboli Preventive Maintenance

Technical checks on opened tower

Tower

Slider guide •

Play of the slider •

Preventive Maintenance Checklist

Condition of bearings • {

CPU and display board •

Drive band •

• Standard (mandatory)

{ Optional (if necessary)

Table of measured temperatures

Set value* Display Stromboli [°C] Display Temp. probe [°C] Difference [°C] Limit Not OK

[°C] of OK

error

5 °C

5 °C

5 °C

*Set values need to be entered manually depending on the titrator connected with the Stromboli. For the DL39 enter 50 °C, 100 °C and

300 °C. When using C30, enter 50 °C, 150 °C and 250 °C.

The preventive maintenance activities listed above were performed by the METTLER TOLEDO authorized

service specialist, what is confirmed with the signature below:

Name Signature

METTLER TOLEDO 2/2 Stromboli Preventive Maintenance

You might also like

- Preventive Maintenance Checklist: For Titration Excellence TitratorsDocument1 pagePreventive Maintenance Checklist: For Titration Excellence TitratorsFernando Chacmana LinaresNo ratings yet

- giSAIA-KOP-J Data eDocument3 pagesgiSAIA-KOP-J Data eKonstantin ИстинныйNo ratings yet

- Earth Leakage Relays: Do You Also Need?Document10 pagesEarth Leakage Relays: Do You Also Need?iskandarismailNo ratings yet

- VW 2005 Touareg Maintenance ProvisionalDocument3 pagesVW 2005 Touareg Maintenance Provisionalkooora2No ratings yet

- Porovnanie Mi 2892 Mi 2885 Mi 2883Document1 pagePorovnanie Mi 2892 Mi 2885 Mi 2883Monster LifeNo ratings yet

- Qdoc - Tips Ul 508aDocument56 pagesQdoc - Tips Ul 508aAlexNo ratings yet

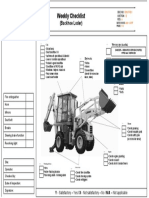

- Backhoe WEEKLY EditedDocument1 pageBackhoe WEEKLY EditedGayan BandaraNo ratings yet

- Backhoe WEEKLY EditedDocument1 pageBackhoe WEEKLY EditedGayan BandaraNo ratings yet

- Periodical Service KOMATSU D155-6: Maintenance SheetDocument2 pagesPeriodical Service KOMATSU D155-6: Maintenance SheetAndaru GunawanNo ratings yet

- DWDWD1352Document83 pagesDWDWD1352str.maintenance.reNo ratings yet

- Biowatt Collaudo Svizzera GeDocument2 pagesBiowatt Collaudo Svizzera GeAhmed El-AdawyNo ratings yet

- Designed To Chase: #ChaseeverydreamDocument2 pagesDesigned To Chase: #ChaseeverydreamGuillermo BellorinNo ratings yet

- Thermowells Threaded TRC 0320Document2 pagesThermowells Threaded TRC 0320Fernando ChavezNo ratings yet

- PL444 Technical Set UpDocument26 pagesPL444 Technical Set UpBilel Ben SlamaNo ratings yet

- 11 Railway SIRIUS Relays 3RP 3RS 3TX - EN PDFDocument21 pages11 Railway SIRIUS Relays 3RP 3RS 3TX - EN PDFAkhil ChoureNo ratings yet

- Short Operating Manual For Vehicle Test LaneDocument3 pagesShort Operating Manual For Vehicle Test LaneLaurentiu AvramNo ratings yet

- Komatsu Pc35r 8Document6 pagesKomatsu Pc35r 8elminetorsystemNo ratings yet

- Medium Pressure Filters Models 15CN, 40CN, 80CN: P A G EDocument7 pagesMedium Pressure Filters Models 15CN, 40CN, 80CN: P A G EHidralteka SandelisNo ratings yet

- Power Electronics: Ministop Motor Brake Relay BA 9034NDocument6 pagesPower Electronics: Ministop Motor Brake Relay BA 9034NSantosh KadamNo ratings yet

- Diesel Engine Fire Pump Controllers: Americas Europe Middle East AsiaDocument2 pagesDiesel Engine Fire Pump Controllers: Americas Europe Middle East AsiaAle LabraNo ratings yet

- AutoTrak Service LevelsDocument2 pagesAutoTrak Service LevelspendexxNo ratings yet

- 1Service+Manual+ISM,+ISMe,+and+QSM11+Volu...Document867 pages1Service+Manual+ISM,+ISMe,+and+QSM11+Volu...consultasNo ratings yet

- E-Cat HT PDFDocument2 pagesE-Cat HT PDFArif Hidayat ViscaNo ratings yet

- 760 Automatic Handheld Pressure CalibratorDocument6 pages760 Automatic Handheld Pressure CalibratorAngelDuqueNo ratings yet

- Mechanical Checksheet Day1Document1 pageMechanical Checksheet Day1Nazim MirzaNo ratings yet

- QA10 PS D85SS-2 Dan 2ADocument2 pagesQA10 PS D85SS-2 Dan 2AAndaru GunawanNo ratings yet

- Varco TDS-4S & TDS-4H Top Drive Pocket GuideDocument21 pagesVarco TDS-4S & TDS-4H Top Drive Pocket GuideMuhammad SaiedNo ratings yet

- r10 04c m3 Parker Pneumatic Regulator DatasheetDocument2 pagesr10 04c m3 Parker Pneumatic Regulator DatasheetJacobo SuarezNo ratings yet

- Redring Water Heating BrochureDocument11 pagesRedring Water Heating BrochureWaydeNo ratings yet

- Alarm check valve features and specificationsDocument3 pagesAlarm check valve features and specificationsLIJINNo ratings yet

- 11 - Installation Section - 1Document40 pages11 - Installation Section - 1mkctNo ratings yet

- Type TA Class 10: Thermal Overload RelaysDocument18 pagesType TA Class 10: Thermal Overload RelaysKwong Hwo TiangNo ratings yet

- C H 2 8 0 0 / 2 8 5 0 S I D e M o U N T Controls: Technical DataDocument1 pageC H 2 8 0 0 / 2 8 5 0 S I D e M o U N T Controls: Technical DatamartNo ratings yet

- Single-Phase SSR With Detachable Heatsink: SR1 SeriesDocument2 pagesSingle-Phase SSR With Detachable Heatsink: SR1 Seriestechnical supportNo ratings yet

- STR Siq 0114Document5 pagesSTR Siq 0114Mohammad AkilNo ratings yet

- B11 Data Sheet - Regulador de PresiónDocument2 pagesB11 Data Sheet - Regulador de PresiónBayronPalacioNo ratings yet

- kx125 1997Document236 pageskx125 1997manugude613No ratings yet

- 50 MM Diameter Incremental Rotary Encoders: E50 SeriesDocument2 pages50 MM Diameter Incremental Rotary Encoders: E50 SeriesAdet WildanNo ratings yet

- Regulador de Presión de Agua SRHDocument13 pagesRegulador de Presión de Agua SRHJavier Santana GarcíaNo ratings yet

- The Univac GP & WP Extended Life Range: Delivering Pumping Solutions For Over 150 YEARSDocument6 pagesThe Univac GP & WP Extended Life Range: Delivering Pumping Solutions For Over 150 YEARSghaleb alhouraniNo ratings yet

- Series: Service ManualDocument6 pagesSeries: Service Manualuds600No ratings yet

- High Efficiency Catalog US PDFDocument68 pagesHigh Efficiency Catalog US PDFvelmuruganNo ratings yet

- ST Diaphragm Valve Rubber LinedDocument2 pagesST Diaphragm Valve Rubber Linedsaroat moongwattanaNo ratings yet

- Ds.37.din .RBR .LN .NRHW .25.v1.1Document2 pagesDs.37.din .RBR .LN .NRHW .25.v1.1Marketing RNSNo ratings yet

- Airfoil Surface Pressure and Wake Velocity ExperimentDocument24 pagesAirfoil Surface Pressure and Wake Velocity ExperimentAh WenNo ratings yet

- Generaror Inspection ChecklistDocument1 pageGeneraror Inspection Checklistyibelta abebeNo ratings yet

- M.E.M.01.C.EN.00 - Maintenance ManualDocument10 pagesM.E.M.01.C.EN.00 - Maintenance ManualGorazdSklepičNo ratings yet

- AODE-4R75E VacTest PDFDocument2 pagesAODE-4R75E VacTest PDFAlonso IbarraNo ratings yet

- RF4 Series Filtros ParkerDocument7 pagesRF4 Series Filtros ParkerCarla MaluendaNo ratings yet

- Veeder Root VaporTEKDocument2 pagesVeeder Root VaporTEKVinod MenonNo ratings yet

- Danfoss Vane Tip LUG SylaxDocument18 pagesDanfoss Vane Tip LUG SylaxmaggamNo ratings yet

- Fire Safety Assessment of Electrical Devices Under Regard of Airworthiness Authorities RequirementsDocument20 pagesFire Safety Assessment of Electrical Devices Under Regard of Airworthiness Authorities RequirementsCORAL ALONSONo ratings yet

- AdditelCatalog 2017-www - Eigroup.biz PDFDocument76 pagesAdditelCatalog 2017-www - Eigroup.biz PDFkarkar ManhNo ratings yet

- Opel Combo Cargo Specsheets A4l HR DigiDocument2 pagesOpel Combo Cargo Specsheets A4l HR DigiChidi OkoloNo ratings yet

- Generator 3406Document2 pagesGenerator 3406AS_865025438No ratings yet

- FlowPak General Valve TitleDocument12 pagesFlowPak General Valve TitleRaphael AndradeNo ratings yet

- 760 Datasheet-1804V06 PDFDocument6 pages760 Datasheet-1804V06 PDFmustafa nashaatNo ratings yet

- 5.19 JSP Power Transformer High Voltage TestDocument4 pages5.19 JSP Power Transformer High Voltage Testmuhammad.younisNo ratings yet

- HDW-580-T5 - (DOOSAN-DP180LAF) - (H1) - (STAMFORD) - (Data-Sheet) - EN 5Document1 pageHDW-580-T5 - (DOOSAN-DP180LAF) - (H1) - (STAMFORD) - (Data-Sheet) - EN 5Nomi DostNo ratings yet

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- DA100M enDocument2 pagesDA100M enFernando Chacmana LinaresNo ratings yet

- C20 - C30 - Quick Guide - Memo Card - 51710619ADocument12 pagesC20 - C30 - Quick Guide - Memo Card - 51710619AFernando Chacmana LinaresNo ratings yet

- Preventive Maintenance SOP: GTP™ - Good Titration Practice™Document12 pagesPreventive Maintenance SOP: GTP™ - Good Titration Practice™Fernando Chacmana LinaresNo ratings yet

- G20 - Quick Guide - Memo Card - 51710742Document16 pagesG20 - Quick Guide - Memo Card - 51710742Fernando Chacmana LinaresNo ratings yet

- V20 - V30 Quick Guide - Memo Card - 51710605Document12 pagesV20 - V30 Quick Guide - Memo Card - 51710605Fernando Chacmana LinaresNo ratings yet

- Preventive Maintenance SOP: GTP™ - Good Titration Practice™Document14 pagesPreventive Maintenance SOP: GTP™ - Good Titration Practice™Fernando Chacmana LinaresNo ratings yet

- Spider TM 6-98Document70 pagesSpider TM 6-98Fernando Chacmana LinaresNo ratings yet

- User Manual: Retail ScalesDocument14 pagesUser Manual: Retail ScalesFernando Chacmana LinaresNo ratings yet

- APPX ManualDocument66 pagesAPPX ManualFernando Chacmana LinaresNo ratings yet

- Ehnv1 Est1: EQP-, EP-and Two-Phase Titration Function FunctionsDocument2 pagesEhnv1 Est1: EQP-, EP-and Two-Phase Titration Function FunctionsFernando Chacmana LinaresNo ratings yet

- Control of Packed Goods - Net Version: Manual Number: KTI-07-01/05/06/ADocument28 pagesControl of Packed Goods - Net Version: Manual Number: KTI-07-01/05/06/AFernando Chacmana LinaresNo ratings yet

- Preventive Maintenance SOP: GTP™ - Good Titration Practice™Document10 pagesPreventive Maintenance SOP: GTP™ - Good Titration Practice™Fernando Chacmana LinaresNo ratings yet

- Compact Scales: Models CS200, CS2000 and CS5000Document2 pagesCompact Scales: Models CS200, CS2000 and CS5000Fernando Chacmana LinaresNo ratings yet

- User Manual: Retail ScalesDocument14 pagesUser Manual: Retail ScalesFernando Chacmana LinaresNo ratings yet

- TPS1200 Total Station: User S GuideDocument28 pagesTPS1200 Total Station: User S GuideFernando Chacmana LinaresNo ratings yet

- Normas para Análisis TérmicoDocument23 pagesNormas para Análisis TérmicoFernando Chacmana LinaresNo ratings yet

- User Manual: Counting Scales - WTC/LW SeriesDocument19 pagesUser Manual: Counting Scales - WTC/LW SeriesFernando Chacmana LinaresNo ratings yet

- QuickGuide en ME ModelsDocument2 pagesQuickGuide en ME ModelsFernando Chacmana LinaresNo ratings yet

- Re40v4 E2001 PDFDocument80 pagesRe40v4 E2001 PDFFernando Chacmana LinaresNo ratings yet

- APPX ManualDocument66 pagesAPPX ManualFernando Chacmana LinaresNo ratings yet

- Standards For Thermal Values (FP/MP) April 2009: Standard No. Year Title Short Description RemarkDocument5 pagesStandards For Thermal Values (FP/MP) April 2009: Standard No. Year Title Short Description RemarkFernando Chacmana LinaresNo ratings yet

- Theinternational System of Units (Si) : B U Reau International Des Poids Et Mesure SDocument72 pagesTheinternational System of Units (Si) : B U Reau International Des Poids Et Mesure SClaudiu IonescuNo ratings yet

- pH-Guide enDocument57 pagespH-Guide enDragana SrdicNo ratings yet

- Analizador de Humedad - 30029586 - WP - MA - RoutineTesting - enDocument16 pagesAnalizador de Humedad - 30029586 - WP - MA - RoutineTesting - enFernando Chacmana LinaresNo ratings yet

- CATALOGO - Incubadoras IMC18Document32 pagesCATALOGO - Incubadoras IMC18Fernando Chacmana LinaresNo ratings yet

- Normas para Análisis TérmicoDocument23 pagesNormas para Análisis TérmicoFernando Chacmana LinaresNo ratings yet

- CATALOGO - Centrifuga Labofuge 200 Thermo ScientificDocument2 pagesCATALOGO - Centrifuga Labofuge 200 Thermo ScientificFernando Chacmana Linares100% (1)

- Lista de Tamices Disponibles Astm E11Document1 pageLista de Tamices Disponibles Astm E11Fernando Chacmana LinaresNo ratings yet

- Power AdministrationDocument17 pagesPower AdministrationWaseem KhanNo ratings yet

- 11 Axis FormationDocument61 pages11 Axis Formationapi-3800038100% (1)

- Sanei SK1-31 Technical ManualDocument60 pagesSanei SK1-31 Technical Manualcompu sanaNo ratings yet

- QP-SSOP-07 Employee Health - v1.0Document2 pagesQP-SSOP-07 Employee Health - v1.0Marisse Cruz0% (1)

- NabDocument31 pagesNabSouvik DeyNo ratings yet

- Avrami 1939 Kinetics of Phase Change. I General TheoryDocument11 pagesAvrami 1939 Kinetics of Phase Change. I General TheoryrobertNo ratings yet

- Unit SpaceDocument7 pagesUnit SpaceEnglish DepNo ratings yet

- Innovative Solution For Biomedical Waste ManagementDocument5 pagesInnovative Solution For Biomedical Waste Managementaysh2383No ratings yet

- 105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023Document15 pages105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023UnknownNo ratings yet

- Homo Deus PDFDocument14 pagesHomo Deus PDFThaw TarNo ratings yet

- PHYS 419 Classical Mechanics Lecture Notes on Quadratic Air ResistanceDocument3 pagesPHYS 419 Classical Mechanics Lecture Notes on Quadratic Air ResistanceComp 3rdNo ratings yet

- Why Does Music Move UsDocument4 pagesWhy Does Music Move UskhanhngocnguyennnNo ratings yet

- BiographyDocument3 pagesBiographyPatricia Anne Nicole CuaresmaNo ratings yet

- CAEN A2518 Rev16Document18 pagesCAEN A2518 Rev16Arnaud RomainNo ratings yet

- Apollo / Saturn V: Insert Disk Q and The Fold OverDocument4 pagesApollo / Saturn V: Insert Disk Q and The Fold OverRob ClarkNo ratings yet

- FundamentalsDocument39 pagesFundamentalsMoses KibikyaboNo ratings yet

- Bms PCC and RCC PDFDocument27 pagesBms PCC and RCC PDFKeshav SethiNo ratings yet

- Glue Blender: Main FeaturesDocument2 pagesGlue Blender: Main FeaturesCarlos Maduro BuendíaNo ratings yet

- Edited Sourcebook For Providing TA On PopDev Integration PDFDocument60 pagesEdited Sourcebook For Providing TA On PopDev Integration PDFIbrahim Jade De AsisNo ratings yet

- Quarter 4 - MELC 11: Mathematics Activity SheetDocument9 pagesQuarter 4 - MELC 11: Mathematics Activity SheetSHAIREL GESIMNo ratings yet

- Cce RF Cce RR: RevisedDocument12 pagesCce RF Cce RR: Revisedvedanth rajNo ratings yet

- Logical FallaciesDocument15 pagesLogical FallaciesLouis Marvil AbalaNo ratings yet

- Ucla Dissertation CommitteeDocument7 pagesUcla Dissertation CommitteeWriteMyPapersDiscountCodeCleveland100% (1)

- Add Math Form 4Document4 pagesAdd Math Form 4Nor Hanina88% (25)

- CO2 Declaration Summary - Template - 1.2Document3 pagesCO2 Declaration Summary - Template - 1.2Musa GürsoyNo ratings yet

- 9 E.T.H.E.RDocument53 pages9 E.T.H.E.Rjamjam_95678853100% (17)

- An Introduction To The Philosophy of Physics by Marc Lange PDFDocument340 pagesAn Introduction To The Philosophy of Physics by Marc Lange PDFMohamad Daoud100% (1)

- SPEX 201 Lab 1 - Motion Analysis Techniques - STUDENT - 2023Document8 pagesSPEX 201 Lab 1 - Motion Analysis Techniques - STUDENT - 2023tom mallardNo ratings yet

- Architect's Professional Practice 2Document48 pagesArchitect's Professional Practice 2Joshua CorpuzNo ratings yet

- Questions of Reliability Centered MaintenanceDocument15 pagesQuestions of Reliability Centered Maintenancemariana100% (1)