Professional Documents

Culture Documents

Flare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical Plants

Uploaded by

debasish bhowmickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flare Gas Ignition System: For Oil and Gas Producing Facilities and Petrochemical Plants

Uploaded by

debasish bhowmickCopyright:

Available Formats

Product Information: Gas Systems

Flare Gas

Ignition System

for oil and gas producing facilities

and petrochemical plants

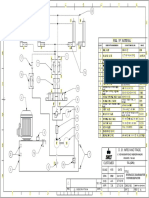

Hamworthy‘s flare gas ignition system has been developed Flare Gas Ignition Cabinet

to guarantee safe and reliable ignition of the flare The flare gas ignition cabinet is installed at a safe distance from

whenever required. the flare stack and a guide pipe leads to the flare tip. The

system is suitable for all flare tips and may ignite several flares

The system can be used under any weather or operating on one flare deck. It combines high reliability and availability

conditions. With no electronic equipment or movable parts over the lifetime of the facility with low maintenance

located in the high heat radiation areas, the system is requirements, and is easily retrofitted into existing installations.

reliable and easy to maintain. It does not need any pilot burners, and has no equipment on

the flare deck that is sensitive to heat, such as cables,

Ignition Pellet instrumentation, or electrodes.

The ignition pellet is launched through a guide pipe to the

flare tower. The pellet bursts and generates a shower of

sparks when exiting the guide pipe. The resulting shower

of sparks is directed towards the flare tip and instantly

ignites the gas cloud. The system is designed to operate for

flare towers up to 2000 meters from the launching unit.

The pellets are safe to handle and are stored in the

launching unit.

Ignition Pellet Flare gas ignition cabinet for automatic operation

Flare Gas Ignition System Gas Systems

3

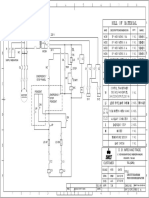

Long operating distance

2000 meters

2

Launcher Ignition

Pellet

Basic Specification

Launching medium: Compressed air

Launching pressure: 5-7 bar (110 psi)

Launching range: up to 2000m+

Ignition pellet (L x D): 100mm x 20mm

Ignition pellet (weight): 80 gram The flare gas ignition system has been developed by

Hamworthy Technology and Products and is protected by

Min. bending radius: 3.6 m

Norwegian and International patents.

Hamworthy Technology & Products is a Norwegian supplier of high Our main technology including the electrostatic coalescence (VIEC), zero

technology products and systems to oil and gas installations worldwide, continuous flaring on oil & gas production plants and zero emission

specialising on the separation of oil and water, gas recovery, gas technology for floating production units are all patented. Our products are

conditioning and gas conversion. designed to meet the requirements of environmental standards and legislation.

Hamworthy Technology and Products

PO. Box 144, NO-1371 Asker, Norway

Tel: +47 815 48 500 Fax: +47 61 815 48 510 The manufacturers reserve the right to alter the

specification and data to incorporate improvements in design.

ref: HTP004 0310

E-mail: htp.sales@hamworthy.com Certified drawings will be issued on request.

www.hamworthy.com © All details copyright Hamworthy plc.

a subsidiary of Hamworthy plc

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 2000 Meters: Long Operating DistanceDocument2 pages2000 Meters: Long Operating DistanceAhmedNo ratings yet

- Flamonitec Bfi Products Catalog 2021-11 En-2Document28 pagesFlamonitec Bfi Products Catalog 2021-11 En-2Gennithony EsonNo ratings yet

- E3160EDocument17 pagesE3160Eslmanov2ysNo ratings yet

- D.1 General Katalog BfiDocument28 pagesD.1 General Katalog Bfihardy ferrysianNo ratings yet

- Ontstekings Systemen 1Document8 pagesOntstekings Systemen 1aliNo ratings yet

- Elyxxon Low Tension High Energy Electronic Ignition SystemDocument15 pagesElyxxon Low Tension High Energy Electronic Ignition Systemomar alnasserNo ratings yet

- IVA Presentation - March 2023Document45 pagesIVA Presentation - March 2023eagarat.processplusNo ratings yet

- Bro Smitsvonk Products en PDFDocument24 pagesBro Smitsvonk Products en PDFHeri SetyantoNo ratings yet

- Fire Protection: SolutionsDocument8 pagesFire Protection: SolutionsBibhu Ranjan MohantyNo ratings yet

- Fire Suppression SystemDocument10 pagesFire Suppression SystemNanang Apriliant PigaroNo ratings yet

- Kanthal Ladle HeatingDocument4 pagesKanthal Ladle HeatingETA THERMALNo ratings yet

- Ground FlareDocument12 pagesGround FlarezopitaNo ratings yet

- FM 200Document4 pagesFM 200Vikram ShettyNo ratings yet

- WDG IV O2 AnalyserDocument4 pagesWDG IV O2 Analyserabdul rehmanNo ratings yet

- Esdti Spray Dryer: The Cost Effective SolutionDocument4 pagesEsdti Spray Dryer: The Cost Effective SolutionpressNo ratings yet

- SPECTREX 4040iDocument2 pagesSPECTREX 4040iLupiNo ratings yet

- Hamim Enterprise: A Life Safety CompanyDocument13 pagesHamim Enterprise: A Life Safety CompanyTaher AzadNo ratings yet

- Olympus Thickness GagesDocument8 pagesOlympus Thickness GagessukimeNo ratings yet

- Datasheet Flare Tips: - FN Series - Pipe FlareDocument2 pagesDatasheet Flare Tips: - FN Series - Pipe FlarejowarNo ratings yet

- FN Flare Tips DatasheetDocument2 pagesFN Flare Tips DatasheetHector RodriguezNo ratings yet

- Ignition Transformers For Burners: AccessoriesDocument20 pagesIgnition Transformers For Burners: AccessoriesNattakorn sangmarkNo ratings yet

- General Specifications: Model GC8000 Process Gas ChromatographDocument17 pagesGeneral Specifications: Model GC8000 Process Gas ChromatographhajduzoliNo ratings yet

- Esa - PBC & PBST (E3280e)Document28 pagesEsa - PBC & PBST (E3280e)crvitor1No ratings yet

- I8-500a Datasheet 2021Document4 pagesI8-500a Datasheet 2021Abdou MohNo ratings yet

- EN 12101-2 Certified Smoke VentDocument2 pagesEN 12101-2 Certified Smoke VentJoshuaCheongChuenKitNo ratings yet

- GGA-35St and GGA-11St Extinguishing Aerosol Generators: Modern FIREACTION Fire Suppression TechnologyDocument3 pagesGGA-35St and GGA-11St Extinguishing Aerosol Generators: Modern FIREACTION Fire Suppression TechnologyAry TubagusNo ratings yet

- PROTEGO Correct Application of Flame Arresters March 2021Document76 pagesPROTEGO Correct Application of Flame Arresters March 2021Pablo HerreroNo ratings yet

- Hepworth - Soil and Waste Systems 8th Version 06th July 2020 1Document44 pagesHepworth - Soil and Waste Systems 8th Version 06th July 2020 1Anand KumarNo ratings yet

- 40-40I Flame DetectorDocument2 pages40-40I Flame DetectorSumeet Sisir SarkarNo ratings yet

- Coal Conveyor Protection-Ih153es Ir Ember DetectorDocument72 pagesCoal Conveyor Protection-Ih153es Ir Ember DetectorShanmuganathan ShanNo ratings yet

- Technical Datasheet Dynameco 300 TA08 E 05.12.2019Document3 pagesTechnical Datasheet Dynameco 300 TA08 E 05.12.2019Tamjeed AhmecNo ratings yet

- PPT-080 110Document3 pagesPPT-080 110Emanuel CondeNo ratings yet

- Flame ScannerDocument4 pagesFlame ScannerAlok Kumar NayakNo ratings yet

- Presentations PDFDocument135 pagesPresentations PDFDileep DudiNo ratings yet

- 2019 02 20 Dorgard Pro Handbook V1.4Document24 pages2019 02 20 Dorgard Pro Handbook V1.4bogdan darcaciuNo ratings yet

- S-ThermoCable Cut SheetDocument2 pagesS-ThermoCable Cut SheetuelectronicfernandezNo ratings yet

- Elevated FlareDocument16 pagesElevated FlareDeepak SreekumarNo ratings yet

- Clean Verbatim With TimestampingDocument2 pagesClean Verbatim With TimestampingMoiz Ahmed KhanNo ratings yet

- Flare Stack MonitoringDocument4 pagesFlare Stack MonitoringAnonymous hOog7yGJwNo ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- Up To Efficiency!: MBTU ModelsDocument8 pagesUp To Efficiency!: MBTU ModelslordsethdarknessNo ratings yet

- ITP Steam TurbineDocument4 pagesITP Steam Turbinecandra trisilawatiNo ratings yet

- Self-Recuperative Burners High Speed Free FlameDocument17 pagesSelf-Recuperative Burners High Speed Free FlameKarl WeierstrassNo ratings yet

- MX 200 Fire Extinguishing SystemsDocument4 pagesMX 200 Fire Extinguishing SystemsAsad NizamNo ratings yet

- T Proc Notices Notices 090 K Notice Doc 87199 27033258Document19 pagesT Proc Notices Notices 090 K Notice Doc 87199 27033258zusama856No ratings yet

- ProReact Plus Digital LHD Cable Installation ManualDocument9 pagesProReact Plus Digital LHD Cable Installation ManualAlexandru CraiovanNo ratings yet

- Quemador WG-30Document16 pagesQuemador WG-30chuyNo ratings yet

- (Magazine) Oil and Gas Petrochem Equipment 11 2014Document52 pages(Magazine) Oil and Gas Petrochem Equipment 11 2014Vũ Tuấn AnhNo ratings yet

- Combined Flame and Graphite Furnace Solutions: Product SpecificationsDocument3 pagesCombined Flame and Graphite Furnace Solutions: Product SpecificationsAbdullah EjazNo ratings yet

- Passive Fire ProtectionDocument6 pagesPassive Fire ProtectionSonny RamosNo ratings yet

- Ultra FL800Document2 pagesUltra FL800Vincent GabrielNo ratings yet

- Stairwell PresentationDocument32 pagesStairwell PresentationEdz EduardoNo ratings yet

- SD-1620 Smoke Dampers: Description FeaturesDocument3 pagesSD-1620 Smoke Dampers: Description FeaturesJuan Yenque GalloNo ratings yet

- Datasheet Spartan Craneflood wl48Document3 pagesDatasheet Spartan Craneflood wl48NEJA JEMAL AmireNo ratings yet

- KFSS Manual TCSDocument15 pagesKFSS Manual TCSVishal SanasNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Structural Design of 3t Jib CraneDocument2 pagesStructural Design of 3t Jib Cranedebasish bhowmickNo ratings yet

- 407-Gail - Pata - Jib CraneDocument1 page407-Gail - Pata - Jib Cranedebasish bhowmickNo ratings yet

- 3 R 316 Fahm Latest - Nandikeshwari EnggDocument18 pages3 R 316 Fahm Latest - Nandikeshwari Enggdebasish bhowmickNo ratings yet

- 10 JuneDocument1 page10 Junedebasish bhowmickNo ratings yet

- Tax Invoice: Techinova Engineering Analysis Services LLPDocument1 pageTax Invoice: Techinova Engineering Analysis Services LLPdebasish bhowmickNo ratings yet

- D.B. Impex & Trade (D054, PR: 920981446Document2 pagesD.B. Impex & Trade (D054, PR: 920981446debasish bhowmickNo ratings yet

- SUJIT PAUL (1 TON) (BOS) (G.A) - ModelDocument1 pageSUJIT PAUL (1 TON) (BOS) (G.A) - Modeldebasish bhowmickNo ratings yet

- 85 DB Impex Flare Ignition SystemDocument3 pages85 DB Impex Flare Ignition Systemdebasish bhowmickNo ratings yet

- 85 DB Impex Flare Ignition SystemDocument3 pages85 DB Impex Flare Ignition Systemdebasish bhowmickNo ratings yet

- 85 DB Impex Flare Ignition SystemDocument3 pages85 DB Impex Flare Ignition Systemdebasish bhowmickNo ratings yet

- Pilot & Flare System WolfDocument1 pagePilot & Flare System Wolfdebasish bhowmickNo ratings yet

- E 24Document61 pagesE 24kisan singhNo ratings yet

- Pilot & Flare System WolfDocument1 pagePilot & Flare System Wolfdebasish bhowmickNo ratings yet

- The Present Application Is A ContinuationDocument11 pagesThe Present Application Is A Continuationdebasish bhowmickNo ratings yet

- Technical SpecificationsDocument2 pagesTechnical Specificationsdebasish bhowmickNo ratings yet

- Steel Work Design and Analysis of A Mobile Floor Crane: December 2015Document10 pagesSteel Work Design and Analysis of A Mobile Floor Crane: December 2015Miguel MesiasNo ratings yet

- Bro Flare Pilot Burner enDocument3 pagesBro Flare Pilot Burner endebasish bhowmickNo ratings yet

- Cost Est For Self-ProppeledstackerDocument1 pageCost Est For Self-Proppeledstackerdebasish bhowmickNo ratings yet

- Pilot & Flare System WolfDocument1 pagePilot & Flare System Wolfdebasish bhowmickNo ratings yet

- Design and Fabrication of Battery Operated Forklift: Journal Europã©En Des Systã Mes Automatisã©S January 2020Document7 pagesDesign and Fabrication of Battery Operated Forklift: Journal Europã©En Des Systã Mes Automatisã©S January 2020debasish bhowmickNo ratings yet

- 334Document5 pages334abozaid19100% (1)

- Anker Hoist Block DetailsDocument13 pagesAnker Hoist Block Detailsdebasish bhowmickNo ratings yet

- Hydraulic DiagramDocument1 pageHydraulic Diagramdebasish bhowmickNo ratings yet

- Pioneer Castor Catalogue 2008Document24 pagesPioneer Castor Catalogue 2008SunnySinghNo ratings yet

- DBXT F A3 128 HC 01 - CYLINDER - ModelDocument1 pageDBXT F A3 128 HC 01 - CYLINDER - Modeldebasish bhowmickNo ratings yet

- Electrical Circuit DiagramDocument1 pageElectrical Circuit Diagramdebasish bhowmickNo ratings yet

- Abb Drive CatalogDocument44 pagesAbb Drive Catalogdebasish bhowmickNo ratings yet

- Baumer EncoderDocument10 pagesBaumer Encoderdebasish bhowmickNo ratings yet

- Chain Pull CalculationsDocument39 pagesChain Pull Calculationsmech_abhi100% (2)

- EL220 Signals and Systems: Experiment # 12Document6 pagesEL220 Signals and Systems: Experiment # 12Choudhary Abdul AqeelNo ratings yet

- Service Manual: Digital HD Video Camera RecorderDocument69 pagesService Manual: Digital HD Video Camera RecorderDanNo ratings yet

- Seria As: Caracteristici Tehnice Articole StandardDocument12 pagesSeria As: Caracteristici Tehnice Articole StandardDan StroescuNo ratings yet

- En Collection of Data Sheets MPS PA 090804Document194 pagesEn Collection of Data Sheets MPS PA 090804rajaa latifiNo ratings yet

- Rakit Lampu LedDocument11 pagesRakit Lampu LedIbnusyam UtihNo ratings yet

- Grid-Tied PV String Inverter: User ManualDocument52 pagesGrid-Tied PV String Inverter: User ManualBanjo MirandillaNo ratings yet

- Catalog Geophone Electronic - Model ECO 10Document2 pagesCatalog Geophone Electronic - Model ECO 10Alejandro FernándezNo ratings yet

- WWW - MK-Electronic - De: Epson Stylus Photo Px800Fw No.1Document11 pagesWWW - MK-Electronic - De: Epson Stylus Photo Px800Fw No.1Miguel CastilloNo ratings yet

- Andrew Hwxxx6516dsvtmDocument2 pagesAndrew Hwxxx6516dsvtmЕвгений ГрязевNo ratings yet

- 380kva Amf Panel, SCHDocument11 pages380kva Amf Panel, SCHRITENDRA GHOSHNo ratings yet

- Datasheet Led 3MMDocument5 pagesDatasheet Led 3MMVictor Chavez torresNo ratings yet

- Lal SeriesDocument19 pagesLal Seriessaviye6587No ratings yet

- Instructions For Use Osm2 1Document44 pagesInstructions For Use Osm2 1Elident ServiceNo ratings yet

- LUMEL Current Transformer Catalog 2022Document50 pagesLUMEL Current Transformer Catalog 2022Bianca OlaruNo ratings yet

- Lukas Kaul - Practical Arduino Robotics - A Hands-On Guide To Bringing Your Robotics Ideas To Life Using Arduino-Packt Publishing (2023)Document334 pagesLukas Kaul - Practical Arduino Robotics - A Hands-On Guide To Bringing Your Robotics Ideas To Life Using Arduino-Packt Publishing (2023)gaby21marian3712100% (1)

- ECE4371 Class9Document34 pagesECE4371 Class9Satyasundar PanigrahiNo ratings yet

- Ed - 2Document54 pagesEd - 2JaiNo ratings yet

- System/Battery Type Emerson Narada 12NDT100A Narada 12NDT180 Vision CT12 180XDocument2 pagesSystem/Battery Type Emerson Narada 12NDT100A Narada 12NDT180 Vision CT12 180XBysNo ratings yet

- Electromagnetic Induction and Alternating CurrentDocument31 pagesElectromagnetic Induction and Alternating CurrentsunliasNo ratings yet

- TRENDCOM ManualDocument14 pagesTRENDCOM ManualAndrés Ain-ActiveNo ratings yet

- JackDocument118 pagesJackJoão ArtilheiroNo ratings yet

- You're Hired-25 Top Interview Questions For Circuit DesignersDocument4 pagesYou're Hired-25 Top Interview Questions For Circuit DesignersPrasanth YgNo ratings yet

- Electrical Power System Protection PDFDocument18 pagesElectrical Power System Protection PDFAlberto José Bermúdez AriasNo ratings yet

- vr7000 Brochure PDFDocument4 pagesvr7000 Brochure PDFvangNo ratings yet

- GEH 3416 Shunt Trip DeviceDocument3 pagesGEH 3416 Shunt Trip DevicejadliftboatsetorecordsNo ratings yet

- Glofa GM7Document30 pagesGlofa GM7luis palaciosNo ratings yet

- Standard Questioner For Radar Navigation, Radar Plotting and Use of ArpaDocument5 pagesStandard Questioner For Radar Navigation, Radar Plotting and Use of ArpaAbdo KhamisNo ratings yet

- Electrolux EW23BC71IS0 Refrigerator Tech SheetDocument2 pagesElectrolux EW23BC71IS0 Refrigerator Tech SheetEdison EspinalNo ratings yet

- Annexure C Details 16.06.17Document6 pagesAnnexure C Details 16.06.17Prasanth KumarNo ratings yet

- Title: HV365WXC-200 Product Specification: Beijing Boe Display TechnologyDocument27 pagesTitle: HV365WXC-200 Product Specification: Beijing Boe Display Technologynani_amlprm5912No ratings yet