Professional Documents

Culture Documents

Stellite 21 Alloy: Stellite Cobalt-Based Alloys

Uploaded by

Mehrdad NejatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stellite 21 Alloy: Stellite Cobalt-Based Alloys

Uploaded by

Mehrdad NejatiCopyright:

Available Formats

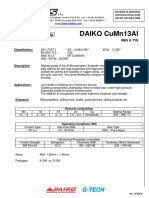

STELLITETM 21 ALLOY

STELLITETM COBALT-BASED ALLOYS consists of complex carbides in an alloy matrix. They are

resistant to wear, galling, and corrosion and retain these properties at high temperatures. Their

exceptional wear resistance is due mainly to the unique inherent characteristics of the hard carbide

phase dispersed in a CoCr alloy matrix.

STELLITETM 21 consists of a CoCrMo alloy matrix containing dispersed hard carbides which

strengthen the alloy and increase its hardness, but also decrease the ductility. The type, shape,

size, and distribution of the carbides is strongly influenced by the processing history of the alloy,

and for this reason the mechanical properties of StelliteTM 21 are very dependent upon the

manufacturing route and any subsequent heat treatments. Due to the low volume fraction of

carbides, the Co-based alloy matrix dominates the wear and corrosion properties. StelliteTM 21 has

excellent cavitation, galling and metal-to-metal sliding wear resistance, but is not recommended for

severe hard particle abrasion. The surface can work harden considerably during wear or even

during machining, and the use of correct machining tools and techniques is important to achieve

optimal results. StelliteTM 21 has excellent resistance to thermal and mechanical shock.

StelliteTM 21 is similar to the medical implant alloy ASTM F-75 and was previously also known as

StelliteTM 8.

CORROSION RESISTANCE

StelliteTM 21 is resistant to oxidizing and reducing gaseous atmospheres up to 1150°C (2100°F).

Because its ternary alloying element is Mo and not W, it has higher resistance to reducing or

complex environments (e.g. sulphuric acid, hydrochloric acid, and sour gas) than CoCrW alloys

such as StelliteTM 6. The typical electrode potential in sea water at room temperature is approx. -

0.3 V (SCE). Like stainless steels, StelliteTM 21 corrodes primarily by a pitting mechanism and not

by general mass loss in seawater and chloride solutions.

NOMINAL CHEMICAL COMPOSITION (MASS%)

ALLOY Co Cr Ni Fe Mo Others

StelliteTM 21 Bal. 27,0 2,5 1,5 5,5 C, B, Si, Mn

PHYSICAL PROPERTIES

ALLOY Hardness Density Melting Range

StelliteTM 21 27 - 40 HRC / 290 - 430 HV ~ 8,33 g/cm3 ~ 1295 – 1435°C

Stellite™, Tribaloy™, Nistelle™, Stelcar™, Jet Kote™, and Delcrome™

are registered trademarks of Kennametal Inc.

Document Number: MDS St21 rev. 00

NOMINAL HOT HARDNESS (HV resp. DPH) OF UNDILUTED WELD DEPOSIT

20°C 100°C 200°C 300°C 400°C 500°C 600°C 700°C 800°C 900°C

347 279 248 228 208 197 181 153 123 92

EXAMPLE FOR TENSILE PROPERTIES AT ROOM TEMPERATURE

Ultimate Tensile Yield Stress Elongation

PRODUCT FORM

Strength Rm Rp (0,2%) A

Casting, As cast ~ 710 MPa ~ 565 MPa <3%

PRODUCT FORMS

Components

Castings Cladded / Hardfaced PM / HIP parts* ALM parts*

* On special request.

Consumables for Cladding / Hardfacing and Additive Layer Manufacturing (ALM)

Rods TIG-Welding Oxy-Acetylene Welding

Electrode MMA Welding

Cored Wire MIG Welding Submerged Arc Welding

Powder PTA Cladding Laser Cladding HVOF Spraying ALM

TYPICAL STRUCTURES

Cas Casted StelliteTM 21 Alloy (Resin Shell Casting) Cas Welded StelliteTM 21 Alloy (TIG Cladding)

You might also like

- Deloro MDS Stellite20 Rev00Document2 pagesDeloro MDS Stellite20 Rev00hp2114bNo ratings yet

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiNo ratings yet

- Stellite 12Document2 pagesStellite 12xy2zjgNo ratings yet

- Stellite Grade 12-DatasheetDocument2 pagesStellite Grade 12-DatasheetNinad PawarNo ratings yet

- Stellite 12 Technical DataDocument2 pagesStellite 12 Technical DataJakeTheSnake69No ratings yet

- TOOLCORD MMA Electrodes for HardfacingDocument1 pageTOOLCORD MMA Electrodes for HardfacingbrunizzaNo ratings yet

- MSrinivas - STEELS FOR CRITICAL APPLICATIONSDocument46 pagesMSrinivas - STEELS FOR CRITICAL APPLICATIONSamit gajbhiye100% (1)

- Kennametal Stellite - Cored Weld Wire DatasheetDocument2 pagesKennametal Stellite - Cored Weld Wire DatasheetharikrishnanNo ratings yet

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Document1 pageManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baeNo ratings yet

- Stellite 6Document2 pagesStellite 6백승훈No ratings yet

- Citorail OerlikonDocument1 pageCitorail OerlikonGiancarlo BlandinoNo ratings yet

- Aircraft MaterialsDocument16 pagesAircraft MaterialsManicharanNo ratings yet

- CuZn05-convertedDocument2 pagesCuZn05-convertedwjjt6chgtmNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- Gemet 504Document1 pageGemet 504A K NairNo ratings yet

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006No ratings yet

- Stainless Steel 1.4462 Sheet & PlateDocument3 pagesStainless Steel 1.4462 Sheet & PlatePaulNo ratings yet

- Polymet Full Product CatalogueDocument2 pagesPolymet Full Product Catalogue.xNo ratings yet

- Maraging Steels For Aero Space ApplicationDocument33 pagesMaraging Steels For Aero Space ApplicationKalikota Prasad100% (1)

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- Microsoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFDocument56 pagesMicrosoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFamitNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- stellite 6Document2 pagesstellite 6Shreenivas ThakurNo ratings yet

- CuZn20-convertedDocument2 pagesCuZn20-convertedwjjt6chgtmNo ratings yet

- Api 571 CorrosionDocument5 pagesApi 571 CorrosionArun GuptaNo ratings yet

- Cuznpb2 leadedDocument3 pagesCuznpb2 leadedwjjt6chgtmNo ratings yet

- 21crmov5-7: Steel GradeDocument1 page21crmov5-7: Steel GradeEdward PongracNo ratings yet

- CuZn15-convertedDocument2 pagesCuZn15-convertedwjjt6chgtmNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanNo ratings yet

- Self-shielded electrode for heavy component repairDocument1 pageSelf-shielded electrode for heavy component repairAravind rajNo ratings yet

- Case Hardening Alloy Steel Bar 6587Document3 pagesCase Hardening Alloy Steel Bar 6587CelsoNo ratings yet

- Armco Pure Iron PDFDocument12 pagesArmco Pure Iron PDFsmith willNo ratings yet

- Ati 2205 PDFDocument6 pagesAti 2205 PDFGetapo RaminNo ratings yet

- Development of High Heat Input Welding Offshore Steel As Normalized ConditionDocument5 pagesDevelopment of High Heat Input Welding Offshore Steel As Normalized Conditionadenorla1No ratings yet

- .Au-Aluminium Alloy 3003Document5 pages.Au-Aluminium Alloy 3003ali alhamilNo ratings yet

- Base Metal Alloys Used in Fixed and RemoveableDocument72 pagesBase Metal Alloys Used in Fixed and RemoveableKhushi DesaiNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- Advances in Wear Resistant Alloys and ApplicationsDocument56 pagesAdvances in Wear Resistant Alloys and ApplicationsMilanWaNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- TDZ AlloyDocument1 pageTDZ AlloyIan MacMoyNo ratings yet

- Stainless Steel 321 Technical DataDocument2 pagesStainless Steel 321 Technical Datasmith willNo ratings yet

- Cordierite Ceramic Honeycomb - 611553Document2 pagesCordierite Ceramic Honeycomb - 611553Pacy MugishoNo ratings yet

- Stellite Alloys For HardfacingDocument15 pagesStellite Alloys For HardfacingSandeep MatetiNo ratings yet

- Centralloy G4852 Micro R (Cast Austenitic Stainless Steel)Document2 pagesCentralloy G4852 Micro R (Cast Austenitic Stainless Steel)Anonymous w6TIxI0G8lNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet

- Creep-Resistant Steels - TWIDocument6 pagesCreep-Resistant Steels - TWIJlkKumarNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Stabilized Ferritic Stainless Steel for Automotive Exhaust SystemsDocument37 pagesStabilized Ferritic Stainless Steel for Automotive Exhaust SystemsShashank SaxenaNo ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Rolls Royce/Allison 501-K Gas Turbine Anti-Fouling Compressor Coatings EvaluationDocument9 pagesRolls Royce/Allison 501-K Gas Turbine Anti-Fouling Compressor Coatings EvaluationMehrdad NejatiNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- In 738alloy PreliminaryData 497Document12 pagesIn 738alloy PreliminaryData 497Gustavo PalaciosNo ratings yet

- Nimonic Alloy 80ADocument24 pagesNimonic Alloy 80AdharmatejakademNo ratings yet

- Guidelines For Hard Facing Onto SteelsDocument7 pagesGuidelines For Hard Facing Onto SteelsmohamedfirozNo ratings yet

- CMAS Behavior of Yttrium Aluminum Garnet (YAG) and Yttria-Stabilized Zirconia (YSZ) Thermal Barrier CoatingsDocument6 pagesCMAS Behavior of Yttrium Aluminum Garnet (YAG) and Yttria-Stabilized Zirconia (YSZ) Thermal Barrier CoatingsMehrdad NejatiNo ratings yet

- Microstructural Characterization of The Interaction Between 8YPSZ (EB-PVD) Thermal Barrier Coatings and A Synthetic CASDocument6 pagesMicrostructural Characterization of The Interaction Between 8YPSZ (EB-PVD) Thermal Barrier Coatings and A Synthetic CASMehrdad NejatiNo ratings yet

- High-Temperature Corrosion Mechanism of YSZ Coatings Subject To Calcium-Magnesium-Aluminosilicate (CMAS) Deposits First-Principles CalculationsDocument7 pagesHigh-Temperature Corrosion Mechanism of YSZ Coatings Subject To Calcium-Magnesium-Aluminosilicate (CMAS) Deposits First-Principles CalculationsMehrdad NejatiNo ratings yet

- End of Chapter SET 3Document5 pagesEnd of Chapter SET 3NurAisha AhmadNo ratings yet

- Creep: Materials Science Stresses Yield StrengthDocument3 pagesCreep: Materials Science Stresses Yield StrengthSaad khanNo ratings yet

- Effect of Rare Earth Additions On Microstructure and Texture Development of Magnesium Alloy SheetsDocument6 pagesEffect of Rare Earth Additions On Microstructure and Texture Development of Magnesium Alloy SheetsKam DenqNo ratings yet

- Is 13360 2 5 2013Document16 pagesIs 13360 2 5 2013Marioni Antonio HerreraNo ratings yet

- 3-Concept of PrestressingDocument13 pages3-Concept of PrestressingKavi MaranNo ratings yet

- Validating Bernoulli's TheoremDocument26 pagesValidating Bernoulli's TheoremNurul AinNo ratings yet

- Bonding ProcessDocument29 pagesBonding Processtai daisyNo ratings yet

- Microwave Solvothermal Synthesis and Characterization of Manganese-Doped Zno NanoparticlesDocument12 pagesMicrowave Solvothermal Synthesis and Characterization of Manganese-Doped Zno NanoparticlesTamilan TamilNo ratings yet

- Vietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectDocument8 pagesVietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectSudip ShresthaNo ratings yet

- Gravity DamDocument19 pagesGravity DamrahulNo ratings yet

- Lecture 4 Flexural MembersDocument27 pagesLecture 4 Flexural MembersEdwin RodriguezNo ratings yet

- Irf 7401Document9 pagesIrf 7401Danijel PavlešićNo ratings yet

- Hydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCDocument18 pagesHydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCmoorpvrNo ratings yet

- 2008 Al Phy Ib MSDocument7 pages2008 Al Phy Ib MSstanleywongNo ratings yet

- Luviquat UltraCare - An Effective Conditioning/StylingDocument6 pagesLuviquat UltraCare - An Effective Conditioning/StylingaboodftayehNo ratings yet

- Preparation, Purification and Properties of ColloidsDocument55 pagesPreparation, Purification and Properties of ColloidsNandan PomalNo ratings yet

- A Comparative Study On Sound Transmission Loss and Absorption Coefficient of Acoustical Materials PDFDocument13 pagesA Comparative Study On Sound Transmission Loss and Absorption Coefficient of Acoustical Materials PDFHo Zhen MengNo ratings yet

- Strength of MaterialsDocument29 pagesStrength of MaterialsMeennnNo ratings yet

- 1.4404 enDocument5 pages1.4404 enyraju88No ratings yet

- Demagnetizing A Tape RecorderDocument3 pagesDemagnetizing A Tape RecorderSzilvester SzilvesterNo ratings yet

- Bayblend Fr3008 HR IsoDocument3 pagesBayblend Fr3008 HR IsoBijesh VenugopalNo ratings yet

- Compound Stress and Strain GuideDocument8 pagesCompound Stress and Strain Guideshweta_7705870% (1)

- ASTM B108B108M 15 Standard Specification For Aluminum Alloy Permanent Mold CastingsDocument22 pagesASTM B108B108M 15 Standard Specification For Aluminum Alloy Permanent Mold CastingsMohit pathakNo ratings yet

- (Prigogine, 1978) Time Structure and FluctuationsDocument9 pages(Prigogine, 1978) Time Structure and FluctuationsOscar Leonardo Aaron Arizpe VicencioNo ratings yet

- Sec4 6 PDFDocument2 pagesSec4 6 PDFpolistaNo ratings yet

- Eudragit Rs 100 PDFDocument2 pagesEudragit Rs 100 PDFMariaNo ratings yet

- Dow CorningDocument12 pagesDow CorningTamara HamiltonNo ratings yet

- Semiconductor Electronics Chapter SummaryDocument15 pagesSemiconductor Electronics Chapter SummaryBhagat Singh RanaNo ratings yet

- B.Tech. Mechanical Engg. (SEMESTER-VII) : Subject:Tribology (030050715)Document8 pagesB.Tech. Mechanical Engg. (SEMESTER-VII) : Subject:Tribology (030050715)Palak NaikNo ratings yet

- Case Study On Inductive Proximity SwitchesDocument4 pagesCase Study On Inductive Proximity SwitchesMANASNo ratings yet