Professional Documents

Culture Documents

TWS600S pump worksheet

Uploaded by

SERGIO ARMANDO SANCHEZ ROQUEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TWS600S pump worksheet

Uploaded by

SERGIO ARMANDO SANCHEZ ROQUECopyright:

Available Formats

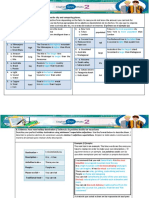

PUMP ID: ADBNAAAAFCNABECFXXAABAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-436

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE RIGHT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #1 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #1 TO BE SHIPPED WITH PUMP #2 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

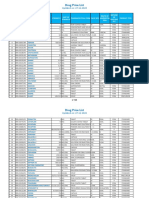

PUMP ID: ADBNAAAAFCNABECFXXAABAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-436

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE RIGHT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #3 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #3 TO BE SHIPPED WITH PUMP #4 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAABAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-436

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE RIGHT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #5 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #5 TO BE SHIPPED WITH PUMP #6 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-436

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE RIGHT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #7 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #7 TO BE SHIPPED WITH PUMP #8 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAABAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-436

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE RIGHT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #9 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #9 TO BE SHIPPED WITH PUMP #10 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-437

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE LEFT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #2 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #2 TO BE SHIPPED WITH PUMP #1 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-437

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/5/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE LEFT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #4 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #4 TO BE SHIPPED WITH PUMP #3 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-437

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE LEFT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #6 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #6 TO BE SHIPPED WITH PUMP #5 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAABCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-437

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 7/14/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 3A105154 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE LEFT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #8 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG 1 PER DWG 3A106328 | BACK TO BACK MOUNTING, TOATL LENGTH NOT SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

TO EXCEED 50.75" | PUMP #8 TO BE SHIPPED WITH PUMP #7 | TO INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

PUMP ID: ADBNAAAAFCNABECFXXAAAAXXXXXXXX

Size:

TWS600S PUMP WORKSHEET Sale's Id: TWS0600-437

PRODUCT: 2.75 TWS600S STROKE 6 GEAR RATIO 4.61 CERTIFICATION SPM ISO 9001 TEMPERATURE 0

CUST WEATHERFORD QTY 1 FLUID END S/N FOR TEMPERATURES LOWER THAN 0C, THE FOLLOWING BAR STOCK

ITEMS MUST BE MADE FROM LOW-TEMP 4340 RATHER THAN THE

PO OR00021889 (AFE#15959) DATE 8/1/2008 PWR END S/N STANDARD TEMPERATURE 4140 CITED ON THE DRAWING BOM

ITEM P/N DESC PACKING NUT SUCTION CVR RET NUT

QTY EA

1 4A105150 FLUID END 2.75 TWS600S ( 5-4 BUTT ) 1 SUCTION CVR DISCHARGE CVR

AUTOFRETTAGE A/F SPEC 2S106400 A/F TOOLING 3A106401 DISCH CVR RET NUT GAGE CONN

2 2A111705 PACKING 2.75 RSL ACID/FRAC (ACIDS TO 28%) - WIPER/HI PERF - NO PEEK 3 GAGE CONN RET NUT DISCH FLG

3 3A106328 DISCH CVR 2.50-3.00 TWS600S ( OPT# 3: 2 1502 GGE - TWO ) TWO PC 1 DISCH FLG

4 2A109609PP VALVING 2.50-3.00 SPM - POLY PROD 6 THE FOLLOWING LOW TEMP STUDS, NUTS, AND BOLTS SHOULD

5 3A102713 2.50-4.50 TWS600 (OPT# 4: 2 1502F - TWO) REPLACE THOSE SPECIFIED ON THE DRAWING AND BOM

DISCH FLG 1

6 3A102536 SUCT MAN 2.50-4.50 TWS600 4 in (PLAIN) 1 STUD NUT

OTHER OTHER

1 1A106616 PWR END TWS600S POWER END-STYLE II 1

2 1A103336 GEAR RED TWS600S GEAR REDUCER - SHORT 1

SIDE LEFT HAND POSITION #1

TESTING: NDE

FOR ALL BAR STOCK COMPONENTS BY LEVEL II INSPECTOR (REQUIRED BY

3 PINION 1 DNV AND OTHER 3RD PARTIES

4 TACH DRV 1

TESTING: PRESSURE

5 4A105055 TOOL KIT TWS600S TOOL KIT 1 WORKING 16845 PSI

6 4P105066 SVC MAN TWS600S SERVICE MANUAL 2

FLUID END TO BE TEST PRESSURED FOR 3 MINUTES AND 15 MINUTES PER

7 2P103989 SHPG SKD TWS600S SHIPPING SKID 1 4S12497 (REQUIRED BY DNV AND OTHER THIRD PARTIES)

8 OTHER 1 UNIT TO BE RUN-IN ON SPM TEST STAND PER INSTRUCTIONS IN OPERATOR

9 MANUAL

" 1

10 " A COPY OF THE SALES ORDER IS INCLUDED WITH THIS PACKAGE.

1 BY: CTM PLEASE REVIEW AND VERIFY CONFORMANCE TO CONTRACT

11 " 1

12 SALES FILE PLANNING QUALITY

FLOW CTRL 1

COMMENTS: THIS IS PUMP #10 OF 10

DISCHARGE COVERS TO BE LOCATED PER FIG #1 PER DWG 3A106328 | PUMP #10 TO BE SHIPPED WITH PUMP #9 | TO SEP. 28, 1994 Revision 1 SEP. 12, 1996 Revision 3

INCLUDE PRESSURE TEST & RUN UP REPORT F-302 MAR. 22, 1995 Revision 2 MAY 24, 2002 Revision 4

You might also like

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12From EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No ratings yet

- Stuck Pipe Freeing WorksheetDocument2 pagesStuck Pipe Freeing WorksheetMurtda AL-SayadNo ratings yet

- ProTech1Ch6 PDFDocument61 pagesProTech1Ch6 PDFweldsv100% (1)

- TPAO production group operation historyDocument40 pagesTPAO production group operation historygregNo ratings yet

- CAMERON France S.A.S: Front SheetDocument27 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- الرياضيات استرشادية داخل ليبيا أساسي 2020 5001Document25 pagesالرياضيات استرشادية داخل ليبيا أساسي 2020 5001Sidra AlbitNo ratings yet

- Fishing Operations: Date Bha # BHA Run DescriptionDocument6 pagesFishing Operations: Date Bha # BHA Run DescriptionRamy SaidNo ratings yet

- Sajad Falah Radha PDFDocument5 pagesSajad Falah Radha PDFSajad FalahNo ratings yet

- Gas Rate Calculation ResultsDocument20 pagesGas Rate Calculation ResultsArif KhanNo ratings yet

- Drilling Jar Manual for Excellence, Integrity and LeadershipDocument13 pagesDrilling Jar Manual for Excellence, Integrity and Leadershipnjileo100% (1)

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Document1 pageAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Stuck Pipe in CTD OperationsDocument5 pagesStuck Pipe in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

- Max Pull On Drill StringDocument1 pageMax Pull On Drill StringMuhammad ShahrukhNo ratings yet

- TCP-DST-01 String Diagram Rajian-07 PDFDocument1 pageTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNo ratings yet

- Basic DrillingDocument65 pagesBasic DrillingAboZaidNo ratings yet

- Drill String 1 DISDocument1 pageDrill String 1 DISpiies85No ratings yet

- HSE Perforation CTDocument21 pagesHSE Perforation CTOchulor IsaacNo ratings yet

- 05 - SRB Hydraulic ProgramsDocument22 pages05 - SRB Hydraulic ProgramsnelsonhugoNo ratings yet

- Mud Report 1Document65 pagesMud Report 1Brahim LetaiefNo ratings yet

- Subsea Exercise No. 8: Complete The Following Questions Based On The Data GivenDocument3 pagesSubsea Exercise No. 8: Complete The Following Questions Based On The Data GivenOgbodu Ejiro DesmondNo ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Caculate Ecd With Engineering Formula 1Document2 pagesCaculate Ecd With Engineering Formula 1NurJan AmAnovNo ratings yet

- ASI-X Packer Size 6.625Document2 pagesASI-X Packer Size 6.625AlexandruVerdesNo ratings yet

- UL G 9-46 Unit #2H WBD PDFDocument7 pagesUL G 9-46 Unit #2H WBD PDFMilad Ebrahimi DastgerdiNo ratings yet

- Perforation SeminarDocument24 pagesPerforation SeminarSuleiman BaruniNo ratings yet

- Casing and Formation DamageDocument4 pagesCasing and Formation DamageManthan MarvaniyaNo ratings yet

- Oil Well CompletionDocument17 pagesOil Well Completionmts1234No ratings yet

- 456 - 42000e TESCO Torque Turn ServicesDocument2 pages456 - 42000e TESCO Torque Turn Servicestedongsaleko100% (1)

- Tools and Parts WGDocument35 pagesTools and Parts WGSerNo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument17 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredscrbdgharaviNo ratings yet

- Brine Fluids PlanningDocument4 pagesBrine Fluids PlanningKolawole AdisaNo ratings yet

- Spe 102661 MS PDFDocument8 pagesSpe 102661 MS PDFPheng Kit WongNo ratings yet

- SPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryDocument9 pagesSPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryAnonymous VNu3ODGavNo ratings yet

- Reservoir Stimulation PDFDocument75 pagesReservoir Stimulation PDFAzumbiNo ratings yet

- Directional Drilling DesignDocument53 pagesDirectional Drilling DesignAfnan AhmadNo ratings yet

- Coiled Tubing Strings LimetsDocument1 pageCoiled Tubing Strings LimetsmanibabuNo ratings yet

- Depth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Document101 pagesDepth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Roger GuevaraNo ratings yet

- Hydraulic Set Packer Rev0Document1 pageHydraulic Set Packer Rev0JasonNo ratings yet

- OVERPULLDocument3 pagesOVERPULLscrbdgharaviNo ratings yet

- HighPressureGas Well KillingDocument18 pagesHighPressureGas Well KillingDonna GrayNo ratings yet

- Drilling Equipment and Hand Tools (Revised)Document72 pagesDrilling Equipment and Hand Tools (Revised)Wai HtutNo ratings yet

- CDS VAM TOP ® 4.5in. 12.6lb-ft L80 13CR API Drift 3.833in.Document1 pageCDS VAM TOP ® 4.5in. 12.6lb-ft L80 13CR API Drift 3.833in.ThierryNo ratings yet

- API CasingDocument3 pagesAPI CasinghamidNo ratings yet

- Acid CalculationsDocument4 pagesAcid CalculationsjoensameNo ratings yet

- TUBEMOVEDocument2 pagesTUBEMOVEChristian MatteoNo ratings yet

- Wellbore Skematic DrawingsDocument74 pagesWellbore Skematic DrawingsMino MinoNo ratings yet

- Leak Off TestDocument2 pagesLeak Off TestLuisBlandónNo ratings yet

- Racture Pressure: Fracture GradientsDocument13 pagesRacture Pressure: Fracture GradientsPrasanti Plaban DashNo ratings yet

- Understanding MWD and LWD Data From Drilling ReportsDocument18 pagesUnderstanding MWD and LWD Data From Drilling ReportsvanthodcNo ratings yet

- DAILY DRILLING REPORT FOR WELL HH 83/1 CDocument1 pageDAILY DRILLING REPORT FOR WELL HH 83/1 CMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Cementing Program For The 13 38 Inch CasingDocument40 pagesCementing Program For The 13 38 Inch CasingMarvin OmañaNo ratings yet

- Hosan 1 EWOR Final CheckDocument40 pagesHosan 1 EWOR Final CheckvengurionNo ratings yet

- Cementing Job - 5 Inch Liner Al Raja 37Document2 pagesCementing Job - 5 Inch Liner Al Raja 37Doni KurniawanNo ratings yet

- Stuck Pipe PDFDocument16 pagesStuck Pipe PDFcarlos801No ratings yet

- CMT Programm Spd18a-07 - 3Document9 pagesCMT Programm Spd18a-07 - 3nabiNo ratings yet

- Freemyer TWS600S IV - OR00059565 4,5 & 3.5Document38 pagesFreemyer TWS600S IV - OR00059565 4,5 & 3.5Carlos Martínez VelázquezNo ratings yet

- SN11145T SECTION 5 SPARE PARTS Print FriendlyDocument12 pagesSN11145T SECTION 5 SPARE PARTS Print Friendlyrig602.mechanicNo ratings yet

- Lube Oil FilterDocument1 pageLube Oil FilterMahar Tahir Sattar MtsNo ratings yet

- HVL Electrical Installation (Document File 1)Document431 pagesHVL Electrical Installation (Document File 1)RaymondNo ratings yet

- Application Format For Child CustodyDocument2 pagesApplication Format For Child CustodyDHUP CHAND JAISWAL100% (3)

- Take Test - Final Exam - INDE8900-34-R-2020FDocument2 pagesTake Test - Final Exam - INDE8900-34-R-2020FAbhiNo ratings yet

- PN15CS1S01Document4 pagesPN15CS1S01joadNo ratings yet

- WHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)Document3 pagesWHO Guidelines For Drinking Water: Parameters Standard Limits As Per WHO Guidelines (MG/L)114912No ratings yet

- ResiboDocument1 pageResiboAlex RespicioNo ratings yet

- 可汗语法48篇(明志教育推荐) PDFDocument163 pages可汗语法48篇(明志教育推荐) PDFtellmewhour100% (2)

- Complete Dummy's Guide to a Diffusion Pumped Vacuum SystemDocument4 pagesComplete Dummy's Guide to a Diffusion Pumped Vacuum Systemjokerbuddy01No ratings yet

- 2018 Federal Income Tax Return PDFDocument8 pages2018 Federal Income Tax Return PDFBrandon BachNo ratings yet

- 2005 Petro Lab GuidelinesDocument11 pages2005 Petro Lab Guidelinesalomaritrq100% (1)

- Case Study in Competency Appraisal II - ABC and EDNDocument5 pagesCase Study in Competency Appraisal II - ABC and EDNRogelio Saupan Jr100% (1)

- Lab Report 2Document5 pagesLab Report 2adrianeNo ratings yet

- AA3 My Favorite City - Comparing Places Ejercicio FinalDocument6 pagesAA3 My Favorite City - Comparing Places Ejercicio FinalCesar Augusto Triana AyalaNo ratings yet

- Differential Pressure TransmitterDocument14 pagesDifferential Pressure TransmitterZainab KadhemNo ratings yet

- Stabilizers: Agusta A W139 Maintenance Course Training ManualDocument6 pagesStabilizers: Agusta A W139 Maintenance Course Training ManualNita PuteriNo ratings yet

- A Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFDocument8 pagesA Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFMeida Putri UtamiNo ratings yet

- Slide BP Texas City RefineryDocument20 pagesSlide BP Texas City Refineryamaleena_muniraNo ratings yet

- EWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books WeightingDocument2 pagesEWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books Weightingguru_3112No ratings yet

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDocument318 pagesPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNo ratings yet

- Libyan cuisine: Bazin, asida and moreDocument3 pagesLibyan cuisine: Bazin, asida and moreAndy Atehortua CiroNo ratings yet

- Outgassing Properties of Vacuum MaterialsDocument47 pagesOutgassing Properties of Vacuum Materialsmax8086No ratings yet

- The Pediatric Mandible I. A Primer On Growth and DevelopmentDocument10 pagesThe Pediatric Mandible I. A Primer On Growth and DevelopmentJulián David Ríos ZuluagaNo ratings yet

- Barriers To Nurse - Patient Communication in Saudi Arabia: An Integrative ReviewDocument10 pagesBarriers To Nurse - Patient Communication in Saudi Arabia: An Integrative Reviewmark3dasaNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak YojanaDocument19 pagesPradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak Yojanapriyajaiswal428No ratings yet

- Which Statement On Physical Development of Infants and Toddlers Is TRUEDocument9 pagesWhich Statement On Physical Development of Infants and Toddlers Is TRUEKristylle Renz100% (1)

- Nichita Stanescu - The Poet of Loneliness and LossDocument28 pagesNichita Stanescu - The Poet of Loneliness and LossEmanuelaCiocanNo ratings yet

- Grundfosliterature 743129Document7 pagesGrundfosliterature 743129Ted Andrew AbalosNo ratings yet

- Airworthiness Directives Record ControlDocument4 pagesAirworthiness Directives Record ControlJuan builesNo ratings yet

- Fire Safety in Public BuildingDocument48 pagesFire Safety in Public BuildingSamirsinh ParmarNo ratings yet

- EVBAT00100 Batterij ModuleDocument1 pageEVBAT00100 Batterij ModuleSaptCahbaguzNo ratings yet

- Cases Digest on Adoption, Guardianship and Related LawsDocument2 pagesCases Digest on Adoption, Guardianship and Related LawsGillian BrionesNo ratings yet