Professional Documents

Culture Documents

Quality Control Manual: UG-120 (C) (1) (-E)

Uploaded by

arif rhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Control Manual: UG-120 (C) (1) (-E)

Uploaded by

arif rhCopyright:

Available Formats

Doc No TMG-FAM-MAN-00002A

QUALITY CONTROL Section 13

MANUAL Page 1 of 3

DOCUMENTATION AND Revision 1

STAMPING Date 12/02/2019

13.1. Scope

This Section describes the system of controlling quality records and stamping

of Code items.

13.2. Records Generation and Accumulation

13.2.1. Upon review for completeness and acceptance by QA/QC Coordinator and Al,

Quality Control Records (QCR) shall be kept on file for retention by the QA/QC

Coordinator.

13.2.2. Such records shall be either original or legible copies of documents and shall

be identified by order.

13.2.3. The QA/QC Coordinator shall retain the original QCR for each order. The QCR

for section VIII div.1 shall include:

1) MDR / MPDR

2) Manufacturing drawings

3) Design calculations, including any applicable Proof Test Reports

4) Material Test Reports and/or material certifications

5) Pressure parts documentation and certifications

6) Welding Procedure Specifications and Procedure Qualification Records

7) Welder/Welding Operator Performance Qualification Records for each

welder who welded on the vessel

8) RT and UT reports

9) Repair procedure and records

10) Inspection Test Plan, MTIR, Weld and NDE Summary Sheet

11) Heat treatment records and test results

12) Post weld heat treatment records

13) Nonconformances and dispositions

14) Hydrostatic test records

15) Transfer forms [see UG-120(c)(1)(-e) ASME BPVC.VIII.1-2017 Edition]

13.2.4. Those documents shall be kept for at least 3 years after certification.

13.2.5. Radiograph shell be retained until the AI sign the MDR / MPDR

13.3. Code Stamping

13.3.1. Manufacturer’s Data Report and Stamping

a) The Design Engineer and QA/QC Coordinator have joint responsibility for

preparing the Manufacturer’s Data Reports with primary responsibility

retained by QA/QC Coordinator.

Doc No TMG-FAM-MAN-00002A

QUALITY CONTROL Section 13

MANUAL Page 2 of 3

DOCUMENTATION AND Revision 1

STAMPING Date 12/02/2019

b) Upon acceptance of the QCR for the Code item intended for shipment, the

QA/QC Coordinator shall sign and date on the MDR / MDPR for

certification.

c) The QA/QC Coordinator shall submit the certified MDR / MDPR with all

applicable Partial Data Reports and QCR to the Al for this review

d) Before signing the MDR by the Al, and with the authorization of the AI, the

QA/QC Coordinator shall be responsible for the application of the

appropriate ASME CM Stamps on the item or Name Plate (Exhibit 13-1).

e) The QA/QC Coordinator shall distribute legible copies of the completed

Manufacturer’s Data Report after signing by the AI as follows:

• National Board of Boiler and Pressure Vessel Inspector: original

(only if applicable sec 13.4)

• AI: 1 copy (if requested)

• Customer/User: 1 copy

• The appropriate enforcement authority in the jurisdiction in which

the vessel is to be installed where required by law: 1 copy.

• QC File: 1 original (if the item is registered with the National Board

issue 2 original)

f) If TMG fabricates code parts, Manufacturer’s Partial Data Report shall be

sent in duplicate to the customer or manufacturer of the code item.

13.4. National Board

Registration of MDR / MDPR with the National Board of Boiler and Pressure

Vessel Inspectors may be required by the Customer or Jurisdiction of

installation. In that case only, National Board Numbers shall be issued by the

QA/QC Coordinator just prior to Code stamping but after final Pressure Test.

For parts not pressure tested, the NB number shall be issued after final

inspection.

QA/QC Coordinator shall prepare and maintain the National Board

Numbers Log (Exhibit 13-2) showing NB No, date of issue, type of vessel,

manufacturer’s serial number, date the MDR/MPDR are posted to the

National Board. National Board Number shall be issued in sequential

(numerical) starting from one (1) without skips or gaps of unused number

or duplication of number MDR/MPDR shall be posted to the National

Board within 30 days after the AI has signed the MDR/MPDR.

Doc No TMG-FAM-MAN-00002A

QUALITY CONTROL Section 13

MANUAL Page 3 of 3

DOCUMENTATION AND Revision 1

STAMPING Date 12/02/2019

13.5. Authorized Inspector

All documents and records prepared for or generated from activities prescribed

by this section shall be made available for review by the AI.

You might also like

- Quality Control Manual: Field Assembly Control 15.1. ScopeDocument4 pagesQuality Control Manual: Field Assembly Control 15.1. Scopearif rhNo ratings yet

- 17-Sec 12 - Record RetentionDocument2 pages17-Sec 12 - Record RetentionMo ZeroNo ratings yet

- R-As0010-Qa-proc-7036 Cfu Factory Acceptance Test Procedurer - 1Document19 pagesR-As0010-Qa-proc-7036 Cfu Factory Acceptance Test Procedurer - 1ngoailong_0609No ratings yet

- Asme QCMDocument84 pagesAsme QCMCaptainTonies100% (2)

- Princely Jets Maintenance ProceduresDocument53 pagesPrincely Jets Maintenance ProceduresSyed Umar AhmedNo ratings yet

- Part 2 (04 Feb 2021)Document53 pagesPart 2 (04 Feb 2021)Syed Umar AhmedNo ratings yet

- Master Document MRB Index Rev RDocument10 pagesMaster Document MRB Index Rev RAdolfo Perez MonteroNo ratings yet

- CFU Factory Acceptance Test Procedure PDFDocument19 pagesCFU Factory Acceptance Test Procedure PDFAgung PrasetyooNo ratings yet

- Welding Consumable Control ProcedureDocument15 pagesWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Vuqla/Kku Vfhkdyi, Oa Ekud Laxbu Jsy Ea Ky Research Designs and Standards OrganisationDocument22 pagesVuqla/Kku Vfhkdyi, Oa Ekud Laxbu Jsy Ea Ky Research Designs and Standards OrganisationDinesh MehtaNo ratings yet

- ConvergentLiners SOW 13MAR2019Document30 pagesConvergentLiners SOW 13MAR2019MASOUDNo ratings yet

- M.O.E Part 2 Maintenance ProceduresDocument73 pagesM.O.E Part 2 Maintenance ProceduresEssam100% (1)

- POWERGRID's pre-commissioning procedures for substation equipmentDocument149 pagesPOWERGRID's pre-commissioning procedures for substation equipmentVeeranki Bharath80% (5)

- Vdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsDocument28 pagesVdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsRene Tapia100% (1)

- BWI NormsDocument7 pagesBWI Normsyoussef achourNo ratings yet

- General Inspection and Repair Remarks For Inspection/Repair ProceduresDocument9 pagesGeneral Inspection and Repair Remarks For Inspection/Repair ProceduresIvan MauricioNo ratings yet

- Calibration Procedure.Document7 pagesCalibration Procedure.Mohammed Kamal71% (7)

- 00 Specification CableDocument3 pages00 Specification CableLino AbetoNo ratings yet

- Total Technical Specs PDFDocument259 pagesTotal Technical Specs PDFBhavesh KeraliaNo ratings yet

- B&M Industrial Services QCSMDocument14 pagesB&M Industrial Services QCSMAb Wajid FarukiNo ratings yet

- CG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0Document30 pagesCG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0masprast.devegaNo ratings yet

- MCP-Maintenance-Procedures Rev1 - 072019Document91 pagesMCP-Maintenance-Procedures Rev1 - 072019Rodolfo ValençaNo ratings yet

- Airworthiness Advisory Circular: Director General of Civil AviationDocument7 pagesAirworthiness Advisory Circular: Director General of Civil AviationraviNo ratings yet

- No. 21 No.21 Guidelines On Approval Procedure For Onboard Loading ComputersDocument3 pagesNo. 21 No.21 Guidelines On Approval Procedure For Onboard Loading ComputersMarlon Alejandro Arboleda TapiaNo ratings yet

- Standard Inspection Report of A Gas Distribution OperatorDocument21 pagesStandard Inspection Report of A Gas Distribution OperatorSaumitra Shankar GuptaNo ratings yet

- U Stamp ManualDocument57 pagesU Stamp ManualJayeshNarang100% (4)

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- Aerospace Quality Management RequirementsDocument60 pagesAerospace Quality Management Requirementsramki1980No ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection and Quality Assurance Requirements for Non-Specific EquipmentDocument8 pagesInspection and Quality Assurance Requirements for Non-Specific EquipmentBayu Mukhammad FirdausNo ratings yet

- Additional Requirements for Saudi Aramco ProjectDocument27 pagesAdditional Requirements for Saudi Aramco Projectmunna100% (2)

- Dm-2016-001 Contractual Requirements For Components and Materials Qualitymanagement v2Document28 pagesDm-2016-001 Contractual Requirements For Components and Materials Qualitymanagement v2Monica FernandezNo ratings yet

- Non Lethal WeaponsDocument21 pagesNon Lethal WeaponsHRCNo ratings yet

- 009 04 - Fy14 CH1Document10 pages009 04 - Fy14 CH1Brian Joseph MugrageNo ratings yet

- Underground UPVC Drainage Method StatementDocument50 pagesUnderground UPVC Drainage Method StatementDiaa GobranNo ratings yet

- Fire Safety Installation Method StatementDocument60 pagesFire Safety Installation Method StatementDiaa GobranNo ratings yet

- Ano 002 Awrg 2.1Document30 pagesAno 002 Awrg 2.1afa.maintNo ratings yet

- PmiDocument10 pagesPmiparaneetharanNo ratings yet

- Calibaration Procedure Rev3Document4 pagesCalibaration Procedure Rev3Zubair Ahmed KhaskheliNo ratings yet

- M72 Certification of Engine Components M72Document7 pagesM72 Certification of Engine Components M72aakhyar_2No ratings yet

- Moe P 2 Rev 1Document63 pagesMoe P 2 Rev 1Trailblazer487No ratings yet

- 23 Samss 030Document31 pages23 Samss 030nadeem shaikh100% (1)

- M BFM 2g1as0 Cjme MSD 940001 - 001Document332 pagesM BFM 2g1as0 Cjme MSD 940001 - 001Rasul MydeenNo ratings yet

- TCE document review proceduresDocument15 pagesTCE document review proceduresbandithaguru100% (1)

- Oil & Gas Rig Inspection Report TemplateDocument8 pagesOil & Gas Rig Inspection Report TemplateAhmed Imtiaz RaoNo ratings yet

- 1 Hooldusprogrammi NaidisDocument7 pages1 Hooldusprogrammi NaidisRodrigo ArgoteNo ratings yet

- 34 Samss 118Document9 pages34 Samss 118naruto256No ratings yet

- SJ E&M Engg 009 2022Document3 pagesSJ E&M Engg 009 2022Puneet BhardwajNo ratings yet

- PJ0044 00 El MRQ 3004 - 0Document8 pagesPJ0044 00 El MRQ 3004 - 0Dwi Mulyanti DwimulyantishopNo ratings yet

- R As0007 Qa Proc 0744 - Fat Procedure Precoat - r0Document42 pagesR As0007 Qa Proc 0744 - Fat Procedure Precoat - r0phamthaituyen100% (1)

- Dow instrument calibration guideDocument2 pagesDow instrument calibration guideAngelo Carlo MalabananNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- CAR & MOE, TPM NotesDocument75 pagesCAR & MOE, TPM Notesbirendra67% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Ground Bed Installation SOPDocument4 pagesGround Bed Installation SOParif rhNo ratings yet

- Tubing DataDocument8 pagesTubing DataGunawan AdeNo ratings yet

- MSP 236 Rev. 5 - Piping Fabrication, Installation, Cleaning & TestingDocument40 pagesMSP 236 Rev. 5 - Piping Fabrication, Installation, Cleaning & Testingarif rh100% (1)

- Transformer Rectifier ReadingsDocument7 pagesTransformer Rectifier Readingsarif rhNo ratings yet

- Soil pH Measurement ProcedureDocument4 pagesSoil pH Measurement Procedurearif rhNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Cathodic Protection Cable Installation ProceduresDocument4 pagesCathodic Protection Cable Installation Proceduresarif rhNo ratings yet

- Cathodic Protection Cable Installation ProceduresDocument4 pagesCathodic Protection Cable Installation Proceduresarif rhNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Quality Control ManualDocument1 pageQuality Control Manualarif rhNo ratings yet

- PAINTING AND GENERAL WORKS-TMG OkDocument6 pagesPAINTING AND GENERAL WORKS-TMG Okarif rhNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- LAND SPRAYING WITH HERBICIDE-TMG OkDocument4 pagesLAND SPRAYING WITH HERBICIDE-TMG Okarif rhNo ratings yet

- Alexander Lee ResumeDocument2 pagesAlexander Lee Resumeapi-352375940No ratings yet

- 3698 8a2fgDocument3 pages3698 8a2fgJampaNo ratings yet

- Scrum Sprint Activities: Understanding the Key Events in an Agile ProjectDocument23 pagesScrum Sprint Activities: Understanding the Key Events in an Agile ProjectWelton DiasNo ratings yet

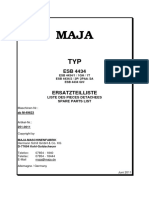

- Maja ESB 4434 SkinnerDocument288 pagesMaja ESB 4434 SkinnerpollosfrescosNo ratings yet

- Railway Ticket Reservation System AbstractDocument2 pagesRailway Ticket Reservation System Abstractb2uty77_593619754100% (1)

- 2WS21ENDocument8 pages2WS21ENcibocrisNo ratings yet

- SAP - Test Acceleration & OptimizationDocument11 pagesSAP - Test Acceleration & Optimizationmofibhai100% (1)

- FL OriginalLineDocument134 pagesFL OriginalLinebrooklynsnowNo ratings yet

- Tableau Sample Resume 2Document6 pagesTableau Sample Resume 2SANTOSH GEEKNo ratings yet

- TM - 1 2840 258 23PDocument276 pagesTM - 1 2840 258 23PSharly_ly80% (5)

- Workbook For StudentsDocument40 pagesWorkbook For StudentsBongiwe ThobekaNo ratings yet

- SIRIM Certified Steel BarsDocument27 pagesSIRIM Certified Steel BarsLay Wee KhooNo ratings yet

- EML 2322L Mechanical Hub DesignDocument8 pagesEML 2322L Mechanical Hub DesignsfjhsakjfhNo ratings yet

- Cloud Computing Meets Project ManagementDocument6 pagesCloud Computing Meets Project ManagementRaj AsavaNo ratings yet

- It8995e 128Document3 pagesIt8995e 128Madu MaduNo ratings yet

- 2nd Industrial RevolutionDocument32 pages2nd Industrial RevolutionDebajit KarNo ratings yet

- Sap RMDocument44 pagesSap RMnarayanaNo ratings yet

- Señales CKP-CMPDocument67 pagesSeñales CKP-CMPAriel MercochaNo ratings yet

- NASA SPACE VEHICLE DESIGN CRITERIA (CHEMICAL PROPULSION): LIQUID ROCKET ENGINE FLOW TURBOPUMPS CENTRIFUGALDocument124 pagesNASA SPACE VEHICLE DESIGN CRITERIA (CHEMICAL PROPULSION): LIQUID ROCKET ENGINE FLOW TURBOPUMPS CENTRIFUGALARturo NeuroNo ratings yet

- Developing Information System SolutionDocument42 pagesDeveloping Information System SolutionAbhijeet Mahapatra71% (7)

- GBAS: A Future Precision Landing System in Low VisibilityDocument5 pagesGBAS: A Future Precision Landing System in Low VisibilityChilaka Mahesh100% (1)

- FORTRON® 1120L4 - PPS - Specialty: DescriptionDocument2 pagesFORTRON® 1120L4 - PPS - Specialty: DescriptionAdam GordonNo ratings yet

- Backhoe Loader Finite Element AnalysisDocument55 pagesBackhoe Loader Finite Element AnalysisPrabhakar Purushothaman100% (2)

- Carpet Shampooing SOPDocument3 pagesCarpet Shampooing SOPshahnawaz2012-1100% (1)

- (the Lean Guidebook Series) Mascitelli, Ronald_ Mascitelli, Ronald-The Lean Design Guidebook _ Everything Your Product Development Team Needs to Slash Manufacturing Cost-Technology Perspectives (2004)Document320 pages(the Lean Guidebook Series) Mascitelli, Ronald_ Mascitelli, Ronald-The Lean Design Guidebook _ Everything Your Product Development Team Needs to Slash Manufacturing Cost-Technology Perspectives (2004)patilssp100% (1)

- ASME B73 Pump Standards OverviewDocument16 pagesASME B73 Pump Standards Overviewdang2172014No ratings yet

- Building Permit FormDocument52 pagesBuilding Permit FormCalvin Wong, Jr.100% (2)

- Manual Breaker Areva MTDocument28 pagesManual Breaker Areva MTJavier Morgan0% (1)

- Brake ClevelandDocument276 pagesBrake ClevelandFran GaritaNo ratings yet

- Lightning Protection Risk Assessment Study - Write UpDocument3 pagesLightning Protection Risk Assessment Study - Write UpPillai Sreejith100% (8)