Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Review and Certification

Schedule Q

A1 Review Quality Documentation for Material Receiving.

Att. IV Sec. 3.3

Material identification Procedure reviewed and shall be implemented for

all materials, parts and components, including partially fabricated Schedule Q

A2

assemblies. (Based on project specs, which define the length of tube and Att. IV Sec. 4.2

part number in the drawings)

Schedule G

A3 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A4 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

Schedule Q

incoming materials shall be visually inspected for damage and

A5 Att. IV

conformance to all applicable inspection releases with Material Test

Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all Schedule Q

A6 applicable requirements, standards and specifications prior to release to Att. IV

be used as part of the work. Sec. 3.3

Traceability - Instrumentation materials shall be traceable from the Schedule Q

A7 manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV

installation, repair, modification and use. Sec. 4.3

Verify that the contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

A8 Att. III

locations as required by the inspection level assigned for the materials

3.2

and equipment identified in SAER-1972 Inspection Requirements.

Vendor to provide usual warranty from the packaged unit manufacturer.

The warranty to include all materials, workmanship and performance

characteristics in accordance with his standard terms and conditions. 34-SAMSS-831

A9

Components supplied by the packaged unit vendor will include, but are Sec. 1

not limited to field instruments, controls, valves, safety systems, pre-wired

field interfaces, plant control system interfaces and electrical systems.

Inspection: The items manufactured to this specification (34-SAMSS-

831) are subject to verification by the Buyer's Inspection Representative 34-SAMSS-831

A10

per Saudi Aramco Inspection Requirement Form 175-340200, attached to Sec. 10.2

the Purchase Order.

Saudi Aramco: Company General Use

Contractor shall produce certification that Instruments and control systems

shall operate continuously under the following ambient air temperatures

without any degradation of the manufacturer's guaranteed performance:

34-SAMSS-831

A11

Sec. 5.1

Vendor to provide certification that the equipment complies the following:

Humidity

34-SAMSS-831

A12 (1) Indoor humidity design basis shall be 20% to 80% relative humidity.

Sec. 5.2

(2) Outdoor design basis shall be 5% to 95% relative humidity (non-

condensing).

Contractor to provide certification that the equipment meets the severe

dust and contaminants requirements detailed below:

Onshore Environment: Usual airborne dust concentration is 1 mg/m³.

During sandstorms, dust concentrations may reach 500 mg/m³. Particle

size distribution is as follows:

(1) 95% of all particles are less than 20 micrometers

(2) 50% of all particles are less than 1.5 micrometers

Elements present in dust include compounds of calcium, silicon,

magnesium, aluminum, potassium, chlorides and sodium. When wetted

34-SAMSS-831

A13 (high humidity conditions) these compounds function as electrolytes and

Sec. 5.3.1

can result in severe corrosion.

Other pollutants present in the atmosphere under the most extreme

conditions are:

H2S ---------------- 20 ppm (vol/vol)

Hydrocarbon ----- 150 ppm (vol/vol)

SO2 --------------- 10 ppm (vol/vol)

CO --------------- 100 ppm (vol/vol)

NOx --------------- 5 ppm (vol/vol)

O3 --------------- 1 ppm (vol/vol)

Storage, Handling and Preservation

The manufacturer's storage, handling and preservation instructions to be Schedule Q

A14

followed. Att. IV Sec. 6.0

B General Requirements

All materials shall be suitable for the specified service, and the Vendor

shall obtain a written approval from the Buyer for all selected materials in 34-SAMSS-831

B1

severe process services. All wetted parts in sour service shall conform to Sec. 9

NACE MR0175/ISO 15156.

Instruments: All instruments shall be technically acceptable to the Buyer.

The Vendor shall submit a list of all selected instrument manufacturers, 34-SAMSS-831

B2

instrument model numbers and specification sheets for approval by the Sec. 9.1

Buyer.

Electrical Requirements: All Electrical equipment intended for operation

in locations classified under the requirements of NFPA 70, Article 500, 34-SAMSS-831

B3

shall be listed or labeled by any of the agencies listed in appendix 2 Sec. 7.1

(Attachment 3 and 4)

34-SAMSS-831

B4 Conduit sealing fittings shall be labeled or listed by UL, FM or CSA.

Sec. 7.1

C Material Requirements for Instruments, Piping, Tubing and Fittings

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags/labels and Schedule Q

C1

nameplates, and shipment checked for damage, prior to acceptance of the Att. IV

shipment

All process-connected instruments shall be cast or forged steel, stainless

34-SAMSS-831

C2 steel or a suitable corrosion resistant alloy equal to or better than the

Sec. 9.1

ASTM specifications.

Cast iron shall not be used for hydrocarbon service, or for any flange- 34-SAMSS-831

C3

mounted instrument. Sec. 9.1

Saudi Aramco: Company General Use

The non-wetted parts of instrument housings or enclosures shall be

stainless steel or low copper aluminum, (0.4% max), and shall be rated as 34-SAMSS-831

C4

NEMA Type 4X or IEC Type IP 65. All junction boxes shall be 316 Sec. 9.1

stainless steel

Enclosures for instruments in outdoor plant areas shall be NEMA Type 4

in accordance with NEMA ICS 6 and NEMA 250 or IEC 60529 Type IP 65. SAES-J-902

C5

Enclosures in severe corrosive environments shall be NEMA Type 4X or Sec.7.1

IEC 60529 Type IP 66.

The field junction box, in a Class I, Zone 2 location and in non-hazardous

areas, shall be a single door NEMA Type 4X or IEC 60529 Type IP 66

box. For non-corrosive environment, the box shall be made of cast

copper-free aluminum (0.6% max copper). For severe corrosive

environment in offshore/onshore installations, the box shall be made of

either 316 SS or UV protected GRP with three side sunshades.

Construction shall meet the following requirements:

7.3.1 Body, door, fittings, breathers, plugs, and other hardware shall be

made from the same material as the box or metallurgical compatible

one.Exception:

Captive screws may be used in lieu of captive clamps provided that the

screws do not penetrate the door gasket. Keylocks and padlocks are not

SAES-J-902

C6 acceptable.

Sec. 7.3

7.3.5 Data/Print pocket on inside of door.

7.3.6 External mounting brackets.

7.3.7 Collar studs for mounting inside panel if applicable.

7.3.8 Ground stud for terminating A/C safety ground wire.

7.3.9 Removable door.

7.3.10 Back panels shall be made from the same material as the box or

metallurgical compatible one

7.3.2 The body shall be smooth-finished type.

7.3.3 Hinge shall be made from the same material as the box or

metallurgical compatible one.

7.3.4 Captive clamps shall be made from the same material as the box or

metallurgical compatible one

Instrument enclosures and junction boxes having an internal volume

exceeding 2,000 cm³ shall be provided with Type 300 Series stainless SAES-J-902

C7

steel breather and drain fittings, or a combination breather and drain Sec. 7.5

fitting.

Instrument Piping and Tubing: Process connections up to and including 34-SAMSS-831

C8

the first block valve (the root valve) shall comply with the piping codes . Sec. 9.2

Piping and tubing materials downstream of the first block valve shall

comply with paragraphs 9.2.1 and 9.2.2. (check list items C16 to C18.)

All threaded fittings shall be forged carbon steel or stainless steel per 34-SAMSS-831

C9

ASME B16.11, and be Class 3000 for systems rated up to and including Sec. 9.2

ANSI Class 900, and Class 6000 for systems rated ANSI Class 1500. All

threaded connections shall be tapered per ASME B1.20.1.

All piping, tubing and valves shall be adequately supported and fastened

in a manner which facilitates replacement, prevents vibration, and

31-SAMSS-004

C10 damage due to incidental loads which may occur during operation or

Sec. 3.2

maintenance work. Refer to Drawing AB-036521 for valve bracing

(See Attachment 2)

Use of any unions in pressurized lines requires the approval of the 31-SAMSS-004

C11

Standards Committee Chairman; Pumps, Seals, and Mixers Sec. 7.5.2.8

Saudi Aramco: Company General Use

All piping systems shall be provided with vent valves at high points and

drain valves at low points. Horizontal runs in pressure piping shall slope 31-SAMSS-004

C12

gradually towards drain points. The minimum slope of drain lines shall be Sec. 7.5.1.17

1:50.

Auxiliary piping such as vent, drain, external flush, warm-up, external

lubrication, and cooling water piping shall be routed to or near the edge of

31-SAMSS-004

C13 the baseplate and shall terminate with flanged connections. These lines

Sec. 7.5.1.6

shall have a block valve, ½-inch minimum, located as close as feasible to

the pump casing connection.

Pipe bends shall have surfaces free of cracks and buckles. Flattening of

the cross section of bends shall not exceed 8 percent of the nominal pipe 31-SAMSS-004

C14

diameter. Bending procedures and heat treatment requirements shall be Sec. 7.5.1.11

in accordance with ASME B31.3

Tubing: Stainless steel tubing shall be seamless, annealed, minimum

wall thickness 1.24 mm, per ASTM A269, Grade TP-316L. Instrument air 34-SAMSS-831

C15

tubing shall be ¼ inch, 3/8 inch or ½ inch OD stainless steel. Wall Sec. 9.2.2.1

thickness shall be 0.75 mm or larger.

Fittings: 316 stainless steel compression fittings shall be either Crawford

Swagelok, Parker Hannifin A-Lok, Parker Hannifin Corp. CPI or Hoke

34-SAMSS-831

C16 Gyrolock. Any proposal to use fittings other than those listed above shall

Sec. 9.2.2.2

be reviewed by Supervisor, Instrumentation Unit, Process Instrumentation

Division, P&CSD.

Flexible hoses shall be stainless steel armored, with integral connectors.

34-SAMSS-831

C17 The hose length shall not exceed 600 mm. The hose lining shall be

Sec. 9.2.2.2

suitable for the process and operating conditions.

Valves and Manifolds: Forged carbon steel valves shall conform to

34-SAMSS-831

C18 ASTM A105, Grade 2. Forged stainless steel valves shall comply with

Sec. 9.3

ASTM A182, Grade F316.

Needle Valves: Needle valves shall be bar stock steel, with ratings as 34-SAMSS-831

C19

required, but at least Class 3000. Sec. 9.3.1

Needle valves shall have 316 stainless steel trim, integral seat, and 34-SAMSS-831

C20

welded bonnet. Needle valves shall have internal screw rising stems. Sec. 9.3.1

Manifolds: Manifolds for flow meter service shall have a rating Class

6000 at 95°C or Class 4000 at 260°C. Manifolds shall have 316 stainless 34-SAMSS-831

C21

steel body, bonnet, stem and seat, and teflon packing. Connections shall Sec. 9.3.2

be ½ inch NPT female at oval flange surface.

D Instrumentation Requirements

General power wiring, for circuits up to 600 V to ground and a maximum

current rating of 15 A, shall be stranded copper; flame retardant PVC,

34-SAMSS-831

D1 XLPE or XLPO insulated; size 14 AWG; have an insulation minimum

Sec. 7.1.1

temperature rating of 90°C and shall comply with NFPA 70 or IEC 60502-

1.

Instrumentation signal wiring shall be stranded copper; flame retardant

PVC, XLPE or XLPO insulated and shall have an insulation minimum

temperature rating of 90°C. The minimum wire size shall be:

(a) 16 AWG single twisted pair/triad from instruments to the nearest skid

34-SAMSS-831

D2 mounted junction box. Cables carrying analog signals shall also be

Sec. 7.1.1

shielded.

(b) 18 AWG for multi-twisted pair/triad cables from junction boxes to other

junction boxes or marshalling cabinets

(c) 22 AWG for multi-conductor cable inter-cabinet wiring.

Saudi Aramco: Company General Use

Specialty cables (e.g., High Temperature, communication, network

34-SAMSS-831

D3 cables) shall be certified by any of the agencies listed in Appendix 2 (See

Sec. 7.1.1

attachment 3)

34-SAMSS-831

D4 Pair/triads of multi-twisted pair/triad control cables shall be numbered.

Sec. 7.1.1

Except for thermocouple wiring, black and white are the preferred colors

for pair conductors and black, white and red for triad conductors unless 34-SAMSS-831

D5

otherwise specified in the purchase order. Blue color insulation or jacket Sec. 7.1.1

shall only be used for intrinsically safe installation.

Splices are not permitted in wiring. When wiring must be extended, 34-SAMSS-831

D6

connections shall be made via terminal blocks. Sec. 7.1.1

Terminals: Wiring connections shall be made to channel (rail) mounted

terminal blocks. These terminal blocks shall have tubular box clamp

connector and compression bar or yoke for wire termination. More than 34-SAMSS-831

D7

two connections per terminal point are not allowed. If open screw type Sec. 7.1.2

terminals are used, terminal lugs shall be ring tongue, compression type,

with insulated sleeves.

Fused terminals shall be used for power distribution, alarm and shutdown 34-SAMSS-831

D8

systems. Sec. 7.1.2

All packaged unit wiring, intended for interface with plant wiring, shall be 34-SAMSS-831

D9

terminated in junction boxes. Sec. 7.1.3

Wire Tagging: Interconnecting wires between skid mounted components

and between skid mounted instruments and the skid termination panel

34-SAMSS-831

D10 shall be tagged. Each tag shall identify the device to which the opposite

Sec. 7.1.5

end of the wire is connected. Heat shrink or ferrule type wire tags with

permanently embossed identification markings shall be used.

Grounding: Provision for grounding the skid structure shall be made at

diagonally opposite corners. The skid structure shall be designed to 34-SAMSS-831

D11

accommodate two-hole compression connector, for (2/0 AWG) copper Sec. 7.1.6

conductor, at each corner.

An identification tag or nameplate of 316 stainless steel shall be attached

securely to the equipment with SS or Monel fasteners. The tag shall be

marked with raised alphanumeric or die stamped with the following

information:

a) Saudi Aramco Purchase Order number

b) Manufacturer 34-SAMSS-831

D12

c) Part/Model Number Sec. 11

d) Serial Number

e) Date of Manufacture

f) Mark/Tag Number

The tag or nameplate shall be located so that the information can be read

after installation of the equipment or components.

Class I, Division 2. In Class I, Division 2 locations, meters, instruments,

and relays shall comply with 501.105(B)(1) through (B)(6).

That is all meters, instruments, and relays, including kilowatt-hour

meters, instrument transformers, resistors, rectifiers, and thermionic

tubes, shall be provided with enclosures identified for Class I, Division 1 NEC Article

D13

locations. Enclosures for ClassI, Division 1 locations include explosion 501.105(B)

proof enclosures and purged and pressurized enclosures.

Alternatively, equipment shall be permitted to be marked to indicate the

temperature class for which it is suitable, using the temperature class (T

Code) of Table 500.8(B). [See Attachment 4]

Saudi Aramco: Company General Use

Wiring Methods: In Class I, Division 2 locations, the following wiring

methods shall be permitted:

(1) All wiring methods permitted in NEC Art. 501.10(A).

(2) Threaded rigid metal conduit, threaded steel intermediate metal

conduit.

(3) Enclosed gasketed busways, enclosed gasketed wireways.

(4) Type PLTC cable in accordance with the provisions of

Article 725, or in cable tray systems. PLTC shall be installed in a manner

to avoid tensile stress at the termination fittings.

(5) Type ITC cable as permitted in 727.4.

(6) Type MI, MC, MV, or TC cable with termination fittings, or in cable tray

systems and installed in a manner to avoid tensile stress at the NEC Article

D14

termination fittings. 501.10(B)(1)

(7) In industrial establishments with restricted public access where the

conditions of maintenance and supervision ensure that only qualified

persons service the installation and where metallic conduit does not

provide sufficient corrosion resistance, reinforced thermosetting resin

conduit (RTRC), factory elbows, and associated fittings, all marked with

the suffix -XW, and Schedule 80 PVC conduit, factory elbows, and

associated fittings shall be permitted.

Where seals are required for boundary conditions as defined in 501.15(A)

(4), the Division 1 wiring method shall extend into the Division 2 area to

the seal, which shall be located on the Division 2 side of the Division 1–

Division 2 boundary.

Flexible Connections: Where necessary to employ flexible connections,

as at motor terminals, flexible fittings listed for Class I, Division 1 locations NEC Article

D15

or flexible cord in accordance with the provisions of NEC Art. 501.140 501.10 (A)(2)

shall be permitted.

Flexible Cords, Class I, Divisions 1 and 2:

(A) Permitted Uses: Flexible cord shall be permitted:

(1) For connection between portable lighting equipment or

other portable utilization equipment and the fixed portion

of their supply circuit.

The length of the flexible cord shall be continuous.

(B) Installation: Where flexible cords are used, the cords

shall comply with all of the following: NEC Article

D16 (1) Of a type listed for extra-hard usage 501.140(A)(1) &

(2) Contain, in addition to the conductors of the circuit, a grounding (B)

conductor complying with NEC Art. 400.23

(3) Connected to terminals or to supply conductors in an approved

manner

(4) Supported by clamps or by other suitable means in such a manner that

there is no tension on the terminal connections

(5) Provided with suitable seals where the flexible cord enters boxes,

fittings or enclosures of the explosion proof type

E Local Control and Alarm Display Cabinet Requirements

Finish: The cabinet finish shall be per manufacturer's standard unless

34-SAMSS-831

E1 stated otherwise. The color of the coating shall be as specified in the

Sec. 7.2.1

Purchase Order.

Design: VVortex coolers, heat pumps, or air conditioners may be used to

reduce 34-SAMSS-831

E2

internal cabinet temperature and shall be per manufacturer's standard Sec. 7.2.2

unless stated otherwiseInstrumentation Division, P&CSD.

Drawings: Vendor shall provide wiring diagrams or wiring list showing

termination strips and all electronic interconnections, with names and 34-SAMSS-831

E3

equipment/terminal identification. All spare terminals, terminal strips and Sec. 7.2.3

wires shall appear on the vendor wiring drawings or list.

Saudi Aramco: Company General Use

Indication Lights, Pushbuttons and Switches: Indication lights,

pushbuttons and switches shall be of the oil tight, heavy duty type. Long-

life type dated lamps or LED cluster lamps shall be used. Indication lights

34-SAMSS-831

E4 and pushbuttons shall have the following color:

Sec. 7.2.4

Red - abnormal, trip, shutdown, off, closed, emergency

Yellow - (pre-) alarm

Green - normal, on, open, permissive start

Controllers and Instrumentation: The vendor shall verify that all

equipment, including digital controllers and displays are suitable for

34-SAMSS-831

E5 operation in the ambient conditions specified in Section 5. Controllers and

Sec. 7.2.5

displays shall be installed in locations where vibration is negligible. Digital

displays shall be screened from direct sunlight.

Alarm and Shutdown Systems: Alarm and shutdown systems shall be 34-SAMSS-831

E6

of fail-safe design. Sec. 7.3.1

Solenoid valves and relays shall be energized during normal operating 34-SAMSS-831

E7

conditions. Sec. 7.3.1

All contacts of direct process-operated, manual shutdown and equipment 34-SAMSS-831

E8

status switches shall be closed during normal operating conditions. Sec. 7.3.1

Initiating devices for shutdown systems shall be independent, dedicated

primary elements having their own individual process connections. 34-SAMSS-831

E9

Primary elements in control or indicating loops shall not be used to initiate Sec. 7.3.2

shutdowns.

34-SAMSS-831

E10 Each shutdown signal shall have an alarm.

Sec. 7.3.2

Switch contacts shall be single-pole, double-throw (SPDT) as a minimum.

Unless otherwise specified, the minimum contact rating for disconnecting

34-SAMSS-831

E11 inductive loads shall be:

Sec. 7.3.4

a) 0.4 A @ 125 V DC

b) 5.0 A @ 120 V AC/60 Hz

Shutdown logic shall be designed to incorporate test facilities to permit 34-SAMSS-831

E12

initiating devices and output devices to be tested on line. Sec. 7.3.5

Inlet and outlet bypass switches shall be provided as necessary.

34-SAMSS-831

E13 Password protected software bypass switches are acceptable. The

Sec. 7.3.5

implementation of an input or output bypass shall be alarmed.

Solenoid valves shall have Code HT high-temperature molded coils,

suitable for 180°C, with silicone rubber insulated coils and connection 34-SAMSS-831

E14

wires. Viton elastomers shall be used, for seating and other resilient, Sec. 7.3.6

unless otherwise specified.

Control Valves: Refer to SATIP-700-01 for requirements of control 34-SAMSS-831

E15

valves. Sec. 7.4

All control Valves shall be flanged. Threaded control valves (for size 1½" 34-SAMSS-831

E16

and smaller) are acceptable Sec. 7.4

The minimum flange rating shall be ANSI Class 300, RF for valve sizes up 34-SAMSS-831

E17

to and including 16-in. Sec. 7.4

Self acting thermostatic control valves shall not be used without prior

34-SAMSS-831

E18 approval of Supervisor, Instrumentation Unit, Process Instrumentation

Sec. 7.4

Division, P&CSD.

The application, sizing, design and installation of safety relief valves (PZV)

shall meet the requirements of ASME SEC I, ASME SEC IV, ASME SEC 34-SAMSS-831

E19

VIII D1, and ASME SEC VIII D2; API RP 520, Parts I and II; API RP 521; Sec. 7.5

API STD 526, and/or API STD 527, as applicable.

F Installation Requirements

Mounting : All instruments shall be mounted as close to the process 34-SAMSS-831

F1

connection as possible. Sec. 8.1.1

Saudi Aramco: Company General Use

34-SAMSS-831

F2 Impulse lines shall be as short as possible.

Sec. 8.1.1

The location of instruments shall be so that direct drainage of condensate, 34-SAMSS-831

F3

water or process fluids from adjacent equipment has no adverse effect. Sec. 8.1.1

34-SAMSS-831

F4 Instruments shall be mounted in locations where vibration is negligible.

Sec. 8.1.1

All local instrumentation and associated control equipment shall be readily 34-SAMSS-831

F5

accessible from grade, platform, fixed walkway or fixed ladder. Sec. 8.1.1

Local indicating instruments shall be visible from where related equipment 34-SAMSS-831

F6

is operated or primary instruments are tested or calibrated. Sec. 8.1.1

Pressure and D/P instruments in liquid or condensable vapor service

shall be self-venting (i.e., mounted below the process connections) with all

impulse lines sloping downward approximately 1:10 minimum toward the

34-SAMSS-831

F7 instrument.Where this is not physically possible due to the location of the

Sec. 8.1.1

process connections (such as lube oil systems), then it is acceptable to

mount the pressure instrument above the process connection as long as a

high point vent is provided

Pressure and D/P instruments in gas service shall be self-draining (i.e.,

34-SAMSS-831

F8 mounted above the process connections) with all lines sloping downward

Sec. 8.1.1

approximately 1:10 minimum toward the process connection.

Pressure transmitters in gas service may be mounted on panels below

their process connections provided that the process connections are

34-SAMSS-831

F9 located on the top of the process lines, low point drains are provided, and

Sec. 8.1.1

the impulse lines slope toward the low point. For other applications refer

to API RP 551.

Impulse tubing shall be made with metallurgy compatible to process and 34-SAMSS-831

F10

ambient conditions. Threaded fittings shall be used. Sec. 8.1.1

Cables between skid mounted instruments and junction boxes shall be

routed in conduits. Armored cables may be routed on trays.The conduit 34-SAMSS-831

F11

installation shall be in accordance with NFPA 70 and 17-SAMSS-515 . Sec. 7.1.4

Refer to SATIP-P-104-05.

Different instruments signals shall be segregated from each other and 34-SAMSS-831

F12

from power wiring. Sec. 7.1.4.3

Temperature sensors shall be fitted with terminal heads and installed in

34-SAMSS-831

F13 thermowells. For details, see Standard Drawing AB-036019. (Attachment

Sec. 8.1.1

5)

Tagging: Instruments shall have permanently attached engraved

phoenolic / laminate or plastic nameplates, showing instrument tag 34-SAMSS-831

F14

numbers. Phoenolic nameplates shall be installed with two stainless steel Sec. 8.1.2

screws.

Level Gauge Glasses: Refer to Standard Drawing AB-036521 for typical

34-SAMSS-831

F15 liquid level gauge glasses installations. Weld pad type level gauges are

Sec. 8.1.1.2

acceptable for lube oil tanks.

Saudi Aramco: Company General Use

Safety Relief Valves:

All PZV shall be accessible for inspection and maintenance. When the

mass of PZV exceeds 25 kg (50 lbs), and the location is inaccessible for

cranes, davits shall be installed. PZV of 1 inch and larger shall have a 1-

inch drain between inlet block valve and PZV, and a 1-inch vent between

34-SAMSS-831

F16 PZV and outlet block valve. The system's discharge piping shall be self-

Sec. 8.1.1.3.1

draining toward the discharge end. Pocketing of discharge lines is

prohibited. The use of traps or other devices with operating mechanisms

shall be avoided. The discharge line shall be heat-traced when PZV

handle viscous materials, or materials that can solidify as they cool to

ambient temperature.

Inlet and Outlet Block Valves:

Block valves for maintenance isolation shall be installed in both the inlet

and outlet piping except for PZVs in ASME SEC I fired-boiler service.

Block valves shall be accessible for inspection and maintenance.

Block valves and vents need not be installed when a spare packaged unit

is provided or the packaged unit can be shutdown, isolated and

depressurized for the removal of the PZV for maintenance. Full-opening

ball valves are preferred for block valve applications. Gate valves used as

block valves shall have rising stems, and shall be installed with the stem 34-SAMSS-831

F17

horizontal. Port areas of inlet and outlet block valves shall not be less than Sec. 8.1.1.3.2

the nominal areas of the respective openings of the PZV. The pressure

drop of the block valves shall be included in the PZV piping calculation.

The pressure drop due to inlet block valve and piping shall not exceed 3%

of the PZV set pressure.

Block valves shall be capable of being car-sealed. PZVs venting to the

atmosphere or to atmospheric tanks do not require outlet block valves.

Block valves shall be provided with a position indicator. Block valves shall

be painted orange.

Process Connections: All threaded process connections shall be

tapered per ASME B1.20.1. All threaded process connections to vessels,

standpipes and lines, except thermowells, shall have heavy welding

bosses per Standard Drawing AE-036175, and threaded gate type block

valves as close to the vessel, standpipe or line as possible. Fittings

between the block valve and the welding boss, other than the pipe nipple,

are not allowed. The two threaded connections between the welding boss, 34-SAMSS-831

F18

pipe nipple and block valve shall be seal or bridge-welded per Standard Sec. 8.2.1

Drawing AB-036521. Appendix 1 (Attachment 7) shows the type of

welding (e.g., seal or bridge) for each application, but does not apply to

thermowells and flanged connections. Commercially available forged steel

branch outlets of Class 6000 rating are considered equivalent (Thredolets

or Socklets of Bonney Forge or equal). Couplings or half couplings shall

not be used, unless provision is made for a full penetration weld.

Instrument Piping and Tubing: The instrument piping and tubing

installation shall ensure the reliable and accurate operation of the

instrument(s) involved, and allow sufficient access for maintenance, 34-SAMSS-831

F19

calibration and testing. It shall be possible to test all alarm and shutdown Sec. 8.3

initiating devices, without interfering with the process operation of the

packaged unit.

Saudi Aramco: Company General Use

Instrument tubing shall be adequately supported to eliminate any vibration

transmission to the instruments or excessive load to the piping

connection, process line or vessel. Tubing to and from non-indicating 34-SAMSS-831

F20

instruments shall have a plugged tee or equivalent test point for calibration Sec. 8.3

and testing purposes. All threaded connections shall be tapered per

ASME B1.20.1.

All incoming and outgoing interconnection lines shall terminate in

bulkhead fittings. The lines shall be marked with the tag numbers of the

34-SAMSS-831

F21 corresponding instruments. Bulkhead fittings shall be installed with

Sec. 8.3

adequate spacing to ensure that any connection can be removed without

the need to remove other fittings.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract)

3. SAES-J-902 - Electrical Systems for Instrumentation, 1 January 2018

4. 34-SAMSS-831 - Instrumentation for Packaged Units, 14 May 2018

5. 31-SAMSS-004 - Centrifugal Pumps , 1 January 2017

6. NFPA 70 - National Electrical Code 2017

ATTACHMENTS:

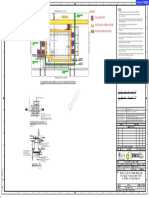

1. Attachment 1: STD. DWG. AB-036521 Sht 1 Rev 09 - Valve Bracings

2. Attachment 2: NFPA 70 Table 500.8(C) - Classification of Maximum Surface Temperature

3. Attachment 3 STD. Dwg. AB-036019 Sht. 1 Rev 21 - Temperature Sensors in Thermowells

4. Attachment 4: LIB. DWG. DB-950046 - Liquid Level Guage Glasses, Instrument Piping Details

5. Attachment 5: 34-SAMS-831 Appendix 1 - Instrument/Process Connections

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a

specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose

labeling the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

5. Notes - This check list is for Mechanical Equipment Skid - Zone or DIV 2 locations only (Does not apply for Custom engineered Package units but

only for pre-engineered, pre-assembled and pre- wired skid mounted packaged units)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Attachment 2: STD. DWG. AB-036521 Sht 1 Rev 09 - Valve Bracings

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Attachment 2: NFPA 70 Table 500.8(C) - Classification of Maximum Surface Temperature

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Attachment 3: STD. DWG. AB-036019 Sht. 1 Rev 21 - Temperature Sensors in Thermowells

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Attachment 4: LIB. DWG. DB-950046 - Liquid Level Guage Glasses, Instrument Piping Details

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

General - Mechanical Equipment Skid - Zone or DIV. 2

SAIC-J-6019 24-Jul-18 INST

Locations - Material Receiving

Attachment 7: 34-SAMS-831 Appendix 1 - Instrument/Process Connections

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- SAIC-X-3001 Rev 2Document2 pagesSAIC-X-3001 Rev 2josephjohn2No ratings yet

- ARAMCO RT Inpection Check List - SAIC-RT-2001Document15 pagesARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- SAIC-J-6401 - Rev 0Document4 pagesSAIC-J-6401 - Rev 0Adel KlkNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- A4.00-1-3to5-The Pits of Wob 1e ModuleDocument18 pagesA4.00-1-3to5-The Pits of Wob 1e ModuleNoomaa Lake100% (1)

- ThesisTheMoment 2Document43 pagesThesisTheMoment 2Mark Kenneth P. OntejoNo ratings yet

- Dry Wall SpecsDocument8 pagesDry Wall Specsc1565No ratings yet

- URS - South Luzon Mega DC - Rev 5.1Document34 pagesURS - South Luzon Mega DC - Rev 5.1Charlie MendozaNo ratings yet

- Ijebu Mushin Capital Projects 2022 - UnpricedDocument68 pagesIjebu Mushin Capital Projects 2022 - Unpricedoseni momoduNo ratings yet

- Furni 2 MergedDocument63 pagesFurni 2 MergedRhobie Bulan100% (1)

- CD 359 Design Requirements For Permanent Soffit Formwork-WebDocument14 pagesCD 359 Design Requirements For Permanent Soffit Formwork-WebAbinashNo ratings yet

- AiscDocument2 pagesAiscAekJayNo ratings yet

- Preliminary Structural Report IDPDocument32 pagesPreliminary Structural Report IDPMuhd IbrahimNo ratings yet

- City Hall Plan 30x40Document1 pageCity Hall Plan 30x40Joy Dawis-AsuncionNo ratings yet

- Subject: QSCT Class: Be Civil MCQ On Unit No.2 Taking Out Quantities & Detailed EstimateDocument9 pagesSubject: QSCT Class: Be Civil MCQ On Unit No.2 Taking Out Quantities & Detailed EstimateShinde vishal100% (2)

- 2021 The Factors That Influence Nigerian Traditional ArchitectureDocument3 pages2021 The Factors That Influence Nigerian Traditional ArchitectureYiskeprifun ElbatureNo ratings yet

- Industrial Webbing TapeDocument20 pagesIndustrial Webbing TapeJane StoneNo ratings yet

- Bailey Bridge: Field Manual No. 5-277 Headquarters Department of The Army Washington, DC, 9 May 1986Document373 pagesBailey Bridge: Field Manual No. 5-277 Headquarters Department of The Army Washington, DC, 9 May 1986Dilhara WickramaarachchiNo ratings yet

- Brick MUR Final LectureDocument31 pagesBrick MUR Final LectureMd Rakibul HasanNo ratings yet

- Masonry Army FM 5-428Document119 pagesMasonry Army FM 5-428calayflorNo ratings yet

- Model Chart of Quality Control Process For Ready Mixed Concrete PlantsDocument5 pagesModel Chart of Quality Control Process For Ready Mixed Concrete PlantsShraddha PatelNo ratings yet

- Analysis and Design of A Multi-Storey Reinforced Concrete BuildingDocument40 pagesAnalysis and Design of A Multi-Storey Reinforced Concrete BuildingAbinayaNo ratings yet

- Curtain Wall Manual - Section 8 InstallationDocument32 pagesCurtain Wall Manual - Section 8 InstallationphilipNo ratings yet

- Motivation For Hydraulic Transient AnalysisDocument14 pagesMotivation For Hydraulic Transient AnalysisDeepak JoyNo ratings yet

- Water Supply Plumbing Systems in Buildings & Houses: D.Eloise Sanhitha R.No: 20021A0115Document13 pagesWater Supply Plumbing Systems in Buildings & Houses: D.Eloise Sanhitha R.No: 20021A0115115 Sanhitha DevadhiNo ratings yet

- Triton Workcentre 2000Document28 pagesTriton Workcentre 2000MiraNo ratings yet

- Kz01-Cv-Lay-14-6010-001 - Master Point 2Document1 pageKz01-Cv-Lay-14-6010-001 - Master Point 2Admin UTSNo ratings yet

- Material Contract Work - Agreement Dated 19 Sep-2021 - CsDocument8 pagesMaterial Contract Work - Agreement Dated 19 Sep-2021 - Cssureshkumar0% (1)

- AZ - CSD Sanitary Sewers Engineering Standard PresentationDocument50 pagesAZ - CSD Sanitary Sewers Engineering Standard PresentationNilu BishiNo ratings yet

- It 5421Document16 pagesIt 5421ANSHORI PAGANNo ratings yet

- SEMINAR REPORT RCC RoadDocument25 pagesSEMINAR REPORT RCC RoadAkshay GhorpadeNo ratings yet

- ACICO Products CatalogueDocument54 pagesACICO Products CatalogueKarthikeyan .NNo ratings yet

- Etymology and History: Gypsum Is A SoftDocument2 pagesEtymology and History: Gypsum Is A SoftIndra PriadiNo ratings yet

- Hand SketchDocument3 pagesHand SketchNevena StojkovicNo ratings yet