Professional Documents

Culture Documents

Saic P 3426

Uploaded by

spravin231Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic P 3426

Uploaded by

spravin231Copyright:

Available Formats

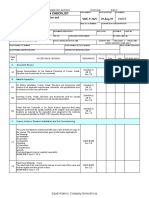

SAUDI ARAMCO ID/PIEU-30-April-2019 - REV.2019.04.00 (Standards Cutoff - April 30,2019) Rev.2019.04.

00 30-Apr-19

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

VSD - Air Cooled LV Adjustable Frequency Drive (AFD)

SAIC-P-3426 29-Aug-19 ELECT

Material Receiving

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. Document Review

Review documents of Material Receiving for the VSD - Air Cooled LV Schedule Q

A1

Adjustable Frequency Drive (AFD). Att. IV Sec 3.3

Identification procedure reviewed and implemented for the VSD - Air Schedule Q

A2

Cooled LV Adjustable Frequency Drive (AFD). Att. IV Sec 4.2

Material identification shall be implemented for all materials, parts and

components, including partially fabricated assemblies. VSD - Air Cooled

Schedule Q

A3 LV Adjustable Frequency Drive (AFD) shall be identified by using tags,

Att. IV Sec 4.2

stamps, color coding, stencils or labels. The location and method of

identification shall not affect the function or quality of the material.

Schedule Q

Outstanding punch list items from pre-shipment inspections shall be

A4 Att. lII Sec 3.24,

cleared.

3.25

B. General Requirements

Documentation for traceability reviewed and implemented. VSD - Air

Cooled LV Adjustable Frequency Drive (AFD) shall be traceable from the Schedule Q

B1

manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV Sec 4.3

installation, repair, modification and use.

Documented Control System shall be implemented for all Saudi Aramco Schedule Q

B2

supplied material and equipment. Att. IV Sec 5

C. Material Inspection

QC Before Installation- VSD - Air Cooled LV Adjustable Frequency Drive

Schedule Q

C1 (AFD) shall conform to all applicable requirements, standards, and

Att. IV Sec 3.3

specifications prior to release to be used as part of work.

Incoming VSD - Air Cooled LV Adjustable Frequency Drive (AFD) shall be Schedule Q

C2

visually inspected for damage / defects occurred during transportation. Att. IV Sec 3.3

VSD - Air Cooled LV Adjustable Frequency Drive (AFD) shall be new and Schedule G

C3

unused. Sec. 2.1

VSD - Air Cooled LV Adjustable Frequency Drive (AFD) shall be in

accordance with the Saudi Aramco-approved project-specific design Schedule G

C4

drawings, diagrams, schedules, lists, databases, and associated design Sec. 4.1

documents.

Check that the Contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier Schedule Q

C5

locations as required by the inspection level assigned for the materials Att. llI Sec 1.2

and equipment identified in SAEP-1151 Inspection Requirements.

Saudi Aramco: Company General Use

The Adjustable Frequency Drive System shall be supplied in accordance

C6 with the 9COM Material # and as specified in 16-SAMSS-517, IEC 60146 16-SAMSS-517,

& 61136 or NEMA ICS 7.

The application of AFDs on existing motors shall be reviewed by SAES-P-116

C7

CSD/ESD. Sec. 17.1

Low Voltage AFDs shall meet the requirements of either:

SAES-P-116

C8 a) The IEC 60146 and IEC 61136 series of standards.

Sec. 17.3

b) NEMA ICS 7.

The AFD system supplier shall perform, or directly oversee the SAES-P-116

C9

commissioning and startup of all drive systems 2000 kW and larger. Sec. 17.4.3

Bypasses shall not be incorporated around the AFD.

Commentary Note:

SAES-P-116

C12 Bypass systems are generally unnecessary, are not practical for some

Sec. 17.4.4

motor designs, and may require uneconomical additions to piping and

valve systems.

As indicated within 16-SAMSS-517, the AFD system supplier is

responsible to provide the buyer with any specific cabling requirements to,

SAES-P-116

C13 and between the devices associated with the AFD system (e.g., to and

Sec. 17.4.5

from the AFD isolation transformer filter, motor, etc.). The AFD

manufacturer shall concur to the cable design and installation.

The drive system and its components shall be designed and

16-SAMSS-517

C14 manufactured for a service life of 20 years. Required maintenance and

Sec. 7.3

caring to achieve this service lifetime shall be part of the documents

If the PDS consists of the supply of equipment from different companies,

the manufacturer shall be responsible for the integrity, and the technical 16-SAMSS-517

C15

coordination of the entire system. The manufacturer shall supply the entire Sec.7.6

PDS system.

If the motor within the PDS is an existing motor at a Saudi Aramco facility,

the manufacturer shall be responsible for identifying what motor

16-SAMSS-517

C16 information is required in order to engineer the entire PDS system. The

Sec. 7.7

manufacturer shall allow a minimum of four (4) weeks for this information

to be supplied.

The components of the PDS will be installed in locations separated from

each other. The manufacturer shall provide all cabling

16-SAMSS-517

C17 constraints/specifications between the components. This information shall

Sec.7.7

be provided a maximum of four (4) weeks after placement of the purchase

order.

All microprocessor based electronics shall automatically undergo a self-

diagnostic routine each time power is applied. Drive operation shall be 16-SAMSS-517

C18

prevented from starting until this routine is complete and no system faults Sec. 20.4

are detected

Flammable liquids (such as oils and esters) shall not be used as an 16-SAMSS-517

C19

insulating or current interrupting media Sec.7.8

16-SAMSS-517

C20 Polychlorinated Biphenyls (PCBs) shall not be used

Sec. 7.10

16-SAMSS-517

C21 All documentation shall be in English.

Sec. 7.11

Saudi Aramco: Company General Use

The labeling, listing, or certification of electrical equipment required by the

National Electrical Code (NEC) to be approved for use in hazardous

locations shall be based upon at least one of the following standards or

procedures:

(a) UL standards (for approved enclosures and fittings: UL 886).

16-SAMSS-517

C22 (b) FM procedures.

Sec. 7.15

(c) CSA standards.

(d) CENELEC EN 50014 and EN 50018 (for flameproof enclosures EEx d

II).

(e) CENELEC EN 50014 and EN 50019 (for increased safety apparatus

EEx e II).

The Complete Drive Module (CDM) shall be designed to be fully

16-SAMSS-517

C23 operational and maintainable with access only to the front of the

Sec. 7.14

assembly.

The drive equipment that is installed indoors shall be suitable for

continuous operation under the following service conditions:

a) Ambient air temperature:

i) A minimum of 5 degrees

ii) A maximum of 40 degrees 16-SAMSS-517

C24

iii) Average temperature, measured over a period of 1 month, is a Sec.8.2.2

maximum of 35 degrees.

b) Relative humidity (average value):

i) For a period of 24 hours, does not exceed 95%.

ii) For a period of 1 month, does not exceed 90%.

The drive equipment that is installed outdoors shall be suitable for

continuous operation under the following service conditions:

a) Ambient air temperature: (unless a more extreme temperature is

specified within Data Schedule 1)

16-SAMSS-517

C25 i) A minimum of 0 degrees.

Sec. 8.2.3

ii) A maximum of 50 degrees.

iii) Average, measured over a period of 1 month, is a maximum of 45

degrees.

b) Relative humidity may be temporarily 100%.

Electrical Area Classification of outdoor equipment shall be as specified 16-SAMSS-517

C26

within Data Schedule 1. Sec.8.2.4

Nominal input voltage levels to the PDS shall be as specified within Data 16-SAMSS-517

C27

Schedule 1. Sec.8.3.1

The Buyer shall provide a maximum of two sources of power to the BDM*:

a) Main Supply

b) Ancillary Supply: This will be distributed within the BDM to supply the 16-SAMSS-517

C28

auxiliary, control and field excitation power supplies. Sec. 8.3.8

* the exception is if the Buyer supplies the control power via a UPS or DC

system. This will then be considered a third power source into the BDM.

Operating Range:

(a) Continuous rating: 100%

(b) Adjustable starting current: 40% to 110%

(c) Overload Capability: 110% for 60 secs.

16-SAMSS-517

C29 (d) Speed control range of PDS: 30% to 105% (unless a more extreme

Sec.9.1

speed range is specified within Data Schedule 1). The motor's

horsepower rating must be based upon operating the driven equipment,

under process conditions over this speed range.

All the above are minimum ranges.

Efficiency:

16-SAMSS-517

C30 The minimum efficiency of the CDM shall be 95% at rated load and

Sec.9.3

frequency.

Power factor:

16-SAMSS-517

C31 The minimum power factor of the PDS shall be 90% between 75% and

Sec. 9.4

105% of rated speed.

Saudi Aramco: Company General Use

Acceleration/deceleration segments shall be provided which have the

following characteristics:

16-SAMSS-517

C32 a) A minimum of two segments shall be provided.

Sec. 9.5

b) Acceleration and deceleration rates shall each be independently field

adjustable for each segment (i.e., two adjustments per segment).

The BDM shall be of the metal enclosed type and will be installed an air 16-SAMSS-517

C33

condition controlled environment Sec. 10.1.1

16-SAMSS-517

C34 The total enclosure shall be fabricated from sheet steel.

Sec. 10.1.2

Maximum vertical section (or CDM) height shall be 3000 mm unless 16-SAMSS-517

C35

specified otherwise within Data Schedule 1. Sec. 10.1.3

Enclosures located outdoors shall have the following characteristics:

A) If "severe corrosive environment" has been specified within Data

Schedule 1 the enclosure design shall be either:

i) Type 4X per NEMA 250 with the exception that painted or coated

carbon steel sheet metal material shall not be used.

ii) Type 3 or 4 per NEMA 250 manufactured of copper free cast aluminum. 16-SAMSS-517

C36

iii) IP6X per IEC 529 and manufactured of stainless steel, copper free cast Sec. 10.1.7

aluminum or non-metallic material. The 'X' shall be a numeral between '4'

and '8' inclusive.

iv) In hazardous areas, enclosures shall meet the above ratings in

addition to the rating required for the hazardous area (e.g., 4/7, 3/7, EEx d

II/IP 65).

Enclosures located outdoors shall have the following characteristics:

B) If Data Schedule 1 specifies that the outdoor equipment is not being

installed within a "severe corrosive environment", it is acceptable that the

enclosures meet the requirements of either:

i) Type 4, 4X, 6, 6P, 3/7, 4/7 or 4X/7 per NEMA 250.

ii) IPYX per IEC 529 Where 'Y' shall be the numeral '5' or '6' and 'X' shall

be a numeral between '4' and '8' inclusive.

iii) "EEx d II" per CENELEC EN 50014 and 50018 in Class I, Division 1

and Division 2 provided all of the following conditions are met:

16-SAMSS-517

C37 1) Cable entry is per the ANSI/NFPA 70 (i.e., NEC).

Sec. 10.1.7

2) If installed within a Class 1, Division 1 environment, the overall

enclosure shall be flameproof EEx d II (explosion proof) as a whole, not

only its components.

3) The enclosure is constructed of a conductive metal or has integral

metal bonding devices that ensures a positive low resistance bond

between conduits or/and cable armors entering or terminating at the

enclosure.

4) "EEx e II" per CENELEC EN 50014 and 50019 only within Class I,

Division 2 locations.

Enclosures required to be approved by the NEC for use in hazardous 16-SAMSS-517

C38

areas shall labeled, listed or certified. Sec.10.1.8

As a minimum, the following shall each be within separate grounded,

metal compartments:

a) Main circuit disconnector (if provided by manufacturer)

b) Control Panel

c) Indoor Source Filter (if required) 16-SAMSS-517

C39

d) Source converter Sec. 10.2.1

e) DC Link

f) Load inverter

g) Indoor Motor Filtering (if required)

h) Indoor Pump equipment (if required)

Saudi Aramco: Company General Use

Hinged doors shall be provided for compartments housing routinely

serviceable equipment. As a minimum, hinged doors shall be provided for

the following:

a) Main circuit disconnector (if provided by manufacturer) 16-SAMSS-517

C40

b) Control Panel Sec. 10.2.2

c) Source converter

d) Load inverter

e) Pump equipment

Hinged doors and exterior removable panels shall be equipped with 16-SAMSS-517

C41

captive hardware. Sec. 10.2.3

16-SAMSS-517

C42 Hinged doors shall be electrically bonded to the stationary enclosure.

Sec. 10.2.4

For the indoor equipment, with all the exterior compartment doors closed,

the CDM shall, as a minimum, meet the requirements and test criteria for 16-SAMSS-517

C43

a IP2X degree of protection requirements as defined by IEC 60529. "X" is Sec. 10.2.IEC1

any number.

For the outdoor equipment, with all the exterior compartment doors

closed, the CDM shall, as a minimum, meet the requirements and test 16-SAMSS-517

C44

criteria for a IPYX degree of protection requirements. "Y" shall be the Sec. 10.2.IEC2

numeral 5 or 6, "X" shall be athe numeral between 4 and 8 inclusive.

The power, grounding, control, and communication cabling shall enter/exit

16-SAMSS-517

C45 via the top and/or bottom of the drive as specified within Data Schedule 1

Sec. 10.3.1

or on the Reference Drawings.

Appropriate raceways/wireways shall be provided within the enclosure to

allow the field cabling to be routed to the termination locations within the 16-SAMSS-517

C46

enclosure. Design shall ensure that the field cable and wire bending Sec. 10.3.2

radius shall be a minimum of 12 cable diameters.

All unpainted hardware shall be of a non-oxidizing or non-corrosive

material (e.g., stainless steel, brass, etc.) or shall be plated with a material 16-SAMSS-517

C47

which will inhibit oxidation and corrosion (e.g., zinc, cadmium, chromium, Sec. 10.4.1

etc.)

The exterior of the PDS equipment shall be of a uniform color. The color 16-SAMSS-517

C48

shall be the manufacturer's standard. Sec. 10.4.2

All conductors shall be copper, silver or alloys of these materials with the

following exceptions:

(a) Parts which are internal to a pre-manufactured device (e.g., internals

of contactor, circuit breaker, electronic equipment, etc.).

16-SAMSS-517

C49 (b) Connectors supplied as integral parts or components of manufactured

Sec. 11.1

equipment such as molded case circuit breakers, contactors, switches,

etc., provided the connectors are approved for copper conductors.

(c) Plating of the copper, silver or copper/silver alloy base conductor

material is acceptable.

The drive shall be equipped with a ground bus, either extending the full

width of the assembly of CDM enclosures or sectioned ground bus linked

16-SAMSS-517

C50 together using cable of higher ampacity than the ground bus. All

Sec. 11.1

connections shall be via bolted connections and all necessary hardware to

interconnect the bus between shipping splits shall be supplied.

A space heater system shall be installed within each CDM compartment

for use when the equipment is in storage prior to installation. The system

shall have the following characteristics:

(a) Shall be designed to eliminate internal condensation with a relative 16-SAMSS-517

C51

humidity of 95% and temperature fluctuations from 0 to 50°C. Sec. 13.1

(b) Shall operate at 120 VAC. The heaters shall be interconnected and

one connection point provided for the Buyer to connect the external

branch circuit.

Saudi Aramco: Company General Use

A motor space heater control system shall be provided within the control

panel. This system shall have the following characteristics:

(a) Shall be controlled by a relay which energizes the motor space

heater(s) when motor the isolation contactor poles are open or the

contactor is withdrawn. The relay shall have a minimum of two (2)

16-SAMSS-517

C52 normally closed contacts to which the field motor space heater leads will

Sec. 13.2

be connected.

(b) One ammeter shall be provided to monitor the current of the motor

space heater. This meter shall be installed within the BDM.

(c) A 120 VAC branch circuit for the space heater shall be field connected

by the Buyer.

Low voltage circuit breakers shall have the following additional

characteristics:

a) Meet the requirements of IEC 60947-2. 16-SAMSS-517

C53

b) Rated Operational Voltage (minimum): 240/415V or 415 V. Sec. 3.2

c) Utilization Category: A or B.

d) Rated Ultimate Short Circuit Breaking Capacity (minimum): 10 kA.

If the transformer is rated greater than 5 MVA, a set of CTs shall be

installed on the secondary terminals to allow the installation of a Buyer

16-SAMSS-517

C54 supplied transformer differential protection scheme. The manufacturer

Sec. 14

shall coordinate with the Buyer on the size and characteristics of these

CTs.

The voltage rating of the motor shall be at the discretion of the 16-SAMSS-517

C55

manufacturer, however, the preference is 4000 V, 6600 V or 13,200 V. Sec. 15.1.1

If installed indoors and associated with a CDM 10,000 kW or larger, the 16-SAMSS-517

C56

inductor shall be liquid cooled. Sec. 16

Power conversion bridges within a BDM rated 10,000 kW and larger shall

be liquid cooled. All others shall be either liquid or forced air cooled at the

16-SAMSS-517

C57 discretion of the manufacturer. The cooling method and heat dissipation of

Sec. 17.1

the indoor CDM equipment shall be identified by the manufacturer within

Data Schedule 2.

Bushings and insulators installed outdoors and directly exposed to the

16-SAMSS-517

C58 environment shall have a minimum leakage distance of 40 mm per kV

Sec. 18.1

line-to-line of the system nominal voltage.

The voltage THD at the point of connection of the FS to the Saudi Aramco

power source shall not exceed 5.0% and individual voltage distortion shall

16-SAMSS-517

C59 not exceed 3.0%. This criteria shall be met with all connection

Sec. 18.2.1

combinations of the Saudi Aramco bus systems and energization

combinations of PDSs.

All control, metering and protection devices, with manual features which

are operable with the compartment closed, (e.g., selector switches, push- 16-SAMSS-517

C60

buttons, motor protection relay, etc.) shall be mounted a maximum of Sec. 19.1.1

1800 mm from the base of the vertical section.

Drive shall be factory wired to accommodate the installation of a field

emergency STOP normally-closed contact. The design shall include this

STOP contact within a hard-wired control circuit which trips the Buyer

16-SAMSS-517

C61 supplied circuit breaker which feeds the FS. Only electro-mechanical

Sec.19.1.2

switching devices (i.e., not solid-state) are permitted within this hardwired

circuit. Activation of this push-button shall instantaneously open the circuit

breaker.

All fuses shall have the following characteristics:

16-SAMSS-517

C62 a) Be of the non-renewable, non-expulsion type

Sec. 19.2

b) Fuse body shall not be of glass

Indicating lights shall have the following characteristics:

a) Fixture shall have a built-in voltage-reducing device (i.e., transformer,

resistor, etc.).

16-SAMSS-517

C63 b) Light/circuit design shall allow the permanent shorting out of the lamp

Sec. 19.5

terminals without affecting drive operation.

c) Lamps shall be high density LED (Light Emitting Diode) type.

d) Lamp shall be field replaceable.

Saudi Aramco: Company General Use

An emergency STOP push-button shall be semi-flush mounted in the

16-SAMSS-517

C64 control panel door. Activation shall instantaneously shut down the drive

Sec. 19.6.1

power electronics and open the motor isolation contactor.

If activation of any individual push-button, control switch or function button

16-SAMSS-517

C65 will cause an immediate drive reaction they shall be guarded, recessed or

Sec. 19.6.2

constructed in such a manner as to prevent accidental actuation.

The BDM shall be equipped with an alphanumeric panel display showing 16-SAMSS-517

C66

drive parameters, operating status and alarms. Sec. 20.1.1

All metering, indication and data logging functions shall be visible from the 16-SAMSS-517

C67

front of the drive with all compartment doors closed. Sec. 20.1.2

Unless specified otherwise within the purchasing documents, the speed

reference to the drive shall be via a 4-20 mADC, 24 VDC non-isolated

16-SAMSS-517

C68 signal. 4 mA shall refer to the minimum operational speed. If this

Sec. 20.1.3

reference signal is lost, the drive shall decelerate to the minimum

operating speed.

16-SAMSS-517

C69 Metering systems shall 2% or better full scale accuracy.

Sec.20.2.1

Mechanical interlocks shall be provided to prevent:

If main circuit disconnectors are used, the compartment door housing the

disconnectors from being opened if the disconnector is in the closed

16-SAMSS-517

C70 position. This interlock shall be defeatable with the use of a tool (i.e.,

Sec. 21.1 & 21.2

screw-driver, wrench, etc.) and two separate operations.

If an earthing switch is used, the switch from being closed if the line side

of the switch is energized.

Interlocking and safety features shall also comply with any additional 16-SAMSS-517

C71

requirements presented within IEC 60298. Sec. 3.2

A complete set of special tools shall be provided for each group of drive 16-SAMSS-517

C72

assemblies within a substation. Sec. 23

All nameplates/equipment tags shall be attached with mechanical 16-SAMSS-517

C73

hardware. Sec. 24.1

Nameplates/equipment tags for outdoor equipment shall be stainless steel

16-SAMSS-517

C74 with stamped or engraved lettering and shall be attached with stainless

Sec. 24.2

steel hardware.

Nameplates indicating the manufacturer 's shop order number, date,

catalog designation and manufacturing location should be provided on all 16-SAMSS-517

C75

equipment in addition to the nameplate information required by the Sec. 24.3

Standards indicated within the Supplement.

All panel mounted devices shall be identified by escutcheon or nameplate

16-SAMSS-517

C76 on the front of the panel and by a nameplate on the rear of the panel

Sec. 24

adjacent to the device terminals.

Device nameplates shall be in the English language according to 16-SAMSS-517

C77

American usage. Sec. 24.4

Equipment shall be identified with the Buyer's and the manufacturer's

order numbers and any other designations requested on the Buyer's

16-SAMSS-517

C78 shipping instructions. These shipping instructions shall also include any

Sec. 26.1

special protective shipping or storage packaging required because of

long-term storage prior to installation or energization.

Foreign material which must be removed prior to energization shall be

clearly identified by distinctive colors and legends. Temporary warning

16-SAMSS-517

C79 signs stating "REMOVE TEMPORARY MATERIALS BEFORE

Sec. 26.2

ENERGIZATION" shall be conspicuously posted on the exterior of the

equipment.

Saudi Aramco: Company General Use

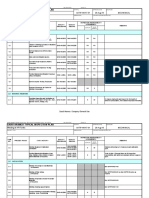

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), Contract Specific

2. Schedule Q - Quality Requirements (Pro Forma Contract), Contract Specific

3. SAES-P-116 - Switchgear and Control Equipment,8 August 2017

4.16-SAMSS-517 - Adjustable Frequency Drive System – 1 kV and Above -12 June 2017

5. NEMA ICS 7 - Industrial Control and Systems: Adjustable Speed Drivers, 2006 Edition

6. NEMA ICS 7.1 - Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive Systems, 2006

Edition

7. SAEP-1151 Inspection Requirements for Contractor Procured Materials & Equipment, 1 November 2017

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saic P 3423Document7 pagesSaic P 3423spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Sac Inspection Checklist: Procedure Review: WPS For API Tank Construction SACIC-W-2075 21-Sep-21 WeldDocument4 pagesSac Inspection Checklist: Procedure Review: WPS For API Tank Construction SACIC-W-2075 21-Sep-21 Weldhusnain aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalikNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- SACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingDocument4 pagesSACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- SAIC-W-2103 Review of WPS (DCW)Document10 pagesSAIC-W-2103 Review of WPS (DCW)mahmoud hegazyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- SAIC-P-3705 Rev 3Document9 pagesSAIC-P-3705 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldjeswinNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistspravin231No ratings yet

- Saic P 3424Document3 pagesSaic P 3424spravin231No ratings yet

- Saic P 3423Document7 pagesSaic P 3423spravin231No ratings yet

- Saic P 3425Document3 pagesSaic P 3425spravin231No ratings yet

- Saudi Aramco Typical Inspection PlanDocument12 pagesSaudi Aramco Typical Inspection Planspravin231No ratings yet

- Satip W 017 01Document13 pagesSatip W 017 01spravin231No ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01spravin231No ratings yet

- Satip X 600 02Document15 pagesSatip X 600 02spravin231No ratings yet

- Satip W 014 01Document12 pagesSatip W 014 01spravin231No ratings yet

- Satip y 101 01Document12 pagesSatip y 101 01spravin231No ratings yet

- Kalsi P S - Organic Reactions and Their Mechanisms 5eDocument26 pagesKalsi P S - Organic Reactions and Their Mechanisms 5eeasy BooksNo ratings yet

- Getting Things Done BasicsDocument60 pagesGetting Things Done Basicswestelm12100% (10)

- Intern JanataDocument59 pagesIntern JanataKhairul IslamNo ratings yet

- 9.LearnEnglish Writing A2 Instructions For A Colleague PDFDocument5 pages9.LearnEnglish Writing A2 Instructions For A Colleague PDFوديع القباطيNo ratings yet

- Syllabus Financial AccountingDocument3 pagesSyllabus Financial AccountingHusain ADNo ratings yet

- The Art of Starting OverDocument2 pagesThe Art of Starting Overlarry brezoNo ratings yet

- Graph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)Document8 pagesGraph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)LeeshaaLenee Paramanantha KumarNo ratings yet

- The Sphere Circumscribing A TetrahedronDocument4 pagesThe Sphere Circumscribing A TetrahedronRaghuveer ChandraNo ratings yet

- Report On Sonepur MelaDocument4 pagesReport On Sonepur Melakashtum23No ratings yet

- Product Management Mcnaughton - 0Document4 pagesProduct Management Mcnaughton - 0Andrey MatusevichNo ratings yet

- Dual Nature of Radiation and MatterDocument5 pagesDual Nature of Radiation and Mattercopadag753No ratings yet

- Netflix Annual Report 2010Document76 pagesNetflix Annual Report 2010Arman AliNo ratings yet

- Table of SpecificationDocument2 pagesTable of SpecificationAya AlisasisNo ratings yet

- Fin 320 - Individual AssignmentDocument14 pagesFin 320 - Individual AssignmentAnis Umaira Mohd LutpiNo ratings yet

- Ekoplastik PPR Catalogue of ProductsDocument36 pagesEkoplastik PPR Catalogue of ProductsFlorin Maria ChirilaNo ratings yet

- AC Hipots 15-200kVDocument4 pagesAC Hipots 15-200kVfelipe.aounNo ratings yet

- IRDM Assignment-I PDFDocument4 pagesIRDM Assignment-I PDFPiyush AggarwalNo ratings yet

- Ev Conversion PDFDocument2 pagesEv Conversion PDFShannonNo ratings yet

- Focus: Optimised Efficiency For The Paper IndustryDocument24 pagesFocus: Optimised Efficiency For The Paper IndustryZoran BadurinaNo ratings yet

- Honeymoon in Vegas Word FileDocument3 pagesHoneymoon in Vegas Word FileElenaNo ratings yet

- Legal NoticeDocument3 pagesLegal NoticeT Jayant JaisooryaNo ratings yet

- Concept of InsuranceDocument4 pagesConcept of InsuranceNazrul HoqueNo ratings yet

- Cognitive InfocommunicationsDocument229 pagesCognitive Infocommunicationsradhakodirekka8732No ratings yet

- Matter and Materials (Grade 6 English)Document80 pagesMatter and Materials (Grade 6 English)Primary Science Programme100% (5)

- 2-Amino-5-Aryl-2-Oxazolines.: (,ee TableDocument7 pages2-Amino-5-Aryl-2-Oxazolines.: (,ee TableChristopher HowellNo ratings yet

- BasicsDocument1 pageBasicsRishi Raj100% (1)

- SOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalDocument10 pagesSOLIDWORKS 2022 Whitepaper UsingDesignAutomationtoReduceCostsIncreaseProfitability FinalAlba R.No ratings yet

- Train Collision Avoidance SystemDocument4 pagesTrain Collision Avoidance SystemSaurabh GuptaNo ratings yet

- Sri Anjaneya Cotton Mills LimitedDocument63 pagesSri Anjaneya Cotton Mills LimitedPrashanth PB50% (2)

- HGP Year End Report 2021-2022 NewDocument169 pagesHGP Year End Report 2021-2022 Newangelica sungaNo ratings yet