Professional Documents

Culture Documents

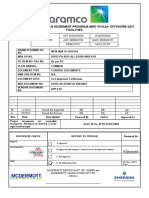

Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Inst

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Inst

Uploaded by

nisha_khanCopyright:

Available Formats

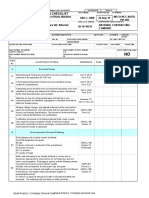

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 INST

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Review and Certification

Schedule Q

A1 Review Quality Documentation for Material Receiving.

Att. IV Sec. 3.3

Identification - Instrumentation materials shall be identified by using tags,

Schedule Q

stamps, color coding, stencils or labels. The location and the method of

A2 Att. lV

identification shall not affect the function or quality of the item being

Sec. 4.2

identified.

Schedule G

A3 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A4 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

Schedule Q

incoming materials shall be visually inspected for damage and

A5 Att. IV

conformance to all applicable inspection releases with Material Test

Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all Schedule Q

A6 applicable requirements, standards and specifications prior to release to Att. IV

be used as part of the work. Sec. 3.3

Traceability - Instrumentation materials shall be traceable from the Schedule Q

A7 manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV

installation, repair, modification and use. Sec. 4.3

Verify that the contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

A8 Att. III

locations as required by the inspection level assigned for the materials

3.2

and equipment identified in SAEP-1150 Inspection Requirements.

Storage, Handling and Preservation

The manufacturer's storage, handling and preservation instructions to be Schedule Q

A9

followed. Att. IV Sec. 6.0

B General Requirements

Individuals responsible for special handling, storage and preservation

Schedule Q

B1 shall be fully qualified to do so, and supplied with predetermined WORK

Att. IV Sec. 6.0

and inspection instructions.

The CONTRACTOR shall provide documentation that the required

Schedule Q

B2 Storage, Handling and Preservation (SHP) activities have been

Att. IV Sec. 6.0

performed.

Saudi Aramco: Company General Use

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags / labels and Schedule Q

B3

nameplates, and shipment checked for damage, prior to acceptance of the Att. lV sec.4.2

shipment

Material requirements for: IP01A Copper Tubing Components for Air Supply and Signal transmission

C

systems. (Based on material, temp. and usage the appropriate sec of PIP PCSIP001 has to be used.

Tube Fittings: Brass, flareless compression type. The fitting PIP PCSIP 001

C1

nomenclature shall be in accordance with ISA RP 42.1. Sec. 4.1.3

Pipe Fittings and Nipples: Brass screwed fittings, couplings, and unions

per ASME B31.3 and ASTM B453. Sizes 1/4-inch, 3/8-inch, and 1/2-inch. PIP PCSIP 001

C2

All NPT threads are to meet requirements of ANSI B1.20.1. All nipples are Sec. 4.1.7

brass, to be extra strong, temper reference 061.

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic PIP PCSIP 001

C3

fillers, certified nontoxic. Sec. 4.1.8

Material Requirements for: IP-12P Type 304 Stainless Steel Tubing Components for Instrument

D

Process Connections

Surface finish shall be free of any imperfections that would prevent PIP PCSIP 001

D1

sealing when using flareless compression-type tube fittings. Sec. 4.4.2.3

Tube Fittings: Type 316 stainless steel, flareless compression type PIP PCSIP 001

D2

Fitting nomenclature shall be in accordance with ISA RP 42.1. Sec. 4.4.3

Pipe Fittings and Nipples: Type 304 stainless steel 3000# forged alloy

screwed fittings, couplings and unions per ASME B31.3 and ASTM A182.

PIP PCSIP 001

D3 Sizes 1/4-inch, 3/8-inch and 1/2-inch. All NPT threads are to meet

Sec. 4.4.7

requirements of ANSI B1.20.1. All nipples are 304 stainless steel,

schedule 80 minimum.

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic PIP PCSIP 001

D4

fillers, certified nontoxic. Sec. 4.4.8

Material Specification: IP-02A Polyvinyl Chloride-Coated Copper Tubing Components for Air Supply

E

and Signal Transmission Systems

Surface finish shall be free of any imperfections that would prevent PIP PCSIP 001

E1

sealing when using flareless compression-type tube fittings. Sec. 4.2.2.3

Tube Fittings: Brass, flareless compression type Fitting nomenclature PIP PCSIP 001

E2

shall be in accordance with ISA RP 42.1. Sec. 4.2.3

Pipe Fittings and Nipples: Brass screwed fittings, couplings and unions

per ASME B31.3 and ASTM B453. Sizes 1/4-inch, 3/8-inch and 1/2-inch. PIP PCSIP 001

E3

All NPT threads are to meet requirements of ANSI B1.20.1. All nipples are Sec. 4.2.7

brass, to be extra strong, temper reference 061.

Material Specification: IP-03A Type 316 Stainless Steel Tubing Components for Air Supply and Signal

F

Transmission Systems

Surface finish shall be free of any imperfections that would prevent PIP PCSIP 001

F1

sealing when using flareless compression-type tube fittings. Sec. 4.3.2.3

Tube Fittings: Type 316 stainless steel, flareless compression type PIP PCSIP 001

F2

Fitting nomenclature shall be in accordance with ISA RP 42.1. Sec. 4.3.3

Pipe Fittings and Nipples: 304 stainless steel 3000# forged alloy

screwed fittings, couplings and unions per ASME B16.11, ASTM A182,

PIP PCSIP 001

F3 and ASTM A276. Sizes 1/4-inch, 3/8-inch and 1/2-inch. All NPT threads

Sec. 4.3.7

are to meet requirements of ANSI B1.20.1. All nipples are 304 stainless

steel, 80S per ASME B36.19, minimum.

Saudi Aramco: Company General Use

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic PIP PCSIP 001

F4

fillers, certified nontoxic. Sec. 4.3.8

Material Specification: IP-13P Type 316 Stainless Steel Tubing Components for Instrument Process

G

Connections

Surface finish shall be free of any imperfections that would prevent PIP PCSIP 001

G1

sealing when using flareless compression-type tube fittings. Sec. 4.5.2.3

Tube Fittings: Type 316 stainless steel, flareless compression type PIP PCSIP 001

G2

Fitting nomenclature shall be in accordance with ISA RP 42.1. Sec. 4.5.3

Pipe Fittings and Nipples: Type 316 stainless steel 3000# forged alloy

screwed fittings, couplings and unions per ASME B31.3 and ASTM A276. PIP PCSIP 001

G3

Sizes 1/4, 3/8 and 1/2 inch. All NPT threads are to meet requirements of Sec. 4.5.7

ANSI B1.20.1. All nipples are 316 stainless steel, schedule 80 minimum.

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic PIP PCSIP 001

G4

fillers, certified nontoxic. Sec. 4.5.8

H Material Specification: IP-14P Monel 400 Tubing Components for Instrument Process Connections

Surface finish shall be free of any imperfections that would prevent PIP PCSIP 001

H1

sealing when using flareless compression-type tube fittings. Sec 4.6.2.3

Tube Fittings: Monel 400, flareless compression type Fitting PIP PCSIP 001

H2

nomenclature shall be in accordance with ISA RP 42.1. Sec 4.6.3

Pipe Fittings and Nipples: Monel 400, 3000# forged alloy screwed

fittings, couplings and unions per ASME B31.3 and ASTM B165. Sizes PIP PCSIP 001

H3

1/4-inch, 3/8-inch, and 1/2-inch. All NPT threads are to meet requirements Sec 4.6.7

of ANSI B1.20.1. All nipples are Monel 400, schedule 80 minimum.

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic PIP PCSIP 001

H4

fillers, certified nontoxic. Sec 4.6.8

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract)

3. SAES-J-100 - Process Flow Metering, 1 January 2018

4. PIP PCSIP001- Instrument Piping and Tubing Systems Specifications

5. PIP PCCIP001 - Instrument Piping and Tubing Systems Criteria

6. O Brien Tracepak Instructions. http://www.obcorp.com/WebPages/literatu.htm

7. Swagelok Tubing data. Http://www.swagelok.com

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

5. Remarks: O'Brien is taken as a sample manufacturer. The Vendor has to be approved by the proponent and CSD per standards. The most

frequently used tubes are given here. Please use the appropriate Sec of the PIP for other type of tube material.

Saudi Aramco: Company General Use

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Cat C1.1 Diesel Engine Service and Workshop ManualDocument42 pagesCat C1.1 Diesel Engine Service and Workshop Manualmaq mayor100% (11)

- Learn ExcelDocument423 pagesLearn ExcelMuneeb Khan100% (225)

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- TA-04 Manual de Partes F121-WDDocument534 pagesTA-04 Manual de Partes F121-WDJulio Cesar CorderoNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Power BI Certification Prep Level 1Document56 pagesPower BI Certification Prep Level 1kavi_mt2008100% (6)

- Disable Protection of The Inverter-3Document19 pagesDisable Protection of The Inverter-3fox787880% (44)

- ARAMCO RT Inpection Check List - SAIC-RT-2001Document15 pagesARAMCO RT Inpection Check List - SAIC-RT-2001Anonymous hBBam1nNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- SAIC-K-4031 Rev 7 TTW & Window Mounted Air ConditionerDocument2 pagesSAIC-K-4031 Rev 7 TTW & Window Mounted Air ConditionershahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Lubrizol Engineered Polymers Injection Molding GuideDocument12 pagesLubrizol Engineered Polymers Injection Molding GuideOmer SenNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- En 571-1 - Penetrent TestingDocument18 pagesEn 571-1 - Penetrent TestingVasilica Barbarasa100% (1)

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Introduction To Work Study George Kanawaty 4edDocument542 pagesIntroduction To Work Study George Kanawaty 4edtextile028100% (2)

- Rotary DryerDocument12 pagesRotary DryerImam Baliqin100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalikNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistOmer aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic P 3424Document3 pagesSaic P 3424spravin231No ratings yet

- SACIC-T-5702 OSP Ductbank-Manhole & Handhole Hardware - Storage, Handling, and Preservation (RTS)Document2 pagesSACIC-T-5702 OSP Ductbank-Manhole & Handhole Hardware - Storage, Handling, and Preservation (RTS)Arshad ImamNo ratings yet

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNo ratings yet

- SAIC W 2009 Revw Control of Weld Consum (EE) RLC FFDocument1 pageSAIC W 2009 Revw Control of Weld Consum (EE) RLC FFAnonymous S9qBDVkyNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- SAIC-W-2009 Revw-Control of Weld Consum - On PlotDocument1 pageSAIC-W-2009 Revw-Control of Weld Consum - On PlotAnonymous S9qBDVkyNo ratings yet

- SAIC-X-3001 Rev 2Document2 pagesSAIC-X-3001 Rev 2josephjohn2No ratings yet

- SACIC-T-5707 OSP Ductbank-Plastic Innerducts and Accessories - Material ReceivingDocument2 pagesSACIC-T-5707 OSP Ductbank-Plastic Innerducts and Accessories - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- CamScanner 10-13-2021 23.17Document2 pagesCamScanner 10-13-2021 23.17nisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Color Gradient: 1 Axial GradientsDocument3 pagesColor Gradient: 1 Axial GradientsManuel MensaNo ratings yet

- 一年备件清单 The List of Spare Parts in one yearDocument13 pages一年备件清单 The List of Spare Parts in one yearMohamed el attarNo ratings yet

- (SMS) Sunstar Scanner CSE-IsE - System Modelling and SimulationDocument25 pages(SMS) Sunstar Scanner CSE-IsE - System Modelling and SimulationSahanaNo ratings yet

- Use of Mobile Mesh Networks For Inter-Vehicular CommunicationDocument4 pagesUse of Mobile Mesh Networks For Inter-Vehicular CommunicationdharanyadeviNo ratings yet

- Online FDP On Demystifying 5G RF Asics (24 Aug-04 Sept, 2020)Document4 pagesOnline FDP On Demystifying 5G RF Asics (24 Aug-04 Sept, 2020)Mohit SharmaNo ratings yet

- Oscilloscope: 1. DefinitionDocument9 pagesOscilloscope: 1. DefinitionSandi WiarsanaNo ratings yet

- FS SWM WTE Greater MalangDocument316 pagesFS SWM WTE Greater MalangBenny Aryanto SihalohoNo ratings yet

- 10 Simple But Useful Math Hacks For Everyday UseDocument13 pages10 Simple But Useful Math Hacks For Everyday UseluknokNo ratings yet

- Attanance ABSTRACTDocument6 pagesAttanance ABSTRACTSebastin AshokNo ratings yet

- 1 Windows Server 2012 Mcsa 70 411 m1 SlidesDocument21 pages1 Windows Server 2012 Mcsa 70 411 m1 Slidesnyonie22messiNo ratings yet

- Vancouver Convention CentreDocument3 pagesVancouver Convention CentreNabeel AhmedNo ratings yet

- Department of Computer Science and Engineering Welcomes NBA Expert CommitteeDocument45 pagesDepartment of Computer Science and Engineering Welcomes NBA Expert Committeekotresh_hmkNo ratings yet

- Ad90 PDFDocument4 pagesAd90 PDFMuhammad Eitch-BeeNo ratings yet

- Battery Sizing NicdDocument4 pagesBattery Sizing NicdMandip Pokharel0% (1)

- Vetting Hurdle or OpportunitiesDocument2 pagesVetting Hurdle or OpportunitiesSurayos ChuephanichNo ratings yet

- Awards of Icici Bank in 2012Document4 pagesAwards of Icici Bank in 2012Gaurav VermaNo ratings yet

- BS EN 12275 - 1998 ME Connectors SR & TMDocument16 pagesBS EN 12275 - 1998 ME Connectors SR & TMKannan LakshmananNo ratings yet

- Job Offer Format FujikinIncDocument1 pageJob Offer Format FujikinIncVinh NguyenNo ratings yet

- Kioti Daedong CX2510 (H), CX2510 (H) (N) - EU Tractors Service ManualDocument19 pagesKioti Daedong CX2510 (H), CX2510 (H) (N) - EU Tractors Service ManualLisakolyNo ratings yet

- SBL2 e Dual Serial To Ethernet Users ManualDocument30 pagesSBL2 e Dual Serial To Ethernet Users Manualsrc.sussi822No ratings yet

- GE Proteus Can Bus SN3971 - 23264960.000Document6 pagesGE Proteus Can Bus SN3971 - 23264960.000tha_ansNo ratings yet