Professional Documents

Culture Documents

Saic P 3859

Uploaded by

Niel TanedoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic P 3859

Uploaded by

Niel TanedoCopyright:

Available Formats

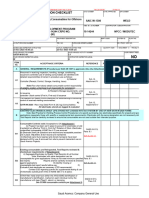

#

SAUDI ARAMCO ID/PIEU-30-September-2019 - REV.2019.09.00 (Standards Cutoff - Sep 30, 2019) Rev 47 30-Sep-19

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

LV Panelboard - Industrial Panelboard (≤400A) Material

SAIC-P-3859 15-Dec-19 ELECT

Receiving

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. DOCUMENT REVIEW

Review documents of Material Receiving for the LV Panelboard - Schedule Q

A1

Industrial Panelboard (≤400A). Att. IV Sec. 3.3

Identification procedure reviewed and implemented for the LV Panelboard Schedule Q

A2

- Industrial Panelboard (≤400A). Att. IV Sec. 4.2

Material identification shall be implemented for all materials, parts and

components, including partially fabricated assemblies. LV Panelboard -

Schedule Q

A3 Industrial Panelboard (≤400A) shall be identified by using tags, stamps,

Att. IV Sec. 4.2

color coding, stencils or labels. The location and method of identification

shall not affect the function or quality of the material.

B. GENERAL REQUIREMENT

Documentation for traceability reviewed and implemented. LV Panelboard

Schedule Q

- Industrial Panelboard (≤400A) shall be traceable from the manufacturer

B1 Att. IV

and supplier through delivery, storage, fabrication, erection, installation,

Sec. 4.3

repair, modification and use.

Documented Control System shall be implemented for all Saudi Aramco Schedule Q

B2

supplied material and equipment. Att. lV Sec.5

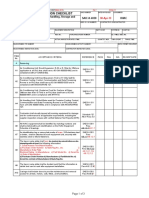

C. MATERIAL INSPECTION

QC Before Installation- LV Panelboard - Industrial Panelboard (≤400A)

Schedule Q

C1 shall conform to all applicable requirements, standards, and specifications

Att. IV Sec. 3.3

prior to release to be used as part of work.

Incoming LV Panelboard - Industrial Panelboard (≤400A) shall be visually Schedule Q

C2

inspected for damage / defects occurred during transportation. Att. IV Sec. 3.3

Schedule G

C3 LV Panelboard - Industrial Panelboard (≤400A) shall be new and unused.

Sec. 2.1

LV Panelboard - Industrial Panelboard (≤400A) shall be in accordance

Schedule G

C4 with the Saudi Aramco-approved project-specific design drawings,

Sec. 2.1

diagrams, schedules, lists, databases, and associated design documents.

Check that the Contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

C5 Att. llI

locations as required by the inspection level assigned for the materials

Sec. 3.2

and equipment identified in SAEP-1151, Engineering Procedure.

Certifications:

Circuit Breaker Listing / Labeling - All main, feeder and branch circuit 16-SAMSS-518

C6

breakers and enclosures shall be third-party tested, and listed or labeled Sec 5.2

as meeting the requirements of UL standard 489.

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

16-SAMSS-518

C7 Panelboards shall fully comply with NEMA PB1 and UL67.

Sec 5.2

Branch circuit breakers used for switching of 277V fluorescent light

circuits shall be listed as meeting the requirements of UL 489 and shall SAES-P-100

C8

be marked "SWD" or "HID". Sec. 5.2

[NFPA 70, NEC 240.83(D)]

Branch circuit breakers used for switching of 277V in high-intensity

discharge (e.g., HPS, MH, or MV) light circuits shall be listed as meeting SAES-P-100

C9

the requirements of UL 489 and shall be marked as "HID". Sec. 5.2

[NFPA 70, NEC 240.83(D)]

Panelboards installed outdoors shall be suitable for continuous operation

under the following service conditions:

(1) Ambient air temperature:

a) A maximum of 50°C.

b) A minimum of 0°C, unless a lower temperature is specified within Data

Schedule 1.

c) Average temperature, measured over a period of 1 month, is a

maximum of 45°C.

(2) Altitude is less than 1000 meters, unless a higher altitude is

specified within Data Schedule 1.

16-SAMSS-518

C10

(3) Average value of the relative humidity: Sec. 7.2

a) For a period of 24 hours, does not exceed 95%

b) For a period of 1 month, does not exceed 90%.

(4) Relative humidity may be temporarily 100%,

(5) Exposure to the following

a) Air-borne dust concentration of 1 mg/m³ with 95% of all particles less

than 20 micrometers in diameter. "Dust" includes compounds of calcium,

sodium, magnesium, silicon and aluminum.

b) Pollutants such as H2S - 20 ppm, SO2 - 10 ppm, CO - 75 ppm, NOX -

5 ppm, hydrocarbons - 100 ppm, NaCl - 300 ppm and MgCl - 50 ppm.

The current rating of a panelboard shall be no more than smaller of the

following:

a. The ampacity of the main bus bars

b. The 16-SAMSS-518

C11

current rating or the trip rating of the main circuit breaker Sec. 7

(NEMA PB1

Sec 3.2)

SAES-P-116

C12 Panelboards used in industrial facilities shall be rated 400A or less.

Sec. 15.3

Standard ratings of main bus shall be 100, 110, 125, 150, 175, 200, 225, 16-SAMSS-518

C13

250, 300, 350 & 400 amperes. (NEMA PB 1, Sec. 2.10.1) Sec. 7

16-SAMSS-518

The minimum wire-bending space at terminals shall be as shown in table

C14

16.1. (UL67, Sec. 16.1)

Sec. 5.2

16-SAMSS-518

The minimum width of wire gutter and wire-bending space shall be as

C15

shown in Table 16.2. (UL 67, Sec. 16.2)

Sec. 5.2

16-SAMSS-518

The ampacity of some of the more common size bus bars shall be as

C16

shown in Table 11.2. (UL 67, Sec. 11.3)

Sec. 5.2

Panelboards shall be equipped with a minimum of 10% spare breakers

and a minimum of 10% spare pole spaces. The sizes of the spare SAES -P-116

C17

breakers shall be representative of the connected breakers within the Sec. 15.1

panelboard.

The standard ratings of main circuit breakers used in panelboards shall be

16-SAMSS-518

C18 100, 110, 125, 150, 175, 200, 225, 250, 300, 350, and 400 amperes.

Sec.5.2

(NEMA PB1, Sec. 2.10.3)

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

The standards short circuit current rating of circuit breakers used in

panelboards shall be its interrupting rating of

16-SAMSS-518

C19 10, 000; 14,000; 18,000; 20,000; 22,000; 25,000; 30,000; 35,000; 42,000;

Sec.5.2

50,000; 65,000; 85,000; 100,000; 125,000; 150,000; or 200,000

rms symmetrical amperes. (NEMA PB1, Sec. 3.5.1)

The frequency rating of AC panelboards shall be 50, 60, or 50/60 Hz. 16-SAMSS-518

C20

(NEMA PB1, Sec.3.3) Sec.5.2

If a panelboard uses a snap switch at 30 amperes or less in any branch

16-SAMSS-518

circuit, the rating of the panelboards shall be not more than 200A unless

C21

there is an overcurrent protection rated at 200 amperes or less within the

Sec. 5.2

panelboard on the line side of such a switch. (NEMA PB1, Sec. 3.2.1)

5.2 Panelboards shall fully comply with NEMA PB 1 and UL 67.

16-SAMSS-518

C22

Exception to 5.2:

Sec. 5.2

Flameproof panelboards shall comply with the relevant IEC standards.

Panelboard configuration and ratings (i.e., voltage, current and the

Schedule G

C23 number of phases for which they are designed) shall match the electrical

Sec.2.1

system.

Panelboard short-circuit ratings and circuit breaker interrupting ratings Schedule G

C24

shall exceed the available fault current from the system (as calculated). Sec.2.1

Each panelboard shall be conspicuously marked on the trim or deadfront

16-SAMSS-518

shield with a product safety label that complies with ANSI Z535. If the

C25

panel is supplied with a door, this label shall be visible when the door is in

Sec. 5.2

the open position. (NEMA PB1, Sec.2.11.1)

Specific Material Requirements: SAES-P-100

C26

All

All feeder and branch

interrupting devicescircuits

shall bemust

fullyhave

ratedmolded-case

for the short circuit

circuit breakers.

duty. Refer Sec. 5.3

to SAES-P-116 for additional details and exceptions.

SAES-P-100

C27

Commentary Note: Sec. 5.4

This means, for example, that designs based upon series-rated or

cascade-rated

All equipment

circuit breakers must beshall

trip not

freebe used.

and capable of being closed and SAES-P-100

C28

opened by hand. (NFPA 70, NEC 240.80) Sec. 5.

SAES-P-100

C29 Only secondary-selective switchgear shall be used to feed critical loads.

Sec. 5.5

Exception:

Critical facilities or equipment fed from a single-ended substation bus SAES-P-100

C30

which has a standby generator capable of automatically supplying the Sec. 5.5

required power to the bus within 10 seconds after a power failure are

permitted.

Basic Design Codes

Electrical power systems shall be designed and constructed in

SAES-P-100

C31 accordance with the latest edition of Volume 4 of SBC, NFPA 70, NFPA

Sec. 5.2

70 E and ANSI C2, as supplemented or modified by the Saudi Aramco

Engineering Standards. In general, SBC supersedes other codes except

when specifically stated within any of the MSAER documents.

The circuit breakers installed shall be of the proper type and rating. SAES-P-100

C33

(NFPA 70, NEC 240.86) Sec. 5.5

Breakers indicated as multiple-pole shall be common trip type. SAES-P-100

C34

(NEMA AB3, Sec 3.1.5 & 5.4.3) Sec. 5.5

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

If the breaker size is not specified within the purchasing documents, 16-SAMSS-518

C35

breakers shall have a minimum trip rating of 20 Amp. Sec. 12.1

Breakers operating at greater than 240 Volts shall be equipped with

padlockable lock-off devices.

16-SAMSS-518

C36

Sec. 12.2

12.2 (Addition) to NEMA PB 1 and UL 67: Breakers operating at greater

than 240 Volts shall be equipped with padlockable lock-off devices.

Circuit Breakers Types - Tandem, twin, or half-size breakers shall not be

used.

16-SAMSS-518

C37

Sec. 12.3

(Addition) to NEMA PB 1 and UL 67: Tandem, twin, or half-size breakers

shall not be used.

The circuit directory shall be located on the face or back of the panel door. SAES-P-100

C38

(NFPA 70, NEC 408.4). Sec. 5.2

16-SAMSS-518

The specific application of indoor and outdoor type enclosure shall be as

C39

shown in NEMA 250, Table 1 and 2. (NEMA 250, Sec. 2)

Sec. 5.2

Enclosure - NEMA vs. IP Ratings - The conversion of NEMA enclosure 16-SAMSS-518

C40 type ratings to IEC 60529 enclosure classification designation ( IP ) shall

be as shown in Table A-1. (NEMA 250, Annex A) Sec. 5.2

16-SAMSS-518

The size of knockouts for panelboards shall be as shown in Table 3.

C41

(NEMA 250 Sec.3)

Sec. 5.2

Enclosure Type - In outdoor plant areas, within the perimeter of process

units, equipment and terminal enclosures shall be:

(a) NEMA 250/NEMA ICS 6 Type 4; or

SAES-P-104

C42

Sec. 7.1

(b) NEMA Type 3 manufactured copper free cast aluminum (0.4 of

1% maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP54 or better.

In outdoor plant areas, outside the perimeter of process units, and other

industrial areas, equipment and terminal enclosures shall be:

SAES-P-104

C43

(a) NEMA Type 3 or 4; or Sec. 7.2

(b) IEC 60529 Type IP54 or better.

In outdoor plant and other industrial areas located in severe corrosive

environments enclosures shall be:

(a) NEMA Type 4X (except galvanized and/or painted or coated carbon

steel sheet metal enclosures are not permitted); or SAES-P-104

C44

(b) NEMA Type 3 or 4, manufactured of copper free cast aluminum (0.4 Sec. 7.3

of 1% copper maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP54 or better, manufactured of stainless steel

(Type 304 or better), copper free cast aluminum, or plastic (including

fiberglass).

Enclosures having an internal volume exceeding 2,000 cm³ shall be

SAES-P-104

C45 provided with Type 300 Series stainless steel breather and drain fittings,

Sec. 7.7

or a combination breather and drain fitting.

Enclosure Type - If a "severe corrosive environment", is not specified, it is

acceptable that the panelboard enclosure meet the requirements of either:

16-SAMSS-518

C46 a) Type 4, 4X, 6, 6P, 3/7, 4/7 or 4X/7 per NEMA 250.

Sec. 9.2.2

b) Type 3 per NEMA 250 and manufactured of copper free cast aluminum,

plastic or galvanized carbon sheet metal.

Enclosures rated Type 3, 4 or 4X per NEMA 250 shall be equipped with 16-SAMSS-518

C47

Type 300 Series stainless steel hardware. Sec. 9.2.3

A filler plate shall provided to close an opening that would otherwise be 16-SAMSS-518

C48 closed by subsequent installation of a circuit breaker other device. ( UL

67, Sec 10) Sec. 5.2

For panelboards which provide branch circuits operating at phase-to- 16-SAMSS-518

C49 neutral voltage levels, a neutral bus shall be provided within the

panelboard. Sec. 5.6

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

The neutral busbar shall have an ampacity not less than that of the other

busbars, except that the neutral in a 3-wire d-c system or single-phase a-c 16-SAMSS-518

C50 panelboard or in a 3-phase, 4 wire panelboard, rated more than 200

amperes , shall not be have an ampacity less than 200 amperes . Sec. 5.2

(UL 67 , Sec. 11.6.1)

A neutral busbar intended for use in a panelboard with increased neutral 16-SAMSS-518

C51 ampacity shall have an ampacity of 125%, 150%, 175%, or 200% of the

other phase bars. (UL 67, Sec 11.6.2) Sec. 5.2

When the main neutral terminal is located at the electrical center of the

main neutral bus bar, the ampacity of each half of the bus bar shall not be

less than half the values specified in Section 11.6.1 above. The electrical 16-SAMSS-518

C52 center is identified as the point at which the neutral current to one side of

the bus bar is equal to the other side, taking into considerations the total Sec. 5.2

number of terminals located in the neutral bus bar and the current

associated with each. (UL 67, Sec. 11.6.3)

16-SAMSS-518

Lugs shall be UL listed to accept solid or stranded copper cables. Lugs

C53

shall be bolted in place.

Sec. 5.2

A panelboard having a wiring gutter, wiring space or terminal

16-SAMSS-518

compartment shall be provided with a cover, barrier, or partition extending

C54

around or from the side or sides of all bases or groups of bases of circuit

Sec. 5.2

breakers within the enclosure. (UL 67, Sec. 9.1.1)

16-SAMSS-518

Panelboard shall be deadfront unless it is intended for use where it will be

C55

accessible only to qualified personnel. (UL 67, Sec 9.1.3)

The main terminal may be in the form of a main terminal kit if the Sec. 5.2

panelboard is specifically designed for use interchangeably either with

those terminals or with a main circuit breaker. The main terminal kit may

consist of individual terminals of may be an assembly consisting of:

a) Terminals

16-SAMSS-518

C56

b) Bus bars that provide connection between those

Sec. 5.2

terminals and the main bus bars of the panelboard, and

c) A mounting means for those components.

(UL 67, Sec. 12.2.1)

Separate feed through terminal intended for connecting single feed-

16-SAMSS-518

through circuit and tap conductors to a panelboard shall provide terminals

C57

for tap conductors of ampacity not less than the current rating of the

Sec. 5.2

panelboard. (UL 67, Sec.12.2.3)

The number of individual branch circuit neutral terminals shall not be less 16-SAMSS-518

C58 than 75 percent of the total number of poles provided for in the

panelboard. (UL 67, Sec.12.3.11) Sec. 5.2

All conductors shall be copper, silver or alloys of these materials with the

following exceptions: (1)

Parts which are internal to a pre-manufactured device

16-SAMSS-518

C59 (e.g., internals circuit breaker).

Sec. 10.1

( 2 ) Connectors supplied as integral parts or components of

manufactured equipment such as molded case circuit breakers provided

the connectors are approved for copper conductors.

Plating of the copper, silver or copper/silver alloy base conductor material 16-SAMSS-518

C60

is acceptable. Sec. 10.1.3

The main circuit bus system shall be of rigid material (i.e., cable or flexible 16-SAMSS-518

C61

conductors shall not be used). Sec. 10.2

16-SAMSS-518

C62 A ground bus shall be provided within the panelboard.

Sec. 11

White Nameplates with black lettering shall be provided to identify the 16-SAMSS-518

C63

panelboard with the tag number indicated within Data Schedule 1. Sec. 13

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Materials, Tools and Equipment (MP LSTK & LSPB Pro Forma), Contract Specific

2. Schedule Q -- Quality Requirements (MP LSTK & LSPB Pro Forma), Contract Specific

3. SAES-P-100 -- Basic Power System Design Criteria, 01 January 2018

4. SAES-P-116 -- Switchgear and Control Equipment, 8 August 2017

5. NEMA PB1 -- Panelboards, 2011

6. UL 67 -- Panelboards, 23 May 2008

7. NEMA 250 -- Enclosures for Electrical Equipment (1000 Volts Maximum), 2003

8. UL 489/NEMA AB 1 -- Molded-Case Circuit Breakers, Molded Case Switches, and Circuit-Breaker Enclosures, 2002

9. NFPA 70 -- National Electrical Code, 2017

10. SAES-P-104 - Wiring Methods and Materials, 01 January 2018

11.16-SAMSS-518 -- Low Voltage Panelboards, 22 August 2019

12. NEMA AB3 -- Molded Case Circuit Breakers and their Application - 2013

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalikNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials ReceivingDocument2 pagesSAIC-T-5205 Rev 8In-Plant Voice Paging System - Page Party Station - Outdoor - Materials Receivinghomsalwaled88No ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Sac Inspection Checklist: Procedure Review: WPS For API Tank Construction SACIC-W-2075 21-Sep-21 WeldDocument4 pagesSac Inspection Checklist: Procedure Review: WPS For API Tank Construction SACIC-W-2075 21-Sep-21 Weldhusnain aliNo ratings yet

- Saic W 1308Document21 pagesSaic W 1308mathew.genesis.inspNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Ayc Ic & Itp Roll Up DoorDocument10 pagesAyc Ic & Itp Roll Up Doormoytabura96No ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- SACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingDocument3 pagesSACIC-T-5705 OSP Ductbank-Maintenance & Service Hole Hardware - Material ReceivingArshad ImamNo ratings yet

- SAIC-L-2092 Rev 7Document12 pagesSAIC-L-2092 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Document6 pagesARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- SAIC-P-3005 Rev 7 FinalDocument2 pagesSAIC-P-3005 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- SAIC-P-3008 Rev 7 FinalDocument10 pagesSAIC-P-3008 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- Artu EngDocument2 pagesArtu EngUsman MalikNo ratings yet

- ANSI Y32.9-1972 Simbologia Instalações PrediaisDocument42 pagesANSI Y32.9-1972 Simbologia Instalações PrediaisAlexandre PereiraNo ratings yet

- W22 Smoke Extraction: Motor For Smoke Exhaustion African MarketDocument60 pagesW22 Smoke Extraction: Motor For Smoke Exhaustion African MarketAgustynho MagimbaNo ratings yet

- Pr1613adf PDFDocument2 pagesPr1613adf PDFhaerulamriNo ratings yet

- Mains Interruption Counter With Indicator Circuit DiagramDocument6 pagesMains Interruption Counter With Indicator Circuit DiagramSelvy SalfitriNo ratings yet

- PhysicsDocument17 pagesPhysicsRahul Yadav100% (1)

- Zen Opt ManualDocument171 pagesZen Opt ManualLynda ArchardNo ratings yet

- DOD Gonkulator How It Works OriginalDocument1 pageDOD Gonkulator How It Works OriginaltttymonNo ratings yet

- WECC White Paper On Modeling Hybrid Power PlantDocument21 pagesWECC White Paper On Modeling Hybrid Power PlantxNo ratings yet

- 109 Top A.C PDFDocument11 pages109 Top A.C PDFavv45675% (4)

- Elec Report (Draft)Document19 pagesElec Report (Draft)AHMEDNo ratings yet

- 2021 - Power System Stability Issues & Classifications and Research Prospects in The Context of High-Penetration of Renewables and Power ElectronicsDocument16 pages2021 - Power System Stability Issues & Classifications and Research Prospects in The Context of High-Penetration of Renewables and Power ElectronicsJULIÁN ESTIBEN MESA CALLENo ratings yet

- MFJFJDocument4 pagesMFJFJShiva Paddam25% (4)

- CMT2210LC en V0.9 20170817Document20 pagesCMT2210LC en V0.9 20170817Ta ToNo ratings yet

- Diesel Engine Fire Pump ControllerDocument12 pagesDiesel Engine Fire Pump ControllerCARLOS RIVERANo ratings yet

- Digital Key Coded LockDocument11 pagesDigital Key Coded LockEngr. Zeeshan mohsin100% (1)

- Alternator Chart MS-2288FL - LR 7-09 PDFDocument1 pageAlternator Chart MS-2288FL - LR 7-09 PDFigrekqaNo ratings yet

- 5 THDocument20 pages5 THbertovalenNo ratings yet

- Testing and Commissioning of MVHV CablesDocument7 pagesTesting and Commissioning of MVHV CablesFernando Patiño GuevaraNo ratings yet

- Tm170tig PVCDocument9 pagesTm170tig PVCAndrea MorsianiNo ratings yet

- Gek 45375JDocument42 pagesGek 45375JBolivar MartinezNo ratings yet

- RCA E13344 Chasis TX808H - DiagramaDocument7 pagesRCA E13344 Chasis TX808H - DiagramaVictor Antonio Rojas RojasNo ratings yet

- Chapter 10: Medico - Legal Investigation of WoundsDocument10 pagesChapter 10: Medico - Legal Investigation of WoundsSamantha GNo ratings yet

- 4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualDocument24 pages4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualsancakemreNo ratings yet

- Ingecon Sun Storage 1play TL DatasheetDocument4 pagesIngecon Sun Storage 1play TL DatasheetagismeroNo ratings yet

- BTB08 400CDocument10 pagesBTB08 400CAlan AldereteNo ratings yet

- Compressor Manual P 251511 Om Ssp1 GBR 3-A4Document82 pagesCompressor Manual P 251511 Om Ssp1 GBR 3-A4PRKrauseNo ratings yet

- Summary Faraday's LawDocument4 pagesSummary Faraday's LawReg TbNo ratings yet

- Kinetix 6000 Multi-Axis Servo Drive: Installation ManualDocument255 pagesKinetix 6000 Multi-Axis Servo Drive: Installation ManualLuis Claudio Ramos100% (1)

- HawelsDocument3 pagesHawelsAbhishek TiwariNo ratings yet