Professional Documents

Culture Documents

Saic P 3425

Uploaded by

spravin231Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic P 3425

Uploaded by

spravin231Copyright:

Available Formats

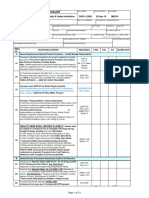

SAUDI ARAMCO ID/PIEU-30-April-2019 - REV.2019.04.00 (Standards Cutoff - April 30,2019) Rev.2019.04.

00 30-Apr-19

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Cranes, Hoists, Elevators - Installation and

SAIC-P-3425 29-Aug-19 ELECT

Pre-Commissioning

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. Document Review

Schedule Q

Review documentation for the Material Receiving of Cranes, Hoists,

A1 Att. IV

Elevators and Accessories for any comments.

Sec. 3.3

B. Material Inspection

QC Before Installation- Cranes, Hoists, Elevators and Accessories shall Schedule Q

B1 conform to all applicable requirements, standards, and specifications prior Att. IV

to release to be used as part of work. Sec. 3.3

Schedule Q

Incoming Cranes, Hoists, Elevators and Accessories shall be visually

B2 Att. IV

inspected for damage / defects occurred during transportation.

Sec. 3.3

Check that the Contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

B3 Att. III

locations as required by the inspection level assigned for the materials

Sec. 1.2

and equipment identified in SAEP-1151 Inspection Requirements.

C. Cranes, Hoists or Elevators Installation and Pre-Commissioning

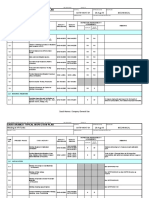

The crane manufacturer shall furnish with each crane at least one copy of

the manual. The manual shall include general information applicable to

the following:

(a) installation

(b) operation

(c) inspection SAES-B-053

C1

(d) testing Sec. 3.2

(e) lubrication

(f) maintenance

(g) parts

(h) wiring diagram (may be supplied separately)

[ASME B30.2 Sec.2-1.16.1]

Rated Load Markings - Crane:

The rated load of the crane shall be marked on each side of the crane and SAES-B-053

C2

shall be legible from the ground or floor. Sec. 3.2

[ASME B30.2 Sec.2-1.1.1]

Saudi Aramco: Company General Use

Rated Load Markings - Hoists

(a) The rated load of the hoist shall be marked on the hoist or trolley unit

or its load block and shall be legible from the ground or floor. SAES-B-053

C3

(b) If the crane has more than one hoisting unit, each hoist shall have its Sec. 3.2

rated load marked as per Sec.2-1.1.2(a).

[ASME B30.2 Sec.2-1.1.2]

Manufacturer’s Identification Markings:

The crane shall be marked with manufacturer’s identification

information, on a plate or label attached to the crane, as follows:

(a) name and address of manufacturer SAES-B-053

C4

(b) manufacturer’s model or serial number Sec. 3.2

(c) voltage of AC or DC power supply and phase and frequency of AC

power supply

[ASME B30.2 Sec.2-1.1.3]

Clearance shall be maintained between the crane and the building, as well

as parallel running cranes and cranes operating at a different elevation SAES-B-053

C5

under all normal operating conditions. Sec. 3.2

[ASME B30.2 Sec.2-1.2.1(a)]

Construction of Runways and Rails:

(1) The crane runways and supporting structures shall be designed to

withstand the loads and forces imposed by the crane

SAES-B-053

C6 (2) Runway columns shall be securely anchored to foundation

Sec. 3.2

(3) Rails shall be level, straight, joined, and spaced to the crane span

compatible with the design of the crane.

[ASME B30.2 Sec.2-1.3.2(a)]

Runway Stops:

(1) Stops shall be provided at the limits of travel of the bridge.

(2) Stops shall engage the bumpers or bumper pads mounted on the

SAES-B-053

C7 bridge.

Sec. 3.2

(3) Stops shall be designed to withstand the forces applied to the

bumpers.

[ASME B30.2 Sec.2-1.3.2(b)]

Toolbox: If a receptacle is provided for the stowing of tools and oil cans, it

shall be made of a noncombustible material and shall be securely SAES-B-053

C8

fastened in the cab or on the service platform. Sec. 3.2

[ASME B30.2 Sec.2-1.5.4]

The door(s) of electrical control cabinets shall either open at least 90 deg.

SAES-B-053

C9 or be removable.

Sec. 3.2

(ASME B30.2 Sec.2-1.7.1(e)]

Service platforms shall have a slip-resistant walking surface. SAES-B-053

C10

(ASME B30.2 Sec.2-1.7.1(g)] Sec. 3.2

Stops and Bumpers: Trolley Stops

(a) Stops shall be provided at the limits of travel of the trolley.

(b) Stops shall engage the bumpers or bumper pads mounted on the

SAES-B-053

C11 trolley.

Sec. 3.2

(c) Stops shall be designed to withstand the forces applied by the

bumpers.

[ASME B30.2 Sec.2-1.8.1]

Each hoisting unit of the crane shall be equipped with at least one holding

brake. The holding brake shall be applied to the motor shaft or a gear

SAES-B-053

C12 reducer shaft and shall have a torque rating not less than the percentage

Sec. 3.2

of rated load hoisting torque at the point where the brake is applied.

[ASME B30.2 Sec.2-1.12.1]

Wiring and equipment shall comply with Article 610 of ANSI/NFPA 70, SAES-B-053

C13

National Electrical Code. [ASME B30.2 Sec.2-1.13.1(a)] Sec. 3.2

The control circuit voltage shall not exceed 600V for AC or DC. SAES-B-053

C14

[ASME B30.2 Sec.2-1.13.1(b)] Sec. 3.2

The control circuit voltage in pendant push buttons shall not exceed 150V

SAES-B-053

C15 for AC or 300V for DC.

Sec. 3.2

[ASME B30.2 Sec.2-1.13.1(c)]

Saudi Aramco: Company General Use

Where multiple conductor cable is used with a suspended push-button

station, the station shall be supported so that the electrical conductors are SAES-B-053

C16

protected from strain. Sec. 3.2

[ASME B30.2 Sec.2-1.13.1(d)]

Pendant control stations shall be constructed to prevent electrical shock.

The push-button enclosure shall be at ground potential and marked for SAES-B-053

C17

identification of functions. Sec. 3.2

[ASME B30.2 Sec.2-1.13.1(e)]

Floor-Operated Cranes:

A warning device should be provided for installations where the ability of SAES-B-053

C18

the operator to warn persons in the path of the load is impaired.[ASME Sec. 3.2

B30.2 Sec.2-1.15.2(a)]

Types of Devices. One or more of the following devices shall be provided

when required [ASME B30.2 Sec.2-1.15.3]:

(a) Manually operated gong SAES-B-053

C19

(b) Power-operated bell, siren, or horn Sec. 3.2

(c) Rotating beacon

(d) Strobe light

Personnel responsible for the supervision, installation, operation,

inspection, or maintenance of the crane shall be familiar with the SAES-B-053

C20

applicable contents of the manual furnished with the crane. Sec. 3.2

[ASME B30.2 Sec.2-1.16.2]

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract)

2. Schedule Q - Quality Requirements (Pro Forma Contract)

3. SAES-B-053 - Machine Safety Guarding, Elevators, Escalators, and Conveyors, 15 August 2017

4. ANSI B30.2 - Overhead and Gantry Cranes, 2011 Edition

5. SAEP-1151 Inspection Requirements for Contractor Procured Materials & Equipment, 30 January 2017

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saic P 3424Document3 pagesSaic P 3424spravin231No ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Traffic Signage - Installation Page 2Document2 pagesTraffic Signage - Installation Page 2moytabura96No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Structural Steel - Erection Inspection SAIC-M-1025 1-Nov-09 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Structural Steel - Erection Inspection SAIC-M-1025 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 ElectDocument1 pageSaudi Aramco Inspection Checklist: Cable Tray, Metallic Tray Systems - Material Receiving SAIC-P-3302 3-Jul-18 Electkarthi51289No ratings yet

- Saic A 1013Document2 pagesSaic A 1013karthi51289No ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008karthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 InstDocument18 pagesSaudi Aramco Inspection Checklist: Skid For Non-Hazardous Locations - Material Receiving SAIC-J-6020 24-Jul-18 Instnisha_khanNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saic P 3424Document3 pagesSaic P 3424spravin231No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistspravin231No ratings yet

- Saic P 3423Document7 pagesSaic P 3423spravin231No ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- Saudi Aramco Typical Inspection PlanDocument12 pagesSaudi Aramco Typical Inspection Planspravin231No ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01spravin231No ratings yet

- Satip W 017 01Document13 pagesSatip W 017 01spravin231No ratings yet

- Satip X 600 02Document15 pagesSatip X 600 02spravin231No ratings yet

- Satip W 014 01Document12 pagesSatip W 014 01spravin231No ratings yet

- Satip y 101 01Document12 pagesSatip y 101 01spravin231No ratings yet

- Palanguia PowDocument44 pagesPalanguia PowShyra MaximoNo ratings yet

- STAHL Overhead Travelling CranesDocument44 pagesSTAHL Overhead Travelling CranesIgnacio Moratinos Castañeda100% (2)

- BC Method of StatementDocument5 pagesBC Method of StatementMuhterem UncuNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- Inspection Request Form For Beam Launching WorkDocument2 pagesInspection Request Form For Beam Launching WorkWr ArNo ratings yet

- Mini Crane Maeda mc104Document4 pagesMini Crane Maeda mc104Camilo Corrales M.No ratings yet

- Incremental Launch Method For Steel Truss Bridge ErectionDocument11 pagesIncremental Launch Method For Steel Truss Bridge ErectionaapennsylvaniaNo ratings yet

- Rotating Equip Installation Procedure - Method StatementDocument14 pagesRotating Equip Installation Procedure - Method StatementSonu Vakkayil MathewNo ratings yet

- CPD15FJ5 3 ManualDocument83 pagesCPD15FJ5 3 ManualGWormNo ratings yet

- Tower Crane Test ReportDocument10 pagesTower Crane Test ReportanandreevNo ratings yet

- The Yellow Book 2008Document198 pagesThe Yellow Book 2008Beto Ac75% (4)

- Grove RT422 22TDocument4 pagesGrove RT422 22TTeo DeustchNo ratings yet

- Crawler Crane 35 TonDocument4 pagesCrawler Crane 35 TonPratama Trendy Leo100% (1)

- introduction Z/: Advantages of Utilizing The Construction EquipmentsDocument66 pagesintroduction Z/: Advantages of Utilizing The Construction Equipmentsweston chegeNo ratings yet

- 09 12 30 Co SG Rev01Document125 pages09 12 30 Co SG Rev01MuhammadFaridNo ratings yet

- JCPT0808 JCPT1612DCB Operatots ManualDocument99 pagesJCPT0808 JCPT1612DCB Operatots ManualJames GamingNo ratings yet

- Yard Layout Drydocks World DubaiDocument2 pagesYard Layout Drydocks World DubaiImran Koi LukmanNo ratings yet

- Liebherr LTM 1250 6 1Document12 pagesLiebherr LTM 1250 6 1Andrei BleojuNo ratings yet

- Wire Ropes Used in Mines and Their Installation PDFDocument18 pagesWire Ropes Used in Mines and Their Installation PDFKumarNo ratings yet

- C1 Conveyor Systems PDFDocument60 pagesC1 Conveyor Systems PDFTomekNo ratings yet

- Annexure 15 Indian StandardsDocument2 pagesAnnexure 15 Indian Standardskanha15102003100% (2)

- NOHSC 1010 (1994) National Standard For Plant PDFDocument67 pagesNOHSC 1010 (1994) National Standard For Plant PDFJayNo ratings yet

- Crane Boom Case Study OffshoreDocument1 pageCrane Boom Case Study OffshoreSiddhant AgarwalNo ratings yet

- Operating Instructions: Disconnector 3DN1 N00 With 3DN0 Attached Earthing Switch (40-50ka)Document79 pagesOperating Instructions: Disconnector 3DN1 N00 With 3DN0 Attached Earthing Switch (40-50ka)Takhmil Imam RifaiNo ratings yet

- Liebherr Offshore Cranes Product Range enDocument20 pagesLiebherr Offshore Cranes Product Range enCarlos Gonzalez Torres0% (1)

- Crane 3 GP160-0516-2Document222 pagesCrane 3 GP160-0516-2cengiz kutukcuNo ratings yet

- Miller Forged HooksDocument12 pagesMiller Forged Hooksshrikant mishraNo ratings yet

- 07 CBM RigsDocument5 pages07 CBM RigsRahesa Wahyu NalendraNo ratings yet

- As 1418.2-1997 Cranes (Including Hoists and Winches) Serial Hoists and WinchesDocument8 pagesAs 1418.2-1997 Cranes (Including Hoists and Winches) Serial Hoists and WinchesSAI Global - APACNo ratings yet

- Terex PDFDocument48 pagesTerex PDFmovie hunter100% (1)