Professional Documents

Culture Documents

2019 - Chapter 31F Marine Oil Terminals 77

Uploaded by

sidhappy860 ratings0% found this document useful (0 votes)

36 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 page2019 - Chapter 31F Marine Oil Terminals 77

Uploaded by

sidhappy86Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MARINE OIL TERMINALS

Division 10

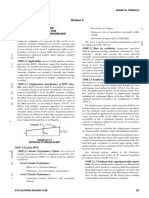

SECTION 3110F 1. Equipment shall be provided with a safety dis-

MECHANICAL AND ELECTRICAL EQUIPMENT connecting device to isolate the entire electrical

system from the electrical mains in accordance

3110F.1 General. This section provides the minimum stan-

with Article 430 of the California Electrical Code

dards for mechanical and electrical equipment at MOTs.

[10.8].

See Section 3101F.3 for definitions of “new” (N) and

2. Motor controllers and 3-pole motor overload

“existing” (E).

protection shall be installed and sized in accor-

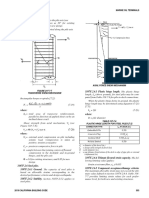

3110F.2 Marine loading arms. dance with Article 430 of the California Electri-

3110F.2.1 General criteria. Marine loading arms and cal Code [10.8].

ancillary systems shall conform to ASME B31.3 [10.1], 33 3. Control circuits shall be limited to 120 volts and

CFR 154.510 [10.2] and OCIMF “Design and Construc- shall comply with Articles 500 and 501 of the

tion Specification for Marine Loading Arms” [10.3]. Each California Electrical Code [10.8]. Alternatively,

loading arm used for transferring oil shall have a means intrinsically safe wiring and controls may be pro-

of being drained or closed before being disconnected. vided in accordance with Article 504 of the Cali-

The following shall be considered when determining fornia Electrical Code [10.8] and UL Std. No.

the loading arm maximum allowable extension limits: 913 [10.9].

1. Vessel sizes and manifold locations 4. Grounding and bonding shall comply with the

requirements of Article 430 of the California

2. Lowest-low water level (datum) Electrical Code [10.8] and Section 3111F.

3. Highest-high water level Section 3111F includes requirements for electrical

4. Maximum vessel surge and sway equipment, wiring, cables, controls and electrical aux-

5. Maximum width of fendering system iliaries located in hazardous areas.

For each loading arm, the maximum allowable move- 3110F.2.2.3 Remote operation. The remote control

ment envelope limits shall comply with 2 CCR 2380 system, where provided, shall conform to the recom-

[10.4]. mendations of the OCIMF [10.3]. The remote opera-

tion shall be facilitated by either a pendant control

Loading arms and ancillary systems shall have a seis- system or by a hand-held radio controller (N).

mic assessment in accordance with Section 3104F.5. For

seismic evaluation, design and strengthening of loading The pendant control system shall be equipped with a

arms and ancillary equipment, seismic loads shall be com- plug-in capability to an active connector located either

in the vicinity of the loading arms, or at the loading

> puted per Section 3104F.5.4.1 and the procedure in Sec-

> tion 8.5.3 of ASCE/COPRI 61 [10.5]. For strength arm outboard end on the triple swivel, and hard-wired

evaluation of supports and attachments, see Section into the control console. The umbilical cord running

3107F.7. from the triple swivel to the control console shall be

attached to the loading arm. Other umbilical cords

3110F.2.2 Electrical and hydraulic power systems. shall have sufficient length to reach the maximum oper-

3110F.2.2.1 Pressure and control systems (N). ational limits (N).

1. Pressure gauges shall be mounted in accordance The radio controller if installed shall comply with 2

with ASME B40.100 [10.6]. CCR 2370 [10.4] and 47 CFR Part 15 [10.10] require-

2. The hydraulic drive cylinders shall be mounted ments for transmitters operating in an industrial envi-

and meet either the mounting requirements of ronment (N/E).

NFPA T3.6.7 R3 [10.7] or equivalent. 3110F.3 Oil transfer hoses (N/E). Hoses for oil transfer ser-

vice shall be in compliance with 2 CCR 2380 [10.4] and 33

3. In high velocity current (>1.5 knots) areas, all

CFR 154.500 [10.11].

new marine loading arms shall be fitted with

quick disconnect couplers and emergency quick Hoses with nominal diameters of 6 inches or larger shall

release systems in conformance with Sections 6.0 have flanges that meet ASME B16.5 [10.12], or hoses with

and 7.0 of [10.3]. In complying with this require- nominal diameters of 6 inches or less may have quick discon-

ment, attention shall be paid to the commentary nect fittings provided that they meet ASTM F1122 [10.13].

and guidelines in Part III of reference [10.3]. The minimum hose length shall safely accommodate the

4. Out-of-limit, balance and the approach of out-of- vessel’s size and maximum movements during transfer opera-

limit alarms shall be located at or near the load- tions and mooring (see Section 3105F.2).

ing arm console. 3110F.4 Lifting equipment: winches and cranes. Lifting

3110F.2.2.2 Electrical components (N). The following equipment for oil service activities, other activities (if opera-

criteria shall be implemented: tion or failure could cause an oil release) or spill response,

2019 CALIFORNIA BUILDING CODE 569

You might also like

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- MSC Guidelines for Ship Service Generator SwitchboardDocument4 pagesMSC Guidelines for Ship Service Generator Switchboardkiwi cNo ratings yet

- ABS 2010 SVR RCN1 Jul2010Document10 pagesABS 2010 SVR RCN1 Jul2010Marc FazioliNo ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 3Document1 page2019 - Chapter 31F Marine Oil Terminals 3sidhappy86No ratings yet

- Ui Sc180rev4Document9 pagesUi Sc180rev4Maan MrabetNo ratings yet

- 2 Cable Trunking and DuctsDocument8 pages2 Cable Trunking and Ductsaanouar77No ratings yet

- RULES FOR BUILDING AND CLASSING MOBILE OFFSHORE DRILLING UNITSDocument6 pagesRULES FOR BUILDING AND CLASSING MOBILE OFFSHORE DRILLING UNITSneoNo ratings yet

- 1 04 039 03 PDFDocument9 pages1 04 039 03 PDFanuragpugaliaNo ratings yet

- 2020 New Mexico Electrical Code (based on 2020 NFPA 70 National Electrical Code)Document8 pages2020 New Mexico Electrical Code (based on 2020 NFPA 70 National Electrical Code)Tulja AmatyaNo ratings yet

- Partbii IIIDocument388 pagesPartbii IIIsaravananNo ratings yet

- NRC Standard Review Plan for Station Blackout EventsDocument23 pagesNRC Standard Review Plan for Station Blackout EventsAhmed AwaiseNo ratings yet

- Company Directive: Engineering Specification Ee Spec: 7/3Document20 pagesCompany Directive: Engineering Specification Ee Spec: 7/3rajamasaNo ratings yet

- Chapter 31f MotemsDocument81 pagesChapter 31f MotemsAbelNo ratings yet

- Section 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Document12 pagesSection 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Suresh KumarNo ratings yet

- U.S. NRC guide on seismic design classification for nuclear plantsDocument11 pagesU.S. NRC guide on seismic design classification for nuclear plantsAmar MistryNo ratings yet

- TCST11110R0 Pilot CablesDocument25 pagesTCST11110R0 Pilot CablesshabeerNo ratings yet

- Ngts - 3 24 10Document41 pagesNgts - 3 24 10akmezimNo ratings yet

- Trafo RTCCDocument363 pagesTrafo RTCCKrishna Chandavar0% (1)

- Conditiong Monitoring Techniques For Electric Cables Used in Nuclear Power PlantsDocument16 pagesConditiong Monitoring Techniques For Electric Cables Used in Nuclear Power PlantsGualadrakeNo ratings yet

- 110 26Document9 pages110 26Armin Fernández GerardoNo ratings yet

- California Building Code MOTEMS 2014Document85 pagesCalifornia Building Code MOTEMS 2014Søren MørchNo ratings yet

- P-46-08 - Power TransformerDocument81 pagesP-46-08 - Power TransformerNasrullahNo ratings yet

- Circuit Breaker Technical SpecificationsDocument24 pagesCircuit Breaker Technical SpecificationssanjayNo ratings yet

- Special Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)Document12 pagesSpecial Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)sahil4INDNo ratings yet

- Circular #03DSV2015 Electrical Load AnalysisDocument4 pagesCircular #03DSV2015 Electrical Load AnalysisMarco SantosNo ratings yet

- 150 - 5345-10H CCRsDocument30 pages150 - 5345-10H CCRsAsk EntertainmentNo ratings yet

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- Ipss 1-10-018-03Document5 pagesIpss 1-10-018-03Deepjyoti DasNo ratings yet

- Mooring and Berthing AnalysisDocument6 pagesMooring and Berthing AnalysisIgnatius Samraj67% (3)

- Fts Batara Mooring DesignDocument42 pagesFts Batara Mooring DesignBaluqia AkhbarNo ratings yet

- Steel Vessels For Service On Rivers and Intracoastal Waterways 2007Document5 pagesSteel Vessels For Service On Rivers and Intracoastal Waterways 2007Alfi DelfiNo ratings yet

- Automaticctrc Uitreclosers-Specification: (Second Revision)Document13 pagesAutomaticctrc Uitreclosers-Specification: (Second Revision)joydeep_d3232No ratings yet

- Specification For Single Motor Control Units For Voltages Not Exceeding 1000 V Ac (First Revision) IPSS:1-04-039-03Document9 pagesSpecification For Single Motor Control Units For Voltages Not Exceeding 1000 V Ac (First Revision) IPSS:1-04-039-03GopalMahanta100% (1)

- NGTS 201 Issue2 PDFDocument27 pagesNGTS 201 Issue2 PDFjuanluismartosNo ratings yet

- Electrical Equipment EnclosuresDocument40 pagesElectrical Equipment EnclosuresLeon de RuijterNo ratings yet

- RG1 166Document8 pagesRG1 166tugceceran90No ratings yet

- An - GRC-109 TM 11-5820-474-14Document129 pagesAn - GRC-109 TM 11-5820-474-14dr7zyq100% (1)

- Technical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerDocument26 pagesTechnical Specification of PLCC: Wbsetcl Page - 1/26 Battery ChargerpvenkyNo ratings yet

- P6 Chapter02Document13 pagesP6 Chapter02HADY ELKHSHENNo ratings yet

- Seismic Qualification of Equipment for Nuclear Power PlantsDocument4 pagesSeismic Qualification of Equipment for Nuclear Power PlantsJuan Manuel Gutierrez AguilarNo ratings yet

- AIS-102 Part 1Document57 pagesAIS-102 Part 1Prashant A UNo ratings yet

- Comments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - ADocument188 pagesComments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - AdipakkupatelNo ratings yet

- 4545-Paper by Steve FergusonDocument9 pages4545-Paper by Steve Fergusonsudheer1044No ratings yet

- NTPC FGD System Technical SpecificationDocument100 pagesNTPC FGD System Technical SpecificationPiyush MalviyaNo ratings yet

- CBFDocument17 pagesCBFPhilip D'cruzNo ratings yet

- AC 43.13 - 1A Chapter - 12-13 PDFDocument28 pagesAC 43.13 - 1A Chapter - 12-13 PDFElmer Villegas100% (1)

- JKR Specification For 11 KV High VoltageDocument16 pagesJKR Specification For 11 KV High VoltageCherry AngNo ratings yet

- MSN 1779 (M+F) : Merchant Shipping NoticeDocument8 pagesMSN 1779 (M+F) : Merchant Shipping NoticezenonzielinskiNo ratings yet

- Power Line Carrier Communication: Engineering DepartmentDocument29 pagesPower Line Carrier Communication: Engineering DepartmentFaisalabad West T/L &S/SNo ratings yet

- Automatic Circuit RecloserDocument16 pagesAutomatic Circuit RecloserFarraziNo ratings yet

- Nepalese Civil Airworthiness Requirements: Section CDocument6 pagesNepalese Civil Airworthiness Requirements: Section CSantosh SahNo ratings yet

- Electrical Installations Section Provides Safety GuidelinesDocument2 pagesElectrical Installations Section Provides Safety GuidelinesMuh Kurniawan SNo ratings yet

- Wapda P 46 2008Document81 pagesWapda P 46 2008Engr Awais Khan100% (7)

- Lightning and Other Overvoltage ProtectionDocument10 pagesLightning and Other Overvoltage ProtectionAhdab ElmorshedyNo ratings yet

- Offshore Mooring StandardsDocument8 pagesOffshore Mooring StandardsradrottenNo ratings yet

- 15-5 (Part 4) Electrical Power SupplyDocument17 pages15-5 (Part 4) Electrical Power SupplytalabizNo ratings yet

- Is 900-Code of Practice For Installation and Maintenance of Induction MotorDocument37 pagesIs 900-Code of Practice For Installation and Maintenance of Induction MotormailbkraoNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- 2019 - Chapter 31F Marine Oil Terminals 54Document1 page2019 - Chapter 31F Marine Oil Terminals 54sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 59Document1 page2019 - Chapter 31F Marine Oil Terminals 59sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 58Document1 page2019 - Chapter 31F Marine Oil Terminals 58sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 64Document1 page2019 - Chapter 31F Marine Oil Terminals 64sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 57Document1 page2019 - Chapter 31F Marine Oil Terminals 57sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 55Document1 page2019 - Chapter 31F Marine Oil Terminals 55sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 56Document1 page2019 - Chapter 31F Marine Oil Terminals 56sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 60Document1 page2019 - Chapter 31F Marine Oil Terminals 60sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 61Document1 page2019 - Chapter 31F Marine Oil Terminals 61sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 40Document1 page2019 - Chapter 31F Marine Oil Terminals 40sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 53Document1 page2019 - Chapter 31F Marine Oil Terminals 53sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 52Document1 page2019 - Chapter 31F Marine Oil Terminals 52sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 44Document1 page2019 - Chapter 31F Marine Oil Terminals 44sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 50Document1 page2019 - Chapter 31F Marine Oil Terminals 50sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 41Document1 page2019 - Chapter 31F Marine Oil Terminals 41sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 45Document1 page2019 - Chapter 31F Marine Oil Terminals 45sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 49Document1 page2019 - Chapter 31F Marine Oil Terminals 49sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 32Document1 page2019 - Chapter 31F Marine Oil Terminals 32sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 42Document1 page2019 - Chapter 31F Marine Oil Terminals 42sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 43Document1 page2019 - Chapter 31F Marine Oil Terminals 43sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 46Document1 page2019 - Chapter 31F Marine Oil Terminals 46sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 51Document1 page2019 - Chapter 31F Marine Oil Terminals 51sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 34Document1 page2019 - Chapter 31F Marine Oil Terminals 34sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 47Document1 page2019 - Chapter 31F Marine Oil Terminals 47sidhappy86No ratings yet

- Marine Oil Terminals Seismic Analysis RequirementsDocument1 pageMarine Oil Terminals Seismic Analysis Requirementssidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 36Document1 page2019 - Chapter 31F Marine Oil Terminals 36sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 48Document1 page2019 - Chapter 31F Marine Oil Terminals 48sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 35Document1 page2019 - Chapter 31F Marine Oil Terminals 35sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 38Document1 page2019 - Chapter 31F Marine Oil Terminals 38sidhappy86No ratings yet

- 2019 - Chapter 31F Marine Oil Terminals 37Document1 page2019 - Chapter 31F Marine Oil Terminals 37sidhappy86No ratings yet

- Incidentrequest Closed Monthly JunDocument250 pagesIncidentrequest Closed Monthly Junأحمد أبوعرفهNo ratings yet

- Design For Six Sigma Za PrevodDocument21 pagesDesign For Six Sigma Za PrevodSrdjan TomicNo ratings yet

- Law On Sales: Perfection Stage Forms of Sale When Sale Is SimulatedDocument21 pagesLaw On Sales: Perfection Stage Forms of Sale When Sale Is SimulatedRalph ManuelNo ratings yet

- Polity by LaxmikantDocument3 pagesPolity by LaxmikantJk S50% (6)

- SQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsDocument6 pagesSQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsAchamyeleh TamiruNo ratings yet

- BSW, BS,,AF, BA and Metric Tool SizeDocument4 pagesBSW, BS,,AF, BA and Metric Tool SizeUNES100% (1)

- 6wa Retrofit GuideDocument13 pages6wa Retrofit GuideAnonymous X5q33TQ100% (1)

- DRW Questions 2Document16 pagesDRW Questions 2Natasha Elena TarunadjajaNo ratings yet

- Report of Six Months Industrial TrainingDocument38 pagesReport of Six Months Industrial TrainingJibran BashirNo ratings yet

- 10 Steps To Dream Building: - A Publication of Center My CenterDocument19 pages10 Steps To Dream Building: - A Publication of Center My CenterRamalakshmi100% (2)

- One SheetDocument1 pageOne Sheetadeel ghouseNo ratings yet

- Slimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsDocument2 pagesSlimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsJon GosnellNo ratings yet

- Connect Debug LogDocument20 pagesConnect Debug LogrohanZorba100% (1)

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Demethanizer OperationDocument6 pagesDemethanizer OperationHoustonAbducteeNo ratings yet

- Prison Architect Calculator (V2.0)Document11 pagesPrison Architect Calculator (V2.0)freakman89No ratings yet

- Davall Stock Gears Worm Wheel Gear Sets 17pages PDFDocument17 pagesDavall Stock Gears Worm Wheel Gear Sets 17pages PDFharish ahireNo ratings yet

- ISO 9001 Quality Management ProceduresDocument7 pagesISO 9001 Quality Management ProceduresFendi100% (1)

- Describe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementDocument3 pagesDescribe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementAlemayehu Demeke80% (5)

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- Trains-Dutch-East-Indies - Dirk TeweuenDocument30 pagesTrains-Dutch-East-Indies - Dirk TeweuenMohamad AliwafaNo ratings yet

- Dialogic DSI Signaling Servers: SIU Mode User ManualDocument304 pagesDialogic DSI Signaling Servers: SIU Mode User ManualAdiansyah Rama67% (3)

- Lecture 9 - StatisticsDocument4 pagesLecture 9 - StatisticsMohanad SulimanNo ratings yet

- Microprocessor 8086 Memory and ArchitectureDocument13 pagesMicroprocessor 8086 Memory and ArchitecturehrrameshhrNo ratings yet

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- 122 - Motion For Leave To File Rule 11 MotionDocument3 pages122 - Motion For Leave To File Rule 11 MotionRipoff ReportNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- Accounting Basics: Recording TransactionsDocument8 pagesAccounting Basics: Recording TransactionsRegina Bengado100% (1)