Professional Documents

Culture Documents

3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance Criteria

Uploaded by

Ibrahim shaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.6 Visual Examination: Part B Types of Tests, Test Methods, and Acceptance Criteria

Uploaded by

Ibrahim shaikCopyright:

Available Formats

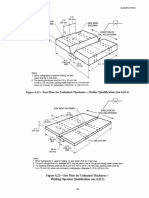

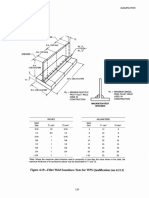

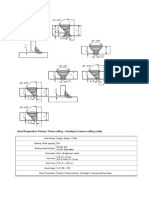

AWS D1.2/D1.2M:2014 CLAUSE 3.

QUALIFICATION

(4) Position 4F (Overhead)—The test plates shall be and AWS D1.2/D1.2M are in conflict, AWS D1.2/D1.2M

so placed that each fillet weld is deposited on the under shall take precedence.

side of a horizontal surface and against a vertical surface

3.5.1 Visual examination is required for WPS qualifica-

[see Figure 3.5(D)].

tion and performance qualification.

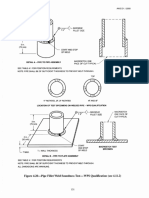

3.4.1.4 Fillet Welds—Pipe (see Figure 3.6). In mak-

3.5.2 Mechanical Tests

ing the tests to qualify fillet welds on pipe, the test pipe

shall be welded in the positions outlined below: 3.5.2.1 Tension tests for strength of groove welds

shall be required for WPS qualification.

(1) Position 1F (Pipe Inclined-Rotated)—The test

pipe shall be placed with its axis at approximately 45° 3.5.2.2 Bend tests for soundness and ductility of

and rotated during welding so that the filler metal is groove welds are required for WPS qualification and per-

deposited in the flat position [see Figure 3.6(A)]. formance qualification, except as allowed in 3.5.3.

(2) Position 2F (Pipe Vertical-Fixed)—The test pipe 3.5.2.3 Nick-break fracture tests are required to deter-

shall be placed with its axis approximately vertical. The mine soundness of groove welds containing castings for

filler metal shall be placed on the outer surface of the WPS qualification as described in 3.9.1.

pipe at its juncture with the abutting plate or pipe. The 3.5.2.4 To determine the soundness of fillet welds for

assembly shall not be rotated during welding [see Figure performance qualification, a fillet weld fracture test shall

3.6(B)]. be required. For WPS qualification, a fracture test or a

(3) Position 2FR (Pipe Horizontal-Rotated)—The test fillet weld bend test may be used to determine soundness.

pipe shall be placed with its axis approximately horizon- 3.5.3 RT may be used in lieu of bend tests for perfor-

tal and rotated during welding so that filler metal is mance qualification of groove joints in wrought materi-

deposited in the horizontal position [see Figure 3.6(C)]. als. The RT procedure technique and acceptance criteria

(4) Position 4F (Overhead-Fixed)—The test pipe shall be in conformance with the requirements of Clause

shall be placed with its axis approximately vertical. The 5, Part B and Part D, respectively, of this code.

filler metal shall be placed against the outer surface of

the pipe at its juncture with the abutting plate or pipe.

The assembly shall not be rotated during welding [see 3.6 Visual Examination

Figure 3.6(D)].

3.6.1 Examination Procedure. Visual inspection of the

(5) Position 5F (Pipe Horizontal-Fixed)—The test weld surface shall be performed on the test weldment

pipe shall be placed with its axis approximately horizon- prior to cutting any mechanical test specimens, except

tal and with the welding joint vertical. The assembly that macroetching of cut sections is included in the

shall not be rotated during welding [see Figure 3.6(E)]. examination of fillet welds and PJP groove welds. Liquid

penetrants, magnifying lenses, scales or templates may

be used as aids in determining whether the sample weld-

ment passes the criteria described in 3.6.2 or 3.6.3.

Part B

3.6.1.1 For detecting discontinuities that are open to

Types of Tests, Test Methods, the surface, PT may be used. The methods set forth in

and Acceptance Criteria ASTM E165, Standard Recommended Practice for Liq-

uid Penetrant Inspection Method, shall be used, and the

standards of acceptance shall be in conformance with

3.5 Types and Purposes of Tests 5.14.

The tests described in Part B (3.5 through 3.11) are 3.6.1.2 The macroetched specimen for the fillet weld

intended to determine the strength or degree of sound- test assembly or the PJP groove weld test assembly shall

ness of welds made in conformance with the WPS or the be taken from the end of the sample weldment. The macro-

soundness of welds made by a welder, welding operator, etch specimens for fillet welded pipe or tubing welded

or tack welder. assemblies shall be taken by sectioning longitudinally

through the center of the pipe or tubing. One cut face of

The provisions of AWS B4.0, Standard Methods for the specimen shall be smoothed and etched with a suit-

Mechanical Testing of Welds, may be used for the testing able etchant to give a clear definition of the weld metal

of welds made for WPS or performance qualification. and HAZ. Etching solutions, procedures, and safety

However, in instances where the provisions of AWS B4.0 requirements are given in Annex G.

13

You might also like

- Module 1: Code Basics: Part QW WeldingDocument12 pagesModule 1: Code Basics: Part QW WeldingaliNo ratings yet

- 4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsDocument1 page4.12 Complete Joint Penetration (CJP) Groove Welds For Thbular ConnectionsIbrahim shaikNo ratings yet

- AWS D1.1-D1.1M-2015 - Pagina-110Document1 pageAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezNo ratings yet

- Modul Tambahan Kualifikasi Las (KL)Document27 pagesModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- Qualification of Welding Procedures and WeldersDocument10 pagesQualification of Welding Procedures and WelderstxjiangNo ratings yet

- Api 1104 VT TestDocument2 pagesApi 1104 VT TestKali AbdennourNo ratings yet

- Astm A66Document3 pagesAstm A66Darwin DarmawanNo ratings yet

- API 1104 VT TestDocument2 pagesAPI 1104 VT TestRao Javaid IqbalNo ratings yet

- QW-171 Toughness Tests: (A) The Two Base Metals, or (B) The Weld Metal and The Base MetalDocument1 pageQW-171 Toughness Tests: (A) The Two Base Metals, or (B) The Weld Metal and The Base MetalMo ZeroNo ratings yet

- Bend Test AceptenDocument1 pageBend Test AceptenArung IdNo ratings yet

- AWS D1.1 - Acceptance Criteria For RTDocument11 pagesAWS D1.1 - Acceptance Criteria For RTHoras Canman67% (3)

- ASTM A 66 - 87 (Reapproved 1995)Document2 pagesASTM A 66 - 87 (Reapproved 1995)geraldo leoncioNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- AWS D1.5 Criterios RXDocument6 pagesAWS D1.5 Criterios RXJuan NavaNo ratings yet

- Steel Screw Spikes: Standard Specification ForDocument2 pagesSteel Screw Spikes: Standard Specification ForKrishna Sai100% (1)

- Astm A66 07 PDFDocument3 pagesAstm A66 07 PDFJavier Ricardo Romero BohorquezNo ratings yet

- N.004 - ASTM B557 - Standard Methods of Tension Testing Wrought and Cast Aluminum - and Magnesium - Alloy ProductsDocument20 pagesN.004 - ASTM B557 - Standard Methods of Tension Testing Wrought and Cast Aluminum - and Magnesium - Alloy ProductsAdriene SantosNo ratings yet

- A066 Steel Screw Spikes PDFDocument3 pagesA066 Steel Screw Spikes PDFAnonymous 1GK9Hxp5YKNo ratings yet

- Flexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingDocument3 pagesFlexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingsamerNo ratings yet

- Steel Screw Spikes: Standard Specification ForDocument3 pagesSteel Screw Spikes: Standard Specification ForVivi VargasNo ratings yet

- 3.3 Qualification of Welders, Welding Operators, and Tack WeldersDocument1 page3.3 Qualification of Welders, Welding Operators, and Tack WeldersIbrahim shaikNo ratings yet

- Api 107Document14 pagesApi 107Yersin Hernandez AldanNo ratings yet

- C1604C1604MDocument5 pagesC1604C1604MJorge Luis Arevalo Lopez100% (1)

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- Sampling Procedure For Impact Testing of Structural SteelDocument5 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultomNo ratings yet

- b 557m - 02 عينة الشد المستطيلةDocument19 pagesb 557m - 02 عينة الشد المستطيلةMohamad Marwan HamwiNo ratings yet

- Codes and StandardsDocument33 pagesCodes and StandardsMohd AmaniNo ratings yet

- QW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Document2 pagesQW-162 Guided-Bend Test Procedure: QW-466.1 Figure QW-466.2 Figure QW-463.1 (F)Gangadhar SahuNo ratings yet

- FW Brochure 12-08 UpdateDocument29 pagesFW Brochure 12-08 UpdateAhmed shabanNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionhavona100% (1)

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- Ur W28rev2Document25 pagesUr W28rev2Karla JTNo ratings yet

- IP23 - Procedure For Welder Performance QualificationDocument25 pagesIP23 - Procedure For Welder Performance QualificationsajiNo ratings yet

- VT Procedure: 1 - PurposeDocument4 pagesVT Procedure: 1 - PurposeElvin Menlibai100% (1)

- Bend Test ProcedureDocument9 pagesBend Test ProcedureRavi pandeyNo ratings yet

- Astm G58Document7 pagesAstm G58pachosilverNo ratings yet

- PCI-MNL-116-99-Structural-QC-Manual - Test Percentage of Welding For PrecastDocument2 pagesPCI-MNL-116-99-Structural-QC-Manual - Test Percentage of Welding For PrecastEng-TaYsEeRNo ratings yet

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- AWS D1 Visual InspectionDocument2 pagesAWS D1 Visual InspectionBHUSHAN KALENo ratings yet

- Welder Performance Qualification AsmeDocument14 pagesWelder Performance Qualification AsmeAhmad RizkiNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- C1604C1604M PDFDocument5 pagesC1604C1604M PDFGiancarlo CalleNo ratings yet

- Vitrified Clay Pipe: Standard Test Methods ForDocument4 pagesVitrified Clay Pipe: Standard Test Methods Fornisha_khanNo ratings yet

- C 469 PDFDocument5 pagesC 469 PDFTommy Cr100% (3)

- C469Static Modulus of ElasticityDocument4 pagesC469Static Modulus of Elasticityronnie_syncinNo ratings yet

- Extracted Pages From ASME BPVC 2021 Section IX-2Document2 pagesExtracted Pages From ASME BPVC 2021 Section IX-2Roberto Carlos Arana ChumpitazNo ratings yet

- WPS Guides For Plug and Slot WeldsDocument4 pagesWPS Guides For Plug and Slot WeldsBrad BorgesNo ratings yet

- BKI Rules For Classification and ConstructionDocument4 pagesBKI Rules For Classification and ConstructionwongyuliongNo ratings yet

- RP 2007-18 App.BDocument24 pagesRP 2007-18 App.BdrailotaNo ratings yet

- Flexion de VigasDocument4 pagesFlexion de VigasAdán Cogley CantoNo ratings yet

- Asme IX BQ Art 11Document5 pagesAsme IX BQ Art 11Maria Alexandra Lange LenzNo ratings yet

- FSEL Concrete Compression Rev 00Document10 pagesFSEL Concrete Compression Rev 00Isaiah Paul SacramentoNo ratings yet

- UR W28 Welding Procedure Qualification Tests of Steels (Rev.2 Mar 2012)Document25 pagesUR W28 Welding Procedure Qualification Tests of Steels (Rev.2 Mar 2012)Dagoberto AguilarNo ratings yet

- Sampling Procedure For Impact Testing of Structural SteelDocument4 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultom100% (1)

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- 2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Document1 page2-6-ASME Sect. IX-2013-Section of Pipe Welder Qual.-Qw 452.6Tina MartinezNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Induction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesDocument1 pageInduction Training Record - Itr: Elmar Marinas LLC PO Box 4955, Umm Al Quwain, United Arab EmiratesIbrahim shaikNo ratings yet

- Pipe Bending: Case StudyDocument4 pagesPipe Bending: Case StudyIbrahim shaikNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- Pipe & Tube BrochureDocument18 pagesPipe & Tube BrochureIbrahim shaikNo ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- Bc-10 Phase 3 CTR 31: Tamba BVDocument47 pagesBc-10 Phase 3 CTR 31: Tamba BVIbrahim shaikNo ratings yet

- 2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignDocument1 page2.7 Filler Plates: AWS D1.2/D1.2M:2014 Clause 2. DesignIbrahim shaikNo ratings yet

- 3.3 Qualification of Welders, Welding Operators, and Tack WeldersDocument1 page3.3 Qualification of Welders, Welding Operators, and Tack WeldersIbrahim shaikNo ratings yet

- ISO 9001 2015 CluasesDocument1 pageISO 9001 2015 CluasesIbrahim shaikNo ratings yet

- Design 5fDocument1 pageDesign 5fIbrahim shaikNo ratings yet

- Design 5fDocument1 pageDesign 5fIbrahim shaikNo ratings yet

- Joints Edge PreparationDocument4 pagesJoints Edge PreparationIbrahim shaikNo ratings yet

- ISO 9001 2015 CluasesDocument1 pageISO 9001 2015 CluasesIbrahim shaikNo ratings yet

- Design 4Document1 pageDesign 4Ibrahim shaikNo ratings yet

- ARC WELDING Safely PDFDocument2 pagesARC WELDING Safely PDFdannywdcgmailNo ratings yet

- Design: 2.1 ScopeDocument1 pageDesign: 2.1 ScopeIbrahim shaikNo ratings yet

- 2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Document1 page2.5 Fillet Welds: Clause 2. Design AWS D1.2/D1.2M:2014Ibrahim shaikNo ratings yet

- Figure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Document1 pageFigure 4.21-Test Plate For Unlimited Thickness-Welder Qualification (See 4.23.1)Ibrahim shaikNo ratings yet

- 4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsDocument1 page4.13 PJP Tubular T-, Y-, or K-Connections and Butt JointsIbrahim shaikNo ratings yet

- Figure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Document1 pageFigure 4.19-Fillet Weld Soundness Tests For WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- Stainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Document6 pagesStainless Steel Socket Button and Flat Countersunk Head Cap Screws (Metric)Ibrahim shaikNo ratings yet

- AWS D1.2 at Extent of TestingDocument1 pageAWS D1.2 at Extent of TestingIbrahim shaikNo ratings yet

- Figure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Document1 pageFigure 4.20-Pipe Fillet Weld Soundness Test-WPS Qualification (See 4.11.2)Ibrahim shaikNo ratings yet

- 14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmDocument1 page14 EN 14509:2013 AVCP3: Declared Performance For IND - INDUSTRIAL Panel 1120 - 1180mmIbrahim shaikNo ratings yet

- Ergonomic Notations: Guide ForDocument76 pagesErgonomic Notations: Guide ForIbrahim shaikNo ratings yet

- Bevel PreparationDocument1 pageBevel PreparationIbrahim shaikNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- Bevel PreparationDocument1 pageBevel PreparationIbrahim shaikNo ratings yet

- ManifestDocument4 pagesManifestRicardo GomesNo ratings yet

- Nocchi Pentair Pompe VLRDocument14 pagesNocchi Pentair Pompe VLRThomas MyszkaNo ratings yet

- Business Events in Oracle Applications - A Sample ImplementationDocument6 pagesBusiness Events in Oracle Applications - A Sample ImplementationAshish HarbhajankaNo ratings yet

- Module M-07: EquipmentDocument1 pageModule M-07: EquipmentRobles DreschNo ratings yet

- PrivateDocument774 pagesPrivateazoz alseanNo ratings yet

- Dyna 2000iDocument6 pagesDyna 2000iAmerico GuzmanNo ratings yet

- Cgma ProgramsDocument22 pagesCgma ProgramsKunal RanaNo ratings yet

- ESA-ESTL-TM-0065 01 - New Cage Designs - Ball Riding CagesDocument44 pagesESA-ESTL-TM-0065 01 - New Cage Designs - Ball Riding CagesAnonymous lEX5U51wOANo ratings yet

- How To Mix Vocals - The Definitive Guide (15 Steps) 4 PDFDocument50 pagesHow To Mix Vocals - The Definitive Guide (15 Steps) 4 PDFLucas eduardoNo ratings yet

- CTAN160 - 4-20ma Current Loop ControlDocument3 pagesCTAN160 - 4-20ma Current Loop ControlSam eagle goodNo ratings yet

- GreenBiz Baseline Survey 2023Document6 pagesGreenBiz Baseline Survey 2023Maina KanyottuNo ratings yet

- Lecture 2Document98 pagesLecture 2pushpendra singhNo ratings yet

- Sample Integration MS 1 Level Seq 1Document3 pagesSample Integration MS 1 Level Seq 1sol heimNo ratings yet

- A Sophisticated Secured Smart Metering SystemDocument8 pagesA Sophisticated Secured Smart Metering SystemTesterNo ratings yet

- 21 Cryptos Magazine April 2018 OpDocument94 pages21 Cryptos Magazine April 2018 OpOnur Onuk100% (2)

- Introduction To Classification - PPT Slides 1Document62 pagesIntroduction To Classification - PPT Slides 1Saurabh PratapNo ratings yet

- Item StockDocument50 pagesItem StockRizki AmrullahNo ratings yet

- Ebook - IELTS WT1 (2021)Document14 pagesEbook - IELTS WT1 (2021)Trần Lê Uyên PhươngNo ratings yet

- Learning Management System (Lms Moodle)Document14 pagesLearning Management System (Lms Moodle)FantaNo ratings yet

- Upload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowDocument2 pagesUpload A Document For Free Download Access.: Select Files From Your Computer or Choose Other Ways To Upload BelowMasoud MonjeziNo ratings yet

- Computer ArchitectureDocument21 pagesComputer ArchitectureAsad JavedNo ratings yet

- Cpu286 Instruction ManualDocument24 pagesCpu286 Instruction ManualGilberto FigueroaNo ratings yet

- Tekapur Pistolska Mega 65 Zimska enDocument2 pagesTekapur Pistolska Mega 65 Zimska enEzeval GráficaNo ratings yet

- Installation Instructions For RCM Eccentric Adjustable Idler Set Subaru EJ20/22/25Document4 pagesInstallation Instructions For RCM Eccentric Adjustable Idler Set Subaru EJ20/22/25николай дехтярNo ratings yet

- FT ExadropDocument2 pagesFT ExadropABRAHAM MANUEL MEDINA LEYTONNo ratings yet

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocument6 pagesUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Sophos Application Whitelisting: Advanced Server Protection Made SimpleDocument6 pagesSophos Application Whitelisting: Advanced Server Protection Made SimplemaniccheNo ratings yet

- Care Home Laundry Process 2Document1 pageCare Home Laundry Process 2Uma PremeshNo ratings yet

- Unit 9 - Lesson D: Identity Theft: Touchstone 2nd Edition - Language Summary - Level 3Document2 pagesUnit 9 - Lesson D: Identity Theft: Touchstone 2nd Edition - Language Summary - Level 3Janeth GuerreroNo ratings yet

- Suasana Sekolah Bari Raya-Score and PartsDocument17 pagesSuasana Sekolah Bari Raya-Score and PartsoAeonNo ratings yet