Professional Documents

Culture Documents

Strengthening of Concrete Beams by External Strengthening of Concrete Beams by External Prestressing

Uploaded by

christi SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthening of Concrete Beams by External Strengthening of Concrete Beams by External Prestressing

Uploaded by

christi SCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/341278337

Strengthening of concrete Beams by External Strengthening of concrete Beams by external prestressing

Conference Paper · January 2009

CITATION READS

1 8

3 authors, including:

Kamal Sh. Mahmoud Mohammed Rasheed

Al-Mustansiriya University Al-Mustansiriya University

22 PUBLICATIONS 20 CITATIONS 30 PUBLICATIONS 40 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Behavior of Pre-stressed Concrete Deep Beams View project

the two project View project

All content following this page was uploaded by Kamal Sh. Mahmoud on 10 May 2020.

The user has requested enhancement of the downloaded file.

Effect of External Prestressing Strands on the Buckling

Stage Behaviour of Steel Beams

Kamal Sh.Mahmoud,phD1;Mohammed M.Rasheed,PhD2;Mustafa A.Yousif,PhD3

1,3 Mustansiriayh University,2 Dhofar University

Abstract Results and Discussion

Seven simply supported steel beams were fabricated and tested to explain Full experimental buckling outcomes of the beams tested are listed in

the influence of external prestressing strands on the buckling stage Table.2.

behavior of steel beams. Steel beams have the same gross sectional area, Buckling load:

clear span length and the strengthened sample was implemented by two During the tests, it was found that the buckling load increased about (8%,

external prestressing strands. 48%, 56%, 84%, 40% and 114% with increasing the eccentricity location

The results show that the maximum buckling load of strengthened tested from (0 to 165) mm, respectively compared with reference steel beam. On

beams increases with the increasing of strand eccentricity and the the other hand, it can be observed that the increasing percentage in

maximum enhancement in buckling load of strengthened tested beams buckling load to ultimate load ratio (𝑃𝑐/𝑃𝑢) increase about (7.439%,

reaches to 114% compared with the reference beam. Also, the maximum 14.228%, 12.83%, 13.763%, 12.587% and 14.465%) with increasing the

percentage increases in buckling to ultimate load ratio ( Pc/Pu ) of eccentricity location from (0 to 165) mm, respectively compared with

strengthened tested beams reaches to 14.465% compared with reference reference steel beam. So, it can be seen that the buckling load and the

beam. increasing percentage in buckling load to ultimate load ratio (𝑃𝑐 /𝑃𝑢)

increase approximately with constant percentage when the eccentricity

location was increased. The buckling load and the percentage increased in

buckling load to ultimate load (Pc /Pu) of tested beams are shown in Table

Introduction .2 and Fig. 2.

Great durability, formability, yielding, tensile strength and thermal Buckling Strain of the Tested Beams:

conductivity, are the generally important properties of steel, so steel is During the tests it was found that the buckling strain positions often don’t

considerably the most important material for constriction with strength of change from top region of the tested beams and the existence of

approximately ten times that of concrete that due to a its high ductility, externally prestressing strand leads to improve the top region and

uniform and homogeneous properties, high strength to weight ratio, high improve the web resistance under applied load, as shown in Table. 3.

elastic modules, high amount of energy absorption in seismic action, can On the other hand, it was found that the increasing percentage in strain in

be easily recycled, quicker to fabricate and erect. Because of the low self- top flange at buckling stage with increasing the eccentricity location from

weigh, the dimension of steel frame can be reducing [1]. Creating (0 to 165 mm) compared with reference steel beam, while the increasing

permanent stress in the steel member in order to develop resistance percentage in strain in bottom flange at buckling stage decreases with

against applied service load is called as prestressing. Prestressing is a increasing the eccentricity location compared with reference steel beam.

method to introduce an internal stress in steel sections to counter balance

stressed caused by external loads so as to improve the performance and

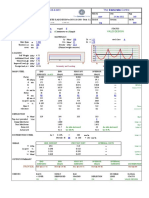

durability of steel members [2, 3]. Table 2. Experimental strain and load results of steel beams at buckling stage.

The main purpose of this work is to inspect and get more info about the Exp. Max. Experimental strain.at mid span at buckling

buckling behaviour of steel beams strengthened by external prestressing Maximum

Buckling stages (εc. x 10-6)

No. Sample applied load

strands at different eccentricity location and comparing with reference load, (Pc)

(Pu),(kN) Bottom Top Bottom of

(kN) Top flange

steel beam. flange of web web

Ref. O 287.5 250 -3921 6431 -1500 5166

1 OM000 289 270 -1440 1885 -2566 1707

2 OM101 372.5 370 -16000 2559 -11932 1809

Experimental Program 3 OM112 397.5 390 -15100 5350 -6303 1435

4 OM123 357.5 350 -13060 3610 -4554 2603

The variable parameters involved in this research are concentrated mainly

5 OM234 537.5 535 -12459 5855 -11893 2880

on the presence of external prestressing strands and layout of

6 OM105 465 460 -4052 3002 -16227 1838

prestressing level (i.e. the eccentricity of the external prestressing strand

(e)). Seven simply supported steel beams were fabricated and tested to

explain the influence of external prestressing strands on the buckling

stage behaviour of steel beams. Steel beams have the same gross

sectional area, ends steel plate (25 x 125 x 250 mm), clear span length

(2850 mm) and the strengthened sample was implemented by two

external prestressing strands of (12.7 mm) diameter. Hot rolled steel

section, H248 x 124 with 25.7 kg/m of SS400 is specified in JISG 3101

requirement is used in this study [7, 8 and 9].

All the details of tested specimens are shown in Table .1 and Fig. 1.

(A) Buckling load of tested beams (B) Percentages of increasing Buckling load of tested beams

Figure.2 Buckling and Percentages of increasing in buckling load of tested beams compared with reference steel

Table 1. Tested Beams Details beam

No. Sample Strand Profile Beams Eccentricity of prestressing Table 3. Experimental results of strain in tested beams

Shape strands (𝑒), (mm) Exp. Strain and percentage increase in strain at mid span locations at buckling stages

First buckling segment part

𝑒 1* 𝑒2** 𝑒3***

Bottom of web (εc) ×10 -6

Percentage of increase in

Percentage of increase in

Percentage of increase in

Percentage of increase in

Bottom flange (εc) × 10-6

Ref. O ---- ---- ---- ----

Top of web (εc) ×10-6

Top flange (εc) × 10-6

location

Sample

bottom of web,%

bottom flange, %

top flange, %

1 OM000 Straight 0 0 0

top web,%

2 OM101 Draped 96 0 19.5

O -3921 0 6431 0 -1500 0 5166 -3921 Top of web

3 OM112 Draped 96 20 35.5 OM000 -1440 -63.274 1885 -70.688 -2566 71.066 1707 -1440 Top of flange

OM101 -16000 308.059 2559 -60.208 -11932 695.466 1809 -16000 Top of web

4 OM123 Straight 96 96 96 OM112 -15100 285.105 5350 -16.809 -6303 320.200 1435 -15100 Top of web

OM123 -13060 233.078 3610 -43.865 -4554 203.600 2603 -13060 Top of web

5 OM234 Straight 165 165 165 OM234 -12459 217.750 5855 -8.9566 -11893 692.866 2880 -12459 Top of web

OM105 -4052 3.340 3002 -53.319 -16227 981.800 1838 -4052 Top of web

6 OM105 Sine-wave 96 0 -39

Where: - e1* = Eccentricity of external prestressing strands at middle span, e2** = Eccentricity of external prestressing

strands at end span, e3*** = Eccentricity of external prestressing strands at shear zone. Conclusions

The following conclusions are drawn from the experimental results:

1. The maximum buckling load of strengthened tested beams increases

with the increasing of strand eccentricity at constant applied jacking

stress. The enhancement in maximum buckling load of strengthened

tested beams reaches to 114% in the OM234 sample compared with

the reference beam.

2. The percentage increase in buckling to ultimate load ratio (𝑃𝑐/𝑃𝑢) for

the strengthened tested beams increases with the increasing of strand

eccentricity. The maximum percentage increases in buckling to

ultimate load ratio (𝑃𝑐/𝑃𝑢) of strengthened tested beams reaches to

14.5% in the OM234 sample as compare with the reference beam.

3. The percentage increase in strain in top flange in the buckling stage for

strengthened tested beams increases with the increasing of strand

Figure.1 Prestressing strands profiles of tested beams eccentricity at constant applied jacking stress. While the strain in

bottom flange decreased.

References

1.Abi Aghayere and Jason Vigil, (2009), “Structural Steel Design”, Pearson International Edition.

Contact 2.Yusuf Ozcatalbas; Alpay Ozer,(2007), “Investigation of Fabrication and Mechanical Properties of Internally Prestressed Steel I beam", Materials and Design

28, PP.1988-1993, Available online at www.elsevier.com/locate/matdes

3. Manssekar R.,Siva Kumar P .and Lakshmikandhan K.N, 2014, “Experimental Investigation on Strengthening of RC Beams by External prestressed.” Asian

Journal of Civil Engineering, Vol.5, No. 3,pp. 350-362

<Kamal Sh. Mahmoud> 4. Mohamed H.,(2015),"Strengthening of concrete Beams by External Strengthening of concrete Beams by external prestressing", International Journal of

Scientific and Engineering Research, Vol.6, Issue 4, April.PP.76-87.

<Mustansiriayh University, Baghdad, Iraq> 5.Dabaon A.,Sakr A.,and Omnia K. "Ultimate Behaviour of Externally Prestressed Composite Beams with Partial Shear Connection", M.Sc. Thesis, Department

of Structural Engineering, Ain Shams University, Egypt, May 2005.

Email: kamalshahada5@gmail.com 6. Wu and Bowman, Examination of post-tensioned Steel Bridges in India, (2000),".Final Report ,School of Civil Engineering, Purdue University ,West

Website: )http://www.uomustansiriyah.edu.iq( Lafayette, July.

7. JIS G3101 SS400 Structural Carbon Steel Plate Specification, Available online at , http://www.steels-supplier.com/steel-standard/jis-g310-ss400-

Phone:+9647703497933 structural-carbon-steel-plate-specification.html.

8. International enterprise centre Zhengzhou city in China, Available online at, http://www.shipbuilding-steel.com.

9.Amendment to Thai Industrial Standard for Hot rolled structural steel section: TIS 1227-2539(1996), (English): Hot rolled structural steel section, Available

online at, https://archive.org/details/th.cs.1227.e.2539.

10. Daly A.F, and Woodward R.J. (2000),"Strengthening of Concrete Structures using External Post-Tensioning", Annex L, Rehab on, Strategy for Maintenance

and Rehabilitation .IPS-0063.Available online at, http://www. civil.ist.utl.pt/~ cristina/RREst/Annex_L.pdf

11.ASTM Designation A370, (2014), “Standard Testing Method and Definitions for Mechanical Testing of Steel Products”, ASTM International, Pennsylvania,

United States.

12.ASTM designation A416/A416M-12a, (2012), “Standard Specification for Steel Strand, uncoated Seven- Wire for Prestressed Concrete”, ASTM

International, Pennsylvania, United States.

View publication stats

You might also like

- Retrofitting Concrete Beams with UHTCDocument28 pagesRetrofitting Concrete Beams with UHTCபுருஷோத்தமன் சரவணன்100% (2)

- An Accurate Method For The Calculation of UltimateDocument12 pagesAn Accurate Method For The Calculation of UltimateManoj KumarNo ratings yet

- Predicting The de Ection of RC Beams Strengthened With FRP LaminatesDocument9 pagesPredicting The de Ection of RC Beams Strengthened With FRP LaminatesRikson TandelilinNo ratings yet

- Structural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionDocument20 pagesStructural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionTJPRC PublicationsNo ratings yet

- Thin-Walled Structures: Burak Evirgen, Ahmet Tuncan, Kivanc TaskinDocument11 pagesThin-Walled Structures: Burak Evirgen, Ahmet Tuncan, Kivanc Taskinjust meNo ratings yet

- Torsional behavior of ultra-high performance concrete squared beamsDocument12 pagesTorsional behavior of ultra-high performance concrete squared beamsMitobaba Josue GiresNo ratings yet

- Shear_Strength_of_Steel_Fiber-Reinforced_Concrete_Document10 pagesShear_Strength_of_Steel_Fiber-Reinforced_Concrete_Siva GuruNo ratings yet

- Research Paper IRJET CorrectionDocument8 pagesResearch Paper IRJET CorrectiondipakNo ratings yet

- Deformation of Progressively Cracking Reinforced Concrete BeamsDocument11 pagesDeformation of Progressively Cracking Reinforced Concrete BeamsCE19D506 Shaik Farooq AhamedNo ratings yet

- 1-s2.0-S0143974X21005691-main (1)Document21 pages1-s2.0-S0143974X21005691-main (1)pp cerejoNo ratings yet

- Applied SciencesDocument38 pagesApplied SciencesZarr AkshNo ratings yet

- 1-s2.0-S0143974X22002036-mainDocument9 pages1-s2.0-S0143974X22002036-mainpp cerejoNo ratings yet

- Zhou 2011Document9 pagesZhou 2011wewNo ratings yet

- ACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedDocument9 pagesACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedMuchtar SufaatNo ratings yet

- Comparison of solid vs hollow reinforced concrete beams under combined loadsDocument19 pagesComparison of solid vs hollow reinforced concrete beams under combined loadsEmanuel MarquesNo ratings yet

- Materials and Design: H. Akbarzadeh, A.A. MaghsoudiDocument18 pagesMaterials and Design: H. Akbarzadeh, A.A. MaghsoudiQudrati Al WasiewNo ratings yet

- Reinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake Loading PDFDocument20 pagesReinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake Loading PDFPrabu RengarajanNo ratings yet

- Reinforced Concrete Curved Beams Literature ReviewDocument11 pagesReinforced Concrete Curved Beams Literature ReviewDam HoangNo ratings yet

- An Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFDocument21 pagesAn Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFM. Murat ErginNo ratings yet

- Experimental Investigation On Shear Capacity of STDocument18 pagesExperimental Investigation On Shear Capacity of STadnan-651358No ratings yet

- Higherconcrete Review UHPCDocument6 pagesHigherconcrete Review UHPCمحمد الطاهر لقويNo ratings yet

- Computers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliDocument17 pagesComputers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliSayna KellenyNo ratings yet

- Test 65647213564651321315Document10 pagesTest 65647213564651321315uvezfGRNo ratings yet

- Behaviour of Reinforced Concrete Frame Structures With Construction Joints Under Lateral Loads (1998) (10.1680 - Macr.1998.50.2.133) - LDocument13 pagesBehaviour of Reinforced Concrete Frame Structures With Construction Joints Under Lateral Loads (1998) (10.1680 - Macr.1998.50.2.133) - Losvaldo contrerasNo ratings yet

- 3experimental Flexural Performance of Concrete Beams Reinforced With AnDocument24 pages3experimental Flexural Performance of Concrete Beams Reinforced With AnMohamed MowafyNo ratings yet

- Finite Element Analysis of Corrugated Web Beams Under BendingDocument16 pagesFinite Element Analysis of Corrugated Web Beams Under Bendingmaple_leaves2004No ratings yet

- Analysis of Ductility in Partially Prestressed Concrete Flexural MembersDocument24 pagesAnalysis of Ductility in Partially Prestressed Concrete Flexural Membersdavidalejo82No ratings yet

- Shear Ductility of Reinforced Lightweight ConcreteDocument13 pagesShear Ductility of Reinforced Lightweight ConcreteBahaa HussainNo ratings yet

- The Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsDocument7 pagesThe Effect of Medium Strain Rates On The Mechanical Properties of High Performance SteelsPierre GarciaNo ratings yet

- Punching Shear Strength of Reinforced Concrete Column Footings Under Eccentric Compression: Experiment and AnalysisDocument2 pagesPunching Shear Strength of Reinforced Concrete Column Footings Under Eccentric Compression: Experiment and AnalysisHà Nguyễn Thành TháiNo ratings yet

- 16.hou 2019 IOP Conf. Ser. Earth Environ. Sci. 304 042057Document5 pages16.hou 2019 IOP Conf. Ser. Earth Environ. Sci. 304 042057la barberNo ratings yet

- Improving Seismic Performance of FramedDocument13 pagesImproving Seismic Performance of FramedLucas HoodNo ratings yet

- Shear Strength of High-Strength Concrete Beams Modeling and DesignDocument7 pagesShear Strength of High-Strength Concrete Beams Modeling and Designchristian rodriguezNo ratings yet

- IJCE v5n1p30 enDocument18 pagesIJCE v5n1p30 enGENIE CIVIL BLIDA BEREPNo ratings yet

- BazantDocument11 pagesBazantHernan David Florez OlivaresNo ratings yet

- Fatigue Testing and Finite Element Modeling of Arm-to-Pole Connections in Steel Transmission Pole StructuresDocument16 pagesFatigue Testing and Finite Element Modeling of Arm-to-Pole Connections in Steel Transmission Pole StructuresCenascenascenascenasNo ratings yet

- Extructura FinalDocument10 pagesExtructura FinalSergio RodriguezNo ratings yet

- PC Research PaperDocument5 pagesPC Research PaperghNo ratings yet

- Effect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyDocument16 pagesEffect of Reinforcement On The Failure Load of RC Beams: Osama Salem, Arafa El-HellotyHesham EdressNo ratings yet

- Characteristics of High-Speed Cyclic Test of Beam-Column JointsDocument9 pagesCharacteristics of High-Speed Cyclic Test of Beam-Column JointsMarimuthu KaliyamoorthyNo ratings yet

- Influence of Steel Fiber On Compressive Properties of Ultra-High Performance Fiber-Reinforced ConcreteDocument12 pagesInfluence of Steel Fiber On Compressive Properties of Ultra-High Performance Fiber-Reinforced ConcreteGemiezNo ratings yet

- Shear Capacity of Steel Fibre Reinforced Concrete Coupling Beams UsingDocument13 pagesShear Capacity of Steel Fibre Reinforced Concrete Coupling Beams UsingCuriosoNo ratings yet

- Bending Strength and Design Methods of The 6082 T6 Aluminum Allo - 2020 - StructDocument18 pagesBending Strength and Design Methods of The 6082 T6 Aluminum Allo - 2020 - StructSuhas RamachandraNo ratings yet

- CBM 2016 1Document14 pagesCBM 2016 1SHEIKH MUHAMMAD FAHADNo ratings yet

- (DUCTILITY OKKKKKKK) Theoretical Study On Effect of Confinement On Flexural Ductility of Normal and High-Strength Concrete BeamsDocument12 pages(DUCTILITY OKKKKKKK) Theoretical Study On Effect of Confinement On Flexural Ductility of Normal and High-Strength Concrete Beamsjuan carlos molano toroNo ratings yet

- Pstruct 2019 111459Document11 pagesPstruct 2019 111459Mn HmoodNo ratings yet

- Randl 2018Document8 pagesRandl 2018isabela erenoNo ratings yet

- Test and Numerical Model of Curved Steel-Concrete CompositeDocument29 pagesTest and Numerical Model of Curved Steel-Concrete CompositeTanjil MominNo ratings yet

- Behaviour of Non-Seismic Detailed RC BC ConnectionDocument17 pagesBehaviour of Non-Seismic Detailed RC BC ConnectionmekidesNo ratings yet

- Behavior of Large Deep Beams Subjected To Monotonic and Reversed Cyclic ShearDocument9 pagesBehavior of Large Deep Beams Subjected To Monotonic and Reversed Cyclic ShearMunna SagiNo ratings yet

- A Fiber Beam Element With Axial Bending and ShearDocument9 pagesA Fiber Beam Element With Axial Bending and ShearVictoriawan MuhammadNo ratings yet

- Applsci 12 11289Document23 pagesApplsci 12 11289Neethu NirmalNo ratings yet

- Combined Effect of Imperfections On Ultimate Strength of Cracked PlatesDocument11 pagesCombined Effect of Imperfections On Ultimate Strength of Cracked PlatesKariim DiíbNo ratings yet

- Materials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuDocument15 pagesMaterials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuAbdulkhaliq AbdulyimahNo ratings yet

- Experimental Model For Predicting The Semi-Rigid Connections' Behaviour With Angles and StiffenersDocument12 pagesExperimental Model For Predicting The Semi-Rigid Connections' Behaviour With Angles and StiffenersMerve MerveNo ratings yet

- ArcDocument17 pagesArcFatima AhmedNo ratings yet

- Damage Assessment of Square RC Bridge Columns Subjected To Torsion Combined With Axial Compression, Flexure, and ShearDocument10 pagesDamage Assessment of Square RC Bridge Columns Subjected To Torsion Combined With Axial Compression, Flexure, and Shearishaq AllalNo ratings yet

- Nuclear Materials and Energy: K. Fukumoto, T Onitsuka, T Itoh, H Sakasegawa, H TanigawaDocument5 pagesNuclear Materials and Energy: K. Fukumoto, T Onitsuka, T Itoh, H Sakasegawa, H TanigawaAhmad Raza TararNo ratings yet

- Nipetal 2013-Ultimatebehaviourofsteelbracesundercyclicloading PDFDocument48 pagesNipetal 2013-Ultimatebehaviourofsteelbracesundercyclicloading PDFMohamed AhmedNo ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- ZK-290-Jacket NGDL - FinalDocument4 pagesZK-290-Jacket NGDL - Finalchristi SNo ratings yet

- ZK-290-Deck NGDL - FinalDocument24 pagesZK-290-Deck NGDL - Finalchristi SNo ratings yet

- ZK-290 CORROSION ALLOWNACE - FinalDocument2 pagesZK-290 CORROSION ALLOWNACE - Finalchristi SNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument30 pagesSpreadsheets To BS 8110: The Concrete Centrechristi SNo ratings yet

- Load Combinations.Document2 pagesLoad Combinations.christi SNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)christi SNo ratings yet

- Input: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)Document11 pagesInput: Spreadsheets To BS 8110 Advisory Group Edge Column B1 (Akin To D&D)christi SNo ratings yet

- Sample MDRDocument4 pagesSample MDRchristi SNo ratings yet

- Spreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271Document24 pagesSpreadsheets To BS 8110: VK 14-Jan-2022 1 - 3271christi SNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument14 pagesSpreadsheets To BS 8110: The Concrete Centrechristi SNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- RCC11 Element DesignDocument6 pagesRCC11 Element Designchristi SNo ratings yet

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)christi SNo ratings yet

- RCC52 Column Chart GenerationDocument8 pagesRCC52 Column Chart Generationchristi SNo ratings yet

- Spans: Spreadsheets To BS 8110 & EC2Document16 pagesSpans: Spreadsheets To BS 8110 & EC2AhmedAlghzawiNo ratings yet

- RCCe41 Continuous Beams (A & D)Document20 pagesRCCe41 Continuous Beams (A & D)christi SNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)christi SNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching Shearchristi SNo ratings yet

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Document8 pagesContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- Engineering Mathematics IDocument312 pagesEngineering Mathematics Ichristi SNo ratings yet

- Estimating & Costing-1 PDFDocument229 pagesEstimating & Costing-1 PDFGokul Kannan100% (1)

- RCC31 One-Way Slabs (A&D)Document17 pagesRCC31 One-Way Slabs (A&D)Mehdi YazdchiNo ratings yet

- D ConcreteStruc N24Document8 pagesD ConcreteStruc N24Hareesh KilaruNo ratings yet

- Greenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464Document4 pagesGreenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464christi SNo ratings yet

- Civil Engineering Drawing IIDocument68 pagesCivil Engineering Drawing IIchristi S100% (1)

- Civil Engineering Drawing I PDFDocument122 pagesCivil Engineering Drawing I PDFsankar san0% (2)

- Civil Engineering Drawing IIDocument68 pagesCivil Engineering Drawing IIchristi S100% (1)

- Civil Engineering Drawing I PDFDocument122 pagesCivil Engineering Drawing I PDFsankar san0% (2)

- Engineering Mathematics IIDocument192 pagesEngineering Mathematics IIchristi SNo ratings yet

- SI-3221 Rekayasa Fondasi-Daya Dukung Fondasi Dangkal Part 1 Rev 00Document26 pagesSI-3221 Rekayasa Fondasi-Daya Dukung Fondasi Dangkal Part 1 Rev 00Margaretha StgNo ratings yet

- Through Bolt Connection PDFDocument197 pagesThrough Bolt Connection PDFAkhil VNNo ratings yet

- Mechanical Sample Book PDF For Gate Exam PDFDocument28 pagesMechanical Sample Book PDF For Gate Exam PDFEashwaran SadasivamNo ratings yet

- KURSUS - PENYIASATAN - KEJURUTERAAN - FORENSIK - Case - 1Document23 pagesKURSUS - PENYIASATAN - KEJURUTERAAN - FORENSIK - Case - 1Sathiswaran SelvamNo ratings yet

- ARC Reinforcement Handbook - 6th EdDocument78 pagesARC Reinforcement Handbook - 6th EdChris EvansNo ratings yet

- Tensile Test Properties from Stress-Strain CurvesDocument9 pagesTensile Test Properties from Stress-Strain CurveszaimNo ratings yet

- Concrete T Beam DesignDocument8 pagesConcrete T Beam DesignRajesh Raman100% (1)

- Seismic Design Criteria For Slab-Column ConnectionsDocument12 pagesSeismic Design Criteria For Slab-Column ConnectionsIvan Jansen S.No ratings yet

- Kirchhoff Plate Field EquationsDocument16 pagesKirchhoff Plate Field Equationsaachi2004No ratings yet

- Earthquake Resistant Design of Structures Course ContentDocument1 pageEarthquake Resistant Design of Structures Course ContentDanielRoblesTorresNo ratings yet

- Bs Na en 1993 1 1 2005Document16 pagesBs Na en 1993 1 1 2005yogs_184100% (1)

- Moment Curvature CurveDocument25 pagesMoment Curvature CurveWahabAshrafNo ratings yet

- Evaluation of Liquefaction Risk of Reinforced Soil by Stone ColumnsDocument10 pagesEvaluation of Liquefaction Risk of Reinforced Soil by Stone ColumnsMarco Dos Santos NevesNo ratings yet

- Ce2306-Design of RC ElementsDocument8 pagesCe2306-Design of RC ElementsAnu PartheeNo ratings yet

- Biot Theory (Almost) For Dummies-Patzek - Oral PDFDocument32 pagesBiot Theory (Almost) For Dummies-Patzek - Oral PDFNima DaneshNo ratings yet

- Tensile Test Lab Report MAE 361Document3 pagesTensile Test Lab Report MAE 361mrm3zaNo ratings yet

- Numerical Modeling of Composite Beam To Reinforced Concrete Wall Joints - Part I - Calibration of Joint Components PDFDocument15 pagesNumerical Modeling of Composite Beam To Reinforced Concrete Wall Joints - Part I - Calibration of Joint Components PDFRosNo ratings yet

- RC DetailingDocument82 pagesRC DetailingkishoreNo ratings yet

- Seismic Analysis of Horseshoe Tunnels Under Dynamic Loads Due To EarthquakesDocument8 pagesSeismic Analysis of Horseshoe Tunnels Under Dynamic Loads Due To EarthquakesPaloma CortizoNo ratings yet

- Program ReSlope (3.0) Notes: Reinforced Slope DesignDocument28 pagesProgram ReSlope (3.0) Notes: Reinforced Slope Designsimone stanoNo ratings yet

- Design of Steel Tension MembersDocument15 pagesDesign of Steel Tension MembersSelamawitTafesse100% (1)

- EM & SOMDocument8 pagesEM & SOMVikram RaoNo ratings yet

- CE 470-Lect-7 (Design of Long Columns in Nonsway Frames) (Read-Only)Document40 pagesCE 470-Lect-7 (Design of Long Columns in Nonsway Frames) (Read-Only)Jamal RkhNo ratings yet

- Tutorial 38 Coupled Drawdown AnalysisDocument23 pagesTutorial 38 Coupled Drawdown AnalysisImad SoutajiNo ratings yet

- Changes in Is 1893 and Is 13920Document61 pagesChanges in Is 1893 and Is 13920Kamarajan100% (1)

- Influence of Soil Structure Interaction On Seismic Demands - 2019 - EngineeringDocument15 pagesInfluence of Soil Structure Interaction On Seismic Demands - 2019 - Engineeringabubaker ahmedNo ratings yet

- 01 Rainflow Cycle Counting A Historical Perspective4Document8 pages01 Rainflow Cycle Counting A Historical Perspective4Victor PuglieseNo ratings yet

- Pipeline Defect Assessment ManualDocument18 pagesPipeline Defect Assessment Manualalexrodriguezabc100% (4)

- Design Procedure for LTHA and NLTHA using Modified Ground MotionsDocument4 pagesDesign Procedure for LTHA and NLTHA using Modified Ground MotionsAnita KartikaNo ratings yet

- D.Kober Lectures 3+4 Silos PDFDocument69 pagesD.Kober Lectures 3+4 Silos PDFAmeen MazouniNo ratings yet