Professional Documents

Culture Documents

Testing Construction Materials Ensures Quality

Uploaded by

Gian Aizel JavierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing Construction Materials Ensures Quality

Uploaded by

Gian Aizel JavierCopyright:

Available Formats

CONSTRUCTION MATERIALS AND TESTING c.

Steel and metal reinforcement – single or

bundled reinforcing bars, ties, stirrups, bend bars,

TOPIC 1 dowel bars, GI wire, etc

d. Timber, lumber, and wood materials – fine or

Construction-

straight grained, crooked or cross grained, plank, board,

Is the process of constructing a building infrastructure. timber, surface or dressed lumber, etc

Construction starts with planning, design and financing; e. Forms and scaffolding – galvanized iron sheet,

and continues until the project is built and ready for purlins, etc

use. f. Architectural finishes- tiles, hardware, painting

works, and other auxiliary works

There are three sectors of construction Construction materials

1. Buildings

Familiarization of the basic construction materials is one

- Building constructions is usually further the basic knowledges a civil engineer needs to know.

subdivided into residential and non- residential. When

Comprehending with characteristics and properties of

we say non- residential, those are

construction materials through systematic laboratory

commercial and institutional structures.

tests conforming to standards helps to analyze

2. Infrastructure underlying principles in the design of the structure.

- Is often called heavy civil or heavy engineering.

it includes large public works such as dams,

bridges, high ways, railways, water ,waste water Testing of materials

,and utility distribution.

3. Industrial Before any construction materials are incorporated into

- It includes refineries, processed chemicals, any type of structures, standard specifications must be

power generation mills, and manufacturing plants. followed and in every specification, a test must be

There are ways to break industry into sectors or market. done. Testing of materials is done to ensure the highest

quality of work and extend the service life of any

Building construction projects typically include various structure by constructing according to the prescribed

common elements, such as design, financial, estimating plans and specifications.

and legal considerations. However, many projects of

varying sizes reached undesirable end such as structural Material testing is a measurement of the characteristics

collapse, cost overrun, and or litigation. For this reason, and behavior of such substances as metals, ceramics, or

those with experience in the field make detailed plans plastics under various conditions. The data thus

and maintain careful oversight the preparation of obtained can be used in specifying suitability of

materials and constructing materials during the project materials for various applications.

to ensure a positive outcome.

Without testing either in the field or laboratory, no one,

not even the experts can state definitely if the standard

of quality pf certain material is satisfied.

Construction materials

If quality control is done by slight or other means

Is any material which is used for construction purposes. without benefit of laboratory test, that is purely or

Many naturally occurring substances, such as clay, simply guessing.

rocks, sand and wood, event twigs and leaves, have

been used to constructed structures.

The engineering structures are composed of materials. Since material testing is well established technique to

These materials are known as engineering materials or determine the physical and mechanical of raw materials

building materials or materials of construction. It is and components……we have the standard national and

necessary for the civil engineer to become conversant international bodies. This is where standard

with the properties of such materials. specifications came from.

1. ASTM international – formerly known as

American Society for Testing and Materials, is an

Principal materials used in building structures are

international standards organization that develops and

a. Concrete- coarse and fine aggregates, cement, publishes voluntary consensus technical standards for a

water, etc wide range of materials, products, systems, and

b. Masonry- fine aggregates, cements, water, services. – including construction materials.

CHBs , etc

2. ISO -International Organization of Standardization – quality materials is essential

for the construction of safe and robust

buildings. ISO has more than 100 standards

related to raw materials used in construction,

such as concrete, cement, timber, and glass.

These include standards on terminology, testing

procedures and assessment of safety levels.

TOPIC 2

3. Bureau of Philippine Standards of the

Department of Trade and Industry (DTI- BPS) – They UNIVERSAL TESTING MACHINE PARTS AND FUNCTIONS

serve as the National Standard s Body (NSB) of the

UTM or UNIVERSAL TESTING MACHINCE

Philippines and is mandated to develop, promulgate,

and implement standards for all products in the - From the name itself, this machine is used to

Philippines, to promote standardization activities in the conduct numerous test on various materials from steel,

country, and to ensure the manufacture, production, concrete, and even wood.

and distribution of quality products for the protection - A UTM is an electric machine used in

of the consumer. Under the BPS is the Standards Engineering where the main mechanical

Development Division that develops Philippine National properties of a given specimen of a construction

Standards (PNS). material are being tested.

4. DPWH Blue Book- it contains all the standard - The usual process of UTM is pulling,

specifications of all item of work. This includes the right compressing, and vending or stretching materials until

terminology in every structure or description, the pay they break.

item number, unit of measurement per item, its

construction methodology, material requirement that

includes the required test and number of samples in a

given test.

We don’t need to test all the item one by one.

Sampling and testing

These tests performed by UTM is called as

Samples are taken to represent the total, to know the

1. Compressive Strength Test (ASTM C39)

distinct characteristics. There is no substitute for

2. Flexural Strength Test (ASTM C78)

sampling if the aim is to get an idea of quality. Sampling

is standardized so as to minimize the effect of human 3. Tensile Strength Test (ASTM C1557)

error.

Testing refers to the process of making test son samples Compressive Strength Test and Flexural Strength Test

submitted to determine the degree of compliance of are usually done to concrete specimen samples, and

delivered or constructed materials with the Tensile Strength Test is usually done for reinforcing

specifications. steel bars samples.

Thru this test we can determine the mechanical

CONSTRUCTION MATERIALS AND TESTING properties like tenson, compression, bending, and

shearing of non – metal and metal materials.

CONSTRUCTION MATERIALS ----LABORATORY TEST----

ANALYSIS OR RESULT The universal testing machine is used primarily by

laboratories that manufacture or mold various plastics.

To sum it up, it is important that future civil engineers

like you have the basic knowledge on the various These different test determine the quality of the

materials as well as how suitable it is for particular use.

construction materials, their properties and suitability

when used in the project also the laboratory test, The quality of the material as well as how

standard procedures and equipment to be used and suitable it is for particular use can de easily determined

finally be able to analyze the results of the laboratory by using UTM. In addition, knowledge in the Standard

tests which certifies the suitability of the tested Specification provided by the national and international

construction materials. bodies is a great importance.

UTM – there are two main parts ; HOST MACHINE, and

CONTROLLER MACHINCE.

The HOST MACHINE is cylinder-underneath, hydraulic

loading, and hydraulic clamping specimen, operates

easily and reads correctly. The host machine represents In order to avoid affecting the reading value of machine

where the exact section the test should be conducted. when the specimen is broken, the host machine (figure

B), control machine and computer (figure C) is

separately set-up, and then connected by transverse

link and highpressure hydraulic host.

PARTS AND USES OF UNIVERSAL TESTING MACHINE

The MACHINE CONTROLLER processes the test data,

storages, displays and drawing curves (graph and As laboratory technician/civil engineer, before

illustration) by the computer. The printer can print the operating the machine, you should know first what are

test report and draw the test curve. Perfect statements the use of those piece, what part are you holding at or

operation realizes the archiving capability. maybe when and where to be use this kind of piece.

To be able to familiarize to its function, let’s start with

the figure D. Figure D represents where the exact

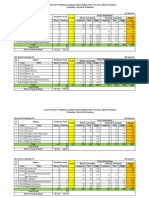

PARAMETERS OF THE UTM

section should test be conducted.

When we say parameters, generally it states a limit that

For the Tensile Strength Test, it should be conduct at

affects how something can be done

the tension section (upper part of the host machine)

using twoflat/round grip plate, upper and lower clamp.

While Compressive And Flexural Strength Test, should

Main Parameter be conducted at the compression and flexural section

(lower part of the host machine) using upper and lower

Before conducting experiment in laboratory, technician

plate, wheel load and bending platform.

and operator must view the tables presented below

first, to familiarize with the specification and limits of

the machine.

Like any other machine we cannot avoid errors.

When we say relative error, it is not the specific or

actual error but a ratio of the absolute error and

experimental value.

Absolute error is the difference between the actual

value and the calculated value.

HRC, Hardness Rockwell C. how hard the material is.

The

cylinder (see figure E) was fixed on bottom support with

bolts. The piston was fixed on work table, while work

table supports column. When piston is moving; work

table, column and upper crosshead also moves. Screw

cross over work table, down end was fixed on bottom,

up end was connected with up crosshead

There is a remote box / controller button at the lower

crosshead so it is easy to adjust the original test space

and can clamp the upper and lower clamp automatically

and column lift upper crosshead, so achieve tensile,

compression and bending test

On the left-upwards side of the control machine (see

Figure F), there are two power switches additional, the

bigger one with mushroom head (Stop Button) is the

emergency stop switch, and the other one (Start/Stop WORKING CONDITION

or On/Off Button) is the power switch.

Before using Universal Testing Machine, certain

The two hand wheels of “Load and Unload are used to condition that are listed below should be observe first

control loading and unloading hydraulic oil. “Pump” is to ensure the safe of operator.

oil pump switch to startup oil pump motor unit (inside

1. Room Temperature at least 10ºC to 35ºC.

controller cabinet). The button of “Jaw” is tensile grip

switch, the tensile grip and remote box will be able to 2. Relative humidity not more that 80%.

work after pressing Jaw Button.

3. No quaky or vibration condition

When clamping samples, take a note that the upper grip

should first clamp and then lower grip will be next, 4. No caustic medium around

otherwise the hydraulic clamps will not work well. 5. Level installation on steady base, level degree no

When doing tensile test, please turn off the tensile grip more than 0.2 /1000 .

button (Jaw) to keep the electrical valve could working

more long time. 6. Power Supply: 3-Phase 220V, 50/60Hz, 2.5KW.

Common Faults and Troubleshooting

In some instances, problems may occur anytime,

particularly when it comes in operating. In UTM, the

main reasons of common faults and troubleshooting are

as follows:

1. Reading value of testing force is unstable.

a. There is air in oil cylinder and oil pipe. Put the air out.

Start the oil pump, meanwhile, rise the cylinder by

software without any loading. The oil cycles for a

moment and the air will be out.

b. Check the joint of oil pipe is permeate the oil. If it

permeates, fasten it firmly or change washers.

2. Oil leakage in tubing joint. Methods for eliminating:

Make the piston go back to the bottom of the cylinder,

and then turn off the oil pump and power supply. If oil

leakage remains after tightening the connector, you

should change combination sealing ring or o-shape seal

ring.

You might also like

- Introduction Importance of Materials TestingDocument61 pagesIntroduction Importance of Materials TestingJIENNY LOU TENGCONo ratings yet

- Reviewer Material Quality Control and Hydrology Division (Promotional Exam)Document99 pagesReviewer Material Quality Control and Hydrology Division (Promotional Exam)Pat Hadji AliNo ratings yet

- Lesson 3 Equipment and Apparatus Used in Testing of MaterialsDocument43 pagesLesson 3 Equipment and Apparatus Used in Testing of MaterialsJii Yan100% (1)

- Ra 544Document9 pagesRa 544John Emerald GoloNo ratings yet

- Construction Material Testing Engineering Course SyllabusDocument2 pagesConstruction Material Testing Engineering Course SyllabusJii YanNo ratings yet

- CE312 Course Outline PDFDocument22 pagesCE312 Course Outline PDFReynald Jhon SeratoNo ratings yet

- OJT RQMT MonitoringDocument4 pagesOJT RQMT MonitoringJerico VeranoNo ratings yet

- Item 803Document8 pagesItem 803Ester MarianNo ratings yet

- Lecture 1 Ce Laws, Ethics and ContractsDocument51 pagesLecture 1 Ce Laws, Ethics and ContractsCjoy De Roxas100% (1)

- Classification of Engineering Services: Reporters: Bryan Rovic Borja John Ray AlentijoDocument9 pagesClassification of Engineering Services: Reporters: Bryan Rovic Borja John Ray AlentijoKamilleNo ratings yet

- Activity Report 2 (Soil Sampling) Fajardo Bsce3aDocument6 pagesActivity Report 2 (Soil Sampling) Fajardo Bsce3aGuilbert FajardoNo ratings yet

- Steel Design Problem Set and Quizzes Model PDFDocument1 pageSteel Design Problem Set and Quizzes Model PDFTaki Tachibana0% (2)

- Admixtures: Hollow Blocks ManufacturingDocument14 pagesAdmixtures: Hollow Blocks ManufacturingGerald De OcampoNo ratings yet

- Module 4 - QuantityDocument12 pagesModule 4 - QuantityKimberly Wealth Meonada MagnayeNo ratings yet

- National Structural Code of The Philippines: Sections 407.1 - 407.9 Details of ReinforcementDocument25 pagesNational Structural Code of The Philippines: Sections 407.1 - 407.9 Details of ReinforcementJeo CandilNo ratings yet

- Quality Control Program: Name of Project Location: Source of FundsDocument27 pagesQuality Control Program: Name of Project Location: Source of FundsFBVid UploadsNo ratings yet

- Ce195-2: Civil Engineering Law, Contracts, Specification and EthicsDocument13 pagesCe195-2: Civil Engineering Law, Contracts, Specification and EthicsoNo ratings yet

- Republic Act 544Document53 pagesRepublic Act 544Lance Moral GumtangNo ratings yet

- The Civil Engineering Licensure Examination SyllabiDocument9 pagesThe Civil Engineering Licensure Examination Syllabiapi-281795875No ratings yet

- Annex 9 - Minimum Materials Testing Requirement FMR PDFDocument3 pagesAnnex 9 - Minimum Materials Testing Requirement FMR PDFAlyyssa Julfa ArcenoNo ratings yet

- Student Member-Registration Form - PICEDocument1 pageStudent Member-Registration Form - PICEKaye MamisaoNo ratings yet

- 1.12. Building Projection Over Public StreetDocument6 pages1.12. Building Projection Over Public StreetGian SanchezNo ratings yet

- CIV 0322 CE Laws, Ethics and Contracts Case AnalysisDocument7 pagesCIV 0322 CE Laws, Ethics and Contracts Case AnalysisJoseph Berlin Juanzon0% (1)

- Structural Analysis of A Two-Storey BuildingDocument12 pagesStructural Analysis of A Two-Storey BuildingFrancis John Payno NuecaNo ratings yet

- Module 2 (Database Management in Construction)Document29 pagesModule 2 (Database Management in Construction)MARTHIE JASELLYN LOPENA100% (1)

- Application Form For Upgrading of Rank 2Document2 pagesApplication Form For Upgrading of Rank 2Yuri ValenciaNo ratings yet

- 3.0 General Properties of MaterialsDocument47 pages3.0 General Properties of MaterialsPearl Mae AngusNo ratings yet

- BD2 W FDocument51 pagesBD2 W FBernard de VeraNo ratings yet

- Ra 544Document45 pagesRa 544jay trinidadNo ratings yet

- PICE Manual of Professional Practice For Civil EngineersDocument128 pagesPICE Manual of Professional Practice For Civil EngineersRyan David MacayanNo ratings yet

- 4.) RCD - Midterm Library Work Quiz - Concept and Solutions (1-Way Slab)Document8 pages4.) RCD - Midterm Library Work Quiz - Concept and Solutions (1-Way Slab)Penuel G. Bantog100% (1)

- Flexural Behavior of Coconut Wood LaminatesDocument9 pagesFlexural Behavior of Coconut Wood Laminatesjun del rosarioNo ratings yet

- Civil Engineer Fee ScheduleDocument7 pagesCivil Engineer Fee Schedulefranz anthonyNo ratings yet

- Reinforced Concrete DesignDocument19 pagesReinforced Concrete DesignAlexander ChuaNo ratings yet

- ES 13 1920A Problem Set 2Document5 pagesES 13 1920A Problem Set 2Charmaine ColetaNo ratings yet

- HCC Civil Engineering Highway CourseDocument9 pagesHCC Civil Engineering Highway CourseMark Magcalas100% (1)

- Reference NSCP 2015 - Section 104Document2 pagesReference NSCP 2015 - Section 104Mark Kenneth P. OntejoNo ratings yet

- CE Laws - RA 544Document9 pagesCE Laws - RA 544Joan Manalo ÜNo ratings yet

- 3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamDocument146 pages3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamJm CampitanNo ratings yet

- Guide Civil Engineer Client RelationshipsDocument7 pagesGuide Civil Engineer Client Relationshipsmondares hectorNo ratings yet

- Analysis and Design of DRBDocument13 pagesAnalysis and Design of DRBACES JEEL CENDA�ANo ratings yet

- 01 Introduction To Quantity SurveyingDocument16 pages01 Introduction To Quantity SurveyingNelson Tapsirul0% (1)

- Jocab Builders: Company ProfileDocument23 pagesJocab Builders: Company ProfileTullao Mark CarloNo ratings yet

- Building System Design - Module - Technical DocumentationDocument47 pagesBuilding System Design - Module - Technical DocumentationJerico D. TadlanganNo ratings yet

- Lecture 6.0 Flexural AnalysisDocument29 pagesLecture 6.0 Flexural AnalysisCharlene CardinozaNo ratings yet

- Review of Specifications and Plan DetailsDocument35 pagesReview of Specifications and Plan DetailsBondoc, Miles Jerome Z.No ratings yet

- Ce Laws, Contracts, Specifications and ProfessionalDocument31 pagesCe Laws, Contracts, Specifications and ProfessionalKatharosJane100% (1)

- STAAD - Pro & STAAD Advanced Concrete: Design of Two-Storey Reinforced-Concrete ResidentialDocument47 pagesSTAAD - Pro & STAAD Advanced Concrete: Design of Two-Storey Reinforced-Concrete ResidentialKaye Kathlene BasubasNo ratings yet

- Guidelines For DPWH Project Engineer PDFDocument5 pagesGuidelines For DPWH Project Engineer PDFKhayrun HadullaNo ratings yet

- Section 2 - Classifications of Engineering ServicesDocument8 pagesSection 2 - Classifications of Engineering ServicesMark Louise Manuel50% (2)

- Appendix 1 BDocument28 pagesAppendix 1 BRikky ZuluetaNo ratings yet

- 2017.04.07 - Nicholaus Building - Structural Assessment LetterDocument2 pages2017.04.07 - Nicholaus Building - Structural Assessment LetterAnonymous Pg7RtdU8uHNo ratings yet

- Formworks (Lecture & Sample Problems) : Quantity Surveying Professor: Engr. Shane Francis B. GarciaDocument28 pagesFormworks (Lecture & Sample Problems) : Quantity Surveying Professor: Engr. Shane Francis B. GarciaJohn AbandoNo ratings yet

- Module 1 Quiz Solution PDFDocument4 pagesModule 1 Quiz Solution PDFBanana QNo ratings yet

- Lecture 1 INTRODUCTION TO EARTHQUAKE ENGINEERING PDFDocument9 pagesLecture 1 INTRODUCTION TO EARTHQUAKE ENGINEERING PDFowaisNo ratings yet

- Module 1Document13 pagesModule 1Myka Mhey BatallonesNo ratings yet

- Lecture Notes in Construction Materials and TestingDocument5 pagesLecture Notes in Construction Materials and TestingRowena Pandan100% (1)

- Module 1 Conmatls Chapter 1Document7 pagesModule 1 Conmatls Chapter 1Bryan YuNo ratings yet

- Module 1 Conmatls Chapter 1Document7 pagesModule 1 Conmatls Chapter 1Kriselle DulayNo ratings yet

- Module 1 Conmatls Chapter 1Document8 pagesModule 1 Conmatls Chapter 1CARL JAMESNo ratings yet

- Javier - Gian Aizel - Midterm - ExamDocument11 pagesJavier - Gian Aizel - Midterm - ExamGian Aizel JavierNo ratings yet

- BASIC EQUIPMENT FOR MATERIAL TESTINGDocument2 pagesBASIC EQUIPMENT FOR MATERIAL TESTINGGian Aizel JavierNo ratings yet

- Composition of CementDocument5 pagesComposition of CementGian Aizel JavierNo ratings yet

- Ecological Concepts: Topic 1Document23 pagesEcological Concepts: Topic 1Gian Aizel JavierNo ratings yet

- Surface Characterisation and Electrochemical Behaviour of Porous Titanium Dioxide Coated 316L Stainless Steel For Orthopaedic Applications PDFDocument6 pagesSurface Characterisation and Electrochemical Behaviour of Porous Titanium Dioxide Coated 316L Stainless Steel For Orthopaedic Applications PDFRahul MadanNo ratings yet

- Project Work: Square Root FunctionDocument13 pagesProject Work: Square Root Function17.Krisha JogiNo ratings yet

- File 1544349402Document16 pagesFile 1544349402Adeline Nkwekeu VasongiNo ratings yet

- Chapter One Workbook With SolutionsDocument8 pagesChapter One Workbook With SolutionsArthur Balieiro0% (1)

- ASME MFC - 02M Measurement of Uncertainty in Fluid Flow in Closed ConduitsDocument76 pagesASME MFC - 02M Measurement of Uncertainty in Fluid Flow in Closed ConduitsSallah Omran100% (1)

- JNTU-Anantapur ECE Electromagnetic Waves and Transmission Lines BookDocument259 pagesJNTU-Anantapur ECE Electromagnetic Waves and Transmission Lines BookNafeez ShaikNo ratings yet

- Activating Prior Knowledge To Raise Level of Scientific LiteracyDocument39 pagesActivating Prior Knowledge To Raise Level of Scientific LiteracySittie AinieNo ratings yet

- Soal PR TermodinamikaDocument10 pagesSoal PR TermodinamikaanjaniNo ratings yet

- ATM145P Time Schedule 2023 - GEDocument6 pagesATM145P Time Schedule 2023 - GExOx LiT NNo ratings yet

- Dynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsDocument2 pagesDynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsMohammad ZeeshanNo ratings yet

- ACFrOgDTpa5-Bgaji-yVnuN PlOKhu5M2acMTkuu8Twu JzWFg38xW7d0gqVFbzA2T6IPR4KJ6OfwRqa53pgC7z8ZaRDz6HytivuJD6CjRtcw l39L2reYNPST7ctsTwIk6cYdOQdm2fVK6Y6hNXDocument15 pagesACFrOgDTpa5-Bgaji-yVnuN PlOKhu5M2acMTkuu8Twu JzWFg38xW7d0gqVFbzA2T6IPR4KJ6OfwRqa53pgC7z8ZaRDz6HytivuJD6CjRtcw l39L2reYNPST7ctsTwIk6cYdOQdm2fVK6Y6hNXIVAN TIONG WEI JUN MoeNo ratings yet

- Unity University Department of Civil EngineeringDocument5 pagesUnity University Department of Civil EngineeringSudhanshu Shekhar SinglaNo ratings yet

- Math 1 All AnswersDocument259 pagesMath 1 All AnswersSheyanNo ratings yet

- Co2 - Co Laser: Physics 111B: Advanced Experimentation Laboratory University of California, BerkeleyDocument16 pagesCo2 - Co Laser: Physics 111B: Advanced Experimentation Laboratory University of California, Berkeleysara3elena3manolacheNo ratings yet

- 1.harmonic Function: 2.properties of Harmonic FunctionsDocument9 pages1.harmonic Function: 2.properties of Harmonic Functionsshailesh singhNo ratings yet

- BS - Reinforced Masonry Design GuideDocument76 pagesBS - Reinforced Masonry Design Guidescgengineer100% (7)

- 67-CS Electrical TechnologyDocument5 pages67-CS Electrical TechnologyMD. ATIKUZZAMANNo ratings yet

- Physics Principles With Applications 7th Edition Giancoli Test BankDocument17 pagesPhysics Principles With Applications 7th Edition Giancoli Test Bankhelgasophie7478k0100% (31)

- Motorcycle-Car Side Impact Simulation:, IncludingDocument10 pagesMotorcycle-Car Side Impact Simulation:, IncludingPromit ChoudhuryNo ratings yet

- Probability Generating Functions ExplainedDocument6 pagesProbability Generating Functions ExplainedAbhishek MangulkarNo ratings yet

- Hollow Core Slab DetailsDocument19 pagesHollow Core Slab DetailsMediks Ferrer100% (1)

- Classification: Decision Tree and Naïve Bayes ModelDocument7 pagesClassification: Decision Tree and Naïve Bayes ModelGabriel TomagosNo ratings yet

- Real Numbers Worksheet 2023 - 24Document4 pagesReal Numbers Worksheet 2023 - 24Zimra SihasNo ratings yet

- 2 - Chemistry - D&F Block Elements - 12 Classes PDFDocument42 pages2 - Chemistry - D&F Block Elements - 12 Classes PDFkrishna mohan G0% (1)

- RT Review - 6Document25 pagesRT Review - 6Hao TranNo ratings yet

- ASTM D1415 Standard Test Method For Rubber Property - International Hardness PDFDocument5 pagesASTM D1415 Standard Test Method For Rubber Property - International Hardness PDFManikanda Saravanan100% (1)

- Stopping Distance WsDocument3 pagesStopping Distance Wsmayana agarwalNo ratings yet

- Slab Design CalculationDocument4 pagesSlab Design CalculationjayNo ratings yet

- Method of Variation of Parameters for Cauchy-Euler EquationsDocument7 pagesMethod of Variation of Parameters for Cauchy-Euler EquationsSaman KadambNo ratings yet

- Motion in One Dimension ICSE OFFICIALDocument10 pagesMotion in One Dimension ICSE OFFICIALSuviAth MehtaNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet