Professional Documents

Culture Documents

Diagonal Members

Diagonal Members

Uploaded by

ARSE0 ratings0% found this document useful (0 votes)

7 views2 pagesOriginal Title

diagonal members

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesDiagonal Members

Diagonal Members

Uploaded by

ARSECopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

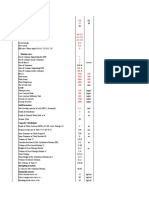

In all cases, (T) – Tensile force; (C) – Compressive force

Structural Design of Roof Trusses to Eurocode 3

All structural steel employed in the design has the following

properties;

fy (Yield strength) 275N/mm2

fu (ultimate tensile strength 430N/mm2

3.4 Design of diagonal Members (considering maximum effects)

LOAD CASE 1: DEAD LOAD + IMPOSED LOAD only

Fu = γGjGk + γQkQk

Ultimate design force (NEd) = 1.35Gk + 1.5Qk #REF! compressive

LOAD CASE 2: DEAD LOAD + IMPOSED LOAD + WIND LOAD

acting simultaneously

Partial factor for permanent actions (DK)

Partial factor for leading variable actions (Wk)

Therefore ultimate design force in the member = Fu = γGjGk + #REF! compressive

γWkWk = Gk + 1.5Wk.

LOAD CASE 3: DEAD LOAD + WIND LOAD acting

simultaneously

Partial factor for permanent actions (DK)

Partial factor for leading variable actions (Wk)

Therefore ultimate design force in the member = Fu = γGjGk + #REF! tensile

γWkWk = Gk + 1.5Wk.

With a maximum length of 2163mm, a little consideration will

show that UA 50 X 50 X 6 will satisfy all the necessary limit

state requirements.

CHECK FOR DEFLECTION

Employing UA 50 X 50 X 6 in all members of the roof truss;

the deflection due to unfactored imposed load calculated

using STAADPRO V8i software is 1.028mm

Allowable deflection for roofs (Table 4.1 ENV 1993-1-1:1992) =

L/250 = 72

1.028mm < 28.8mm. Therefore deflection is ok

4 Conclusion

The analysis and design for the section members have been

successfully carried as shown in the calculations above.

Whenever the wind load effect is greater than the live load

effect, one should always watch out for possible reversal of

stresses during load combinations. The design has shown that

the provision of UA 50 X 50 X 6 for the entire roof truss will

be adequate.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MaterialsDocument9 pagesMaterialsARSE100% (1)

- Moyale Payment #4 Kader Chected AbiyotDocument148 pagesMoyale Payment #4 Kader Chected AbiyotARSENo ratings yet

- Label X (M) Y (M) Elevation (M) Hydraulic Grade (M) Pressure (M H2O)Document6 pagesLabel X (M) Y (M) Elevation (M) Hydraulic Grade (M) Pressure (M H2O)ARSENo ratings yet

- Rectangular Tank Vol 1Document6 pagesRectangular Tank Vol 1ARSENo ratings yet

- Material Request FormDocument1 pageMaterial Request FormARSENo ratings yet

- Earth WorkDocument4 pagesEarth WorkARSENo ratings yet

- Attendance Sheet MyaleDocument2 pagesAttendance Sheet MyaleARSENo ratings yet

- Item No.-1000m3Document7 pagesItem No.-1000m3ARSENo ratings yet

- StatusDocument2 pagesStatusARSE100% (1)

- Elevated 150m3Document7 pagesElevated 150m3ARSENo ratings yet

- 1000m3 ConcreteDocument3 pages1000m3 ConcreteARSENo ratings yet

- Design ExamplesDocument42 pagesDesign ExamplesARSENo ratings yet

- Ug Sump DesignDocument12 pagesUg Sump DesignARSENo ratings yet

- Assignment 1 2022Document5 pagesAssignment 1 2022ARSENo ratings yet

- AugustDocument4 pagesAugustARSENo ratings yet

- Fitting PVCDocument1 pageFitting PVCARSENo ratings yet

- Nehase 1-15Document4 pagesNehase 1-15ARSENo ratings yet

- Material Density ChartDocument2 pagesMaterial Density ChartARSE100% (1)

- July 2023 Status Estimated MoyaleDocument2 pagesJuly 2023 Status Estimated MoyaleARSENo ratings yet

- Design of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsDocument2 pagesDesign of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsARSENo ratings yet

- Payment #2 Electro MechanicalDocument21 pagesPayment #2 Electro MechanicalARSENo ratings yet

- Dci Fitting: Item No Description Unit Quantity Pipes, Valves and Fittings Install Inlet PipeDocument1 pageDci Fitting: Item No Description Unit Quantity Pipes, Valves and Fittings Install Inlet PipeARSENo ratings yet

- Pay#4 EditedDocument114 pagesPay#4 EditedARSENo ratings yet

- Timesheet FormatDocument2 pagesTimesheet FormatARSENo ratings yet

- Other CSi SoftwDocument3 pagesOther CSi SoftwARSENo ratings yet

- Permanent (Dead) Loads: 1.0 Load AnalysisDocument2 pagesPermanent (Dead) Loads: 1.0 Load AnalysisARSENo ratings yet

- Daniel Tian Li: Input Data & Design SummaryDocument4 pagesDaniel Tian Li: Input Data & Design SummaryARSENo ratings yet

- Bottom Chord DesignDocument4 pagesBottom Chord DesignARSENo ratings yet

- Inner Members DesignDocument4 pagesInner Members DesignARSENo ratings yet

- Member Design: Partial Factors For Resistance Classification of Cross Sections Resistance of Cross SectionsDocument14 pagesMember Design: Partial Factors For Resistance Classification of Cross Sections Resistance of Cross SectionsARSENo ratings yet