Professional Documents

Culture Documents

GMCO FOR INDUSTRIAL SERVICES - Welding Procedure Specifications

Uploaded by

MohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GMCO FOR INDUSTRIAL SERVICES - Welding Procedure Specifications

Uploaded by

MohamedCopyright:

Available Formats

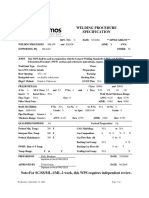

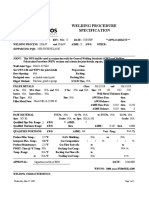

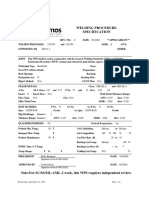

API PROPOSED WELDING PROCEDURE SPECIFICATION

WPS: API 0001-00 REV. NO.: 0 PROCESS: SMAW DATE: 4/7/2021

API QUALIFIED RANGES

Diameter: 2.375” o.d. thru 12.75” o.d. Filler Metal Group: API Group 1

Thickness: 0.187” thru 0.750” Joint Type: Butt/fillet/socket

Material: Yield greater than 42 kip to less than or equal to 65 kip

Positions: Fixed: X N/A

Rolled: Progression: Down

WELD JOINT: Type: Butt Class: Full Penetration

Joint Description: Open Butt Single V- welded from one side only.

Sketch Number: See pg. 2 for typical sketch and bead sequence.

FILLER MATERIALS: API Group No.: 1 AWS Class: E-6010

SFA Class: 5.1 F No.: 3 Sizes (s): 1/8 5/32

Number of Beads: See pg. 2 for typical number and of beads

BASE MATERIALS: Spec: API 5L / X52 to Spec: API 5L / X52

Thickness Welded: 0.187” - 0.750” to 0.187” - 0.750”

Pipe Diameter: 2.375” o.d. thru 12.75” o.d. pipe to Pipe Diameter 2.375” o.d. thru 12.75” o.d. pipe

ASME P No.: 1 Group: 1 to P No.: 1 Group: 1

POSITIONS: Fixed: X

Rolled: PWHT: Time @ º F Temp.: N/A

Progression: Down

Temperature Range º F: N/A

PREHEAT: Minimum Temp º F: 70 GAS: Shielding: N/A Backing: N/A

NOTE: See time between passes. Composition: N/A

INTERPASS TEMP.: N/A Flow Rate: CFH N/A

ELECTRICAL CHARACTERISTICS:

Current: DC Polarity: EP Ranges Amps: See pg. 2

Transfer Mode: N/A WFS/IPM: N/A Volts: See pg. 2

Electrode size and Type See pg. 2 Travel/IPM See pg. 2

MAX. TIME BETWEEN PASSES: 5 minutes between root pass and second pass.

GMCO FOR INDUSTRIAL SERVICES - Welding Procedure Specifications

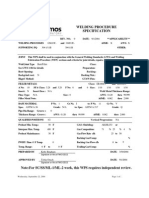

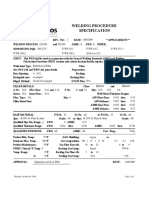

WPS No.: API 0001-00 Rev. No.: 0 Date: 4/7/2021

WELDING TECHNIQUE:

Line-Up Clamp: Optional, if used line-up clamp shall be left until 50% of root bead is complete.

Stringer or Weave Bead: (S) Single Pass Multi Pass

Y (W)Y N/A Y

Cleaning and/or Grinding: Power or hand wire brush, grinder or file

Maximum K/J Heat Input: N/A

JOINT SKETCH AND BEAD NUMBER AND SEQUENCE

37.5° Bevel

t thickness varies

0 – 3/32” land

1/16 – 3/32” gap

NOTE: Weld layers are representative only actual number of passes and layer sequence may vary

due to variation in joint design, thickness and fit-up.

TYPICAL WELDING PARAMETERS

Pass Filler/ Electrode Travel Speed

Number Size Amps Volts in/min. Other

1 E-6010 1/8 70 -100 22 - 26 9 – 12

2 E-6010 5/32 125 –132 22 - 26 9 – 13

3 E-6010 5/32 125 –132 22 - 26 9 – 13

4 E-6010 5/32 125 –132 22 - 26 9 – 13

5 E-6010 5/32 125 –132 22 - 26 9 – 13

6 E-6010 5/32 125 –132 22 - 26 9 – 13

7 E-6010 5/32 125 –132 22 - 26 9 – 13

8 E-6010 5/32 125 –132 22 - 26 9 – 13

PREPARED BY: MOHAMED ATEF BADAWY GMCO - PROJECT ENGINEER DATE: 4/7/2021

Signature

APPROVED BY: DATE: 4/7/2021

Signature

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- API-1000-11 Rev 0 PDFDocument3 pagesAPI-1000-11 Rev 0 PDF213eknoNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Revisi API - 1000 PDFDocument3 pagesRevisi API - 1000 PDF213eknoNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsMohamedNo ratings yet

- API-1000-12 Rev 0 PDFDocument3 pagesAPI-1000-12 Rev 0 PDFBob LeeNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsAnonymous 6LwW4qi6TiNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specificationsamini_mohiNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- 1000 XXXX HY80 HSLA100Document2 pages1000 XXXX HY80 HSLA100srb metallurgNo ratings yet

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Welding Procedure for Stainless Steel PipesDocument2 pagesWelding Procedure for Stainless Steel Pipes模具工程系鄭德彥No ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- CD Welding ProcDocument2 pagesCD Welding ProcAnonymous yCpjZF1rFNo ratings yet

- Wps 2-8Document1 pageWps 2-8Anonymous XYt4Y9qNo ratings yet

- PQR FC-19-23Document2 pagesPQR FC-19-23cycsi02No ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- PQR Babbit SCDocument34 pagesPQR Babbit SCagustinusNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- WPS for Welding HY80 SteelDocument2 pagesWPS for Welding HY80 Steelsrb metallurgNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Mobile audit checklist for pre-startup safety reviewDocument8 pagesMobile audit checklist for pre-startup safety revieweeeeNo ratings yet

- Document Numbering Procedure 20-10-14Document7 pagesDocument Numbering Procedure 20-10-14MohamedNo ratings yet

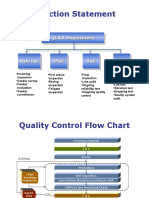

- Function Statement: QC&A DepartmentDocument3 pagesFunction Statement: QC&A DepartmentMohamed100% (1)

- 001 MEP - Method Floor&Wall PenetrationDocument7 pages001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Georgia DCA 2019 Construction Services Submission InstructionsDocument14 pagesGeorgia DCA 2019 Construction Services Submission InstructionsMohamedNo ratings yet

- Audit Non Conformance Report: Nonconformity ObservedDocument2 pagesAudit Non Conformance Report: Nonconformity ObservedMohamedNo ratings yet

- Non-Conformance ReportDocument1 pageNon-Conformance ReportTrần ChâuNo ratings yet

- 2018 DCA Construction Document Log - Instructions: GA DCA Office of Housing Finance and DevelopmentDocument8 pages2018 DCA Construction Document Log - Instructions: GA DCA Office of Housing Finance and DevelopmentMohamedNo ratings yet

- 100 - QC Inspection & Test Plans (Construction Phase)Document4 pages100 - QC Inspection & Test Plans (Construction Phase)MohamedNo ratings yet

- Shops & Studio Safety Inspection Checklist: University of California, San Diego Environment, Health & SafetyDocument6 pagesShops & Studio Safety Inspection Checklist: University of California, San Diego Environment, Health & SafetyMohamedNo ratings yet

- Audit Non Conformance Report: Nonconformity ObservedDocument2 pagesAudit Non Conformance Report: Nonconformity ObservedMohamedNo ratings yet

- Appendix Non Conformance Report SampleDocument1 pageAppendix Non Conformance Report SampleMohamedNo ratings yet

- Acceptance & Rejection ProcedureDocument4 pagesAcceptance & Rejection ProcedureMohamedNo ratings yet

- Material Inspection ChecklistDocument1 pageMaterial Inspection Checklistrahulsiva100% (6)

- NCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013Document2 pagesNCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013MohamedNo ratings yet

- Control of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureDocument9 pagesControl of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureMohamedNo ratings yet

- Sample Lab Inspection ChecklistDocument4 pagesSample Lab Inspection ChecklistMohamedNo ratings yet

- Project Budget RequestDocument3 pagesProject Budget RequestMohamedNo ratings yet

- DFARS Appendix F Guide Receiving ReportsDocument2 pagesDFARS Appendix F Guide Receiving ReportsEr Dhananjay PawaseNo ratings yet

- Audit Non Conformance Report: Nonconformity ObservedDocument2 pagesAudit Non Conformance Report: Nonconformity ObservedMohamedNo ratings yet

- NCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013Document2 pagesNCR, Corrections & Corrective Action Log: Doc. AKI-EHS-P03-F02 Rev. 0 Date: 15.12.2013MohamedNo ratings yet

- Non Conformance Report FormDocument3 pagesNon Conformance Report FormTrần ChâuNo ratings yet

- Sample Lab Inspection ChecklistDocument4 pagesSample Lab Inspection ChecklistMohamedNo ratings yet

- Material Inspection ChecklistDocument1 pageMaterial Inspection Checklistrahulsiva100% (6)

- Project budget overviewDocument1 pageProject budget overviewMohamedNo ratings yet

- Source of Project Budget: Subtotals Total (Scheduled)Document4 pagesSource of Project Budget: Subtotals Total (Scheduled)MohamedNo ratings yet

- Control of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureDocument9 pagesControl of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureMohamedNo ratings yet

- Financial Projections Template 14Document31 pagesFinancial Projections Template 14MohamedNo ratings yet

- Financial Projections Model v6.8.4Document28 pagesFinancial Projections Model v6.8.4Zaini AhNo ratings yet

- Financial Projection SampleDocument13 pagesFinancial Projection SamplePham TrangNo ratings yet

- Introduction To BGP: Border Gateway ProtocolDocument7 pagesIntroduction To BGP: Border Gateway ProtocolKevin KimNo ratings yet

- Building Services ReportDocument108 pagesBuilding Services ReportdiyanahussainNo ratings yet

- Accomplishment Report Filipino 2018 2019Document2 pagesAccomplishment Report Filipino 2018 2019Charlene Co BringasNo ratings yet

- Spare Parts Catalog: 12 AS 2331 TD Material Number: 1353.041.012 Current Date: 12.11.2013Document90 pagesSpare Parts Catalog: 12 AS 2331 TD Material Number: 1353.041.012 Current Date: 12.11.2013Андрей АндрусенкоNo ratings yet

- SPICE Device Model SUM110N06-04L: Vishay SiliconixDocument4 pagesSPICE Device Model SUM110N06-04L: Vishay SiliconixpvickyNo ratings yet

- Digital System Design FundamentalsDocument2 pagesDigital System Design FundamentalsRaut Amit DattatrayNo ratings yet

- PBE2Document420 pagesPBE2mujislavNo ratings yet

- Brittle Coating and Strain GaugeDocument29 pagesBrittle Coating and Strain GaugeAavash ShresthaNo ratings yet

- Clases Inventor 2017Document74 pagesClases Inventor 2017Soe Pyae AungNo ratings yet

- Blockchain Unconfirmed Transaction Hack ScriptDocument2 pagesBlockchain Unconfirmed Transaction Hack ScriptScott BradleyNo ratings yet

- Essay Tik TokDocument6 pagesEssay Tik TokEzayffa HizfarNo ratings yet

- Tadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Document4 pagesTadmor 2017 Modelling Simul. Mater. Sci. Eng. 25 071001Sandya KaranamNo ratings yet

- A5.17 - A5.17m - 97 (R2007) PV Saw ElectrodoDocument5 pagesA5.17 - A5.17m - 97 (R2007) PV Saw ElectrodomsalinasaguilarNo ratings yet

- Technical Specifications For Piling WorksDocument10 pagesTechnical Specifications For Piling WorksArzath SajeerNo ratings yet

- r5220104 Hydraulics and Hydraulic MachineryDocument1 pager5220104 Hydraulics and Hydraulic MachinerySaitheja SharmaNo ratings yet

- Cambridge English Logo Regulations for Preparation CentresDocument2 pagesCambridge English Logo Regulations for Preparation CentresdarshanNo ratings yet

- Ilovepdf MergedDocument33 pagesIlovepdf MergedNavneet KaurNo ratings yet

- Rochester Carb 4 BBL Adjustement 94hg5cDocument12 pagesRochester Carb 4 BBL Adjustement 94hg5cJean-Baptiste Bulliard100% (3)

- Revit Model Checklist: Model Name: PRF - P2 - FXX - PXX - CNS-CON Checked By: Ric ChanDocument79 pagesRevit Model Checklist: Model Name: PRF - P2 - FXX - PXX - CNS-CON Checked By: Ric ChanRajaNo ratings yet

- Instrumentation Cable & Communication Cable Material ListDocument2 pagesInstrumentation Cable & Communication Cable Material ListMathavan ABMNo ratings yet

- Advanced Technologies in Reciprocating Compressor PDFDocument211 pagesAdvanced Technologies in Reciprocating Compressor PDFziza20 Ziza100% (1)

- Minimizing Floor Vibration by Design and RetrofitDocument0 pagesMinimizing Floor Vibration by Design and RetrofitCrosman StefanNo ratings yet

- ISO 11452 4 2001 BCI SampleDocument8 pagesISO 11452 4 2001 BCI SampleSanthosh ManoharanNo ratings yet

- Design Tank-2Document4 pagesDesign Tank-2evrim77No ratings yet

- E-Business Assignment-I: Chintan Shah 1 2 6 Mba Tech. It Trim X, Mumbai Campus 1 7 AugustDocument11 pagesE-Business Assignment-I: Chintan Shah 1 2 6 Mba Tech. It Trim X, Mumbai Campus 1 7 AugustChintan ShahNo ratings yet

- Application of Artificial Neural Network (Ann) in Machining Analysis of Al-Sic Metal Matrix Composites by PCD 1600 InsertsDocument7 pagesApplication of Artificial Neural Network (Ann) in Machining Analysis of Al-Sic Metal Matrix Composites by PCD 1600 InsertsSpeeder JohnNo ratings yet

- Method Statement For Storage Tank Jack LiftingDocument18 pagesMethod Statement For Storage Tank Jack LiftingSyafiq100% (3)

- Chapter 10 - Traps - Interceptors and SeparatorsDocument4 pagesChapter 10 - Traps - Interceptors and SeparatorsNeal JohnsonNo ratings yet

- Paper - Update On Subsea LNG Pipeline TechnologyDocument11 pagesPaper - Update On Subsea LNG Pipeline TechnologyfralgiugiaNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Acting as if Tomorrow Matters: Accelerating the Transition to SustainabilityFrom EverandActing as if Tomorrow Matters: Accelerating the Transition to SustainabilityNo ratings yet