Professional Documents

Culture Documents

ST - 13.06 Steam Traps, Seal Water and Service Piping Arrangements

Uploaded by

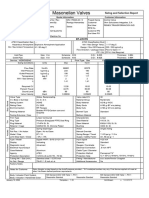

Maksim.em001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST - 13.06 Steam Traps, Seal Water and Service Piping Arrangements

Uploaded by

Maksim.em001Copyright:

Available Formats

Mondi Štětí a.s.

STANDARD

Part 13.06

STEAM TRAPS, WATER AND SERVICE

PIPING ARRANGEMENTS

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06 Page: 1/28

STANDARD

Part 13.06

STEAM TRAPS, SEAL WATER AND SERVICE

PIPING ARRANGEMENTS

Worked out by: Verified by: Approved by:

Name: Name: Name:

Position: Position: Position:

Signed by: Signed by: Signed by:

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06 Page: 2/28

CONTENT

13.06.01 Steam traps, medium and low pressure steam piping, p < 4 MPa,

Typical arrangement indoors

13.06.02 Steam traps, medium and low pressure steam piping, p < 4 MPa,

Typical arrangement outdoors

13.06.03 Steam trap mounting arrangements

13.06.04 Steam traps

13.06.05 Seal water controls

13.06.06 Compressed air supply system DN 20

13.06.07 Wash water hydrant DN 40 with hose reel

13.06.08 Fire hydrant DN 40 with hose reel, Indoors

13.06.09 Fire hydrant 2 x DN 80, Outdoors

13.06.10 Fire hydrant 4 x DN 80, Outdoor area

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06 Page: 3/28

TABLE OF CONTENTS

Page

1 Steam traps medium and low pressure steam piping, p < 4 MPa typical arrangement

indoors ....................................................................................................................................... 4

2 Steam traps medium and low pressure steam piping, p < 4 MPa typical arrangement

outdoors..................................................................................................................................... 5

3 Steam traps steam trap mounting arrangements ............................................................... 6

4 Steam traps............................................................................................................................... 7

5 Seal water controls ................................................................................................................ 10

6 Compressed air supply system DN 20 ............................................................................... 20

7 Wash water hydrant DN 40 with hose reel ........................................................................ 22

8 Fire hydrant DN 40 with hose reel, indoors ....................................................................... 23

9 Fire hydrant 2 x DN 80, outdoors ........................................................................................ 25

10 Fire hydrant 4 x DN 80, outdoor area ................................................................................. 27

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.01 Page: 4/28

1 Steam traps medium and low pressure steam piping, p < 4 MPa typical

arrangement indoors

1.1 Dimensions

4 Check valve

3 Reducer

2 Steam trap with inside filter

1 Shut off valve

Part Description

Notes: Pipe end in a channel must not reach to the water.

1.2 Designation

Name, standard No.

Example: Steam trap arrangement, 13.06.01

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.02 Page: 5/28

2 Steam traps medium and low pressure steam piping, p < 4 MPa typical

arrangement outdoors

2.1 Dimensions

3 Reducer

2 Steam trap with inbuilt filter

1 Shut off valve

Part Description

Notes: Pipe end to the cooling pit must not reach to the water.

Nominal size of the piping at least DN 50.

2.2 Designation

Name, standard No.

Example: Steam trap arrangement, 13.06.02

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.03 Page: 6/28

3 Steam traps steam trap mounting arrangements

Type A Type B

DRAIN TO THE CHANNEL

Type C Type D Type E

CONDENSATE RETURN TO

THE PIPE OR TANK

Notes: Equipment shall be placed at accessible level.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.04 Page: 7/28

4 Steam traps

4.1 Steam traps review

Thermodynamic steam traps

PN DN 10 DN 15 DN 20 DN 25

94 bar 160 --- BK 29 BK 29 BK 29

distribution

25 bar 63 --- BK 37 BK 37 BK 37

distribution

12 bar 25 TD 3-3 TD 3-3 TD 3-3 TD 3-3

distribution

4 bar 16 TD 3-3 TD 3-3 TD 3-3 TD 3-3

distribution

Thermodynamic steam traps suppliers:

BK 29 Gestra

TD 3-3 Spirax Sarco

Float steam traps

PN DN 25 DN 40 DN 50

94 bar distribution 160 UNA Max 39 --- UNA Max 39

25 bar distribution 63 UNA 27 h UNA 27 h UNA 27 h

12 bar distribution 25 UNA 25 h-A013 UNA 25 h-A013 UNA 25 h-A013

875932 *

4 bar distribution 16 UNA 23 h-A04 UNA 23 h-A04 UNA 23 h-A04

2 bar distribution 16 UNA 23 h-A02 UNA 23 h-A02 UNA 23 h-A02

Float steam trap suppliers:

UNA Max 39, UNA 27/25/23 h Gestra

Type CNU Sigmatech

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.04 Page: 8/28

4.2 Drain at pipe

D1 to 40 50 65 80 100 125 150 200 250 300 350 400 450 500 >600

mm 60.3 76.1 88.9 114.3 139.7 168.3 219.1 273.0 323.9 355.6 406.4 457.2 508.0 610.0

D2 25 40 40 65 80 100 125 150 150 200 200 200 250 250 300

mm 33.7 48.3 48.3 76.1 88.9 114.3 139.7 168.3 168.3 219.1 219.1 219.1 273.0 273.0 323.9

L, mm 80 150 200 250 300

Steam

trap type Thermodynamic steam trap Float steam trap

For long steam piping it is recommended to install Gestra AK 35 drainage.

4.3 Float steam TRAP

Float steam trap is used for automatic steam trapping from the equipment operated by

steam. The trap can be used in the vertical and horizontal piping. Allowable standard

overpressure is as follows:

1.30 MPa - temperature up to 120 0C

1.28 MPa - temperature up to 200 0C

1.12 MPa - temperature up to 250 0C

0.96 MPa - temperature up to 300 0C

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.04 Page: 9/28

Allowable overpressure shall be checked case by case before purchasing.

DN D D1 D2 D3 d L L1 L2 V b kg

25 25 115 85 68 14 180 192 86 195 16 8,6

50 50 165 125 102 18 236 269 116 277 20 22

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 10/28

5 Seal water controls

5.1 Supplier

The sealing water units of John Crane Safematic shall be used.

5.2 Systems

Two distinct types are distinguished.

Control unit for stuffing boxes

The sealing water is lead via the control unit to the sealing unit where the main part is mixed

with the medium behind the stuffing box and the surplus water is freely discharged.

Control units for face seal rings

The sealing water is lead to the sealing unit. By a control unit adjusts flow rate. Sealing water

is discharged into a collecting container or a tank.

Suppliers of pumps and equipment that needs sealing water must furnish the following data

for the selection of the suitable type:

-Type of seal

-Volume of sealing water

-Pressure of sealing water

-Sealing water can to be mixed into fluid substance or shall to be discharged separately

-Nominal sizes of hoses

-Connection points (to and from)

The Standard is binding upon all divisions of the Company and it is binding Contractors which

install or repair rotating machines for Mondi Štětí a.s.

5.3 Sealing water requirements

For full operational security, sealing water must be protected by primary and secondary filters

(approx. 50 µ).

Sealing water feed lines must be furnished with solenoid valves that close the line with a

delay of time when pump stops.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 11/28

5.4 Electrical monitoring

Sealing water units shall be equipped by flow switch which enables monitoring in control

system. Opening contact at flow switch activates an alarm at control system.

The flow switch has a local indicating light.

The alarm limit can be adjusted by loosening the shut-off pot.

Individual pumps and equipment that needs sealing water approved by Mondi shall be

provided with electrical flow monitoring.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 12/28

5.5 Control unit for stuffing boxes

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 13/28

Equipment components

SUT-AA-BB-XX*

1. Flow-rate meter SFT-AA-BB

2. Non-return valve **

3. Hose connector

4. Hose clamp

5. Hose 3/8“

6. Stand

7. Alarm unit (flush-seals) ***

IN = sealing water supply

* AA-BB = Spec. in accordance with flow meter

** XX-spec. depending on connection

*** Alarm units, types:

AC-1 or DC-1 (see separate operating instruction 20000101

or 20000116).

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 14/28

Control unit for stuffing boxes

Pipe thread

1. BASE PLATE

NPT-thread

SF(T)-03-BB

2. ACRYLIC COMPONENT SF(T)-08-BB

SF(T)-15-BB

3. MANOMETER COUPLING

4. CONTROL VALVE

5. HOSE CONNECTOR

0-10 bar ; 0-10 bar (AISI 316)

6. MANOMETER (BB)

0-25 bar ; 0-25 bar (AISI 316)

7. SCREW PLUG FOR CONTROL VALVE

8. SCREW PLUG FOR MANOMETER

9. ALARM UNIT AC-1

DC-1

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 15/28

5.6 Control unit for face seal rings

Equipment components

SU-AA-BB-XX *

1. Flow-rate meter SF-AA-BB

2. Non-return valve **

3. Hose connector

4. Hose connector

5. Hose clamp

6. Hose 3/8“

7. Stand

8. Alarm unit ***

IN = sealing water supply

OUT = sealing water discharge

* AA-BB = Spec. in accordance with flow meter

** XX-spec. depending on connection

*** Alarm units, types:

AC-1 or DC-1 (see separate operating instruction 20000101 or 20000116).

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 16/28

Control unit for face seal rings

pipe thread

1. BASE PLATE

NPT-thread

SF(T)-03-BB

2. ACRYLIC SECTION SF(T)-08-BB

SF(T)-15-BB

3. MANOMETER COUPLING

4. CONTROL VALVE

5. HOSE CONNECTOR

0-10 bar ; 0-10 bar (AISI 316)

6. MANOMETER (BB)

0-25 bar ; 0-25 bar (AISI 316)

7. SCREW PLUG FOR CONTROL VALVE

8. SCREW PLUG FOR MANOMETER

9. ALARM UNIT AC-1

DC-1

5.7 Description

The sealing water is led through a control valve to the flow-rate meter. The spring-loaded

floater in the transparent measuring pipe of the flow-rate meter indicates the flow rate. The

rate is continuously adjustable via a control valve by loosening the lock nut and adjusting the

screw. The adjusted rate shall be secured by re-tightening the lock nut. The control valve

may also be used as a shut-off valve.

The water flows from the flow-rate meter into the sealing unit or the stuffing box. The

manometer shows the pressure. The shut-off valve of the manometer permits replacing the

manometer during operation.

With type SF-08-XX (SF-15-XX), the pressure of the return sealing water is controlled by an

integrated pressure control valve.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 17/28

Pressure control is similar to flow-rate control. It is to be noticed that they affect each other

and that adjustments of one of them may require re-adjustments of the other.

The control unit shall be furnished with a cleaning or checking button which frees and moves

the floater and thus permits particles to be flushed out of the measuring pipe. This cleaning

operation shall be available to perform during regular operation. A detrimental effect on flow-

rate and pressure situation of the sealing water is not allowed.

5.8 Designation of units

Item Safematic unit type Specification

01 SFT-08-10 for stuffing boxes, without hoses,

3400-4083A 0-8 l/min, 10 bar

02 SFT-15-10 for stuffing boxes, without hoses,

3400-4093A 0-15 l/min, 10 bar

03 SFET-08-10 for stuffing boxes, without hoses,

3400-4093A with electrical monitoring,

0-8 l/min, 10 bar

04 SFET-15-10 for stuffing boxes, without hoses,

3400-4093A with electrical monitoring,

0-15 l/min, 10 bar

05 SF-08-10 for face seal rings, without hoses,

3400-4049A 0-8 l/min., 10 bar

06 SF-15-10 for face seal rings, without hoses,

3400-4094A 0-15 l/min., 10 bar

07 SFE-08-10 for face seal rings, without hoses,

3400-4049A with electrical monitoring,

0-8 l/min., 10 bar

08 SFE-15-10 for face seal rings, without hoses,

3400-4094A with electrical monitoring,

0-15 l/min., 10 bar

09 SUT-08-10 for stuffing boxes, with non-return valve,

3300-4225A ready connection coupling and 2-m hose

0-8 l/min., 10 bar

10 SUT-15-10 for stuffing boxes, with non-return valve,

3300-4225A ready connection coupling and 2-m hose

0-15 l/min., 10 bar

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 18/28

Item Safematic unit type Specification

11 SUET-08-10 as item 9, but with electrical monitoring

3300-4225A

12 SUET-15-10 as item 10, but with electrical monitoring

3300-4225A

13 SU-08-10 for face seal rings, with non-return valve,

3300-4224A ready connection coupling and 4-m hose

0-8 l/min., 10 bar

14 SU-15-10 for face seal ring, with non-return valve,

3300-4224A ready connection coupling and 4-m hose

0-15 l/min., 10 bar

15 SUE-08-10 as item 13, but with electrical monitoring

3300-4224A

16 SUE-15-10 as item 14, but with electrical monitoring

3300-4224A

17 SFT-50-10 for stuffing boxes, without hoses and

3400-6283 hose connectors 0-50 l/min., 10 bar

18 SF-50-10 for face seal rings, without hoses and

3400-6281 hose connectors

0-50 l/min., 10 bar

19 AC-1 or DC-1 electrical monitoring

Only complete units, i.e. with hoses, valves, ready connection couplings, stands are to be

asked for or ordered in principal.

Electrical monitoring only when explicitly specified by Mondi.

5.9 Installation

For simple servicing and recording, Safematic unit controls should be installed only at easily

accessible places close to equipment that needs sealing water.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.05 Page: 19/28

5.10 Stands

Stand order No 40 4317 can be used for two versions:

1. Installation on pump frame via lateral mounting plate

2. Floor-mounting via base plate

All materials to be 1.4571.

Sketch 1 Sketch 2

Installation on Floor-mounted via

stand arm 404317 base plate

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.06 Page: 20/28

6 Compressed air supply system DN 20

6.1 Dimensions

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.06 Page: 21/28

4 3 Hose connection

R ¾” external thread R 1”

3 3 Valve DN 25 welded/ R 1” thread 1.4404

see valve specification

2 3 Elbow 45° / DN25 – 33.7 x 2.0 EN 10253-4 1.4404

1 1 Elbow 90° / DN25 – 33.7 x 2.0 EN 10253-4 1.4404

Part Pcs Description Standard No. Material

6.2 Designation

Name, DN, standard No.

Example: Compressed air supply system DN 20, 13.06.06

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.07 Page: 22/28

7 Wash water hydrant DN 40 with hose reel

7.1 Dimensions

X – X Specification limit

7 1 Ball valve with welding ends DN 40 1.4404

6 1 Union with butt weld ends R 1 ½ " 1.4404

EN 10241

5 Elbow 48.3 x 2 1.4404, EN 10253-4

4 Pipe 48.3 x 1.6 1.4404, EN 10217-7

2 1 Steel reinforced hose 1 1/2" Length 30 m

1 1 Hose reel, hose 1 1/2"

Part Pcs Description Material

7.2 Designation

Name, standard No.

Example: Wash water hydrant DN 40 with hose reel, 13.06.07

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.08 Page: 23/28

8 Fire hydrant DN 40 with hose reel, indoors

8.1 Dimensions

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.08 Page: 24/28

9 3 Bend with socket 90°, R 1” EN 10241 1.4404

8 3 Welding nipple, R 1” EN 10241 1.4404

7 6 Elbow 90° / DN 25 – 33.7 x 2.0 EN 10253-4 1.4404

EN 10253-4

6 3 Valve DN 25 welding ends 1.4404

see valve specification

5 Pipe DN 25 33.7 x 1.6 EN 10217-7 1.4404

EN 10217-7

4 3 Fire fighting nipple Aluminium

3 3 Valve DN 40 welded/1 1/2” thread 1.4404

see valve specification

2 3 Elbow 45° / DN 40 – 48.3 x 2.0 EN 10253-4 1.4404

EN 10253-4

1 1 Elbow 90° / DN 40 - 48.3 x 2.0 EN 10253-4 1.4404

EN 10253-4

Part Pcs Description Standard No. Material

8.2 Designation

Name, DN, standard No.

Example: Fire hydrant indoors, DN 40, 13.06.08

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.09 Page: 25/28

9 Fire hydrant 2 x DN 80, outdoors

9.1 Dimensions

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.09 Page: 26/28

12 1 Fire fighting nipple Aluminium

11 1 Valve DN 40 PN 16 welded/ R 1 1/2” thread 1.4404

10 1 Pipe DN 40-48.3 x 2.0 1.4404, EN 10217-7

9 2 Valve DN 80 PN 16 with long welding ends 1.4404

8 2 Quick coupling cover Aluminium

7 2 Quick coupling nipple Aluminium

6 2 Welding nipple R 3” external thread 1.4404

5 1 T-piece DN 100/ DN 100 – 114.3 x 114.3 x 2.6 1.4404, EN 10253-4

4 2 Reducer DN 100/ DN 80 – 114.3/ 88.9 x 2.0 1.4404, EN 10253-4

3 2 Elbow 45° / DN 80 – 88.9 x 2.6 1.4404, EN 10253-4

2 2 Elbow 90° / DN 100 – 114.3 x 2.6 1.4404, EN 10253-4

1 4 Pipe DN 80 – 88.9 x 2.0 1.4404, EN 10217-7

Part Pcs Description Material

9.2 Designation

Name, DN, standard No.

Example: Fire hydrant outdoors, 2 x DN 80, 13.06.09

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.10 Page: 27/28

10 Fire hydrant 4 x DN 80, outdoor area

10.1 Dimensions

8 7 10

300

Direction K 9

1

800

6

Direction K

Gravel filling

500

11

Section A - A

5 3 4

Notes: Pipe parts under earth shall be handled with bitumen, other parts shall be painted.

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

Mondi Štětí a.s. STANDARD 13.06.10 Page: 28/28

11 1 Support 1.4404

10 1 Cap DN 150 – 168.3 x 2.6, EN 10253-4 1.4404

9 4 Quick coupling cover Aluminium

8 4 Quick coupling nipple Aluminium

7 4 Ball valve DN 80, PN 16 internal thread, long welding 1.4404

end / R 3” thread

6 1 Embedded collar with cover Cast iron

5 1 Shut-off valve DN 150 PN 16 (ball or gate valve),

flanged

4 2 Loose flange EN 1092-1 Type 02, DN 150, PN 16 P235GH

3 2 Collar EN 1092-1 Type 35, DN 150, PN 16 1.4404

2 1 Elbow 90° / DN 150 – 168.3 x 4.0 1.4404, EN 10253-4

1 1 Pipe DN 150 – 168.3 x 2.6 1.4404, EN 10217-7

Part Pcs Description Material

10.2 Designation

Name, DN, standard No.

Example: Fire hydrant outdoor area, 4 x DN 80, 13.06.10

Version: 1 Valid from: 18.01.2018

Printouts, if any, are not controlled. Printed on: 23/01/2018

You might also like

- ISO 21011 - 2008 Cryogenic Vessels. Valves For Cryogenic ServiceDocument18 pagesISO 21011 - 2008 Cryogenic Vessels. Valves For Cryogenic ServiceMaksim.em001100% (2)

- Write About A Place You Have Recently VisitedDocument2 pagesWrite About A Place You Have Recently Visitedxtiana18No ratings yet

- Instruction Manual: Kosangas LPG Sdn. BHDDocument10 pagesInstruction Manual: Kosangas LPG Sdn. BHDahmad hafizNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- Considerations For Evaluating Control Valve Cavitation: Recommended PracticeDocument60 pagesConsiderations For Evaluating Control Valve Cavitation: Recommended PracticeHoras Canman100% (1)

- Canada National Plumbing CodeDocument14 pagesCanada National Plumbing CodeEngineering ESIINo ratings yet

- Classification of PollutionDocument2 pagesClassification of PollutionmaryaniNo ratings yet

- ST - 13.01.06 Selection of Tee Connection TypesDocument5 pagesST - 13.01.06 Selection of Tee Connection TypesMaksim.em001No ratings yet

- ST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe LinesDocument10 pagesST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe LinesMaksim.em001No ratings yet

- ST - 13.02 Stainless Steel PipingDocument45 pagesST - 13.02 Stainless Steel PipingMaksim.em001No ratings yet

- ST - 13.03 Carbon Steel PipingDocument19 pagesST - 13.03 Carbon Steel PipingMaksim.em001No ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- EH Coriolis & Ultrasonic DSDocument5 pagesEH Coriolis & Ultrasonic DSsendutdutNo ratings yet

- ST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionDocument10 pagesST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionMaksim.em001No ratings yet

- 2FRM16 Re28389 2019-07Document12 pages2FRM16 Re28389 2019-07ElivarjaoNo ratings yet

- DMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFDocument9 pagesDMI-DS-70-005-A4 DS Fire Hydrant Rev.2 Approved - 16.4.19 PDFaerfansNo ratings yet

- 2FRMDocument3 pages2FRMdivortiareNo ratings yet

- ST 15.01.02 Steel Constructions For ChannelsDocument5 pagesST 15.01.02 Steel Constructions For ChannelsMaksim.em001No ratings yet

- Extracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Document3 pagesExtracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Mo OsNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Eyewash & Safety ShowerDocument5 pagesEyewash & Safety Showershiekh faizNo ratings yet

- ST - 13.01.08 Hoses For Steams and ChemicalsDocument7 pagesST - 13.01.08 Hoses For Steams and ChemicalsMaksim.em001No ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- FV-1038N OkDocument1 pageFV-1038N OkJose Luis Guerrero VillalpandoNo ratings yet

- Ebara 3PF 32-160 PDFDocument6 pagesEbara 3PF 32-160 PDFEddie GuillénNo ratings yet

- 40 NB Globe Tag No (1) - 1309Document1 page40 NB Globe Tag No (1) - 1309SIL PROJECTSNo ratings yet

- PT Pressure TransmitterDocument1 pagePT Pressure TransmitterAr RahmanNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- CON-F-17 Rev 01 PNG JOB CARD PUNJABI Page - 1Document1 pageCON-F-17 Rev 01 PNG JOB CARD PUNJABI Page - 1akashsharma.1849.asNo ratings yet

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 pagesAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyNo ratings yet

- MPP Pumps For Antibiotic Solvent Circulation PDFDocument1 pageMPP Pumps For Antibiotic Solvent Circulation PDFAnonymous ua66zYwrpNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12Document1 pageAspen Exchanger Design and Rating Shell & Tube V12TIPAZONo ratings yet

- Proportional Directional Valve - Not Pressure Compensated - Q 40 L/min - Q 32 L/min - P 350 BarDocument3 pagesProportional Directional Valve - Not Pressure Compensated - Q 40 L/min - Q 32 L/min - P 350 BarDavidson GattoniNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- Tag No FT-1033: SHEET: 27 OF 102Document1 pageTag No FT-1033: SHEET: 27 OF 102hendra hermawanNo ratings yet

- SMP For Fire Hydrant SystemDocument4 pagesSMP For Fire Hydrant Systemananthu.uNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- FT 04Document2 pagesFT 04trilok corporationNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- MN 176323 24Document3 pagesMN 176323 24nawaz.ahmed.spnutra.comNo ratings yet

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off Manual Valves - ReactorDocument5 pagesTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off Manual Valves - ReactorMichell TurbayNo ratings yet

- ZM A1 Int enDocument45 pagesZM A1 Int enkobyrtaczNo ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- 0000 46el 0002 - PB - MtoDocument6 pages0000 46el 0002 - PB - MtoBudi HahnNo ratings yet

- Specification Sheet Rev 1Document12 pagesSpecification Sheet Rev 1nishanth NTNo ratings yet

- Falsh Vessel RVDocument5 pagesFalsh Vessel RVJallu PratamaNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Straight-Way Type Valves SN 469: Provided With Progressive Ferrule Compression Couplings On Either SideDocument2 pagesStraight-Way Type Valves SN 469: Provided With Progressive Ferrule Compression Couplings On Either SideChristopher LloydNo ratings yet

- Gcem4011 Co Analyser DocsDocument11 pagesGcem4011 Co Analyser DocsmukurshahNo ratings yet

- Differential Pressure Relief ValvesDocument4 pagesDifferential Pressure Relief ValvesSlobodan HristovNo ratings yet

- CKBDXCV ApDocument2 pagesCKBDXCV ApŁukasz OlszewskiNo ratings yet

- 附件1 海水泵浦之泵浦及馬達數據規格表Document3 pages附件1 海水泵浦之泵浦及馬達數據規格表駱建澄No ratings yet

- 7.1-16'' 10K Double Ram BOP Operation ManualDocument18 pages7.1-16'' 10K Double Ram BOP Operation ManualrahulNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- Industrial Solenoid ValvesDocument36 pagesIndustrial Solenoid Valvesศตวรรษ ฉิมวัยNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- Case 5Document1 pageCase 5nirajkulkarni09No ratings yet

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingFrom EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingRating: 2 out of 5 stars2/5 (1)

- PIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Document6 pagesPIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Maksim.em001No ratings yet

- ISA-75.08-1999 Face-to-Face Dimensions For Flanged Clamp or Pinch ValvesDocument14 pagesISA-75.08-1999 Face-to-Face Dimensions For Flanged Clamp or Pinch ValvesКонстантинПаечкинNo ratings yet

- Pipeline Transportation Systems - Pipeline Valves (Amendments-Supplements To ISO 14313)Document29 pagesPipeline Transportation Systems - Pipeline Valves (Amendments-Supplements To ISO 14313)Jacob Philip100% (1)

- PIP - CS Gate Valve DescriptionsDocument22 pagesPIP - CS Gate Valve Descriptionsgbuckley9630100% (1)

- ST - 13.07 Primary Support Standards For PipingDocument97 pagesST - 13.07 Primary Support Standards For PipingMaksim.em001No ratings yet

- Standard ST13 Piping Standard: Mondi Štětí A.SDocument4 pagesStandard ST13 Piping Standard: Mondi Štětí A.SMaksim.em001No ratings yet

- Standard Dosing Stations: Mondi Štětí A.SDocument12 pagesStandard Dosing Stations: Mondi Štětí A.SMaksim.em001No ratings yet

- Standard Safety Showers: Mondi Štětí A.SDocument6 pagesStandard Safety Showers: Mondi Štětí A.SMaksim.em001No ratings yet

- ST - 13.01.04 Marking of Equipment and PipelinesDocument11 pagesST - 13.01.04 Marking of Equipment and PipelinesMaksim.em001No ratings yet

- Standard Appendix I Flow Substances, Piping Material and Valve Code SelectionDocument20 pagesStandard Appendix I Flow Substances, Piping Material and Valve Code SelectionMaksim.em001No ratings yet

- ST - 13.01.08 Hoses For Steams and ChemicalsDocument7 pagesST - 13.01.08 Hoses For Steams and ChemicalsMaksim.em001No ratings yet

- ST - 13.01.05 Technical Specification For PipingDocument16 pagesST - 13.01.05 Technical Specification For PipingMaksim.em001No ratings yet

- ST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionDocument10 pagesST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionMaksim.em001No ratings yet

- ST 40.02 Air ConditioningDocument4 pagesST 40.02 Air ConditioningMaksim.em001No ratings yet

- ST - 13.01.03 Position Numbering of Equipment and PipingDocument9 pagesST - 13.01.03 Position Numbering of Equipment and PipingMaksim.em001No ratings yet

- ST 40.07 Controlled Production AreasDocument12 pagesST 40.07 Controlled Production AreasMaksim.em001No ratings yet

- ST - 13.01 General Cover PageDocument2 pagesST - 13.01 General Cover PageMaksim.em001No ratings yet

- ST 40.06 Concrete StructuresDocument8 pagesST 40.06 Concrete StructuresMaksim.em001No ratings yet

- ST 15.01.02 Steel Constructions For ChannelsDocument5 pagesST 15.01.02 Steel Constructions For ChannelsMaksim.em001No ratings yet

- ST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsDocument10 pagesST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsMaksim.em001No ratings yet

- Standard Doors: Mondi Štětí A.SDocument8 pagesStandard Doors: Mondi Štětí A.SMaksim.em001No ratings yet

- NMR - WATER Exploration, Presentation - Water - ProjectDocument35 pagesNMR - WATER Exploration, Presentation - Water - Projectmichel louis friedmanNo ratings yet

- Soil Improvement Technique by IIT Chennai Professor Dr. S.R.GandhiDocument214 pagesSoil Improvement Technique by IIT Chennai Professor Dr. S.R.Gandhiarpit67% (3)

- Chapter 6 PDFDocument19 pagesChapter 6 PDFKumar SaketNo ratings yet

- Chain Rule and Pipes & Cisterns - TDY-352Document45 pagesChain Rule and Pipes & Cisterns - TDY-352Ālok KrNo ratings yet

- Earth Is UniqueDocument14 pagesEarth Is UniqueYollyNo ratings yet

- (Best Kept Buried) Beneath The Missing SeaDocument92 pages(Best Kept Buried) Beneath The Missing Seaalfred0% (2)

- New Brighton State Beach Campground MapDocument2 pagesNew Brighton State Beach Campground MapCalifornia State ParksNo ratings yet

- nwp98 Ruc2 PDFDocument4 pagesnwp98 Ruc2 PDFgerntrash2No ratings yet

- 012 Ind Tacr 05c 2Document604 pages012 Ind Tacr 05c 2Sony JsdNo ratings yet

- Design of Hydraulic Structures (BE, Civil) :books, BIS Codes and Useful LinksDocument7 pagesDesign of Hydraulic Structures (BE, Civil) :books, BIS Codes and Useful LinksSantosh Kumar88% (8)

- 115 Sample ChapterDocument7 pages115 Sample ChapterFar FarhaanNo ratings yet

- Chemical Equations & ReactionsDocument78 pagesChemical Equations & ReactionsIshvarya100% (1)

- Removal of Suspended Fine Particulate Matter From Raw Juice PPT ScribdDocument45 pagesRemoval of Suspended Fine Particulate Matter From Raw Juice PPT ScribdKunchey JagadeeshNo ratings yet

- PollutionDocument13 pagesPollutionRahul VatsNo ratings yet

- SW 945Document10 pagesSW 945sintaNo ratings yet

- Pokemon Go Spawn Locations Where Do I Catch Rare PokemonDocument40 pagesPokemon Go Spawn Locations Where Do I Catch Rare PokemonNguyen AbbaNo ratings yet

- ToR EIA PDFDocument5 pagesToR EIA PDFShahparan_sustNo ratings yet

- Close Reading #1.: Sustainable Development Goals IntegrationDocument7 pagesClose Reading #1.: Sustainable Development Goals IntegrationKier Jhoem mahusayNo ratings yet

- Earths SpheresDocument16 pagesEarths SpheresMehmood ChawlaNo ratings yet

- Unit 1 - Living ThingsDocument3 pagesUnit 1 - Living ThingsLoles Lopez FresnedaNo ratings yet

- Job Safety Analysis JSA Applied in ConstDocument11 pagesJob Safety Analysis JSA Applied in Constfadli.lpgNo ratings yet

- Taprogge Tube Cleaning SystemDocument22 pagesTaprogge Tube Cleaning Systemazdrial diansyahNo ratings yet

- Agri Plas GreenhouseDocument6 pagesAgri Plas GreenhouseBendzGeronaNo ratings yet

- USP Presentation MunicipalDocument20 pagesUSP Presentation Municipalcoolvishal2003No ratings yet

- Wastewater Treatment MCQDocument12 pagesWastewater Treatment MCQSadhan PadhiNo ratings yet

- African Sharptooth Catfish Clarias GariepinusDocument25 pagesAfrican Sharptooth Catfish Clarias GariepinusConstantin FAKOUNDENo ratings yet