Professional Documents

Culture Documents

ST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe Lines

Uploaded by

Maksim.em001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST - 13.01.02 Recommended Flow Velocities For Different Fluids in Pipe Lines

Uploaded by

Maksim.em001Copyright:

Available Formats

Mondi Štětí a.s.

STANDARD

Part 13.01.02

RECOMMENDED FLOW VELOCITIES FOR

DIFFERENT FLUIDS IN PIPE LINES

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 1/9

STANDARD

Part 13.01.02

RECOMMENDED FLOW VELOCITIES FOR

DIFFERENT FLUIDS IN PIPE LINES

Worked out by: Verified by: Approved by:

Name: Name: Name:

Position: Position: Position:

Signed by: Signed by: Signed by:

in her own hand in her own hand in his own hand

Version: 1 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 2/9

TABLE OF CONTENTS

Page

1 General ............................................................................................................... 3

2 Flow velocities ................................................................................................... 3

3 Additional guidelines ........................................................................................ 9

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 3/9

1 General

This specification defines recommended flow velocities for different flow substances

in pipe lines.

The specification is intended for the design and procurement of the piping.

For detailed design the pressure loss calculations shall be performed case by case

and the pipe sizes shall be dimensioned to meet the process requirements.

2 Flow velocities

The average flow velocity in a pipe is calculated using the following formula:

where:

v is flow velocity, m/s

Q is volume flow, m3/s

D is inside diameter of pipe, m

The flow velocities given are guide values. Unless separately mentioned the

recommended flow velocities are at the pressure side of a pump.

The recommended values in the suction side shall be about 70 % of the flow velocity

at the pressure side.

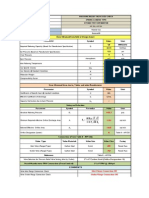

2.1 Water and pumped condensates

The recommended flow velocities are presented in Table 2-1 for each nominal size

DN of a pipe.

In cases where the pressure loss is not determinant such as short branch pipe lines

that do not have an effect on the dimensioning of a pump head, velocities up to Vmax

values given in Table 2-1 can be used.

Lower velocities than presented in Table 2-1 are usually used for pumped

condensates. In normal cases the velocities are about 70 % of the velocity given in

the Table 2-1. For longer pipelines the pipe sizes shall be designed case by case to

avoid flashing in condensate pipelines.

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 4/9

2.2 Steams

The velocity guide values are presented in Table 2-2. The critical steam lines shall be

dimensioned case by case.

The saturated steam pipe lines are normally slightly superheated. If the steam is

clearly superheated, the flow velocities can be increased by 20 percent.

2.3 Airs

DN size Velocity, m/s

Mill air 25 … 200 10 … 15

Instrument air 10 … 25 5 … 10

Instrument air 32 … 200 10 … 15

Conveying air 25 … 200 5 … 30

Vacuum air 10 … 20

2.4 Flammable gases

When defining the flow velocity maximum values for flammable gases, the values

given in the law, regulations and official specifications shall be followed.

Flammable gases: 10 … 20 m/s.

2.5 Non-flammable gases

Non- flammable gases: 15 … 25 m/s.

2.6 Liguefied gases

When defining the flow velocity maximum values for flammable gases, the values

given in the law, regulations and official specifications shall be followed.

Liquefied gases (as liquid): 1 … 3 m/s.

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 5/9

2.7 Flammableliquids, oils and bitumens

For flammable liquids the appearance of a potential static electricity shall be clarified

and the flow velocity shall be restricted to a safe level.

Flammable liquids 1…2 m/s

Oil 0.9 …1.0 kg/dm3 1…2 m/s

Oil 0.8 … 0.9 kg/dm3 1.5…3 m/s

Molten bitumen 1…2 m/s

Hydraulic oil in a suction pipe 0.5…1.5 m/s

Hydraulic oil in a delivery pipe 2…5 m/s

Circulation lubrication oil in a return pipe 0.2 m/s

Circulation lubrication oil in a delivery pipe 1…2 m/s

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 6/9

Table 2-1 Flow Velocities of Water and Pumped condensate1) by Pipe Sizes DN, m/s

1) See Item 2.1.

2) Bigger DN sizes shall be designed case by case taking into account the actual flow conditions, geometry of piping etc .

Table 2-2 Flow Velocities of Steams by Pipe Sizes DN, m/ s

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 7/9

2.8 Acids

The recommended flow velocities for acids in the project are as follows:

Sulphuric acid < 1.5 m/s

Hydrochloric acid 1…1.5 m/s

Nitric acid 1…2 m/s

Phosphoric acid 1…2 m/s

Formic acid 1…2 m/s

2.9 Alkalis

The recommended flow velocities for alkalis in the project are as follows:

Sodium hydroxide 0.5…1.2 m/s

White liquor 0.5…1 m/s

Green liquor 2.5…3.0 m/s

Weak black liquor 1.0…2.0 m/s

Intermediate black liquor 1.0…1.5 m/s

Strong black liquor 0.8…1.2 m/s

Soft soap 0.5…0.8 m/s

Lime mud, lime filtrate,

scrubber dregs, green liquor

dregs, sodium sulphate 1.0…1.5 m/s

2.10 Pulp

The recommended flow velocities for different pulp consistencies are presented in

Table 2-3 for each nominal size DN of a pipe.

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 8/9

Table 2-3 Flow Velocities of Pulp by Pipe Size DN and Consistency, m/s

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

Mondi Štětí a.s. STANDARD 13.01.02 Page: 9/9

2.11 Pulps with consistency 9 ... 12 %

The guide line for the velocity of high consistency pulp lines in DN range DN 400 …

DN 800 is 0.3 … 0.8 m/s. The lines shall always be dimensioned in co-operation with

the pump manufacturer.

2.12 Compounds of solid substance and liquid

For flow media that contain abrasive and heavy solids or the flow media is partially

crystallized, the flow velocity shall be fast enough to prevent the solids to sediment,

but not too fast so that the solids do not cause excessive abrasion (wear) of the

piping.

As a general instruction a flow velocity is 1 … 2 m/s is recommended, but when

necessary the critical velocity shall be calculated for each media case by case.

3 Additional guidelines

The selection of the flow velocity is affected by the pipe size (for larger pipes greater

flow velocity), pipe material and surface roughness, temperature, viscosity, price of

energy, length of the pipeline e.g. in short branches which are not determining the

pump head the velocity can be bigger than in main pipe line, risk for vibration etc.

The optimization of energy use shall be taken into account especially in long pipe

lines.

Version: 00 Valid from: 18.1.2018

Printouts, if any, are not controlled. Printed on: 23.1.2018

You might also like

- ISO 21011 - 2008 Cryogenic Vessels. Valves For Cryogenic ServiceDocument18 pagesISO 21011 - 2008 Cryogenic Vessels. Valves For Cryogenic ServiceMaksim.em001100% (2)

- F2164Document5 pagesF2164Hernando Andrés Ramírez Gil100% (1)

- Manual: Vertical Filter Housing VFH-1-355-10Document17 pagesManual: Vertical Filter Housing VFH-1-355-10viktor_gligorovNo ratings yet

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDocument8 pagesUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rNo ratings yet

- Piping Class - AS20Document2 pagesPiping Class - AS20Дмитрий РыбаковNo ratings yet

- BS en 764-7-2002 - Pressure Equipment Part 7Document42 pagesBS en 764-7-2002 - Pressure Equipment Part 7Edy Wijaya100% (1)

- Globe Stop and Check Valve - en 13709Document4 pagesGlobe Stop and Check Valve - en 13709Nemanja PapricaNo ratings yet

- Design of Fans Working in Potentially Explosive Atmospheres: British Standard Bs en 14986:2007Document40 pagesDesign of Fans Working in Potentially Explosive Atmospheres: British Standard Bs en 14986:2007sainath_84No ratings yet

- Considerations For Evaluating Control Valve Cavitation: Recommended PracticeDocument60 pagesConsiderations For Evaluating Control Valve Cavitation: Recommended PracticeHoras Canman100% (1)

- Acrobat Document2 PDFDocument15 pagesAcrobat Document2 PDFeino6622No ratings yet

- Tank Mixing JGS 210-120-1-66E: ConfidentialDocument9 pagesTank Mixing JGS 210-120-1-66E: ConfidentialPinjala AnoopNo ratings yet

- GBH Enterprises, LTD.: GBHE-EDG-MAC-1508Document39 pagesGBH Enterprises, LTD.: GBHE-EDG-MAC-1508Ossama BohamdNo ratings yet

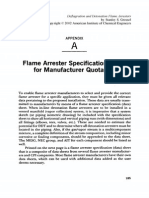

- Flame Arrester - Technical DetailsDocument16 pagesFlame Arrester - Technical DetailsAnonymous 3DHogINo ratings yet

- Thermal Relief Rate Calculation for Jet A1 in 20Document1 pageThermal Relief Rate Calculation for Jet A1 in 20Ascend032100% (1)

- CV - Orifice Diameter PDFDocument8 pagesCV - Orifice Diameter PDFManuelNo ratings yet

- Instrumentation GPSA HandbookDocument6 pagesInstrumentation GPSA HandbookmusaveerNo ratings yet

- TSV CalculationDocument3 pagesTSV CalculationAymen KhlifiNo ratings yet

- Vertical SeparatorDocument38 pagesVertical SeparatorSaidFerdjallahNo ratings yet

- Labelling of explosion proof equipment according to ATEX 2014/34/EUDocument1 pageLabelling of explosion proof equipment according to ATEX 2014/34/EUfrancisNo ratings yet

- Application of UG-140 For Overpressure Protection: FeaturesDocument4 pagesApplication of UG-140 For Overpressure Protection: FeaturesB rg100% (1)

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocument1 pageEXAMPLE SIZING OWS Calculation Per API 421 PDFarnel_ado4412No ratings yet

- Iso 13349-2010Document50 pagesIso 13349-2010rohitshukla23No ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- SEO-Optimized Title for API 685 Centrifugal Pump Data SheetDocument5 pagesSEO-Optimized Title for API 685 Centrifugal Pump Data SheetaltipatlarNo ratings yet

- Piping system design basisDocument6 pagesPiping system design basisDeden SobirinNo ratings yet

- TB8102 Rupture Disc SizingDocument9 pagesTB8102 Rupture Disc SizingtuimeqNo ratings yet

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNo ratings yet

- Flame ArresterDocument16 pagesFlame Arresteriran1362No ratings yet

- Ejector Data SheetDocument5 pagesEjector Data SheetFatih FıratNo ratings yet

- Chien1995 PDFDocument6 pagesChien1995 PDFFelipeMorenoNo ratings yet

- Air Receiver SizingDocument2 pagesAir Receiver Sizingsiby josephNo ratings yet

- Design criteria for determining temperature and pressureDocument19 pagesDesign criteria for determining temperature and pressureKorcan ÜnalNo ratings yet

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochieNo ratings yet

- Calculation of The Built Up Back PressureDocument4 pagesCalculation of The Built Up Back PressureibnuharyNo ratings yet

- Pressure Drop Via The Karman MethodDocument2 pagesPressure Drop Via The Karman MethodAtul kumar KushwahaNo ratings yet

- Flame ArresterDocument2 pagesFlame ArresterAariz KhanNo ratings yet

- Protego PDFDocument18 pagesProtego PDFNemezis1987No ratings yet

- CPI SeparatorDocument77 pagesCPI SeparatorVidyasen100% (1)

- Pressure Regulating Valve SpecificationDocument7 pagesPressure Regulating Valve SpecificationSreejesh Sundaresan100% (1)

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Blower & ScrubberDocument15 pagesBlower & ScrubbervniranjanNo ratings yet

- Ote Outotec Edmeston SX Sulphuric Acid Steel Eng WDocument2 pagesOte Outotec Edmeston SX Sulphuric Acid Steel Eng WacckypenrynNo ratings yet

- Compressor Suction Drums PDFDocument6 pagesCompressor Suction Drums PDFrossifrancesco100% (1)

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- API 618 Compressors1Document2 pagesAPI 618 Compressors1Rhama WijayaNo ratings yet

- Insulation Thickness Calculation of Pipe: T T T T Input RequiredDocument3 pagesInsulation Thickness Calculation of Pipe: T T T T Input RequiredEddie FongNo ratings yet

- Pipe Material For OxygenDocument3 pagesPipe Material For Oxygenc_pythonNo ratings yet

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009No ratings yet

- Fire Protection in Refineries: Api Recommended Practice 2001 Draft Ninth EditionDocument5 pagesFire Protection in Refineries: Api Recommended Practice 2001 Draft Ninth EditionEmilioTSNo ratings yet

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 pagesHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc NguyenNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- Best Potable Water Pressure Tank SeriesDocument6 pagesBest Potable Water Pressure Tank SeriesGhislaine SousaNo ratings yet

- My Time at Urea-2 Plant and Key Equipment DetailsDocument6 pagesMy Time at Urea-2 Plant and Key Equipment DetailsUzair AshrafNo ratings yet

- Cat 6Document5 pagesCat 6fNo ratings yet

- 1.0 J1415 QF200-2 PSA DatasheetDocument2 pages1.0 J1415 QF200-2 PSA DatasheetCarlos MagNo ratings yet

- En 10222-5Document22 pagesEn 10222-5Paul DaasNo ratings yet

- Fuel Oil For Industrial EnginesDocument22 pagesFuel Oil For Industrial EnginesAndrew HillNo ratings yet

- ST - 13.06 Steam Traps, Seal Water and Service Piping ArrangementsDocument29 pagesST - 13.06 Steam Traps, Seal Water and Service Piping ArrangementsMaksim.em001No ratings yet

- Mondi Štětí Standard Tee Connection SelectionDocument5 pagesMondi Štětí Standard Tee Connection SelectionMaksim.em001No ratings yet

- Waqas Ahmsd (2019-Msee-203)Document25 pagesWaqas Ahmsd (2019-Msee-203)muneebsaifNo ratings yet

- Manual Zenner MTKDDocument3 pagesManual Zenner MTKDDanNo ratings yet

- ISA-75.08-1999 Face-to-Face Dimensions For Flanged Clamp or Pinch ValvesDocument14 pagesISA-75.08-1999 Face-to-Face Dimensions For Flanged Clamp or Pinch ValvesКонстантинПаечкинNo ratings yet

- PIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Document6 pagesPIP PNSMV034 Bronze and Iron Globe Valve Descriptions (2004)Maksim.em001No ratings yet

- PIP - CS Gate Valve DescriptionsDocument22 pagesPIP - CS Gate Valve Descriptionsgbuckley9630100% (1)

- Pipeline Transportation Systems - Pipeline Valves (Amendments-Supplements To ISO 14313)Document29 pagesPipeline Transportation Systems - Pipeline Valves (Amendments-Supplements To ISO 14313)Jacob Philip100% (1)

- ST - 13.07 Primary Support Standards For PipingDocument97 pagesST - 13.07 Primary Support Standards For PipingMaksim.em001No ratings yet

- ST - 13.02 Stainless Steel PipingDocument45 pagesST - 13.02 Stainless Steel PipingMaksim.em001No ratings yet

- ST - 13.03 Carbon Steel PipingDocument19 pagesST - 13.03 Carbon Steel PipingMaksim.em001No ratings yet

- Standard ST13 Piping Standard: Mondi Štětí A.SDocument4 pagesStandard ST13 Piping Standard: Mondi Štětí A.SMaksim.em001No ratings yet

- Standard Dosing Stations: Mondi Štětí A.SDocument12 pagesStandard Dosing Stations: Mondi Štětí A.SMaksim.em001No ratings yet

- ST - 13.06 Steam Traps, Seal Water and Service Piping ArrangementsDocument29 pagesST - 13.06 Steam Traps, Seal Water and Service Piping ArrangementsMaksim.em001No ratings yet

- ST - 13.01.05 Technical Specification For PipingDocument16 pagesST - 13.01.05 Technical Specification For PipingMaksim.em001No ratings yet

- Standard Safety Showers: Mondi Štětí A.SDocument6 pagesStandard Safety Showers: Mondi Štětí A.SMaksim.em001No ratings yet

- ST - 13.01.08 Hoses For Steams and ChemicalsDocument7 pagesST - 13.01.08 Hoses For Steams and ChemicalsMaksim.em001No ratings yet

- Mondi Štětí a.s. Standard for Position Numbering of Equipment and PipingDocument9 pagesMondi Štětí a.s. Standard for Position Numbering of Equipment and PipingMaksim.em001No ratings yet

- ST 40.02 Air ConditioningDocument4 pagesST 40.02 Air ConditioningMaksim.em001No ratings yet

- Mondi Štětí Technical Specification for Equipment and Pipeline MarkingDocument11 pagesMondi Štětí Technical Specification for Equipment and Pipeline MarkingMaksim.em001No ratings yet

- Mondi Štětí Standard Tee Connection SelectionDocument5 pagesMondi Štětí Standard Tee Connection SelectionMaksim.em001No ratings yet

- ST - 13.01 General Cover PageDocument2 pagesST - 13.01 General Cover PageMaksim.em001No ratings yet

- ST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionDocument10 pagesST - 13.01.01 Technical Specifications For Flow Substances Piping Material and Valve Type SelectionMaksim.em001No ratings yet

- Mondi Štětí Concrete Structure StandardsDocument8 pagesMondi Štětí Concrete Structure StandardsMaksim.em001No ratings yet

- Standard Appendix I Flow Substances, Piping Material and Valve Code SelectionDocument20 pagesStandard Appendix I Flow Substances, Piping Material and Valve Code SelectionMaksim.em001No ratings yet

- Standard Doors: Mondi Štětí A.SDocument8 pagesStandard Doors: Mondi Štětí A.SMaksim.em001No ratings yet

- ST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsDocument10 pagesST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsMaksim.em001No ratings yet

- MONDI STANDARD controlled production areasDocument12 pagesMONDI STANDARD controlled production areasMaksim.em001No ratings yet

- ST 15.01.02 Steel Constructions For ChannelsDocument5 pagesST 15.01.02 Steel Constructions For ChannelsMaksim.em001No ratings yet

- Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)Document2 pagesErp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ) Erp 2009/125/ec (50 HZ)José Ramón Devan DevanNo ratings yet

- Tds Shoe FinishesDocument22 pagesTds Shoe FinishesHetal PatelNo ratings yet

- IGCSE Chemistry Principles of ChemistryDocument7 pagesIGCSE Chemistry Principles of Chemistrydanielmahsa100% (1)

- SeraFix SeraPadDocument3 pagesSeraFix SeraPadArbab SkunderNo ratings yet

- What Is Brem ?Document12 pagesWhat Is Brem ?hey rizkiNo ratings yet

- AEROSIL® and SIPERNAT® Silica: Versatile Raw Materials For Personal Care FormulationsDocument20 pagesAEROSIL® and SIPERNAT® Silica: Versatile Raw Materials For Personal Care FormulationsSochiTonyNo ratings yet

- Fundamentals of Pipeline Design, Hydraulics & PumpsDocument75 pagesFundamentals of Pipeline Design, Hydraulics & PumpsMIRACLE26No ratings yet

- Les PDFDocument196 pagesLes PDFNeeraj Singh0% (1)

- Installation, Operation, and Maintenance Manual: Gms Series Pumps D, G, J, N & R SizesDocument47 pagesInstallation, Operation, and Maintenance Manual: Gms Series Pumps D, G, J, N & R SizesJabeer AboobackerNo ratings yet

- Cohesion and Adhesion in Liquids Surface Tension and Capillary Action 5Document16 pagesCohesion and Adhesion in Liquids Surface Tension and Capillary Action 5Nirmal JayanthNo ratings yet

- Phases Matter StatesDocument7 pagesPhases Matter StatesRien Jing TianNo ratings yet

- Modeling of Steam Water Direct Contact Condensation Using Volume of Fluid ApproachDocument18 pagesModeling of Steam Water Direct Contact Condensation Using Volume of Fluid ApproachMustafa DemircioğluNo ratings yet

- 5th Grade Science Curriculum MapDocument20 pages5th Grade Science Curriculum MapPerihan SayedNo ratings yet

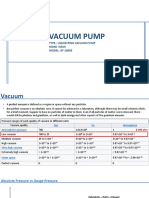

- Vacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EDocument46 pagesVacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EAmit Balot100% (2)

- Reservoir Engineering 2 (PVT & Fluid Properties)Document28 pagesReservoir Engineering 2 (PVT & Fluid Properties)okpaire lawsonNo ratings yet

- Operating Problems and Glycol CareDocument17 pagesOperating Problems and Glycol CareJonathan Mike0% (1)

- 9th Science PBQ Chapter 1 To 15Document31 pages9th Science PBQ Chapter 1 To 15YogithaNo ratings yet

- Basazol Green 20 L, TI, enDocument1 pageBasazol Green 20 L, TI, enCarlos UngarettiNo ratings yet

- Chapter-1: Fundamental Concepts Set-B: Page 1 of 2Document2 pagesChapter-1: Fundamental Concepts Set-B: Page 1 of 2SWAGATAM BAZNo ratings yet

- Instruction: Attempt All Questions. (ASSIGNMENT:-section A: Odd Numbers and Section B: Even Numbers) 1. 2. 3. 4. 5. 6. 7. 8. 9Document2 pagesInstruction: Attempt All Questions. (ASSIGNMENT:-section A: Odd Numbers and Section B: Even Numbers) 1. 2. 3. 4. 5. 6. 7. 8. 9Abi DemNo ratings yet

- Evaporative Condenser Engineering Manual: Technical ResourcesDocument18 pagesEvaporative Condenser Engineering Manual: Technical ResourcesMohamed IbrahimNo ratings yet

- Spiral PresentationDocument30 pagesSpiral Presentationmramos4191No ratings yet

- E+H Entrained AirDocument4 pagesE+H Entrained Airaswin26No ratings yet

- Lesson 11 Solid When Exposed To Diff Temp DAY 1. DenDocument25 pagesLesson 11 Solid When Exposed To Diff Temp DAY 1. DenJESSICA CAMPONo ratings yet

- Felling machine divides bulk materials into equal volumesDocument9 pagesFelling machine divides bulk materials into equal volumesCao Ngoc AnhNo ratings yet

- Heat Exchangers in The Aviation EngineeringDocument18 pagesHeat Exchangers in The Aviation EngineeringvirgilioNo ratings yet

- BS en Iso 14692-3-2017Document46 pagesBS en Iso 14692-3-2017SRIDHAR BABU KONADANo ratings yet

- Fluid Mechanics ProbsetDocument2 pagesFluid Mechanics ProbsetJanine ArtigoNo ratings yet