Professional Documents

Culture Documents

Appendix P Basis For Establishing Allowable Stress Values

Uploaded by

AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix P Basis For Establishing Allowable Stress Values

Uploaded by

AhmedCopyright:

Available Formats

APPENDIX P

BASIS FOR ESTABLISHING

ALLOWABLE STRESS VALUES

P-1 RYpratio of the average temperature dependent

In the determination of allowable stress values for trend curve value of yield strength to the

pressure parts, the Committee is guided by successful room temperature yield strength

experience in service insofar as evidence of satisfactory SRavgpaverage stress to cause rupture at the end

performance is available. Such evidence is considered of 100,000 hr

equivalent to test data where operating conditions are SRminpminimum stress to cause rupture at the end

known with reasonable certainty. In the evaluation of of 100,000 hr

new materials, it is sometimes necessary to be guided SCpaverage stress to produce a creep rate of

to a certain extent by the comparison of test information 0.01% /1000 hr

with available data on successful applications of similar NApnot applicable

materials.

(a) Nomenclature

STpspecified minimum tensile strength at room The maximum allowable stress for Tables ULT-23,

temperature, ksi UCI-23, and UCD-23 shall be the lowest value obtained

RTpratio of the average temperature dependent from the criteria in Table P-1.

trend curve value of tensile strength to the The stress criteria, mechanical properties considered,

room temperature tensile strength and the factors applied to establish the maximum allow-

SYpspecified minimum yield strength at room able stresses for other stress Tables are given in Appen-

temperature dix 1 of Section II, Part D.

574

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

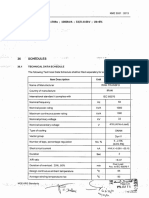

TABLE P-1

CRITERIA FOR ESTABLISHING ALLOWABLE STRESS VALUES

Below Room

Temperature Room Temperature and Above

Licensed by Information Handling Services

Tensile Yield Tensile Yield Stress Creep

Product/Material Table Strength Strength Strength Strength Rupture Rate

S T RT 2

Wrought or cast fer- ULT-23 ⁄3 SYRY NA NA NA NA NA NA NA

4

rous and nonferrous

COPYRIGHT American Society of Mechanical Engineers

ST 2 ST 1.1 2 2

Bolting annealed fer- ULT-23 ⁄3 SY S R ⁄3 SY ⁄3 SYRY 0.67 SR avg 0.8 SR min 1.0 SC

4 4 4 T T

rous and nonferrous

ST SY 1 1.1 1 2

Bolting, with strength ULT-23 ⁄ 5 ST S R ⁄4 SY ⁄3 SYRY 0.67 SR avg 0.8 SR min 1.0 SC

5 4 4 T T

enhanced by heat

treatment or strain [Note

575

hardening, ferrous (1)]

and nonferrous

0.85 2 0.85 (1.1 ⴛ 0.85) 2 2

Welded pipe or tube, ULT-23 ST ⁄3 ⴛ 0.85 SY ST STRT ⁄3 ⴛ 0.85SY ⁄3 ⴛ 0.85 (0.67 ⴛ 0.85) (0.8 ⴛ 0.85) 0.85 SC

4 4 4

ferrous and non- SYRY SR avg SR min

ferrous or

APPENDIX P — NONMANDATORY

0.9 ⴛ 0.85

SYRY

ST ST 1.1

Cast iron UCI-23 NA S R NA NA NA NA NA

10 10 10 T T

ST 2 ST 1.1 2 2

Nodular iron UCD-23 ⁄3 SY S R ⁄3 SY ⁄3 SYRY NA NA NA

5 5 5 T T

NOTE:

(1) For materials whose strength has been enhanced by heat treatment or by strain hardening, the criteria shown shall govern unless the values are lower than the annealed material, in

which case the annealed values shall be used.

Table P-1

You might also like

- Practice Sheet Calculating DensityDocument2 pagesPractice Sheet Calculating Densityapi-2856984310% (2)

- 2010 Toyota Corolla Le 1.8l Common Specs & ProceduresDocument4 pages2010 Toyota Corolla Le 1.8l Common Specs & ProceduresRuben100% (1)

- Reynolds Experiment (Body)Document13 pagesReynolds Experiment (Body)mutencoNo ratings yet

- Discussion Tray DryerDocument3 pagesDiscussion Tray DryerIskandar ZulkarnainNo ratings yet

- Non-Mandatory Appendix PDocument2 pagesNon-Mandatory Appendix PMuhammed Abo-FandoodNo ratings yet

- Calc Tensionador 30PLG 600Document1 pageCalc Tensionador 30PLG 600Cristhian De La BarraNo ratings yet

- TDS - Tyvek Sterilization Reel (1073B)Document2 pagesTDS - Tyvek Sterilization Reel (1073B)Abdullah AtherNo ratings yet

- Heat-to-Heat Variation of Tensile Properties of Annealed 21A Cr-1 Mo SteelDocument47 pagesHeat-to-Heat Variation of Tensile Properties of Annealed 21A Cr-1 Mo Steelscg1234No ratings yet

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet

- Welding Procedure Approval Record FormDocument2 pagesWelding Procedure Approval Record FormSc TanNo ratings yet

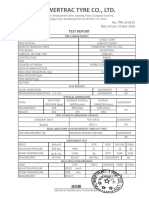

- Test Report TyreDocument42 pagesTest Report Tyredeportesaldia2014No ratings yet

- Is 1367 - 13 PDFDocument4 pagesIs 1367 - 13 PDFsat palNo ratings yet

- Astm F835M 1998Document5 pagesAstm F835M 1998Jesse ChenNo ratings yet

- Freemyer TWS600S IV - OR00059565 4,5 & 3.5Document38 pagesFreemyer TWS600S IV - OR00059565 4,5 & 3.5Carlos Martínez VelázquezNo ratings yet

- Technical Data Sheet: Straight Male Receptacle For SMT Slide Type - Reel of 400Document6 pagesTechnical Data Sheet: Straight Male Receptacle For SMT Slide Type - Reel of 400agus gatelNo ratings yet

- ASTM - A131 Structural Steel For ShipsDocument7 pagesASTM - A131 Structural Steel For ShipsPamellaNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- R300823A-RR - Mukand-Sumi Wire Analysis on 8 Mm (MS02) for TSI_01Document9 pagesR300823A-RR - Mukand-Sumi Wire Analysis on 8 Mm (MS02) for TSI_01KeliyemmalNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Newly Developed Seismic Grade Reinforcing BarsDocument8 pagesWelding Newly Developed Seismic Grade Reinforcing Barsdnageshm4n244No ratings yet

- Appendix B - TP - MMSCY REV A (Material and Manufacturing Specifications For DP-Master Proprietary CY Grades For Drill Pipes)Document5 pagesAppendix B - TP - MMSCY REV A (Material and Manufacturing Specifications For DP-Master Proprietary CY Grades For Drill Pipes)EduardNo ratings yet

- Analysis Elevated Temperature Creep SteelDocument66 pagesAnalysis Elevated Temperature Creep SteelematlisNo ratings yet

- High-Temperature Tensile and Creep Data For Inconel 600Document13 pagesHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- App 1 PDFDocument2 pagesApp 1 PDFSantos RandazzoNo ratings yet

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- Load-Indicating Externally Threaded Fasteners: Standard Specification ForDocument5 pagesLoad-Indicating Externally Threaded Fasteners: Standard Specification ForAhmad Zubair RasulyNo ratings yet

- 2015 Power Sections Catalog PDFDocument274 pages2015 Power Sections Catalog PDFAnonymous VNu3ODGavNo ratings yet

- Load-Indicating Externally Threaded Fasteners: Standard Specification ForDocument4 pagesLoad-Indicating Externally Threaded Fasteners: Standard Specification ForLeviGatsosNo ratings yet

- PT/VT Transformer: Asset Parameters MFR Data Asset RatingsDocument3 pagesPT/VT Transformer: Asset Parameters MFR Data Asset RatingsMuhammad NiamNo ratings yet

- Certificado Guayas Escala Reales MT Ice VictoryDocument2 pagesCertificado Guayas Escala Reales MT Ice Victorycarlomonsalve1No ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- ML 1002007999Document169 pagesML 1002007999Sri KarthickNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- Choke and Kill Armor CK XX Armor CK Xx10k Armor QaDocument1 pageChoke and Kill Armor CK XX Armor CK Xx10k Armor Qaclaudio godinezNo ratings yet

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDocument7 pagesSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceNuNo ratings yet

- Comprehensive Report On Low Temp Solder Alloys For Portable ElectronicsDocument8 pagesComprehensive Report On Low Temp Solder Alloys For Portable ElectronicscalculathorNo ratings yet

- A A A T: A Ffilo..,: I, Iaterial OualityDocument1 pageA A A T: A Ffilo..,: I, Iaterial OualityAlessandra MoonNo ratings yet

- Technical Data Sheet Gpo-3 (Glass Polymer Laminate)Document1 pageTechnical Data Sheet Gpo-3 (Glass Polymer Laminate)macNo ratings yet

- Trunnion CalculationsDocument2 pagesTrunnion Calculationspmech consultantNo ratings yet

- MURD620CT Switchmode Power Rectifier: DPAK Surface Mount PackageDocument5 pagesMURD620CT Switchmode Power Rectifier: DPAK Surface Mount Packagetecnicogato27No ratings yet

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDocument5 pagesSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceAnant RubadeNo ratings yet

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- EGAS70CLP compressor performance and specificationsDocument5 pagesEGAS70CLP compressor performance and specificationsSamuel OsmagNo ratings yet

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNo ratings yet

- Wps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0Document3 pagesWps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0YokeshAnandNo ratings yet

- ITRZA 1789a 1000kVA 98.08.28Document4 pagesITRZA 1789a 1000kVA 98.08.28Karim RahmaniNo ratings yet

- Is 1367 13 1983Document7 pagesIs 1367 13 1983Dharmendra TomarNo ratings yet

- Welding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable CodeDocument5 pagesWelding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable Codeanon_499770No ratings yet

- Strain Gauge (SG)Document97 pagesStrain Gauge (SG)Abdi YudaNo ratings yet

- ECCC RecDocument19 pagesECCC RecsuronocaturatmojoNo ratings yet

- IRF540, RF1S540SM: 28A, 100V, 0.077 Ohm, N-Channel Power Mosfets FeaturesDocument7 pagesIRF540, RF1S540SM: 28A, 100V, 0.077 Ohm, N-Channel Power Mosfets FeaturesJuan Pablo Echeverria CockNo ratings yet

- WPS 002 ASME Section IXDocument4 pagesWPS 002 ASME Section IXIvan KawempyNo ratings yet

- Asme Section Ii A Sa-352 Sa-352m PDFDocument8 pagesAsme Section Ii A Sa-352 Sa-352m PDFdavid perezNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- TDS - Lexan HF1140-111Document2 pagesTDS - Lexan HF1140-111It WittayaNo ratings yet

- Compressor EGAS80CLPDocument5 pagesCompressor EGAS80CLPSamuel OsmagNo ratings yet

- GPP TVS data sheetDocument4 pagesGPP TVS data sheetAntonio DalioNo ratings yet

- A 571Document5 pagesA 571aniketNo ratings yet

- Practica ViscosityDocument7 pagesPractica ViscosityLorenaNo ratings yet

- Heating Wire Selection Criteria: Lamp HeaterDocument12 pagesHeating Wire Selection Criteria: Lamp HeaterwillwNo ratings yet

- Bromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric TitrationDocument10 pagesBromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric TitrationAhmedNo ratings yet

- Leakage Tendencies of Automotive Wheel Bearing Greases: Standard Test Method ForDocument8 pagesLeakage Tendencies of Automotive Wheel Bearing Greases: Standard Test Method ForAhmedNo ratings yet

- Distillation of Petroleum Products at Reduced Pressure: Standard Test Method ForDocument18 pagesDistillation of Petroleum Products at Reduced Pressure: Standard Test Method ForAhmedNo ratings yet

- Water Separability of Petroleum Oils and Synthetic Fluids: Standard Test Method ForDocument4 pagesWater Separability of Petroleum Oils and Synthetic Fluids: Standard Test Method ForMuhammad FidzrusNo ratings yet

- Refractive Index and Refractive Dispersion of Hydrocarbon LiquidsDocument7 pagesRefractive Index and Refractive Dispersion of Hydrocarbon LiquidsAhmedNo ratings yet

- Determining The Water Washout Characteristics of Lubricating GreasesDocument4 pagesDetermining The Water Washout Characteristics of Lubricating GreasesAhmedNo ratings yet

- Sampling Liquefied Petroleum (LP) Gases, Manual Method: Standard Practice ForDocument5 pagesSampling Liquefied Petroleum (LP) Gases, Manual Method: Standard Practice ForAhmedNo ratings yet

- Use of The Petroleum Measurement Tables: Standard Guide ForDocument7 pagesUse of The Petroleum Measurement Tables: Standard Guide ForIng. Adolfo GarciaNo ratings yet

- Density and Relative Density (Specific Gravity) of Liquids by Bingham PycnometerDocument5 pagesDensity and Relative Density (Specific Gravity) of Liquids by Bingham PycnometerAhmedNo ratings yet

- Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionDocument7 pagesHydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionAhmedNo ratings yet

- Measuring Apparent Viscosity of Lubricating Greases: Standard Test Method ForDocument8 pagesMeasuring Apparent Viscosity of Lubricating Greases: Standard Test Method ForAhmedNo ratings yet

- Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureDocument11 pagesWater Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureAhmedNo ratings yet

- Total Inhibitor Content (TBC) of Light Hydrocarbons: Standard Test Method ForDocument3 pagesTotal Inhibitor Content (TBC) of Light Hydrocarbons: Standard Test Method ForAhmedNo ratings yet

- Phosphorus in Lubricating Oils and Additives: Standard Test Methods ForDocument9 pagesPhosphorus in Lubricating Oils and Additives: Standard Test Methods ForAhmedNo ratings yet

- Acidity of Hydrocarbon Liquids and Their Distillation ResiduesDocument3 pagesAcidity of Hydrocarbon Liquids and Their Distillation ResiduesAhmedNo ratings yet

- Water Reaction of Aviation Fuels: Standard Test Method ForDocument3 pagesWater Reaction of Aviation Fuels: Standard Test Method ForAhmedNo ratings yet

- Cone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentDocument8 pagesCone Penetration of Lubricating Grease Using One-Quarter and One-Half Scale Cone EquipmentAhmedNo ratings yet

- Bromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric TitrationDocument10 pagesBromine Numbers of Petroleum Distillates and Commercial Aliphatic Olefins by Electrometric TitrationAhmedNo ratings yet

- Smoke Point of Kerosine and Aviation Turbine Fuel: Standard Test Method ForDocument8 pagesSmoke Point of Kerosine and Aviation Turbine Fuel: Standard Test Method ForAhmedNo ratings yet

- Gage Vapor Pressure of Liquefied Petroleum (LP) Gases (LP-Gas Method)Document5 pagesGage Vapor Pressure of Liquefied Petroleum (LP) Gases (LP-Gas Method)ahmedNo ratings yet

- Estimation of Deleterious Particles in Lubricating Grease: Standard Test Method ForDocument4 pagesEstimation of Deleterious Particles in Lubricating Grease: Standard Test Method ForAhmedNo ratings yet

- D1321Document4 pagesD1321Claudia Lisani100% (1)

- Use of The Petroleum Measurement Tables: Standard Guide ForDocument7 pagesUse of The Petroleum Measurement Tables: Standard Guide ForIng. Adolfo GarciaNo ratings yet

- Water Separability of Petroleum Oils and Synthetic Fluids: Standard Test Method ForDocument4 pagesWater Separability of Petroleum Oils and Synthetic Fluids: Standard Test Method ForMuhammad FidzrusNo ratings yet

- Refractive Index and Refractive Dispersion of Hydrocarbon LiquidsDocument7 pagesRefractive Index and Refractive Dispersion of Hydrocarbon LiquidsAhmedNo ratings yet

- Sampling Liquefied Petroleum (LP) Gases, Manual Method: Standard Practice ForDocument5 pagesSampling Liquefied Petroleum (LP) Gases, Manual Method: Standard Practice ForAhmedNo ratings yet

- Sulfur in Petroleum Products (Lamp Method) : Standard Test Method ForDocument12 pagesSulfur in Petroleum Products (Lamp Method) : Standard Test Method ForAhmedNo ratings yet

- Distillation of Petroleum Products at Reduced Pressure: Standard Test Method ForDocument18 pagesDistillation of Petroleum Products at Reduced Pressure: Standard Test Method ForAhmedNo ratings yet

- Sodium in Residual Fuel Oil (Flame Photometric Method) : Standard Test Method ForDocument3 pagesSodium in Residual Fuel Oil (Flame Photometric Method) : Standard Test Method ForahmedNo ratings yet

- Density and Relative Density (Specific Gravity) of Liquids by Bingham PycnometerDocument5 pagesDensity and Relative Density (Specific Gravity) of Liquids by Bingham PycnometerAhmedNo ratings yet

- Lecture 6-7 Synthesis of Simple Planar MechanismsDocument12 pagesLecture 6-7 Synthesis of Simple Planar MechanismsmayankmaroliyaNo ratings yet

- Resonant Column TestDocument9 pagesResonant Column TestRana SenNo ratings yet

- Bab III Teori Tentang Dioda - 2022Document32 pagesBab III Teori Tentang Dioda - 2022bwaw.samaNo ratings yet

- G10 Lesson2 DLPDocument13 pagesG10 Lesson2 DLPAngeles, Mark Allen CNo ratings yet

- Umat SANISAND README PDFDocument4 pagesUmat SANISAND README PDFDebdeep SarkarNo ratings yet

- Analysis of BeamsDocument14 pagesAnalysis of Beamsمحسن عبدالله البركيNo ratings yet

- Masara mosque-CALCULATION REPORTDocument115 pagesMasara mosque-CALCULATION REPORTmjnasar khan jamalNo ratings yet

- Chapter-4 Quantity SurveyingDocument40 pagesChapter-4 Quantity SurveyingAbdanur JihadNo ratings yet

- Kinematics in Two Dimensions: Projectile and Circular MotionDocument11 pagesKinematics in Two Dimensions: Projectile and Circular MotionKapelsuNo ratings yet

- Week 2 Examples HydraulicsDocument29 pagesWeek 2 Examples HydraulicsIvy Pearl TabagNo ratings yet

- Combined Model of LFC and Voltage Control in Matla SoftwareDocument12 pagesCombined Model of LFC and Voltage Control in Matla SoftwareMahmudul BappiNo ratings yet

- MFDSML 2024 - Iiit NRDocument2 pagesMFDSML 2024 - Iiit NRVijay GopiKrishnanNo ratings yet

- WB Harmonic Shaker TableDocument10 pagesWB Harmonic Shaker TablenetkasiaNo ratings yet

- Mitta 2021 2D Mater. 8 012002Document29 pagesMitta 2021 2D Mater. 8 012002César Arturo Niño CarmonaNo ratings yet

- Cantilever Slab DesignDocument2 pagesCantilever Slab Designsibu_bhusalNo ratings yet

- Gabriel Eugenio CHAO, Dispersive Surface Acoustic Waves in Poroelastic MediaDocument143 pagesGabriel Eugenio CHAO, Dispersive Surface Acoustic Waves in Poroelastic MediaOlegNo ratings yet

- Angle of ReposeDocument3 pagesAngle of ReposeUmar Farouq Mohammed GalibNo ratings yet

- Ce122:Hydrology: Kristine R. Cervancia, Rce, MsceDocument19 pagesCe122:Hydrology: Kristine R. Cervancia, Rce, MsceKristine CervanciaNo ratings yet

- Qualifying Exam Reviewer With Answers New Update 11Document96 pagesQualifying Exam Reviewer With Answers New Update 11Danica CatanduanesNo ratings yet

- B680 BulkDocument3 pagesB680 BulkJM ArcillaNo ratings yet

- VeriVide CAC LED Datasheet 2019Document2 pagesVeriVide CAC LED Datasheet 2019Arthur ThiesenNo ratings yet

- Metals 12 01076 v2Document20 pagesMetals 12 01076 v2Yasa CossioNo ratings yet

- Hydraulics - Civil Engineering Questions and Answers Page 3Document6 pagesHydraulics - Civil Engineering Questions and Answers Page 3umairNo ratings yet

- Nucl - Phys.B v.604Document614 pagesNucl - Phys.B v.604buddy72No ratings yet

- JZC-11F (8208) : Subminiature DC Electromagnetic RelayDocument2 pagesJZC-11F (8208) : Subminiature DC Electromagnetic RelayserjimenezNo ratings yet

- Phase-Field Simulation of Solidification 1Document37 pagesPhase-Field Simulation of Solidification 1戴海龙No ratings yet

- Week 7-Transformers Voltage Regulation and Per Unit calculations-ELEC2300Document30 pagesWeek 7-Transformers Voltage Regulation and Per Unit calculations-ELEC2300Look AxxNo ratings yet