Professional Documents

Culture Documents

Appendix B - TP - MMSCY REV A (Material and Manufacturing Specifications For DP-Master Proprietary CY Grades For Drill Pipes)

Uploaded by

EduardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix B - TP - MMSCY REV A (Material and Manufacturing Specifications For DP-Master Proprietary CY Grades For Drill Pipes)

Uploaded by

EduardCopyright:

Available Formats

Material and Manufacturing Specifications for DP-Master

Proprietary CY Grades for Drill Pipes

Technical

document No #

TP.MMSCY REV A

Material and Manufacturing Specifications for

DP-Master Proprietary CY Grades for Drill Pipes PREPARED BY Stephen Chang 28 Jan 2018

APPROVED BY Veronica Fong 28 Jan 2018

Revision History

Effective Rev Referenced

Changes Prepared By Approved By

Date No. Sections

28 Jan 2018 A Original Release Original Release Stephen Chang Veronica Fong

1.0 Scope

The following specification details the material requirements for DP-Master (DPM) proprietary

CY grades for drill pipes. This procedure shall be used to assure DP-Master‘s manufacturing

process is complete and correct. The specification does not supersede or preclude the use of

customer specifications detailed in the purchase agreement. Please contact DPM Technical

Support for any doubts or if the specific material grade is not specified in this specification.

2.0 Applicable Specifications

2.1 API Specification 5DP / ISO11961 (Latest Edition)

2.2 NACE TM0177 (Latest Edition)

3.0 Material Requirements

3.1 Chemical Composition

The chemical composition for drill pipe tube and tool joints shall be as per Table

1. Each heat used in the manufacture of tube and tool joints shall be analysed to

provide the results of quantitative determinations of phosphorous and sulphur

conforming to Table 1.

Chemical Composition

Phosphorus Sulfur

Max Max

0.02% 0.015%

Table 1

Chemical Composition for Drill Pipe Tube and Tool Joints

3.2 Tensile Requirements

Tensile tests shall be performed at room temperature in accordance with ASTM

A370.

DP-MASTER MANUFACTURING (S) PTE LTD 1 of 5

Material and Manufacturing Specifications for DP-Master

Proprietary CY Grades for Drill Pipes

The test results shall be as a minimum establish the tensile strength, yield

strength and elongation complying with the requirements of Table 2 (Tube),

Table 3 (Tool Joint) and Table 4 (Weld Area). The yield load of the weld zone in

tension shall be greater than the yield load of the tube as per API 5DP.

Tensile Requirements (Tube)

Tensile Test

Yield Strength Elongation

Strength Frequency

Min Max Min Min

120 Ksi 140 Ksi 130 Ksi One per 200

DPM-CY120(N) API

827 MPa 965 MPa 896 MPa or per lot

105 Ksi 120 Ksi 115 Ksi One per 200

DPM-CY105(N) API

724 MPa 827 MPa 793 MPa or per lot

95 Ksi 110 Ksi 105 Ksi One per 200

DPM-CY95(N) API

655 MPa 758 MPa 724 MPa or per lot

Table 2

Tensile Requirements (Tube)

Tensile Requirements (Tool Joint)

Tensile

Yield Strength Elongation Test Frequency

Strength

Min Max Min Min

Welded Drill Pipe &

105 Ksi 115 Ksi 120 Ksi One per 200 or

Pup Joint Tool Joints API

724 MPa 793 MPa 827 MPa per lot

(CY Grade – 105 KSI)

Welded Drill Pipe &

110 Ksi 125 Ksi 125 Ksi One per 200 or

Pup Joint Tool Joints API

758 MPa 862 MPa 862 MPa per lot

(CY Grade – 110 KSI)

Welded Drill Pipe &

115 Ksi 130 Ksi 130 Ksi One per 200 or

Pup Joint Tool Joints API

793 MPa 896 MPa 896 MPa per lot

(CY Grade – 115 KSI)

Welded Drill Pipe &

120 Ksi 135 Ksi 140 Ksi One per 200 or

Pup Joint Tool Joints API

827 MPa 931 MPa 965 MPa per lot

(CY Grade – 120 KSI)

Welded Drill Pipe &

120 Ksi 140 Ksi One per 200 or

Pup Joint Tool Joints - API

827 MPa 965 MPa per lot

(API TJ – 120 KSI)

Table 3

Tensile Requirements (Tool Joint)

DP-MASTER MANUFACTURING (S) PTE LTD 2 of 5

Material and Manufacturing Specifications for DP-Master

Proprietary CY Grades for Drill Pipes

Tensile Requirements (Weld Area)

Elongation

Yield Strength Test Frequency

Min

One per 400

Weld Area (Yw x Aw) ≥ (Ymin x Adp) As per API 5DP API welds or per

weld lot

Table 4

Tensile Requirements (Weld Area)

3.3 Hardness

Tool Joints:

Hardness tests on tool joints shall be performed at room temperature as

specified by API 5DP. In through wall hardness verification, the maximum

average hardness should not exceed 32.0 HRC. Testing frequency should be

one through wall hardness test every 200 tool joint box/pin or per lot.

Weld Zone:

Hardness tests on weld zone shall be performed at room temperature as

specified by API 5DP. The maximum outside surface hardness should not

exceed 37.0 HRC. This should be done for all welds at 3 locations 120o apart.

Maximum average for through-wall hardness should not exceed 37.0 HRC.

Testing frequency should be one through wall hardness test for every 400 welds

or per weld lot.

3.4 Charpy V-notch Absorbed-energy Requirement

The minimum absorbed-energy requirements shall be as in Table 5. Testing

should be performed as specified in API 5DP.

In addition, not more than one impact specimen shall exhibit an absorbed energy

below the minimum average absorbed-energy requirement, and in no case shall

an individual impact specimen exhibit an absorbed below the minimum specimen

absorbed-energy requirement.

DP-MASTER MANUFACTURING (S) PTE LTD 3 of 5

Material and Manufacturing Specifications for DP-Master

Proprietary CY Grades for Drill Pipes

Charpy V-notch Impact Energy (LCVN)

Average of

Single Test Specimen

3 Test Frequency

Reading Temperature Size

Specimens

Min Min Max

59 ft-lbs 48 ft-lbs 70 °F 10 mm x

Tubes One per 200 or per lot

80 J 65 J 21 °C 10 mm

40 ft-lbs 35 ft-lbs 70 °F 10 mm x

Tool Joints One per 200 or per lot

54 J 47 J 21 °C 10 mm

12 ft-lbs 10 ft-lbs 70 °F 10 mm x One per 400 or per weld

Weld Zone

16 J 14 J 21 °C 10 mm lot

Table 5

Charpy V-notch Absorbed-energy Requirement for DPM proprietary CY Grade

4.0 NACE Testing

All NACE tests if required should be in accordance to NACE TM0177 (720 hours) unless

specified. Testing requirements shall be as per Table 6.

NACE Testing Requirements When Specified

NACE NACE

Capability TM0177 TM0177 Specimen

Test Test

%SMYS Method Solution Size

70% Full Size

CYN Tubes Method A Solution A

(63%) (3.81mm dia.)

CYN Tool Joints 65% Method A Solution D Full Size

Table 6

NACE Testing Requirements for CYN Tubes and Tool Joints

5.0 Manufacturing and Inspection

Manufacturing and Inspection as per API 5DP unless otherwise specified by the customer and

stated in the Purchase Order.

DP-MASTER MANUFACTURING (S) PTE LTD 4 of 5

Material and Manufacturing Specifications for DP-Master

Proprietary CY Grades for Drill Pipes

6.0 Rejection

Any material that is out of the specified tolerance shall be rejected.

7.0 Documentation

Mill certificates and material test reports shall be retained by the manufacturer or processing

facility and be fully traceable to each individual component threaded with rotary shouldered

connections.

Said documentation shall be retained for five (5) years.

8.0 Marking

Drill pipes manufactured to DPM-CY grade shall be stencilled on the exterior of the drill pipe as

per API 5DP and include the DPM-CY grade. Example shown below for 5” 19.5# DP DPM-

CY120N PSL-1:

DPM API 5DP DATE 5” 19.5 DPM-CY120N PSL-1

DP-MASTER MANUFACTURING (S) PTE LTD 5 of 5

You might also like

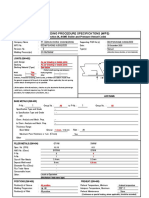

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- QPT Charts BarDocument8 pagesQPT Charts BarKacak BergayaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Quantities Survey MethodsDocument73 pagesQuantities Survey MethodsparvezNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- 7) Bolt & Nut Sample MTC 3.1 - AIIDocument2 pages7) Bolt & Nut Sample MTC 3.1 - AIITri Aditha NugrahaNo ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- Hungr Et Al 2005 - Landslide Travel DistanceDocument30 pagesHungr Et Al 2005 - Landslide Travel DistanceJosé Ignacio RamírezNo ratings yet

- 4G Fcaw WPSDocument3 pages4G Fcaw WPSdjafourNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Welding Prosedur Specification Wps Pre QualifiedDocument8 pagesWelding Prosedur Specification Wps Pre QualifiedryanonedNo ratings yet

- 5 6129845971313492097 PDFDocument5 pages5 6129845971313492097 PDFCangkang SainsNo ratings yet

- API 510 Data SheetsDocument11 pagesAPI 510 Data SheetshahahNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Material Specification & TestDocument3 pagesMaterial Specification & TestmunimiutNo ratings yet

- Er Spine JV RFQ 110 2 - SupplierDocument10 pagesEr Spine JV RFQ 110 2 - Supplierحسام رسميNo ratings yet

- Driscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetDocument2 pagesDriscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetmariannyNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Arwana Home Booster Pump APP-pw-125Document2 pagesArwana Home Booster Pump APP-pw-125LarryMatiasNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- Prepared By: Certified By: Witnessed byDocument1 pagePrepared By: Certified By: Witnessed bySudhir KotkarNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)Document4 pagesQw-483 Suggested Format For Welding Procedure Qualification Records (PQR)aliNo ratings yet

- 5.5 DPDocument20 pages5.5 DPGobinda SinhaNo ratings yet

- Anexo 4 - Dimensionamiento PSV-7004 1Document2 pagesAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- 12 Samss 018Document4 pages12 Samss 018Dhaval PatelNo ratings yet

- Pipeliner 70S-G: Conformances Key FeaturesDocument2 pagesPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Wps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0Document3 pagesWps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0YokeshAnandNo ratings yet

- QCSDocument1 pageQCSashNo ratings yet

- Schott KyDocument7 pagesSchott KysateeshNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- P91TPDocument37 pagesP91TPPhong ĐỗNo ratings yet

- TPG 150 KV LADocument1 pageTPG 150 KV LANobel Paul SimorangkirNo ratings yet

- LANWA Product Portfolio Final-LoresDocument20 pagesLANWA Product Portfolio Final-Loreschanna hettiarachchiNo ratings yet

- Rep PQR 02Document3 pagesRep PQR 02shaniraj BirajdarNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- WPS Mig 2Document1 pageWPS Mig 2rafetguzelsoyNo ratings yet

- Welder Qualification FormatDocument1 pageWelder Qualification FormatScribdTranslationsNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- A 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqDocument11 pagesA 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqrolando cuadro blancoNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedNo ratings yet

- DataSheet L3HC 140-225 AHOKVO-GDocument1 pageDataSheet L3HC 140-225 AHOKVO-GJAC 91No ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Vgsi PL Te Report 200420 Pile StrengthDocument19 pagesVgsi PL Te Report 200420 Pile StrengthTruyền NguyễnNo ratings yet

- Gas-Insulated Switchgear Type 8DQ1: Technical DataDocument2 pagesGas-Insulated Switchgear Type 8DQ1: Technical DataLalit KotturiNo ratings yet

- Cybenetics - Evaluation - Report - Corsair - RM1200x (Shift)Document17 pagesCybenetics - Evaluation - Report - Corsair - RM1200x (Shift)bassamNo ratings yet

- Pressure Relief Valve Scenario Summary: General Job DataDocument6 pagesPressure Relief Valve Scenario Summary: General Job DatajorgekarlosprNo ratings yet

- Pages From A115-Ca902 - En-D Nema Motor ControlDocument16 pagesPages From A115-Ca902 - En-D Nema Motor Controlpamav10892No ratings yet

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- Acy 428Document1 pageAcy 428EduardNo ratings yet

- TSH-AR-00.0005 Rev.5Document10 pagesTSH-AR-00.0005 Rev.5EduardNo ratings yet

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- DR 039 00184Document2 pagesDR 039 00184EduardNo ratings yet

- Emdqp Ins 212Document20 pagesEmdqp Ins 212EduardNo ratings yet

- IOA 21073 Rev 1Document2 pagesIOA 21073 Rev 1EduardNo ratings yet

- EMDC DQT Well Asset Daily Reporting SpreadsheetDocument42 pagesEMDC DQT Well Asset Daily Reporting SpreadsheetEduardNo ratings yet

- Inspection Report: Wesco LLCDocument8 pagesInspection Report: Wesco LLCEduardNo ratings yet

- Emdqp Ins 211Document10 pagesEmdqp Ins 211EduardNo ratings yet

- EMAR 01 Rev01 FINALDocument12 pagesEMAR 01 Rev01 FINALEduardNo ratings yet

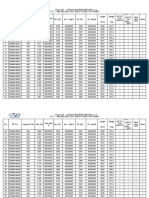

- TALLY LIST PO 2613.2A.9A.10A - 5-1.2' Welded Drill Pipe ST-52ZADDocument114 pagesTALLY LIST PO 2613.2A.9A.10A - 5-1.2' Welded Drill Pipe ST-52ZADEduardNo ratings yet

- Al Nasr Metal Industries Location MapDocument1 pageAl Nasr Metal Industries Location MapEduardNo ratings yet

- ATTA-Quality Plan-19-001Rev.01-signedDocument5 pagesATTA-Quality Plan-19-001Rev.01-signedEduardNo ratings yet

- EMDC DQT Well Asset Daily Reporting Spreadsheet - IOA21073Document42 pagesEMDC DQT Well Asset Daily Reporting Spreadsheet - IOA21073EduardNo ratings yet

- Emdqp Ins 215Document16 pagesEmdqp Ins 215EduardNo ratings yet

- UnpricedDocument4 pagesUnpricedEduardNo ratings yet

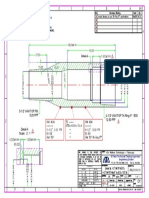

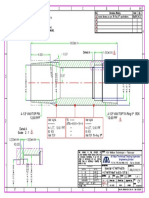

- ATTA.D.0193.18 Rev 01 - Crossover Sub, 3.50 VAM TOP PIn #9.20 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALDocument1 pageATTA.D.0193.18 Rev 01 - Crossover Sub, 3.50 VAM TOP PIn #9.20 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALEduardNo ratings yet

- ATTA.D.0192.18 Rev 01 - Crossover Sub, 4.50 VAM TOP PIn #12.60 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALDocument1 pageATTA.D.0192.18 Rev 01 - Crossover Sub, 4.50 VAM TOP PIn #12.60 X 4.50 VAM TOP TK-Ring II Box #12.60 X 18.00 OALEduardNo ratings yet

- Emtmp Pur 205Document3 pagesEmtmp Pur 205EduardNo ratings yet

- Emtmp Pur 204Document2 pagesEmtmp Pur 204EduardNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- WFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 30th.Document1 pageWFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 30th.EduardNo ratings yet

- Serial Number Thread Depth Before CW Thread Depth After CW W18AFM0115 0.01 0.04 W18AFM0141 0.015 0.05 W18AFM0151 0.01 0.045Document1 pageSerial Number Thread Depth Before CW Thread Depth After CW W18AFM0115 0.01 0.04 W18AFM0141 0.015 0.05 W18AFM0151 0.01 0.045EduardNo ratings yet

- Appendix A - Sample Original Records of Upsetting and Welding InspectionDocument2 pagesAppendix A - Sample Original Records of Upsetting and Welding InspectionEduardNo ratings yet

- DPM04196394 - Material Test CertificatesDocument7 pagesDPM04196394 - Material Test CertificatesEduardNo ratings yet

- WFT SOW - 7'' Liner Hanger - 08082021Document1 pageWFT SOW - 7'' Liner Hanger - 08082021EduardNo ratings yet

- WFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 16th.Document1 pageWFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 16th.EduardNo ratings yet

- WFT SOW - QAQC For 2x 8" Jar For 23" BHA On 25th Oct (Tue) - 2022Document1 pageWFT SOW - QAQC For 2x 8" Jar For 23" BHA On 25th Oct (Tue) - 2022EduardNo ratings yet

- Opatch AutoDocument2 pagesOpatch Autoshuvo_ami24No ratings yet

- Lec1 PDFDocument12 pagesLec1 PDFtogarsNo ratings yet

- Lecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) PDFDocument64 pagesLecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) PDFNafees KhanNo ratings yet

- Comparative Study of Steel Structure With and Without Floating Columns in EtabsDocument13 pagesComparative Study of Steel Structure With and Without Floating Columns in EtabsBehroz BehzadNo ratings yet

- Change LogDocument3 pagesChange Logyoga hendriyantoNo ratings yet

- Dawn C. Meredith, Meaning MakingDocument2 pagesDawn C. Meredith, Meaning MakingMrsriyansyahNo ratings yet

- The Kemetic Tree of LifeDocument1 pageThe Kemetic Tree of LifeFlorin CiudinNo ratings yet

- 1 s2.0 0304386X9190055Q MainDocument32 pages1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- 15Document20 pages15Allen Rey YeclaNo ratings yet

- 23AE23 DS enDocument4 pages23AE23 DS enBhageerathi SahuNo ratings yet

- JPSP - 2022 - 698Document10 pagesJPSP - 2022 - 698hifeztobgglNo ratings yet

- InfoDocument18 pagesInfoKaran Verm'aNo ratings yet

- MA201 Mechanical Vertical Machining Center 133-134Document2 pagesMA201 Mechanical Vertical Machining Center 133-134Ali HashmiNo ratings yet

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- Real Time Operating SystemsDocument15 pagesReal Time Operating SystemsSaro VrsNo ratings yet

- FP 3000 PDFDocument1 pageFP 3000 PDFClaudio Godoy ZepedaNo ratings yet

- FST 3000Document4 pagesFST 3000ariksyaiful82No ratings yet

- Sci - Short Circuit IsolatorDocument2 pagesSci - Short Circuit IsolatorVictor MoraesNo ratings yet

- HydrometerDocument13 pagesHydrometerShubhrajit MaitraNo ratings yet

- JSF + JPA + JasperReports (Ireport) Part 2 - Ramki Java BlogDocument7 pagesJSF + JPA + JasperReports (Ireport) Part 2 - Ramki Java BlogMartin MurciegoNo ratings yet

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraNo ratings yet

- Auto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3Document4 pagesAuto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3sharawany 20No ratings yet

- HV Filter Carts 1Document2 pagesHV Filter Carts 1paulpopNo ratings yet

- Mathematical Analysisand Optimizationfor EconomistsDocument4 pagesMathematical Analysisand Optimizationfor EconomistsGuillermo GómezNo ratings yet

- Pavement Materials - AggregatesDocument14 pagesPavement Materials - AggregatestombasinghNo ratings yet

- Agfa CR 10XDocument4 pagesAgfa CR 10Xwisateru Inti niagaNo ratings yet

- Dot NetDocument9 pagesDot NetSuruBabuThalupuruNo ratings yet