Professional Documents

Culture Documents

6064 - Catalog - PB-1.4 February 2006

Uploaded by

Alfonso López JiménezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6064 - Catalog - PB-1.4 February 2006

Uploaded by

Alfonso López JiménezCopyright:

Available Formats

Phone: (909) 982-1555

Daniel Mechanical Company Fax: (909) 982-1855

1939 West 11th Street Ste. E danmech@sbcglobal.net

Upland, CA 91786 www.danielmechanical.com

Round Fiberglass Reinforced Plastic Air Control Dampers

PB-1.4 Daniel Mechanical Company February 2006

MODEL 203 ROUND FRP AIR CONTROL DAMPER

DANIEL MECHANICAL COMPANY offers 500 procedures and the certified ratings are

precision-engineered FRP butterfly dampers utilizing authorized by AMCA. Damper blade is operated

only highly corrosion resistant parts for air movement using hand lever with locking quadrant. Worm gear

and controls. Dampers are fire retardant, corrosion operators of the pneumatic, electric or hand-operated

resistant, and UV protected. Components are with chain-wheel types are also offered. Long life

designed with replaceable parts for ease of Teflon bearings and custom-designed molded plastic

disassembly. The options of having 316 SST or FRP bushings, located on the exterior of damper, require

blade shafts are available. Additionally, exotic and minimal maintenance and ensure continuous free

corrosion resistant elastomers such as Viton, Hypalon movement of the blade. Stops, (stiffeners as

or EPDM may be selected depending on the process. required), are used to support and seat the FRP blade.

Blades are equipped with circumferential seals for All metal parts are at a minimum 316 stainless steel.

low leakage. Leakage rates are tested using AMCA Dampers range from sizes 4” diameter to 60”

diameter.

STANDARD CONSTRUCTION

FRAME Vinyl ester resin fabricated to ASME/ANSI RTP1

FLANGE NBS PS 15-69-3.4.7 – Integral to web lay-up. ¾” thick with custom-made flange O.D. & I.D.

dimensions to match mating pipe or duct

BLADE Vinyl ester resin similar to damper frame with EPDM blade seal and full circle back stop

AXLE 316 SST with nuts, bolts, and washers (FRP encapsulated if required) or FRP

BEARING TEFLON

HAND LEVER 316 SST with FRP locking quadrant

COLOR White unless specified otherwise

MAXIMUM TEMPERATURE 200°F

MAXIMUM PRESSURE 30” w.g.

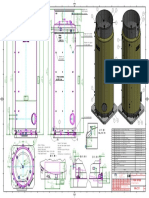

BUTTERFLY DAMPER DETAIL DRAWING

FLANGES AND

BOLT HOLES

PER NBS PS 15-69

TABLE 2 316 SST NUTS, “C”

BOLTS, AND WASHERS

1/4" THICK

EPDM

360° RING

FRP

BACK STOP

I.D.

“B” B.C. O.D.

STANDARD

LOCKING

QUADRANT

316 SST HANDLE

“A”

TOP VIEW SIDE VIEW

PB-1.4 Daniel Mechanical Company February 2006

BUTTERFLY DAMPER DIMENSIONS

SIZES FLANGE FLANGE BOLT BOLT # OF BLADE AXLE “A” “B” “C”

THICKNESS O.D. CIRCLE HOLE BOLT THICKNESS DIA.

DIA. HOLES

6” ¾” 10 3/8” 9” 7/16” 8 3/8” ¾” 6.5” 8” 6”

8” ¾” 12 3/8” 11” 7/16” 8 3/8” ¾” 6.5” 8” 6”

10” ¾” 14 3/8” 13” 7/16” 12 3/8” ¾” 6.5” 8” 12”

12” ¾” 16 3/8” 15” 7/16” 12 3/8” 1” 6.5” 8” 12”

14” ¾” 18 3/8” 17” 7/16” 12 3/8” 1” 6.5” 8” 12”

16” ¾” 20 3/8” 19” 7/16” 16 3/8” 1” 6.5” 8” 12”

18” ¾” 22 3/8” 21” 7/16” 16 3/8” 1 ¼” 6.5” 8” 12”

20” ¾” 24 3/8” 23” 7/16” 20 3/8” 1 ¼” 6.5” 8” 12”

24” ¾” 28 3/8” 27” 7/16” 20 3/8” 1 ¼” 6.5” 8” 12”

30” ¾” 34 3/8” 33” 7/16” 28 3/8” 1 ¼” 6.5” 8” 12”

36” ¾” 40 3/8” 39” 7/16” 32 ½” 1 ¼” 7.5” 8” 12”

42” ¾” 46 3/8” 45” 7/16” 36 ½” 1 7/8” 7.5” 8” 12”

48” ¾” 54 3/8” 52” 9/16” 44 ½” 1 7/8” 7.5” 8” 12”

54” ¾” 60 3/8” 58” 9/16” 44 ½” 1 7/8” 7.5” 8” 12”

60” ¾” 66 3/8” 64” 9/16” 52 ½” 1 7/8” 7.5” 8” 12”

SUGGESTED SPECIFICATIONS FOR ROUND FRP AIR CONTROL DAMPERS

Dampers are installed as shown on plans and per diameter size of 8 inches or less. All other sizes shall be

specifications. Damper frame shall be of one-piece 12 inches long. The damper blade and stiffeners shall be

construction with a resin rich interior corrosion barrier fabricated using the same resin as the damper frame.

minimum of 100 mils. A structural lay-up shall consist of Blade axle shall be made of FRP or 316 SST.

alternate layers of chopped strand mat and woven roving

to conform to ASME/ANSI RTP1 and NBS PS 15-69. Damper shall be provided with a stainless steel hand-

The glass to resin ratio shall be a minimum of 35% and locking quadrant or other actuation devices as required.

65%, respectively. All metal parts shall be at a minimum 316 SST.

The fiberglass flange dimensions shall be per NBS PS 15- Exterior surface of damper shall contain UV inhibitor,

69 Table 2 for diameters and bolthole drilling pattern. The and be gel coated with color to match existing ducting.

flanges shall have a minimum thickness of 3/4 inch and

shall be constructed integral to the cylindrical body of the FRP dampers shall be tested for pressure drop and

damper, using the hand lay-up technique per ASME RTP- leakage in accordance with AMCA Standard 500. Test

1-2000 standard Fig 4-7. The distance between the faces results are shown in the section below.

of the flanges shall be 6 inches for dampers having a

CERTIFIED RATINGS AUTHORIZED BY AMCA

Damper Torque Leakage Blade Fixed Open

Diameter IN LBS Class ΔPs CFM

(Blade Closed)

4” 68 1 - -

12” 210 1 2.42 3,238

24” 525 1 1.91 11,171

36” 788 1 2.76 27,960

48” 1,053 1 - -

Daniel Mechanical Company certifies that the Model 203 dampers shown herein are licensed to bear the AMCA Seal. The ratings shown are based on

tests and procedures performed in accordance with AMCA Publication 511 and comply with the requirements of the AMCA Certified Ratings

Program. The AMCA Certified Ratings Seal applies to air performance and air leakage ratings.

Test method is per AMCA Standard 500-89 Figures 5.4 & 6.3 for blade fixed open, and Figures 5.5 & 6.5 for blade closed. Data are based on a seating

torque of chart listed in-lbs applied to hold the damper in the closed position. Air leakage is based on operation between 50°F - 104°F.

PB-1.4 Daniel Mechanical Company February 2006

Daniel Mechanical Company

1939 West 11th Street Ste. E

Upland, CA 91786

Phone: (909) 982-1555 Fax: (909) 982-1855

E-mail: danmech@sbcglobal.net

Http://www.danielmechanical.com

PB-1.4 Daniel Mechanical Company February 2006

You might also like

- Paracord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsFrom EverandParacord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsRating: 4.5 out of 5 stars4.5/5 (2)

- Sampling of Gold BullionDocument30 pagesSampling of Gold BullionOIL TEST INTERNACIONAL DE COLOMBIA S.A.SNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- VESFG001Document60 pagesVESFG001romeo112976100% (2)

- Graseras AlemitesDocument37 pagesGraseras Alemitesjoroma58No ratings yet

- CDR Tee StrainersDocument2 pagesCDR Tee StrainersM JohnNo ratings yet

- Test Plug BrochureDocument4 pagesTest Plug BrochuresitaNo ratings yet

- Section 10Document53 pagesSection 10Palmério CarvalhoNo ratings yet

- 05 DP 2015 WebDocument34 pages05 DP 2015 WebJesus RoaNo ratings yet

- Drilling Hole Opener WebDocument2 pagesDrilling Hole Opener WebBehrangNo ratings yet

- Elevator Buckets: Proven PerformanceDocument2 pagesElevator Buckets: Proven PerformancenestorNo ratings yet

- Fittingsatco Fittings CatalogDocument36 pagesFittingsatco Fittings CatalogNikko MartinezNo ratings yet

- AMICO - Grating Stair Tread SectionDocument12 pagesAMICO - Grating Stair Tread SectionwijayanataNo ratings yet

- Gland Spec.Document9 pagesGland Spec.Muthuvel GaneshNo ratings yet

- Dremel 2012AccessoryPosterDocument1 pageDremel 2012AccessoryPosterwdowiuueNo ratings yet

- Craftsman CatalogueDocument2 pagesCraftsman CatalogueRiki NurzamanNo ratings yet

- DIN 3015 Clamp Guide for Pipes & HosesDocument32 pagesDIN 3015 Clamp Guide for Pipes & Hosesxuanphuong2710No ratings yet

- Flatness tolerance chartDocument2 pagesFlatness tolerance charteko wahyudiNo ratings yet

- API Casing Float Collar and ShoeDocument2 pagesAPI Casing Float Collar and Shoeisrar haiderNo ratings yet

- Max LifeDocument16 pagesMax LiferyanvlopezNo ratings yet

- Ring Gaskets For 125 LBDocument4 pagesRing Gaskets For 125 LBdjvhNo ratings yet

- Orifice PDFDocument11 pagesOrifice PDFb_wooNo ratings yet

- Tchart PDFDocument3 pagesTchart PDFferdyak1No ratings yet

- Kant-Twist Clamps: Specifications SheetDocument3 pagesKant-Twist Clamps: Specifications SheetOmegacoolNo ratings yet

- EN SS 1025 4 - VariGripDocument4 pagesEN SS 1025 4 - VariGripDemir KarahanNo ratings yet

- Material EsDocument4 pagesMaterial EsPROCO PETNo ratings yet

- ANSI B16.5 Flange Dimensions and Specifications GuideDocument5 pagesANSI B16.5 Flange Dimensions and Specifications GuideClic CsiNo ratings yet

- 0078Document1 page0078buddhansamratNo ratings yet

- 2022-08-15 Bha #8Document2 pages2022-08-15 Bha #8B fattahiNo ratings yet

- Catalogo Dixon Swivels 2007Document48 pagesCatalogo Dixon Swivels 2007victor barreraNo ratings yet

- S12XL 2010 PartsDocument221 pagesS12XL 2010 PartsJuan Ignacio OlariNo ratings yet

- MODELS 4, 6, 8 High-Capacity Strainers and FiltersDocument6 pagesMODELS 4, 6, 8 High-Capacity Strainers and Filterspeter2mNo ratings yet

- Tra Ning On WeldingDocument56 pagesTra Ning On WeldingcarlosNo ratings yet

- CarDocument5 pagesCarHarish GundaNo ratings yet

- Multi-Purpose Hand Benders for Metal FormingDocument2 pagesMulti-Purpose Hand Benders for Metal FormingursindNo ratings yet

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDocument33 pagesASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesNo ratings yet

- DFC Manual Gate ValvesDocument5 pagesDFC Manual Gate ValvesShag ShaggyNo ratings yet

- Cementing ToolsDocument107 pagesCementing Toolswalter acero orpesaNo ratings yet

- 2016 Top 900 PricelistDocument19 pages2016 Top 900 Pricelistapi-317879840No ratings yet

- Fire Damper Construction and Installation SpecificationsDocument7 pagesFire Damper Construction and Installation SpecificationsAmr Adeeb Abd-ElaahNo ratings yet

- material list chiltronDocument2 pagesmaterial list chiltronPepe GuaraNo ratings yet

- Bill of Material for Valves and PipingDocument3 pagesBill of Material for Valves and PipingBhupatiNo ratings yet

- Union Flexible DuctilDocument1 pageUnion Flexible DuctilAnoe NYNo ratings yet

- Asme Ansi b16.11 Fittings Dimension PDFDocument38 pagesAsme Ansi b16.11 Fittings Dimension PDFleon057No ratings yet

- Catalog - GLT Gate ValveDocument9 pagesCatalog - GLT Gate Valveyudii.hidayatNo ratings yet

- ABGURT Stock List For NF PG, ASCO Valve, Tel Tru TM, Hy-Lok Fitting, Vega, Autrol & OmalDocument10 pagesABGURT Stock List For NF PG, ASCO Valve, Tel Tru TM, Hy-Lok Fitting, Vega, Autrol & OmalabdullatifatifNo ratings yet

- Podkop 1Document20 pagesPodkop 1Olin Stej80% (5)

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionAlvaro Enrique MuñozNo ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionHarish Chandra Singh0% (1)

- SST74 (Double) - Scania R580 (4 Axle) Dolly 50Document3 pagesSST74 (Double) - Scania R580 (4 Axle) Dolly 50Felix andreasNo ratings yet

- Formulas, Facts and Figures PDFDocument13 pagesFormulas, Facts and Figures PDFश्रीराज् कथलियिल्No ratings yet

- Fragola Performance CatalogDocument64 pagesFragola Performance CatalogChad MarNo ratings yet

- Fabral 2.5 SSRDocument19 pagesFabral 2.5 SSRAndrewNo ratings yet

- Update Stock Material Pemboran (29 Agustus 2017)Document230 pagesUpdate Stock Material Pemboran (29 Agustus 2017)arrelandrawanNo ratings yet

- Manway Davits ZimmerlinCatalogDocument64 pagesManway Davits ZimmerlinCatalogAnandKumarRavindranNo ratings yet

- AP-53 Bulk Feed Tanks (Brochure)Document4 pagesAP-53 Bulk Feed Tanks (Brochure)Ovidiu RaicovNo ratings yet

- AlemitesDocument30 pagesAlemitesmaximilianoNo ratings yet

- 1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsDocument3 pages1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsfatherbyteNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- CUSA SPEC FRP-001AA-11-11 Pipe FittingsDocument10 pagesCUSA SPEC FRP-001AA-11-11 Pipe FittingsAbbasNo ratings yet

- Kura 27.09.2021 27.09.2021 17.08.2021 KURA Kura - : M (Medium)Document1 pageKura 27.09.2021 27.09.2021 17.08.2021 KURA Kura - : M (Medium)Alfonso López JiménezNo ratings yet

- PO 5386579 Signed AcceptanceDocument1 pagePO 5386579 Signed AcceptanceAlfonso López JiménezNo ratings yet

- CUSA SPEC FRP-001AA-11-11 Pipe FittingsDocument10 pagesCUSA SPEC FRP-001AA-11-11 Pipe FittingsAbbasNo ratings yet

- John Zink Supplier Parts OrderDocument1 pageJohn Zink Supplier Parts OrderAlfonso López JiménezNo ratings yet

- Dispersant (T-2800000) RevADocument1 pageDispersant (T-2800000) RevAAlfonso López JiménezNo ratings yet

- Latex (T-2710400 T-2710500) - RevaDocument1 pageLatex (T-2710400 T-2710500) - RevaAlfonso López JiménezNo ratings yet

- Manways Brochure 2017Document1 pageManways Brochure 2017Alfonso López JiménezNo ratings yet

- Sodium Hydrochloride (T-2850000) - RevaDocument1 pageSodium Hydrochloride (T-2850000) - RevaAlfonso López JiménezNo ratings yet

- UF Resin (T-2710100 T-2710200 T-2710300) - RevaDocument1 pageUF Resin (T-2710100 T-2710200 T-2710300) - RevaAlfonso López JiménezNo ratings yet

- Asme in de CodeDocument4 pagesAsme in de CodeAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev CDocument8 pagesMemory of Mechanical Calculations - SN Tank - Rev CAlfonso López JiménezNo ratings yet

- Water tank assembly diagramDocument1 pageWater tank assembly diagramAlfonso López JiménezNo ratings yet

- UF Resin (T-2710100 T-2710200 T-2710300) - RevaDocument1 pageUF Resin (T-2710100 T-2710200 T-2710300) - RevaAlfonso López JiménezNo ratings yet

- Latex (T-2710400 T-2710500) - RevaDocument1 pageLatex (T-2710400 T-2710500) - RevaAlfonso López JiménezNo ratings yet

- Cable ladder bracket supportDocument1 pageCable ladder bracket supportAlfonso López JiménezNo ratings yet

- Static calculation for thermoplastic cylindrical tankDocument19 pagesStatic calculation for thermoplastic cylindrical tankAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev CDocument9 pagesMemory of Mechanical Calculations - SN Tank - Rev CAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev BDocument8 pagesMemory of Mechanical Calculations - SN Tank - Rev BAlfonso López JiménezNo ratings yet

- Dispersant (T-2800000) RevADocument1 pageDispersant (T-2800000) RevAAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev BDocument8 pagesMemory of Mechanical Calculations - SN Tank - Rev BAlfonso López JiménezNo ratings yet

- Cable ladder bracket supportDocument1 pageCable ladder bracket supportAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev DDocument9 pagesMemory of Mechanical Calculations - SN Tank - Rev DAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev CDocument9 pagesMemory of Mechanical Calculations - SN Tank - Rev CAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev CDocument9 pagesMemory of Mechanical Calculations - SN Tank - Rev CAlfonso López JiménezNo ratings yet

- Memory of Mechanical Calculations - SN Tank - Rev CDocument9 pagesMemory of Mechanical Calculations - SN Tank - Rev CAlfonso López JiménezNo ratings yet

- Mechanical Calculations for Fiberglass Tank ManufacturingDocument7 pagesMechanical Calculations for Fiberglass Tank ManufacturingAlfonso López JiménezNo ratings yet

- Mechanical Calculations for Fiberglass Tank ManufacturingDocument7 pagesMechanical Calculations for Fiberglass Tank ManufacturingAlfonso López JiménezNo ratings yet

- Importers, Stockiest & Suppliers of Ferrous, Non Ferrous Metals & Industrial Raw MaterialsDocument22 pagesImporters, Stockiest & Suppliers of Ferrous, Non Ferrous Metals & Industrial Raw MaterialsVvipul MaheshwariNo ratings yet

- Microbially Influenced CorrosiDocument303 pagesMicrobially Influenced CorrosiLlike Us BravoNo ratings yet

- DOWSIL™ General Purpose Silicone Sealant: Features & BenefitsDocument4 pagesDOWSIL™ General Purpose Silicone Sealant: Features & BenefitsPranshu JainNo ratings yet

- Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer ConcretesDocument6 pagesChemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer ConcretesAmiine BkdNo ratings yet

- Drymix Price List 04092023Document1 pageDrymix Price List 04092023Dhruv ChadderwalaNo ratings yet

- SV5 Safety Valve-Installation Maintenance ManualDocument12 pagesSV5 Safety Valve-Installation Maintenance ManualGOKUL PRASADNo ratings yet

- Everything You Need to Know About PozzolansDocument19 pagesEverything You Need to Know About Pozzolansdavidborg8No ratings yet

- Harga Satuan Dasar Upah dan MaterialDocument576 pagesHarga Satuan Dasar Upah dan MaterialKHOIRUSNo ratings yet

- Marley Alutec Price ListDocument92 pagesMarley Alutec Price ListdduffyNo ratings yet

- Tyco Fig.110-190 Ball Valves DatasheetDocument24 pagesTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- IS072 - Circular Concrete Tanks Without Prestressing PDFDocument59 pagesIS072 - Circular Concrete Tanks Without Prestressing PDFMunira TsurudaNo ratings yet

- Hdpe Pipe Butt Welding ProceduresDocument7 pagesHdpe Pipe Butt Welding ProceduresRodrigo CarizNo ratings yet

- Tanjay 5 VariationDocument20 pagesTanjay 5 VariationJet ArcaNo ratings yet

- PROTEX Data SheetDocument2 pagesPROTEX Data SheetDayanand SharmaNo ratings yet

- Effect of Multi-Pass SMAW Welding On The Surface HDocument7 pagesEffect of Multi-Pass SMAW Welding On The Surface HYousab CreatorNo ratings yet

- Comarison Between Aci 440 and Fib 14 Design GuidelinesDocument10 pagesComarison Between Aci 440 and Fib 14 Design GuidelinesShuvo ShahaNo ratings yet

- Al WeldingDocument70 pagesAl WeldingTuyen NguyenNo ratings yet

- API 607 and 6FA Fire Tested ValvesDocument4 pagesAPI 607 and 6FA Fire Tested ValvesKajer quemarNo ratings yet

- 08.COSHH RegisterDocument38 pages08.COSHH RegisterRichu Pali100% (1)

- Wall Footing CalculationsDocument12 pagesWall Footing Calculationsbsreenu393No ratings yet

- Concrete PavementsDocument16 pagesConcrete PavementsAbigail Joy AbingNo ratings yet

- BLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFDocument22 pagesBLAST FURNACE OPERATIONS-TATA STEEL - Dipika Sinha - 5.6.20 PDFGAGAN SOLANKINo ratings yet

- Sector 7 Infrastructure Cost AnalysisDocument129 pagesSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNo ratings yet

- Part 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door HardwareDocument2 pagesPart 3 Execution: Bujairi F&B Architectural Specification Section 08 71 00 Door Hardwaremus3b1985No ratings yet

- Anchor Reinforcement For Concrete Podium SlabsDocument12 pagesAnchor Reinforcement For Concrete Podium SlabsRobert VochescuNo ratings yet

- Proposed House Plan For MR - NihalDocument1 pageProposed House Plan For MR - NihalSulaksha WimalasenaNo ratings yet

- Xiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDocument2 pagesXiameter OFS-6020 Silane: Diaminofunctional Silane Features ApplicationsDelovita GintingNo ratings yet

- Asean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Document1 pageAsean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Vince Bagsit PolicarpioNo ratings yet

- B111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument12 pagesB111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockSalma FarooqNo ratings yet