Professional Documents

Culture Documents

Midas Gen: 1. Design Information

Midas Gen: 1. Design Information

Uploaded by

GooddayBybsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Midas Gen: 1. Design Information

Midas Gen: 1. Design Information

Uploaded by

GooddayBybsCopyright:

Available Formats

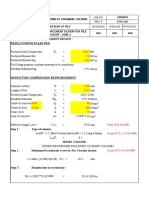

midas Gen Steel Checking Result

Company Project Title

Author Engineer File Name T1 BOTTOM CHORD

z

1. Design Information

Design Code : AISC-ASD89

Unit System : kgf, cm

Member No : 918 y

Material : SS400 (No:2) 0.45

(Fy = 2400.00, Es = 2100000)

Section Name : P 114.3x4.5 (No:22)

(Rolled : P 114.3x4.5).

11.43

Member Length : 702.674

2. Member Forces Outer Dia. 11.4300 Wall Thick 0.45000

Axial Force Fxx = -2671.0 (LCB: 33, POS:I) Area 15.5200 Asz 7.76130

Bending Moments My = -2276.1, Mz = 7544.42 Qyb 30.1907 Qzb 30.1907

Iyy 234.000 Izz 234.000

End Moments Myi = -2276.1, Myj = 8329.84 (for Lb) Ybar 5.71500 Zbar 5.71500

Syy 41.0000 Szz 41.0000

Myi = -2276.1, Myj = -384.80 (for Ly) ry 3.89000 rz 3.89000

Mzi = 7544.42, Mzj = -2466.3 (for Lz)

Shear Forces Fyy = -12.100 (LCB: 40, POS:J)

Fzz = 180.945 (LCB: 40, POS:J)

3. Design Parameters

Unbraced Lengths Ly = 100.382, Lz = 702.674, Lb = 702.674

Effective Length Factors Ky = 1.00, Kz = 1.00

Moment Factor / Bending Coefficient

Cmy = 1.00, Cmz = 1.00, Cb = 1.00

4. Checking Results

Slenderness Ratio

KL/r = 180.6 < 200.0 (Memb:918, LCB: 33)................................... O.K

Axial Stress

fa/Fa = 172.100/331.409 = 0.519 < 1.000 ......................................... O.K

Bending Stresses

fby/Fby = 55.59/1584.00 = 0.035 < 1.000 ......................................... O.K

fbz/Fbz = 184.26/1584.00 = 0.116 < 1.000 ......................................... O.K

Combined Stress (Compression+Bending)

SFy = [Cmy/(1-fa/F'ey)], SFz = [Cmz/(1-fa/F'ez)]

Rmax1 = fa/Fa + SQRT[SFy*(fbcy/Fbcy)^2 + SFz*(fbcz/Fbcz)^2]

Rmax2 = fa/0.60Fy + SQRT[(fbcy/Fbcy)^2 + (fbcz/Fbcz)^2]

Rmax = Max[Rmax1, Rmax2] = 0.764 < 1.000 ......................................... O.K

Shear Stresses

fv/Fv = 0.012 < 1.000 ........................................................... O.K

Modeling, Integrated Design & Analysis Software Print Date/Time : 08/26/2021 07:48

http://www.MidasUser.com

Gen 2018

You might also like

- Installation of Electric Water HeaterDocument7 pagesInstallation of Electric Water Heateramal100% (3)

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- Calculation Check Temporary Tower - LG SlidingDocument9 pagesCalculation Check Temporary Tower - LG Slidingสายัญ บุญพาNo ratings yet

- 1.2M Check 2Document1 page1.2M Check 2HsunamiNo ratings yet

- HEB200Document1 pageHEB200giulioNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationMikeNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design InformationWidi NugrahaNo ratings yet

- DB16 MMDocument1 pageDB16 MMGooddayBybsNo ratings yet

- Envolvente ColumnaDocument1 pageEnvolvente ColumnaOrlando EnriqueNo ratings yet

- Diagonal Web Member PDFDocument1 pageDiagonal Web Member PDFJohn Edrick TanNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- Double Angle BarDocument1 pageDouble Angle BarShadin Asari ArabaniNo ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design InformationErwin d'AdventuraNo ratings yet

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Check Dam Cau Dan SinhDocument2 pagesCheck Dam Cau Dan SinhKhải TrươngNo ratings yet

- Web Members PDFDocument2 pagesWeb Members PDFJohn Edrick TanNo ratings yet

- Design Information: AuthorDocument1 pageDesign Information: AuthorSothea BornNo ratings yet

- Midasgen: 1. Design InformationDocument31 pagesMidasgen: 1. Design Informationduchoang5000No ratings yet

- MIDAS/Civil: 1. Design InformationDocument1 pageMIDAS/Civil: 1. Design Informationtopan full2No ratings yet

- Midas Gen: 1. Design InformationDocument6 pagesMidas Gen: 1. Design InformationChristian Jeremiah TevesNo ratings yet

- Analysis 1Document2 pagesAnalysis 1Việt QuốcNo ratings yet

- Final Pile Design - ResultantDocument3 pagesFinal Pile Design - Resultantvishnumani3011No ratings yet

- Midas Gen: 1. Design InformationDocument56 pagesMidas Gen: 1. Design InformationNyx Phoebe WPNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerbenjipaulNo ratings yet

- Simple Span 72827.1: Single Reinf. Single ReinfDocument7 pagesSimple Span 72827.1: Single Reinf. Single Reinfboat955No ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- Start - FCMDocument47 pagesStart - FCMEddy BongNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Buat Linkset A60Document1 pageBuat Linkset A60nudewaNo ratings yet

- Project: Slab Number: Engineer: Date:: Design Two-Way Slabs (Method 3 of E.I.T.)Document10 pagesProject: Slab Number: Engineer: Date:: Design Two-Way Slabs (Method 3 of E.I.T.)Mars TinNo ratings yet

- Sap DesignDocument1 pageSap DesignReza ErmawanNo ratings yet

- C10-Capacity Closely Space Check-ReportDocument1 pageC10-Capacity Closely Space Check-Reportchirathip vasuvattakulNo ratings yet

- Manual Design of Two Way SlabDocument5 pagesManual Design of Two Way SlabManish JhaNo ratings yet

- C1 W12x65 Full CalculationDocument5 pagesC1 W12x65 Full CalculationShadin Asari ArabaniNo ratings yet

- Precast Driven Pile Section Analysis: Input DataDocument1 pagePrecast Driven Pile Section Analysis: Input DatacivixxNo ratings yet

- Page 2Document1 pagePage 2Edward Albert BañagaNo ratings yet

- Example: FVG 100.00Kn FVQ 30.00Kn HSD 0.20Xfsd 250X150X20Document4 pagesExample: FVG 100.00Kn FVQ 30.00Kn HSD 0.20Xfsd 250X150X20ismet mehmetiNo ratings yet

- MBBearing PlateDocument2 pagesMBBearing Platenongbig1No ratings yet

- Structural Analysis FrondaDocument50 pagesStructural Analysis FrondaKimberly Mae SantosNo ratings yet

- Input Echo, Leg & Lug Item 1, Description: GuideDocument4 pagesInput Echo, Leg & Lug Item 1, Description: GuideSiri SiriNo ratings yet

- Bolt Design (Blodget)Document4 pagesBolt Design (Blodget)Mayuresh KudveNo ratings yet

- Midasit: 1. General InformationDocument9 pagesMidasit: 1. General InformationKomiNo ratings yet

- Full Report Z-PurlinDocument8 pagesFull Report Z-Purlinsaltore123456No ratings yet

- Pt. Sorik Marapi Geothermal Power: Engineering CalculationDocument8 pagesPt. Sorik Marapi Geothermal Power: Engineering CalculationJhonny KienNo ratings yet

- Project Job Number EngineerDocument2 pagesProject Job Number Engineerroan sthaNo ratings yet

- General Information: Member Name: F01Document8 pagesGeneral Information: Member Name: F01JefreyMatuanMondranoNo ratings yet

- BS8110 97Document50 pagesBS8110 97mgdarioNo ratings yet

- BS8110 97 PDFDocument50 pagesBS8110 97 PDFimranmehfoozNo ratings yet

- Appendix E.1. Pipe Support Calculation - PS-CP-01Document10 pagesAppendix E.1. Pipe Support Calculation - PS-CP-01noto.sugiarto50% (2)

- Round HSS Design LRFDDocument4 pagesRound HSS Design LRFDklynchelleNo ratings yet

- Agitator - Ag-C8-102Document4 pagesAgitator - Ag-C8-102uttam prabhuNo ratings yet

- AISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFDocument196 pagesAISC Design Guide 29 - Vertical Bracing Connections - Analysis and Design 2 de 2 PDFMartin Cristobal CupitayNo ratings yet

- Staad Report - FinalDocument25 pagesStaad Report - FinalparthibanNo ratings yet

- Compression Design Section1Document10 pagesCompression Design Section1Anonymous sfkedkymNo ratings yet

- ETABSDocument1 pageETABSJasser BerriosNo ratings yet

- ProkonDocument12 pagesProkonHoài Thương LêNo ratings yet

- 164-166 1 - Steel Beam (B1a)Document3 pages164-166 1 - Steel Beam (B1a)Jomelson AriasNo ratings yet

- Pipe Support ADocument1 pagePipe Support AGooddayBybsNo ratings yet

- Pipe Support BDocument1 pagePipe Support BGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- แบบไฟฟ้า2Document1 pageแบบไฟฟ้า2GooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- แบบไฟฟ้า3Document1 pageแบบไฟฟ้า3GooddayBybsNo ratings yet

- DB16 MMDocument1 pageDB16 MMGooddayBybsNo ratings yet

- LPG Storage Tank Foundation Design Data Tank DataDocument1 pageLPG Storage Tank Foundation Design Data Tank DataGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Calculation Sheet For Battery Rack 80 kVA: DateDocument1 pageCalculation Sheet For Battery Rack 80 kVA: DateGooddayBybsNo ratings yet

- SAS FoundationDocument18 pagesSAS FoundationGooddayBybsNo ratings yet

- RC ColumnDocument1 pageRC ColumnGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- MICROFEAP-P2 For Windows: 0 0.49 M ScaleDocument1 pageMICROFEAP-P2 For Windows: 0 0.49 M ScaleGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- Midas Gen: 1. Design ConditionDocument1 pageMidas Gen: 1. Design ConditionGooddayBybsNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationGooddayBybsNo ratings yet

- HomophilyDocument8 pagesHomophilynumpy333No ratings yet

- Unit 1Document28 pagesUnit 1kloirywbdNo ratings yet

- Fiber ForensicDocument29 pagesFiber ForensicdizaNo ratings yet

- Bead On A Rotating Hoop: A Simple Yet Feature-Rich Dynamical SystemDocument16 pagesBead On A Rotating Hoop: A Simple Yet Feature-Rich Dynamical Systemshoko bananiNo ratings yet

- Hobbes Hidden Monsters PDFDocument23 pagesHobbes Hidden Monsters PDFErika Gomes Peixoto100% (1)

- X3-MIC-G2: New From SolaxDocument2 pagesX3-MIC-G2: New From SolaxSampath HemasingheNo ratings yet

- GenPhys1 12 Q2 Mod5 FluidMechanics Ver2Document43 pagesGenPhys1 12 Q2 Mod5 FluidMechanics Ver2Jean RomarNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.karthick VijayanNo ratings yet

- HS United States History Reconstruction To TodayDocument415 pagesHS United States History Reconstruction To TodayAlejandra DoldNo ratings yet

- AV AidsDocument71 pagesAV AidsSHANTHIPRIYA BODANo ratings yet

- FrankesteinDocument5 pagesFrankesteinMoraineNo ratings yet

- White and Blue Modern Professional Enterprise Risk Management PresentationDocument3 pagesWhite and Blue Modern Professional Enterprise Risk Management PresentationMarjorie BricenioNo ratings yet

- English Morphology ResearchDocument2 pagesEnglish Morphology ResearchNahdatul FikraNo ratings yet

- Most Important Question EnglishDocument65 pagesMost Important Question Englishbadasswhoseyourdad2009No ratings yet

- Cybersemiotics: A Suggestion For A Transdisciplinary Framework For Description of Observing, Anticipatory and Meaning Producing Systems - Soren BrierDocument13 pagesCybersemiotics: A Suggestion For A Transdisciplinary Framework For Description of Observing, Anticipatory and Meaning Producing Systems - Soren BrierJoão ParentiNo ratings yet

- Through Night and DayDocument4 pagesThrough Night and Dayqwerty heroNo ratings yet

- 1st PodiumDocument1 page1st PodiumMrs XNo ratings yet

- Social Responsibility in An Inspector Calls - Themes - AQA - GCSE English Literature Revision - AQA - BBC BitesizeDocument1 pageSocial Responsibility in An Inspector Calls - Themes - AQA - GCSE English Literature Revision - AQA - BBC BitesizeFatimaNo ratings yet

- University of Southern Mindanao-Kidapawan City Campus Lesson PlanDocument3 pagesUniversity of Southern Mindanao-Kidapawan City Campus Lesson PlanAngel Ojatra ArmadaNo ratings yet

- A Guide To Action Learning Along With Tools and TechniquesDocument26 pagesA Guide To Action Learning Along With Tools and TechniquesMaryreneeNo ratings yet

- Prpc324 Module 7Document48 pagesPrpc324 Module 7raiNo ratings yet

- Intro To HGDG and JMC 2013 01Document30 pagesIntro To HGDG and JMC 2013 01cruzserNo ratings yet

- ISPRS SC Spectrum Vol15 No2Document36 pagesISPRS SC Spectrum Vol15 No2ISPRS Student ConsortiumNo ratings yet

- Evolution Activity Choice BoardDocument1 pageEvolution Activity Choice Boardapi-515442701No ratings yet

- Media Bulletin 01 10 2020 PDFDocument44 pagesMedia Bulletin 01 10 2020 PDFSameer SamouaNo ratings yet

- Advances in Environmental Analysis: Methods & Applications EbookDocument40 pagesAdvances in Environmental Analysis: Methods & Applications EbookridermateNo ratings yet

- Yang 2010Document10 pagesYang 2010Li DongyueNo ratings yet

- Assignment 4 - Rizal's Life, Travels, and HomecomingDocument4 pagesAssignment 4 - Rizal's Life, Travels, and Homecomingjasminekatemartinez31No ratings yet

- Job Description - Recruitment AdministratorDocument2 pagesJob Description - Recruitment Administratorreza5No ratings yet