Professional Documents

Culture Documents

NP - Chart Exercise: Complete The Header Information and Step 2 Record The Data (Page 115)

Uploaded by

Rahul PandeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NP - Chart Exercise: Complete The Header Information and Step 2 Record The Data (Page 115)

Uploaded by

Rahul PandeyCopyright:

Available Formats

np - chart exercise

The Practical Sauce Company manufactures a variety of sauces and related products. The

company sees labelling as a critical quality characteristic; portraying a good corporate

image is an important part of their marketing efforts. To ensure accuracy and consistency a

case of 24 jars is checked every 30 minutes and the results recorded. The data collected

has been entered on the control chart overleaf. Use this data and the steps in the tool book

to construct an np-chart.

Step 1 Complete the header information and step 2 Record the data (page 115)

have been completed for you.

Step 3 Calculate the average number (page 116).

np =

∑ np =

k

Step 4 Calculate the control limits (page 117).

np

UCLnp = n p + 3 n p (1 − )=

n

np

LCLnp = n p − 3 n p (1 − )=

n

Step 5 Scale the control chart (page 118).

Largest

=

20

Complete steps 6 to 8 (pages 119–121) on the control chart overleaf.

© PQ Systems Pty Ltd 2002 Manufacturing

ATTRIBUTES CONTROL CHART

Product / Service Chart p np Quality measure Measurement device

Sauce type c u Labelling errors Checklist

User name Location Chart no.

John Brown Practical sauce company AVG.= UCL = LCL = n=

DATE Mar 1

TIME 08:00 08:30 09:00 09:30 10:00 10:30 11:00 11:30 12:00 12:30 13:00 13:30 14:00 14:30 15:00 15:30 16:00 16:30 17:00 17:30 18:00 18:30 19:00 19:30 20:00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Type of discrepancy

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Total number (np, c) 8 10 4 5 7 3 6 9 2 5 10 7 6 4 3 11 7 6 1 8 6 4 9 3 6

Proportion (p, u)

Subgroup size (n) 24

© PQ Systems Pty Ltd 2002 Manufacturing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BSBINS601 Project PortfolioDocument17 pagesBSBINS601 Project PortfolioParash RijalNo ratings yet

- FAR 1 - Journal EntriesDocument3 pagesFAR 1 - Journal EntriesAnime LoverNo ratings yet

- U - Chart Exercise: Step 1Document2 pagesU - Chart Exercise: Step 1Rahul PandeyNo ratings yet

- Presentation ON SMS: Prepared By:Shashank Poddar Metallurgy (5 Sem)Document15 pagesPresentation ON SMS: Prepared By:Shashank Poddar Metallurgy (5 Sem)Rahul PandeyNo ratings yet

- PrintDocument9 pagesPrintRahul PandeyNo ratings yet

- Full Advt 09 - 2023Document10 pagesFull Advt 09 - 2023Muhammad Saquib AnjumNo ratings yet

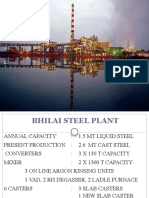

- Bhilai Steel PlantDocument15 pagesBhilai Steel PlantRahul PandeyNo ratings yet

- Blast Furnace Operation and ConstructionDocument13 pagesBlast Furnace Operation and ConstructionRahul PandeyNo ratings yet

- Vocational Training Presentation on Steel Melting Shop-IIDocument39 pagesVocational Training Presentation on Steel Melting Shop-IIRahul PandeyNo ratings yet

- By Chan, Sam and EllyDocument10 pagesBy Chan, Sam and EllyRahul PandeyNo ratings yet

- Chhattisgarh Swami Vivekanand Technical University, Bhilai Scheme of Teaching & Examination B.E. V Semester Metallurgical EngineeringDocument15 pagesChhattisgarh Swami Vivekanand Technical University, Bhilai Scheme of Teaching & Examination B.E. V Semester Metallurgical EngineeringSiddharth VermaNo ratings yet

- A Presentation ON Vocational Training: Sandeep Pradhan 3203810039Document22 pagesA Presentation ON Vocational Training: Sandeep Pradhan 3203810039Rahul PandeyNo ratings yet

- Aditya Pratap Singh: Prepared ByDocument14 pagesAditya Pratap Singh: Prepared ByRahul PandeyNo ratings yet

- Report on steel melting shop processesDocument18 pagesReport on steel melting shop processesRahul PandeyNo ratings yet

- Summer Vocational Training Report: Bhilai Steel Plant, Sail ON "Mill Zone"Document26 pagesSummer Vocational Training Report: Bhilai Steel Plant, Sail ON "Mill Zone"Rahul PandeyNo ratings yet

- Aditya Pratap Singh: Prepared ByDocument14 pagesAditya Pratap Singh: Prepared ByRahul PandeyNo ratings yet

- Presentation ON Steel Melting Shop: Rupendra Naik 3203810037Document19 pagesPresentation ON Steel Melting Shop: Rupendra Naik 3203810037Rahul PandeyNo ratings yet

- Blast Furnac E: S.Megha Metallurgy SemesterDocument18 pagesBlast Furnac E: S.Megha Metallurgy SemesterRahul PandeyNo ratings yet

- Presentation On SMS: BY:-Ram Prasad Choudhary 3203810034Document19 pagesPresentation On SMS: BY:-Ram Prasad Choudhary 3203810034Rahul PandeyNo ratings yet

- Presentation On Steel Melting Shop: BY: Dipti Dubey. Metallurgy 5 SEMDocument18 pagesPresentation On Steel Melting Shop: BY: Dipti Dubey. Metallurgy 5 SEMRahul PandeyNo ratings yet

- Roll No 59Document25 pagesRoll No 59Rahul PandeyNo ratings yet

- A Presentation On Dri-Ii: BY:-Vikash Ranjan Sharma Metallurgy - 5 SEM 3203810051Document15 pagesA Presentation On Dri-Ii: BY:-Vikash Ranjan Sharma Metallurgy - 5 SEM 3203810051Rahul PandeyNo ratings yet

- A Project Report On Summer Vocational Training in Bhilai Steel PlantDocument24 pagesA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyNo ratings yet

- Direct & Indirect Reduction IN Blast Furnace: NAME - Mahendra Kumar Patel. 3203810029 (5 Sem)Document9 pagesDirect & Indirect Reduction IN Blast Furnace: NAME - Mahendra Kumar Patel. 3203810029 (5 Sem)Rahul PandeyNo ratings yet

- A Presentation On Dri-Ii in JSPL, Raigarh: By:-Harish Patel (Meta-5 Sem)Document14 pagesA Presentation On Dri-Ii in JSPL, Raigarh: By:-Harish Patel (Meta-5 Sem)Rahul PandeyNo ratings yet

- Regular SolutionsDocument19 pagesRegular SolutionsRahul PandeyNo ratings yet

- (Steel Melting Shop) : Training Duration:-21 May-28JuneDocument11 pages(Steel Melting Shop) : Training Duration:-21 May-28JuneRahul PandeyNo ratings yet

- A Project Report On Summer Vocational Training in Bhilai Steel PlantDocument24 pagesA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyNo ratings yet

- SolutionsDocument13 pagesSolutionsRahul PandeyNo ratings yet

- Metallurgical Thermo Dynamics9 R H TupkaryDocument208 pagesMetallurgical Thermo Dynamics9 R H TupkaryRahul Pandey100% (7)

- Phase DiagramsDocument72 pagesPhase DiagramsRahul PandeyNo ratings yet

- TRAKHEES CertificateDocument1 pageTRAKHEES CertificatePriyanka JNo ratings yet

- Qoutation: Date: 22/02/2019 Quotation No: QUOT.2019.SET.01Document1 pageQoutation: Date: 22/02/2019 Quotation No: QUOT.2019.SET.01Taqiyuddin Abdul RahmanNo ratings yet

- BC 103. Taxation IncomeDocument8 pagesBC 103. Taxation Incomezekekomatsu0No ratings yet

- 6.financial Status and Framework of GOCCDocument4 pages6.financial Status and Framework of GOCCmadonna azuelaNo ratings yet

- CH 15Document28 pagesCH 15refa260894No ratings yet

- Presentation - Pakistan Railways (Swot Analysis)Document24 pagesPresentation - Pakistan Railways (Swot Analysis)zubair_ahmed_importsNo ratings yet

- Customer StatementDocument1 pageCustomer StatementNgumoha JusticeNo ratings yet

- Types of Media and Media ConvergenceDocument47 pagesTypes of Media and Media ConvergenceEmely FrancoNo ratings yet

- Csec Poa June 2010 p2Document12 pagesCsec Poa June 2010 p2Renelle RampersadNo ratings yet

- Vendor List For Instrumentation Items VeDocument5 pagesVendor List For Instrumentation Items VeSriramsriram SriramNo ratings yet

- Rags2Riches by Reese FernandezDocument1 pageRags2Riches by Reese FernandezChristian Gerard P. BerouNo ratings yet

- Reciept of Vehicle Sale Form July 2019Document1 pageReciept of Vehicle Sale Form July 2019Deep MalaNo ratings yet

- Cost Accounting Part 1 (University of Cebu) Cost Accounting Part 1 (University of Cebu)Document6 pagesCost Accounting Part 1 (University of Cebu) Cost Accounting Part 1 (University of Cebu)Shane TorrieNo ratings yet

- Sales AssDocument5 pagesSales AssPASCHALNo ratings yet

- Bank Of Punjab Internship ReportDocument49 pagesBank Of Punjab Internship ReportHussain HadiNo ratings yet

- Safety Planner and TBT Roster of HCSL For The Month of Oct-21Document4 pagesSafety Planner and TBT Roster of HCSL For The Month of Oct-21Kãùshîk MâjümdérNo ratings yet

- Megersa Business Plan. Mba 2024Document26 pagesMegersa Business Plan. Mba 2024Megersa100% (1)

- Capital BudgetingDocument2 pagesCapital BudgetingAlexis KingNo ratings yet

- Executive SummaryDocument76 pagesExecutive Summarysimantt100% (2)

- Sample Partnership DeedDocument4 pagesSample Partnership DeedShahzad Faisal0% (1)

- Bruh KitchenDocument1 pageBruh KitchenNur HanyNo ratings yet

- Chennai RR Medicos PVT LTD Invoice Copy Dose Meds Technologies Private LimitedDocument1 pageChennai RR Medicos PVT LTD Invoice Copy Dose Meds Technologies Private LimitedSKILLER GaneshNo ratings yet

- Statement of Financial Position: Fundamentals of Accountancy, Business and Management 2Document55 pagesStatement of Financial Position: Fundamentals of Accountancy, Business and Management 2Arminda Villamin75% (4)

- Software Product Launch Plan TemplateDocument6 pagesSoftware Product Launch Plan TemplateShady Mohamed El-KhattabyNo ratings yet

- Inb 372 Course Outline Summer 2022Document6 pagesInb 372 Course Outline Summer 2022Imrul JoyNo ratings yet

- English Homework #3Document11 pagesEnglish Homework #3Yaremi PereiraNo ratings yet

- Multiple Choice Problems ChapterDocument1 pageMultiple Choice Problems ChapterJohn Carlos Doringo100% (1)

- Prelim Quiz 2Document11 pagesPrelim Quiz 2Sevastian jedd EdicNo ratings yet