Professional Documents

Culture Documents

5.19.3 Job Safety Practices Rev 02-Blank

5.19.3 Job Safety Practices Rev 02-Blank

Uploaded by

Shafie ZubierCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.19.3 Job Safety Practices Rev 02-Blank

5.19.3 Job Safety Practices Rev 02-Blank

Uploaded by

Shafie ZubierCopyright:

Available Formats

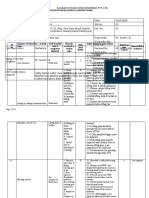

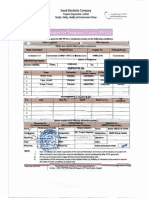

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

DEPARTMENT/DIVISION EHVPD / COA DATE 29 September 2019

EMPLOYEE JOB TITLE 9019 to 9089 A & B and 9050 to 9089 A & B LOCATION RIYADH-BANBAN

380 KV OHTL Shutdown / Modification Works in Existing safety helmets, gloves, eye protection, high-

Personal Protective

JOB/ TASK TITLE Temporary Ckt 9019 to 9050 A & B to Establish 9019 to 9089 A & visibility clothing, safety footwear and safety

B and 9050 to 9089 A & B

Equipment

harnesses.

STEPS HAZARDS

IN EACH STEP, WHAT COULD CAUSE CONTROL REQUIRED TO MINIMIZE/ ELIMINATE HAZARD COMMENTS OF JOB OBSERVATION

LIST ALL STEPS IN

STEPS # INJURY, LOSS DAMAGE, INTRRUPTION, OR

PERFORMING THIS TASK

POLUTION?

a) Obtain permit from concerned external authority

before starting the activity.

b) Ensure ground level is even and good condition to

placed vehicle/trailer.

c) Ensure sufficient clearance is available to move near

Mobilization of Equipment / vehicle / Trailer Moving / energized lines. (More than 10 meter)

STEPS #1 materials tools and Placed near energized line, Un even d) Ensure proper grounding provided.

equipment’s. ground level. e) Ensure all safety documents, calibration certificate

and TUV of equipment’s must be available and valid.

f) Ensure proper operation and good condition of the

equipment before usage.

g) Provide work at height training for all linemen.

Conduct daily tool box talk before start the activity.

a) Obtain permit to work before starting the activity.

b) Provide manual and mechanical handling training to

all.

Manual and mechanical c) All PPEs (hand gloves, safety shoes, helmet, high

STEPS #2 handling of material Slip, Trip, fall from the same level. visibility jacket, goggles and overall) and tools must

tools and equipment’s. be inspected before use on daily basis.

d) Conduct daily TBT before start the activity.

Ensure the availability of first aid box and certified first

aider.

Page 1 of 4 Rev.2 [08-April-2019] Projects Business Unit

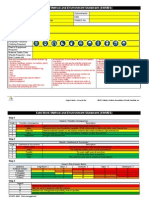

PROJECT NAME:……………………………………………………………………………

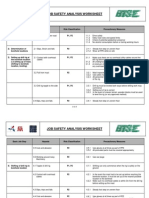

ELEMENT 5.19.3

JOB SAFETY PRACTICES

a) Tool box talk must be done by the team supervisor

before starting the work.

b) Avoid working if lightning threat is suspected.

Induction Voltage c) Work area shall be clearly identified before start of work.

Electrocution (Fatality/injury) d) Ensure Competent Supervision.

Fire /Explosion e) Use proper PPE (Safety Helmet, Safety Shoe, Gloves,

Working near

STEPS #3 Flashes Reflective vest & Goggle).

Live lines

Station tripping f) Work shall not be carried out within 10 M of the over

Damage to the equipment and headlines when the line is live with power.

properties g) Work with proper safety clearance & certificates.

h) Voltage detector and adequate portable grounding

equipment's should be provided to eliminate the risk of

induced voltage by other neighboring live circuits.

a) Ensure proper grounding on both sides identified

adjacent tower’s circuit/s.

b) Presence of competent person (Permit/ LOA holder)

must require while installing or removing the grounding.

c) Competent person must ensure the voltage absence

before installing the grounding.

d) Adequate equipment (VAV) shall be used to ensure the

voltage absence before installing the grounding.

e) Use Safety harness with double lanyard with properly

Fall of men or material from Height,

hooked while working above 1.8 MTR height.

STEPS #4 Climbing the tower Heat Stress or Slippery Condition

f) Ensure always three point of contact while climbing to

the tower & as well as while moving horizontally on

tower.

g) Ensure adequate supervision while working at height.

h) Use vertical life line with fall arrestor.

i) Waist pouch for carrying nut & bolt must be use.

j) Ensure availability of Emergency vehicle @ Site.

k) Work must be stopped during severe weather condition.

Necessary refreshments, cold drinks, ORS etc. to be

provided at the site.

Page 2 of 4 Rev.2 [08-April-2019] Projects Business Unit

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

a) Use Safety harness with double lanyard with properly

hooked while working above 1.8 MTR height.

b) Waist pouch for carrying nuts, bolts and hand tools in ring

available in harness shall be used access the tower.

c) Do not throw up / throw down the materials / tools.

d) Ensure availability of Emergency vehicle @ Site.

e) Mechanical lifting Equipment’s like shovel must be

Removing &

inspected before start of work.

STEPS #5 alternation of Existing Fall of men or material from Height

f) All Lifting Gears like Pulley, Slings, Rope and Insulator

jumper at height

Assembly Should be inspected before Work.

g) Color Coding of T & P Should be Verified

h) Work should be executed by Experienced Foreman.

i) Adequate and damage free guy ropes to be used, tied

properly.

j) Smooth (without jerk) lifting must be ensured.

Competency of the Operator should be verified.

a) Mechanical lifting Equipment’s like shovel must be

inspected before start the work.

b) All Lifting Gears like Pulley, Slings, Rope and Insulator

Failure of rope, slings, pulleys Assembly Should be inspected before Work.

Fall of objects from height c) Color Coding of T & P Should be Verified.

STEPS #6 Insulator Hoisting

Major Injury, Material damage d) Work should be executed by Experienced Foreman.

Using inappropriate tools/equipment e) Adequate and damage free guy ropes to be used & tied

properly.

f) Competency of the Operator should be verified.

Winch should be used for lifting the insulators

STEPS #7 Payout/Stringing of Electric Shock, Induction Voltage, a) Permit should be obtained before the activity.

Conductor & OPGW People being struck by or run over, b) Unauthorized Entry Should Be Prohibited. Prior

Overturning, Asset Damage Permission should be availed from the Client.

c) Competent Person Should Operate Tensioner and Puller.

d) Tensioner and Puller should be provided with grounding.

e) Constant and competent supervision needed for work.

f) Conduct specific tool box talks before starting the activity.

g) Minimum Safe Distance of 10M from energized Lines

Page 3 of 4 Rev.2 [08-April-2019] Projects Business Unit

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

should be maintained.

h) Only trained personnel to be allowed to work

i) Tools needs to be insulated

j) Safety Net should be installed as per Requirement.

k) Tools need to be insulated.

a) Proper Platform should be used for pressing of conductor.

b) Use of appropriate PPE's like full body harness, fall

arrestor, helmet and shoes.

c) Do not throw up / throw down the materials / tools.

d) All the arrangement should be prepared under skilled

foreman.

e) Proper Housekeeping should be done before start of

Conductor & OPGW Major Injury, fatal, material work.

STEPS #8 Clipping, Spacering Damage, Slip/Trip/Fall f) No Technician should stand under the Tower.

and Jumpering Hazards g) Adequate and damage free guy ropes to be used, tied

properly. a) Aluminum ladder with hooks should use to

enter the clipping area.

h) Use of appropriate PPE's like full body harness,

Retractable fall arrestor, helmet and shoes.

i) Spacer Trolley Load Should within the SWL

j) Retractable fall arrester and safety Harness must be used

by the line man during Jumpering work.

JSP Prepared By: Daya Sankar, Faisal & Sethu Signature: Date:

JSP Accepted By: Signature: Date:

JSP Approved By (SEC Site): Signature: Date:

JSP Approved By (SEC): Signature: Date:

Page 4 of 4 Rev.2 [08-April-2019] Projects Business Unit

You might also like

- Electric Powerlines Working Near Swms 10590-3Document12 pagesElectric Powerlines Working Near Swms 10590-3JamesNo ratings yet

- Hard Hat Inspection ChecklistDocument2 pagesHard Hat Inspection ChecklistYussi WaluyoNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Reflection Paper - Facilities ManagementDocument11 pagesReflection Paper - Facilities ManagementMary Charisse SandroNo ratings yet

- Fleet Maintenance and Best Management PracticesDocument8 pagesFleet Maintenance and Best Management Practicesjohnribar100% (2)

- HITACHI EX1200-5 EXCAVATOR Service Repair Manual PDFDocument56 pagesHITACHI EX1200-5 EXCAVATOR Service Repair Manual PDFfjjskekkdmem100% (1)

- Working at Heights Safe Work Method Statement (SWMS)Document3 pagesWorking at Heights Safe Work Method Statement (SWMS)Toga Nainggolan100% (1)

- OshaDocument34 pagesOshaxone1215No ratings yet

- PZ TBT - Height Safety v2Document2 pagesPZ TBT - Height Safety v2AshishNo ratings yet

- ISBN Construction Safety Focus Preventing Falls From Height in Building and Construction 2016 07 PDFDocument1 pageISBN Construction Safety Focus Preventing Falls From Height in Building and Construction 2016 07 PDFZeljkoNo ratings yet

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 pagePermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Site Safety Supervisor - Lifting OperationDocument10 pagesSite Safety Supervisor - Lifting Operationflex xibleNo ratings yet

- Working at Heights: Engr. Jobelle B MalaygayDocument50 pagesWorking at Heights: Engr. Jobelle B MalaygayJohn Cedrik Retardo100% (1)

- Emami Infrastructure Limited: Safety Inspection ReportDocument1 pageEmami Infrastructure Limited: Safety Inspection ReportvarunstuffNo ratings yet

- Nail Gun Pnuematic Work Method Statement SWMS V8Document5 pagesNail Gun Pnuematic Work Method Statement SWMS V8ferny.51No ratings yet

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNo ratings yet

- Replace Overhead Consumer Service CoreDocument4 pagesReplace Overhead Consumer Service Coreryan940No ratings yet

- VII 2 GEN - Health Safety Plan Guidelines Rev01Document34 pagesVII 2 GEN - Health Safety Plan Guidelines Rev01lampardbkNo ratings yet

- Excavation and Trench SafetyDocument7 pagesExcavation and Trench SafetyKarim KachourNo ratings yet

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoNo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- Safe Working On RoofsDocument24 pagesSafe Working On RoofstuNo ratings yet

- Planning Works Using MEWPsDocument7 pagesPlanning Works Using MEWPsJohn GeddesNo ratings yet

- Fall Protection TRAINININGDocument20 pagesFall Protection TRAINININGJaime de la Gala100% (1)

- NEBOSH IGC2 Past Exam Paper March 2013 PDFDocument2 pagesNEBOSH IGC2 Past Exam Paper March 2013 PDFMin Than Min AungNo ratings yet

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkadiNo ratings yet

- Fall Protection: Marnie AlfarDocument42 pagesFall Protection: Marnie AlfarAviects Avie JaroNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Role of Safety OfficerDocument12 pagesRole of Safety OfficerJerry ConsorteNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Hot Work ProceduresDocument10 pagesHot Work ProceduresPaul H TampubolonNo ratings yet

- Safety Flash - FlagmanDocument1 pageSafety Flash - FlagmanarslanahmedkhawajaNo ratings yet

- WC Tea Tea Tea Flavor Label Sparepart Room Insulation InspectionDocument6 pagesWC Tea Tea Tea Flavor Label Sparepart Room Insulation InspectionSuharto AriNo ratings yet

- Contractor Safety Proceduresv1 1Document27 pagesContractor Safety Proceduresv1 1Bambang Setyo Utomo100% (1)

- SWP - (LPG System)Document7 pagesSWP - (LPG System)Md Shahin100% (1)

- Hand and Power Tools Safety ExaminationDocument21 pagesHand and Power Tools Safety ExaminationSharon GonzalezNo ratings yet

- Driving On Site YansabDocument20 pagesDriving On Site YansabjhoniNo ratings yet

- Toolbox Talk Safe LiftingDocument2 pagesToolbox Talk Safe Liftingm.rehanhseNo ratings yet

- Osha3722 PDFDocument2 pagesOsha3722 PDFTharaka Perera100% (1)

- Method Statement For Gypsum Panels WorkDocument8 pagesMethod Statement For Gypsum Panels WorkNikita KasyanovNo ratings yet

- I. Categories of Fall Protection Fall Arrest SystemDocument5 pagesI. Categories of Fall Protection Fall Arrest SystemMikaella ManzanoNo ratings yet

- Method StatementDocument30 pagesMethod StatementSathish KumarNo ratings yet

- TOPIC: Demolition SafetyDocument1 pageTOPIC: Demolition SafetyMohamed HamdallahNo ratings yet

- Scaffolds Scaffolding Work General GuideDocument16 pagesScaffolds Scaffolding Work General GuideTukachungurwa Byarugaba AlexNo ratings yet

- Fall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Document21 pagesFall Prevention Plan: (Only Applicable To Contractor That Have Work Activities More Than 03 Meters and Above.)Md ShahinNo ratings yet

- Appendix-B - Construction Safey Manual at ProjectsDocument112 pagesAppendix-B - Construction Safey Manual at ProjectsvinodNo ratings yet

- DM Code of Construction Safety 195-292 PDFDocument98 pagesDM Code of Construction Safety 195-292 PDFDANo ratings yet

- Risk Assessment Method Statement Documents: April 2007Document11 pagesRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahNo ratings yet

- Lifting Procedure: 1.0 GeneralDocument4 pagesLifting Procedure: 1.0 GeneralMagdy BakryNo ratings yet

- Construction Safety Check ListDocument6 pagesConstruction Safety Check ListJeya Keeshan J KNo ratings yet

- Personal Protection EquipmentDocument10 pagesPersonal Protection EquipmentMargaret NyakioNo ratings yet

- Glenbrook Rd. Demolition and Disposal PlanDocument56 pagesGlenbrook Rd. Demolition and Disposal PlanBruno CarvalheiroNo ratings yet

- Safety, Health and Environment Manual and ProceduresDocument20 pagesSafety, Health and Environment Manual and ProceduresYan's Senora BescoroNo ratings yet

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementKate Hopley100% (3)

- Excavation and Trenching Safe Work ProcedureDocument4 pagesExcavation and Trenching Safe Work Proceduresefina mecNo ratings yet

- Activity3 - Electrical PrecautionsDocument10 pagesActivity3 - Electrical PrecautionsMOHD FAISALNo ratings yet

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaNo ratings yet

- IR Industrial LiftingDocument76 pagesIR Industrial LiftingMark Julius CabasanNo ratings yet

- Plinth Work+dismantling StructureDocument8 pagesPlinth Work+dismantling StructureMuhammad NaqiuNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Ulo - DJ: L.Jioc - iJIDocument3 pagesUlo - DJ: L.Jioc - iJIShafie ZubierNo ratings yet

- PR-PDC-9029-01 - Rev.00 Scaffolding Work Procedure - FinalDocument64 pagesPR-PDC-9029-01 - Rev.00 Scaffolding Work Procedure - FinalShafie ZubierNo ratings yet

- W 13 Daily, Weekly Observation RegisterDocument424 pagesW 13 Daily, Weekly Observation RegisterShafie ZubierNo ratings yet

- Contractors' Top Management Contact Details (2022)Document3 pagesContractors' Top Management Contact Details (2022)Shafie ZubierNo ratings yet

- 3 Daily, Weekly Observation RegisterDocument424 pages3 Daily, Weekly Observation RegisterShafie ZubierNo ratings yet

- Dangers of Oxygen-Deficient Atmospheres: Safetygram 17Document4 pagesDangers of Oxygen-Deficient Atmospheres: Safetygram 17Shafie ZubierNo ratings yet

- Prequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewDocument9 pagesPrequalification Checklist - (Coastline Geophysical Saudi Arabia) 2nd ReviewShafie ZubierNo ratings yet

- 3 March 2022 Week 13 SAFETY OBSERVATION FormDocument4 pages3 March 2022 Week 13 SAFETY OBSERVATION FormShafie ZubierNo ratings yet

- Scorpion Bite Report - 25-06-2020 - 4400012358Document6 pagesScorpion Bite Report - 25-06-2020 - 4400012358Shafie ZubierNo ratings yet

- Drilling & Workover Services Department: Coastline Geophysical Saudi Arabia Limited. Man Power DetailsDocument3 pagesDrilling & Workover Services Department: Coastline Geophysical Saudi Arabia Limited. Man Power DetailsShafie ZubierNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- MEEDCO Daily Wind Speed RecordDocument1 pageMEEDCO Daily Wind Speed RecordShafie ZubierNo ratings yet

- Health, Safety & Environment: Night Work Safety Plan Page 1 of 6Document6 pagesHealth, Safety & Environment: Night Work Safety Plan Page 1 of 6Shafie ZubierNo ratings yet

- Environmental Audit Protocol 2019.. (Updated Protocol 2019)Document56 pagesEnvironmental Audit Protocol 2019.. (Updated Protocol 2019)Shafie ZubierNo ratings yet

- Reasonable Adjustments Request Form - New (2) (2) (3262)Document2 pagesReasonable Adjustments Request Form - New (2) (2) (3262)Shafie ZubierNo ratings yet

- Environmental Inspection ChecklistDocument6 pagesEnvironmental Inspection ChecklistShafie Zubier100% (1)

- Sec Comments List Rectification 1Document4 pagesSec Comments List Rectification 1Shafie ZubierNo ratings yet

- Ohs-Pr-09-26-F01 (A) Initial Incident Notification 26.1Document2 pagesOhs-Pr-09-26-F01 (A) Initial Incident Notification 26.1Shafie ZubierNo ratings yet

- Quality, Safety, Health and Environment Group: Saudi Electricity Company Projects Department-CentralDocument3 pagesQuality, Safety, Health and Environment Group: Saudi Electricity Company Projects Department-CentralShafie ZubierNo ratings yet

- Ohs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordDocument1 pageOhs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordShafie ZubierNo ratings yet

- Ohs-Pr-09-03-F10 (A) Planned Job Observation ReportDocument2 pagesOhs-Pr-09-03-F10 (A) Planned Job Observation ReportShafie Zubier100% (1)

- Ohs-Pr-09-03-F10 (A) Planned Job Observation ReportDocument1 pageOhs-Pr-09-03-F10 (A) Planned Job Observation ReportShafie ZubierNo ratings yet

- Material Safety Data Sheet AC - 770 Catalyst: 1. Chemical Product and Company InformationDocument6 pagesMaterial Safety Data Sheet AC - 770 Catalyst: 1. Chemical Product and Company InformationNICKYNo ratings yet

- MSDSDocument670 pagesMSDSisabelaNo ratings yet

- SkillsFuture SG - Skills Framework For Environmental Services 2020Document100 pagesSkillsFuture SG - Skills Framework For Environmental Services 2020Amani NavitaNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument14 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingKamil AYDINNo ratings yet

- Arc Flash BasicsDocument5 pagesArc Flash BasicsabenitechNo ratings yet

- Sodium Nitrate, ACS: Safety Data SheetDocument8 pagesSodium Nitrate, ACS: Safety Data SheetmallikharjunareddyNo ratings yet

- Risk Assessment - RADocument26 pagesRisk Assessment - RASIVASURIYANNo ratings yet

- MS For Works On AC: Lilongwe Water BoardDocument5 pagesMS For Works On AC: Lilongwe Water Boardbonus zhouNo ratings yet

- Job Safety AnalysisDocument5 pagesJob Safety AnalysisMuhammad Zarif Amir100% (2)

- Polyether Polyol MsdsDocument6 pagesPolyether Polyol MsdsMyo SeinNo ratings yet

- EHS Guidelines Page 1 of 64Document64 pagesEHS Guidelines Page 1 of 64Shyam MurugesanNo ratings yet

- 2.method Statement Excavation and TrenchingDocument4 pages2.method Statement Excavation and Trenchingشاز إياسNo ratings yet

- NFPA Review of The Incident by Ken MastrulloDocument3 pagesNFPA Review of The Incident by Ken MastrullotatacpsNo ratings yet

- Msds 56.21 PDFDocument4 pagesMsds 56.21 PDFHendra Cipto SaputroNo ratings yet

- Ghana - Takoradi Port Expansion Project On Dock Container and Multipurpose Terminal - Esia SummaryDocument18 pagesGhana - Takoradi Port Expansion Project On Dock Container and Multipurpose Terminal - Esia SummaryFranckeml H2ALNo ratings yet

- StyreneDocument3 pagesStyreneNaeem AkramNo ratings yet

- Sk300nlc-10 2 Pcs Boom Op ManualDocument52 pagesSk300nlc-10 2 Pcs Boom Op ManualPHÁT NGUYỄN THẾ75% (4)

- Manual de Operacion Secadores Ra 100 y Ra 125Document76 pagesManual de Operacion Secadores Ra 100 y Ra 125Ricardo López BernalNo ratings yet

- Ks MNL Eng 02 04 (Retriever Tks TR)Document39 pagesKs MNL Eng 02 04 (Retriever Tks TR)chakrapani vagish chandra pandeyNo ratings yet

- Unit 3 Practical 3Document27 pagesUnit 3 Practical 3MUHAMMAD UMARNo ratings yet

- Technical Submittal - FP312 Coating - 080723 - Rev0 - CompressedDocument90 pagesTechnical Submittal - FP312 Coating - 080723 - Rev0 - CompressedAngelo Carlo MalabananNo ratings yet

- Safety Data Sheet: Used Lubricating Oil (For Laboratory Testing Purposes)Document6 pagesSafety Data Sheet: Used Lubricating Oil (For Laboratory Testing Purposes)Om Prakash RajNo ratings yet

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- K To 12 Bread and Pastry Teacher's GuideDocument19 pagesK To 12 Bread and Pastry Teacher's GuideHari Ng Sablay98% (53)

- hsg61 - Health Surveillance at WorkDocument43 pageshsg61 - Health Surveillance at WorkAna Peón100% (1)

- Sds-GreaseDocument8 pagesSds-GreaseMacuto JunieNo ratings yet

- Thiamine HCLDocument5 pagesThiamine HCLHimansu KhandhediaNo ratings yet