Professional Documents

Culture Documents

China State Construction Engineering Corporation. LTD

Uploaded by

Amila SampathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

China State Construction Engineering Corporation. LTD

Uploaded by

Amila SampathCopyright:

Available Formats

China State Construction Engineering Corporation.

LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

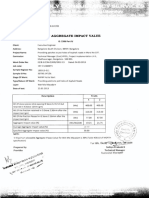

EXISTING LAYER PROFILE

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 06.05.2021

Type Thickness (mm)

Top Soil 280

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

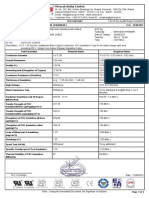

SIEVE ANALYSIS TEST

AASHTO - T88/ BS- 1377

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 18.06.2021

Weight of Sample Before Washing (g) 2769

Weight of Sample After Washing (g) 2161

Sieve Size Weight Retained Retained (%) Passing (%)

(mm) (g)

50 0.0 0.0 100.0

37.5 0.0 0.0 100.0

20 0.0 0.0 100.0

5 544.0 19.6 80.4

2.36 359.0 13.0 67.4

1.18 371.0 13.4 54.0

0.425 358.0 12.9 41.1

0.3 143.0 5.2 35.9

0.075 386.0 13.9 22.0

110

100

90

80

Passing (%)

70

60

50

40

30

20

0.01 0.1 1 10 100

Sieve Size (mm)

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

ATTERBERG LIMITS TEST

AASHTO T-89 & T-90

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 28.06.2021

Liquid Limit

Test No

Number of Blows

Can No

Weight of Can + Wet Soil (g)

NON PLASTIC

Weight of Can + Dry Soil (g)

Weight of Can (g)

Weight of Water (g)

Weight of Dry Soil (g)

Moisture Content (%)

30

29

28

Moisture Content (%)

27

26

25

24

23

22

21

20

10

Number of Blows (in Log Scale)

Plastic Limit

Test No

Can No

Weight of Can + Wet Soil (g)

Weight of Can + Dry Soil (g) Liqued Limit (LL)

Weight of Can (g) Plastic Limit (PL)

Weight of Water (g) Plastic Index (PI)

Weight of Dry Soil (g)

Moisture Content (%)

Average Moisture Content (%)

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

PROCTOR COMPACTION TEST

AASHTO : T 180-98 (Method - D)

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 14.06.2021

Weight of Mould (g) 4814

Volume (cm3) 996

Trail No 1 2 3 4 5

Weight of Wet Soil + Mould (g) 6785 6894 6953 6937 6895

Weight of Wet Soil (g) 1971 2080 2139 2123 2081

Wet Density (g/cm3) 1.979 2.088 2.148 2.132 2.089

Can No 16 17 18 19 20

Weight of Wet Soil + Can (g) 316.48 255.76 289.60 352.79 366.16

Weight of Dry Soil + Can (g) 305.34 245.5 275.86 329.06 336.59

Weight of Moisture (g) 11.1 10.3 13.7 23.7 29.6

Weight of Can (g) 123 108 126 128 116

Weight of Dry Soil (g) 182.3 137.5 149.9 201.1 220.6

Moisture Content (%) 6.1 7.5 9.2 11.8 13.4

Dry Density (g/cm3) 1.865 1.942 1.967 1.907 1.842

1.960

1.940

Dry Density (g/cm3)

1.920

1.900

1.880

1.860

1.840

6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0

Moisture Content (%)

Optimum Moisture Content (OMC) (%) 9.0

Maximum Dry Density (MDD) (g/cm3) 1.967

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF FIELD DRY DENSITY

SAND REPLACEMENT METHOD (BS 1377 - Part 9)

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 06.05.2021

Depth from Surface (mm) 280

Depth of Hole Excavated (mm) 150

Mass of Standard Sand Before Pouring (g) 8000

Mass of Standard Sand After Pouring (g) 4079

Mass of standard Sand in Hole & Cone (g) 3921

Mass of Standard Sand in Cone (g) 1109

Mass of Standard Sand in Hole (g) 2812

Density of Standard Sand (g/cm3) 1.337

Volume of Hole (cm3) 2103

Mass of Container + Wet Soil (g) 3980

Mass of Container (g) 341

Mass of Wet Soil (g) 3639

Wet Density of Soil (cm3) 1.730

Moisture Container No 41

Mass of Can + Wet Soil (g) 227.0

Mass of Can + Dry Soil (g) 216.0

Mass of Can (g) 101.0

Mass of Dry Soil (g) 115.0

Mass of Moisture (g) 11.0

Moisture Content of Soil (Field) (%) 9.6

Field Dry Density of Soil (FDD) (g/cm3) 1.579

Maximum Dry Density of Soil (Lab) (g/cm3) 1.967

Optimum Moisture Content of Soil (Lab) (%) 9.0

Degree of Compaction (%) 80.3

Specified Degree of Compaction (%) 95

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 19.06.2021

Identification of the Specimen 12

Specified Dry Density (g/cm3) 1.869

Specified Moisture Content (%) 9.0

Bulk Density (g/cm3) 2.037

Calibrated Volume of CBR Mould (cm3) 2308

Calibrated Height of Mould (mm) 127

Maximum Dry Density of Soil (MDD)(cm3) 1.967

Specified Degree of Compaction (%) 95.0

SPECIMEN BEFORE SOAKING

Calculated Mass of Dry Soil in Mould (g) 4314

Initial / Field Moisture Content of Sample (%) 1.9

Calculated Mass of Sample Taken for Test (g) 4396

Volume of Water Required to Add (ml) 306.3

Mass of Specimen + Mould With Base Plate Before Soaking (g) 8971

Mass of Mould With Base Plate (g) 4270

Mass of Compacted Specimen in Mould Before Soaking (g) 4701

Bulk Density of Unsoaked Speciman (cm3) 2.037

Moisture Content of Soil While Casting (%) 9.0

Dry Density of Soil Before Soaking (Unsoaked) (cm3) 1.869

Degree of Compaction Before Soaking (%) 95.0

SPECIMEN AFTER 4 DAYS SOAKING

Mass of Specimen + Mould With Base Plate After Soaking (g) 9169

Mass of Compacted Specimen in Mould After Soaking (g) 4899

Bulk Density of Soaked Speciman (cm3) 2.123

Moisture Content of Soil After Soaking (%) 13.5

Dry Density of Soil After Soaking ( Soaked )(cm3) 1.870

Degree of Compaction After Soaking (%) 95.1

Initial Reading of Swell Gauge (Div) 0

Final Reading of Swell Gauge (Div) 15

Swell of Specimen (mm) 0.15

Precentage Swell (%) 0.12

Tested by Checked by Certified by

Materials Technician Engineer Engineer

V.V.KARUNARATNE & CO.

Engineering Laboratory Temple Road, Daladagama, Mahawa

Head Office - No 579,Bulugaha Junction,Kandy Road ,Kelaniya Sri Lanka.

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method AASHTO T-193 (1999)

Project Construction of Upper Elahera Canal from 27+509km to 55+600km Including

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Employer Ministry of Irrigation - Mahaweli Water Security Investment Program

Consultant 0

Description Sabgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 16.09.2016

Identification of the Specimen 1 2 3

Decided Nos of Blows per Layer (Blows) 10 30 65

Identification No of CBR Mould and Base Plate S T U

Calibrated Volume of CBR Mould (cm3) 2117.8 2125 2121

Calibrated Height of Mould (mm) 116.77 116.8 116.52

Maximum Dry Density of Soil (g/cm3) 1.967

Moisture Content at Which the Sample is Cast ( OMC) 9.0

SPECIMEN BEFORE SOAKING

Initial / Field Moisture Content of Sample (%) 1.4 1.4 1.4

Mass of Sample Taken for Test (g) 6000 6000 6000

Volume of Water Required to Add (ml) 450 450 450

Mass of Specimen + Mould With Base Plate Before Soaking (g) 12254 12685 12912

Mass of Mould With Base Plate (g) 8071 8142 8080

Mass of Compacted Specimen in Mould Before Soaking (g) 4183 4543 4832

Bulk Density of Unsoaked Speciman (g/cm3) 1.975 2.138 2.278

Moisture Content of Soil While Casting (%) 9.0 9.0 9.0

Dry Density of Soil Before Soaking ( Unsoaked )(g/cm3) 1.812 1.961 2.090

Degree of Compaction Before Soaking (%) 92.1 99.7 106.2

SPECIMEN AFTER SOAKING

Mass of Specimen + Mould With Base Plate After Soaking (g) 12635 12985 13080

Mass of Compacted Specimen in Mould After Soaking (g) 4564 4843 5000

Bulk Density of Soaked Speciman (g/cm3) 2.16 2.28 2.36

Moisture Content of Soil After Soaking (%) 15.9 12.6 10.5

Dry Density of Soil After Soaking ( Soaked ) (g/cm3) 1.859 2.024 2.133

Degree of Compaction After Soaking (%) 94.5 102.9 108.4

Initial Reading of Swell Gauge (Div) 0 0 0

Final Reading of Swell Gauge (Div) 31 22 10

Swell of Specimen (mm) 31 22 10

Precentage Swell (%) 0.27 0.19 0.09

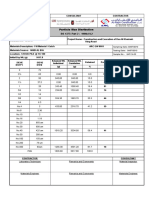

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Penetration (mm) Dial Reading (Div.) Load on Plunger (KN)

B-10 B-30 B-65 B-10 B-30 B-65

0.00 0 0 0 0.00 0.00 0.00

0.25 3 5 6 0.13 0.21 0.25

0.50 4 8 9 0.17 0.34 0.38

0.75 5 9 11 0.21 0.38 0.47

1.00 6 11 12 0.25 0.47 0.51

1.25 7 12 14 0.30 0.51 0.59

1.50 8 14 15 0.34 0.59 0.64

1.75 9 15 17 0.38 0.64 0.72

2.00 10 16 21 0.42 0.68 0.89

2.25 11 17 23 0.47 0.72 0.98

2.50 12 18 25 0.51 0.76 1.06

2.75 13 19 27 0.55 0.81 1.14

3.00 14 20 28 0.59 0.85 1.19

3.25 15 21 30 0.64 0.89 1.27

3.50 16 22 32 0.68 0.93 1.36

3.75 17 23 35 0.72 0.98 1.48

4.00 18 25 37 0.76 1.06 1.57

4.25 19 27 39 0.81 1.14 1.65

4.50 20 28 41 0.85 1.19 1.74

4.75 21 29 43 0.89 1.23 1.82

5.00 22 30 45 0.93 1.27 1.91

5.25 23 31 48 0.98 1.31 2.04

5.50 24 32 50 1.02 1.36 2.12

5.75 25 33 53 1.06 1.40 2.25

6.00 26 34 56 1.10 1.44 2.37

6.25 27 35 58 1.14 1.48 2.46

Load Ring Factor 0.0424 KN/Div.

Penetration (mm) 2.5 5

Standard Load (KN) 13.24 19.96

B-10 0.51 0.93

Force on Plunger (KN) B-30 0.76 1.27

B-65 1.06 1.91

B-10 3.8 4.7

CBR (%) B-30 5.8 6.4

B-65 8 9.6

Maximum Dry Density (MDD) 1.967

Field Dry Density (FD) (g/cm3) 1.58

10 Blows 30 Blows 65 Blows 95 % MDD FD

Dry Density (g/cm3) 1.812 1.961 2.090 1.869 1.58

CBR (%) 4.7 6.4 9.6 5.1 NA

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

CBR Test Result Curves

3.0

2.5

2.0

Load (KN)

1.5

1.0

0.5

0.0

0 1 2 3 4 5 6 7

Penetration (mm)

10 Blows Polynomial (10 Blows) 30 Blows

Polynomial (30 Blows) 65 Blows Polynomial (65 Blows)

Dry Density/Dry Density Relationship

12

10

8

CBR (%)

0

1.75 1.80 1.85 1.90 1.95 2.00 2.05 2.10 2.15

Dry Density (g/cm3)

Tested by Checked by Witnessed by Certyfied by

Materials Technician Materials Engineer Materials Technician Materials Engineer

(Contractor) (Contractor) (Consultant) (Consultant)

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 19.06.2021

Penetration (mm) Dial Reading (Div.) Load on Plunger (KN)

Top Bottom Top Bottom

0.00 0 0 0.00 0.00

0.25 2 3 0.09 0.14

0.50 4 5 0.18 0.23

0.75 7 8 0.32 0.37

1.00 9 10 0.41 0.46

1.25 12 13 0.55 0.60

1.50 12 14 0.55 0.64

1.75 14 16 0.64 0.73

2.00 16 18 0.73 0.82

2.25 18 21 0.82 0.96

2.50 21 23 0.96 1.05

2.75 23 25 1.05 1.15

3.00 24 28 1.10 1.28

3.25 26 31 1.19 1.42

3.50 27 35 1.24 1.60

3.75 29 39 1.33 1.79

4.00 31 42 1.42 1.92

4.25 32 44 1.47 2.02

4.50 33 49 1.51 2.24

4.75 34 53 1.56 2.43

5.00 36 55 1.65 2.52

5.25 39 59 1.79 2.70

5.50 42 62 1.92 2.84

5.75 44 63 2.02 2.89

6.00 45 69 2.06 3.16

6.25 48 71 2.20 3.25

Load Ring Factor 0.0458 kN/Div.

Tested by Checked by Certified by

Materials Technician Engineer Engineer

China State Construction Engineering Corporation. LTD

Engineering Laboratory,

Head Office - No 38/A/1/1 Anagarika Darmapala Mawatha Kandy,

DETERMINATION OF CALIFORNIA BEARING RATIO (CBR)

Test Method - BS 1377: PART 4 : 1990

Construction of Upper Elahera Canal from 27+509km to 55+600km Including

Project

27.7km Long Tunnels UECP- ICB-2A(Nothern Access Road)

Client Ministry of Irrigation - Mahaweli Water Security Investment Program

Description Subgrade Sample

Location Widening Section/02+750 LHS/2.70m from Existing Center

Lab Reference No ED/2021/SOIL/063 Field Reference No TP/08

Date of Sampling 06.05.2021 Date of Test 19.06.2021

CBR Test Result Curves

3.5

3.0

2.5

2.0

Load (KN)

1.5

1.0

0.5

0.0

0 1 2 3 4 5 6 7

Penetration (mm)

Top Polynomial (Top) Bottom Polynomial (Bottom)

Penetration (mm) 2.5 5

Standard Load (kN) 13.24 19.96

Top 0.96 1.65

Force on Plunger (kN)

Bottom 1.05 2.52

Top 7.3 8.3

Soaked CBR (%)

Bottom 8.0 12.6

Accepted Soaked CBR (%) 10.5

Tested by Checked by Certified by

Materials Technician Engineer Engineer

You might also like

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- China State Construction Engineering Corporation. LTDDocument20 pagesChina State Construction Engineering Corporation. LTDAmila SampathNo ratings yet

- Test Results of Aggregate Impact Value: Lab IDDocument7 pagesTest Results of Aggregate Impact Value: Lab IDyoseph dejeneNo ratings yet

- Filter Material For MSE Wall LogDocument2 pagesFilter Material For MSE Wall Logfreanne_0527No ratings yet

- Omnibus Industrial Devlopment Corporation Tpia: Sardar Vallabhbhai National Institute of Technology Contractor:M/s. Rakesh Construction CompanyDocument12 pagesOmnibus Industrial Devlopment Corporation Tpia: Sardar Vallabhbhai National Institute of Technology Contractor:M/s. Rakesh Construction CompanyvikasNo ratings yet

- 04 - PT. VUB Bandara Kediri (Pasir Kelud) PDFDocument11 pages04 - PT. VUB Bandara Kediri (Pasir Kelud) PDFDeny PutraNo ratings yet

- Ecg524 Dec 2019Document8 pagesEcg524 Dec 2019Hairul AsyrafNo ratings yet

- 04 - PT. VUB Bandara Kediri (Pasir Kayan Kalimantan) PDFDocument11 pages04 - PT. VUB Bandara Kediri (Pasir Kayan Kalimantan) PDFDeny PutraNo ratings yet

- Mix Design M - 20Document5 pagesMix Design M - 20souravsrkNo ratings yet

- Use of Industrial Wastes in The Construction of Flexible PavementsDocument6 pagesUse of Industrial Wastes in The Construction of Flexible Pavementssai venkateshNo ratings yet

- Civ T Qac 00134 ProctorDocument6 pagesCiv T Qac 00134 ProctorIsaiahogedaNo ratings yet

- Flakiness Index of Coarse Aggregate: Test DataDocument2 pagesFlakiness Index of Coarse Aggregate: Test DataRuwan Sampath WickramathilakaNo ratings yet

- SIEVE ANALYSIS of Fine Aggregate FinalDocument40 pagesSIEVE ANALYSIS of Fine Aggregate FinalShaiful IslamNo ratings yet

- Test Results of Gradation and Atterberg Limits For WMMDocument13 pagesTest Results of Gradation and Atterberg Limits For WMMLalit KumarNo ratings yet

- Test Report For Gabion Wire: Parameters ResultDocument1 pageTest Report For Gabion Wire: Parameters ResultmirwaisNo ratings yet

- DCL Test Report - Size 12.7 MM - 18-2-2020Document2 pagesDCL Test Report - Size 12.7 MM - 18-2-2020docpt76No ratings yet

- DCL Test EMTX-2018-110006-TEST REPORTDocument2 pagesDCL Test EMTX-2018-110006-TEST REPORTdocpt76No ratings yet

- Tectyl G OS 550 ECO (PDS - EN)Document2 pagesTectyl G OS 550 ECO (PDS - EN)HDSC ChemicalsNo ratings yet

- Monitoring Axial Test - Thci New Factory ProjectDocument1 pageMonitoring Axial Test - Thci New Factory ProjectFajar AjaNo ratings yet

- Ict 1 Furan 17 5 23Document1 pageIct 1 Furan 17 5 23Boddu ThirupathiNo ratings yet

- A73D3A20Document21 pagesA73D3A20Chaw Tze WeeNo ratings yet

- Draft: Test Report For Sieve Analysis-ASTM C-136Document1 pageDraft: Test Report For Sieve Analysis-ASTM C-136civillabNo ratings yet

- CIVE1244 - Tutorial Week 1-2Document22 pagesCIVE1244 - Tutorial Week 1-2Tharun DelpachitraNo ratings yet

- Vicat Test PDFDocument6 pagesVicat Test PDFsyakirohNo ratings yet

- Sieve Analysis BH 3Document74 pagesSieve Analysis BH 3inam ulhaqNo ratings yet

- Ilovepdf Merged PDFDocument60 pagesIlovepdf Merged PDFAtanu PaulNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Cicogrout MCDocument3 pagesCicogrout MCSharookhan ShajahanNo ratings yet

- Quality Test & Engineering Services Test RecordDocument1 pageQuality Test & Engineering Services Test RecordQTESNo ratings yet

- Semester Result PDFDocument1 pageSemester Result PDFKavita SinghNo ratings yet

- HFU-2020AN: Pressurized Outside To in / Dead-End Filtration Ultrafiltration (UF) Membrane ModuleDocument2 pagesHFU-2020AN: Pressurized Outside To in / Dead-End Filtration Ultrafiltration (UF) Membrane ModulePushpak AkhadeNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Government of Telangana Roads & Buildings Department: 01 05/03/19 9+170/ HM Plant Jointly CA 05/03/19 BC JointlyDocument4 pagesGovernment of Telangana Roads & Buildings Department: 01 05/03/19 9+170/ HM Plant Jointly CA 05/03/19 BC JointlyKreesthu ReddyNo ratings yet

- Government of The Peoples Republic of Bangladesh Local Government Engineering Department Office of The Executive Engineer Lged, ChandpurDocument14 pagesGovernment of The Peoples Republic of Bangladesh Local Government Engineering Department Office of The Executive Engineer Lged, ChandpurShaiful IslamNo ratings yet

- Laboratory Course Report: Mansoorp Syed 203219012Document44 pagesLaboratory Course Report: Mansoorp Syed 203219012Santosh YelagandulaNo ratings yet

- Technological University of The PhilippinesDocument7 pagesTechnological University of The PhilippinesJohn Reigh CatipayNo ratings yet

- Tchumene Access Project Project Quality Management System (QMS)Document9 pagesTchumene Access Project Project Quality Management System (QMS)Loforte CumbeNo ratings yet

- 1CX 1.33 SQ - MM. 21 CoilDocument2 pages1CX 1.33 SQ - MM. 21 CoilLaboratory UltracabNo ratings yet

- 2021 International Hi Tech Manufacturing Cleanroom Facilities Estimating Yearbook SAMPLE 1Document10 pages2021 International Hi Tech Manufacturing Cleanroom Facilities Estimating Yearbook SAMPLE 1Familia GonzalezNo ratings yet

- WCC.10002MG (Tanjung Bin)Document10 pagesWCC.10002MG (Tanjung Bin)keymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Final Report Design MixDocument17 pagesFinal Report Design MixDEEPAK KUMAR MALLICKNo ratings yet

- Gatch MaterialDocument7 pagesGatch MaterialamesbNo ratings yet

- Wt. of Original Sample: (G) : ProjectDocument1 pageWt. of Original Sample: (G) : ProjectzeekoNo ratings yet

- Kundila Office Soil InvestigationDocument10 pagesKundila Office Soil Investigationsaminu hamisuNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- HFUG-2020AN: Pressurized Outside To in / Dead-End Filtration Ultrafiltration (UF) Membrane ModuleDocument2 pagesHFUG-2020AN: Pressurized Outside To in / Dead-End Filtration Ultrafiltration (UF) Membrane ModulePushpak AkhadeNo ratings yet

- Optimization of Gating System For Sand Casting Using Sequential Quadratic ProgrammingDocument6 pagesOptimization of Gating System For Sand Casting Using Sequential Quadratic ProgrammingIJRASETPublicationsNo ratings yet

- 3500-06 Weatherproof Housing Datasheet - 141528Document12 pages3500-06 Weatherproof Housing Datasheet - 141528Kourosh52No ratings yet

- Omega: ServicesDocument7 pagesOmega: ServicesSumit JainNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- Test Report: Test Result Physical PropertiesDocument1 pageTest Report: Test Result Physical PropertiesTsc TechnoNo ratings yet

- Performance Evaluation of Hot Mixed Asphalt Using Polymers Modified Bitumen and Marble Dust As A FilDocument9 pagesPerformance Evaluation of Hot Mixed Asphalt Using Polymers Modified Bitumen and Marble Dust As A FilIJRASETPublicationsNo ratings yet

- Punjab Water Supply and Sewerage Division: Bricks Test ReportDocument34 pagesPunjab Water Supply and Sewerage Division: Bricks Test ReportAnbuNo ratings yet

- Water Works Design & Supervision Enterprise: Company NameDocument153 pagesWater Works Design & Supervision Enterprise: Company NamegirumNo ratings yet

- WMM Moisture Correction SheetDocument34 pagesWMM Moisture Correction SheetQuality JamNo ratings yet

- Bit OilDocument42 pagesBit OilAmila SampathNo ratings yet

- Carriageofgoodbysea 121110020207 Phpapp02Document29 pagesCarriageofgoodbysea 121110020207 Phpapp02Amila SampathNo ratings yet

- BAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMDocument1 pageBAR Mark Type and Size No. of Bars in Each No. of Mbrs Total NO. Length of Each BAR MM Shape Code A MMAmila SampathNo ratings yet

- To Lasaght For Pricing - (01-09-2020)Document2 pagesTo Lasaght For Pricing - (01-09-2020)Amila SampathNo ratings yet

- VIEW - 'X': Key PlanDocument1 pageVIEW - 'X': Key PlanAmila SampathNo ratings yet

- 9negotiableinstruments 120527122657 Phpapp01Document33 pages9negotiableinstruments 120527122657 Phpapp01Amila SampathNo ratings yet

- Policy FrameworkDocument19 pagesPolicy FrameworkAmila SampathNo ratings yet

- The Engineer:: Central Expressway Project Section - 03Document1 pageThe Engineer:: Central Expressway Project Section - 03Amila SampathNo ratings yet

- Structural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Document2 pagesStructural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Amila SampathNo ratings yet

- Beam Bar ScheduleDocument12 pagesBeam Bar ScheduleAmila SampathNo ratings yet

- Structural Design Calculation of Culvert at Ch. 7+804: Construction of Package 1J (Ch. 6+900km - Ch. 8+050km)Document1 pageStructural Design Calculation of Culvert at Ch. 7+804: Construction of Package 1J (Ch. 6+900km - Ch. 8+050km)Amila SampathNo ratings yet

- 542) Cida-Dev-Ccr-Fo-07 (E)Document4 pages542) Cida-Dev-Ccr-Fo-07 (E)Amila SampathNo ratings yet

- Structural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Document1 pageStructural Design Calculation of Bridge SUPERSTRUCTURE AT CH. 3+758 - 4+064Amila SampathNo ratings yet

- Bluescope Lysaght Lanka (PVT) LTD: Colombo OfficeDocument3 pagesBluescope Lysaght Lanka (PVT) LTD: Colombo OfficeAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 20181107Document1 pageComment Management Sheet (CMS) P-A Ramp C A1 20181107Amila SampathNo ratings yet

- Schedule of Doors & Windows: Detail of Septic TankDocument1 pageSchedule of Doors & Windows: Detail of Septic TankAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A 37+710 Cross Head - 20181203Document2 pagesComment Management Sheet (CMS) P-A 37+710 Cross Head - 20181203Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Document1 pageComment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Amila SampathNo ratings yet

- Comment Management Sheet (CMS) 20171221 - Structural DesignDocument2 pagesComment Management Sheet (CMS) 20171221 - Structural DesignAmila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Document1 pageComment Management Sheet (CMS) P-A (VD37+710-37+800) P1 & P2-20180716-R1Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Document3 pagesComment Management Sheet (CMS) P-A Ramp C A2 20181029-4893Amila SampathNo ratings yet

- Comment Management Sheet (CMS) OPB 69+902 D 20190507Document1 pageComment Management Sheet (CMS) OPB 69+902 D 20190507Amila SampathNo ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- Comment Management Sheet (CMS) OPB 69+902 D 20190321Document1 pageComment Management Sheet (CMS) OPB 69+902 D 20190321Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Bridge 60+850 To 60+875 C 20190316Document1 pageComment Management Sheet (CMS) Bridge 60+850 To 60+875 C 20190316Amila SampathNo ratings yet

- Comment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Document1 pageComment Management Sheet (CMS) A2 - 38+620-39+073 - 20181112Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Document2 pagesComment Management Sheet (CMS) Design Calculations of Expansion Joints For All Expressway Viaducts (30m Girder) - 20181126Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Example 20171213Document3 pagesComment Management Sheet (CMS) Example 20171213Amila SampathNo ratings yet

- Comment Management Sheet (CMS) Bridge 58+164.2 C 20190326Document2 pagesComment Management Sheet (CMS) Bridge 58+164.2 C 20190326Amila SampathNo ratings yet

- Comment Management Sheet (CMS) 20171221 - Structural DesignDocument2 pagesComment Management Sheet (CMS) 20171221 - Structural DesignAmila SampathNo ratings yet

- Hydraulic Excavator: Engine WeightsDocument28 pagesHydraulic Excavator: Engine WeightsFelipe Pisklevits LaubeNo ratings yet

- Hydrotest Test FormatDocument27 pagesHydrotest Test FormatRähûl Prätäp SïnghNo ratings yet

- Sullivan's Interpersonal TheoryDocument27 pagesSullivan's Interpersonal TheoryJezalen GonestoNo ratings yet

- Lifecycle of A Frog For Primary StudentsDocument10 pagesLifecycle of A Frog For Primary StudentsMónika KissNo ratings yet

- Tugas Bahasa Inggris: ButterflyDocument4 pagesTugas Bahasa Inggris: ButterflyRiyadi TeguhNo ratings yet

- Outbound Idocs Code Error Event Severity Sap MeaningDocument2 pagesOutbound Idocs Code Error Event Severity Sap MeaningSummit YerawarNo ratings yet

- Operator Training ManualDocument195 pagesOperator Training ManualIgnacio MuñozNo ratings yet

- The 100 Best Books For 1 Year Olds: Board Book HardcoverDocument17 pagesThe 100 Best Books For 1 Year Olds: Board Book Hardcovernellie_74023951No ratings yet

- 60 Plan of DepopulationDocument32 pages60 Plan of DepopulationMorena Eresh100% (1)

- Exchange 2010 UnderstandDocument493 pagesExchange 2010 UnderstandSeKoFieNo ratings yet

- Burj Khalifa: Engineer Abdul MananDocument29 pagesBurj Khalifa: Engineer Abdul MananabdulmananNo ratings yet

- Pyle 4ch Marine BTDocument4 pagesPyle 4ch Marine BTRafael VieiraNo ratings yet

- Dosificación Gac007-008 Sem2Document2 pagesDosificación Gac007-008 Sem2Ohm EgaNo ratings yet

- ARRANGING For Marchong or Concert BandDocument13 pagesARRANGING For Marchong or Concert BandCheGus AtilanoNo ratings yet

- Porifera and CnidariaDocument16 pagesPorifera and CnidariaMichaelNo ratings yet

- Method Statement For Construction of Concrete Batching Plant (Combined)Document72 pagesMethod Statement For Construction of Concrete Batching Plant (Combined)NP Dien100% (1)

- Nursing Care Plan For AIDS HIVDocument3 pagesNursing Care Plan For AIDS HIVFARAH MAE MEDINA100% (2)

- ZEROPAY WhitepaperDocument15 pagesZEROPAY WhitepaperIlham NurrohimNo ratings yet

- PCZ 1503020 CeDocument73 pagesPCZ 1503020 Cedanielradu27No ratings yet

- MVC Training Course Prerequisite: WWW - Focustech.InDocument2 pagesMVC Training Course Prerequisite: WWW - Focustech.InLakshman Samanth ReddyNo ratings yet

- Project - Dreambox Remote Video StreamingDocument5 pagesProject - Dreambox Remote Video StreamingIonut CristianNo ratings yet

- Blank Freeway Walls Replaced With Local Designs - Press EnterpriseDocument5 pagesBlank Freeway Walls Replaced With Local Designs - Press EnterpriseEmmanuel Cuauhtémoc Ramos BarajasNo ratings yet

- Visvesvaraya Technological University: Jnana Sangama, Belgavi-590018, Karnataka, INDIADocument7 pagesVisvesvaraya Technological University: Jnana Sangama, Belgavi-590018, Karnataka, INDIAShashi KaranNo ratings yet

- 555 TimerDocument25 pages555 TimerDr-Muhammad Aqeel AslamNo ratings yet

- TOPIC 2 - Fans, Blowers and Air CompressorDocument69 pagesTOPIC 2 - Fans, Blowers and Air CompressorCllyan ReyesNo ratings yet

- TDS-11SH Top Drive D392004689-MKT-001 Rev. 01Document2 pagesTDS-11SH Top Drive D392004689-MKT-001 Rev. 01Israel Medina100% (2)

- MnemonicsDocument1 pageMnemonicsSunil Boyz-uNo ratings yet

- Laminar Premixed Flames 6Document78 pagesLaminar Premixed Flames 6rcarpiooNo ratings yet

- Code of Conduct For Public OfficialDocument17 pagesCode of Conduct For Public OfficialHaNo ratings yet

- Proposal For A Working Procedure To Accurately Exchange Existing and New Calculated Protection Settings Between A TSO and Consulting CompaniesDocument9 pagesProposal For A Working Procedure To Accurately Exchange Existing and New Calculated Protection Settings Between A TSO and Consulting CompaniesanonymNo ratings yet