Professional Documents

Culture Documents

PR 753 Aci CH 001 00

Uploaded by

SIA PRESUPUESTOSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PR 753 Aci CH 001 00

Uploaded by

SIA PRESUPUESTOSCopyright:

Available Formats

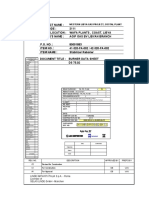

CALCULATION SUMMARY

Project Name : NESTLE Project Location: Sistema 2

Drawing No. : ACI-07 City: Lima, Peru

Design Areas

Design Area Calc. Mode Occupancy Area of Total Water Pressure @ Min. Min. Min. Calculated Hose Margin To

Name (Model) Application Source Density Pressure Flow Heads Streams Source

(ft²) (gpm) (psi) (gpm/ft²) (psi) (gpm) # (gpm) (psi)

Required

ESFR K=25.2 Demand (HW) 2499.6 2175 0.765 40 159.4 12 250 5.4

139.3

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA

Date 12/10/2020 Nº2\PR-753-ACI-CH-001-00.tyc3

Page 1

Copyright © 2002-2012 Tyco Fire Protection Products

HYDRAULIC CALCULATIONS

for

Job Information

Project Name : NESTLE

Contract No. : ACI-07 City: Lima, Peru

Project Location: Sistema 2 Date: 07/10/2020

Contractor Information

Name of Contractor: P&R Arquitectos Consultores

Address: Salzillo 163 San Borja City: Lima, Perú

Phone Number: 225-0212 E-mail: contacto@pyrarquitectos.pe

Name of Designer: O. Ramón

Authority Having Jurisdiction: CGBVP

Design

Remote Area Name ESFR K=25.2

Remote Area Location

Occupancy Classification

Density (gpm/ft²) 0.765

Area of Application (ft²) 2499.6

Coverage per Sprinkler (ft²) 208.3

Number of Calculated Sprinklers 12

In-Rack Demand (gpm) 0

Special Heads

Hose Streams (gpm) 250

Total Water Required (incl. Hose Streams) (gpm) 2175

Required Pressure at Source (psi) 139.3

Type of System Wet

Volume - Entire System (gal) 6381.1 gal

Water Supply Information

Date DD/MM/YYYY

Location

Source W1

Notes

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA

Nº2\PR-753-ACI-CH-001-00.tyc3

Date 12/10/2020 Copyright © 2002-2012 Tyco Fire Protection Products Page 2

Job : NESTLE Node Labels: Node Reference

Pipe Labels: Off

Diagram for Design Area : ESFR K=25.2

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA Nº2\PR-753-ACI-CH-001-00.tyc3

Date 12/10/2020 Copyright © 2002-2012 Tyco Fire Protection Products Page 3

Job : NESTLE

Hydraulic Analysis for : ESFR K=25.2

Calculation Info

Calculation Mode Demand

Hydraulic Model Hazen-Williams

Fluid Name Water @ 60F (15.6C)

Fluid Weight, (lb/ft³) N/A for Hazen-Williams calculation.

Fluid Dynamic Viscosity, (lb·s/ft²) N/A for Hazen-Williams calculation.

Water Supply Parameters

Supply 1 : W1 Flow (gpm) Pressure (psi)

0 173

2000 150

3000 114.5

Supply Analysis

Residual Available

Static Pressure Flow Total Demand Required Pressure

Node at Source Pressure Pressure

(psi) (gpm) (gpm) (psi)

(psi) (psi)

W1 173 150 2000 144.7 2175 139.3

Hoses

Inside Hose Flow / Standpipe Demand (gpm) 250

Outside Hose Flow (gpm) 0

Additional Outside Hose Flow (gpm)

Other (custom defined) Hose Flow (gpm) 0

Total Hose Flow (gpm) 250

Sprinklers

Ovehead Sprinkler Flow (gpm) 1925

InRack Sprinkler Flow (gpm) 0

Other (custom defined) Sprinkler Flow (gpm) 0

Total Sprinkler Flow (gpm) 1925

Other

Required Margin of Safety (psi) 0

W1 - Pressure (psi) 139.3

W1 - Flow (gpm) 2175

Demand w/o System Pump(s) N/A

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA

Nº2\PR-753-ACI-CH-001-00.tyc3

Date 12/10/2020 Copyright © 2002-2012 Tyco Fire Protection Products Page 4

Job : NESTLE

Hydraulic Analysis for : ESFR K=25.2

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA

Date 12/10/2020 Nº2\PR-753-ACI-CH-001-00.tyc3 Page 5

Copyright © 2002-2012 Tyco Fire Protection Products

Job : NESTLE

Hydraulic Analysis for : ESFR K=25.2

Graph Labels

Values

Label Description

Flow (gpm) Pressure (psi)

S1 Supply point #1 - Static 0 173

S2 Supply point #2 2000 150

S3 Supply point #3 3000 114.5

D1 Elevation Pressure 0 35.1

D2 System Demand 2175 139.3

Curve Intersections & Safety Margins

Intersection Safety Margin

Curve Name

Pressure (psi) Flow (gpm) Pressure (psi) @ Flow (gpm)

Supply 143.3 2219.4 5.4 2175

Open Heads

Required Calculated

Head Ref. Head Type Coverage K-Factor

Density Flow Pressure Density Flow Pressure

(ft²) (gpm/psi½) (gpm/ft²) (gpm) (psi) (gpm/ft²) (gpm) (psi)

Overhead

P1 208.3 25.2 0.765 116.6 40 0.773 160.9 40.8

Sprinkler

Overhead

P10 208.3 25.2 0.765 116.6 40 0.777 161.9 41.3

Sprinkler

Overhead

P11 208.3 25.2 0.765 116.6 40 0.776 161.7 41.2

Sprinkler

Overhead

P12 208.3 25.2 0.765 116.6 40 0.776 161.7 41.2

Sprinkler

Overhead

P2 208.3 25.2 0.765 116.6 40 0.772 160.7 40.7

Sprinkler

Overhead

P3 208.3 25.2 0.765 116.6 40 0.771 160.7 40.7

Sprinkler

Overhead

P4 208.3 25.2 0.765 116.6 40 0.767 159.8 40.2

Sprinkler

Overhead

P5 208.3 25.2 0.765 116.6 40 0.766 159.6 40.1

Sprinkler

Overhead

P6 208.3 25.2 0.765 116.6 40 0.766 159.6 40.1

Sprinkler

Overhead

P7 208.3 25.2 0.765 116.6 40 0.766 159.6 40.1

Sprinkler

Overhead

P8 208.3 25.2 0.765 116.6 40 0.765 159.4 40

Sprinkler

Overhead

P9 208.3 25.2 0.765 116.6 40 0.765 159.4 40

Sprinkler

File: D:\PROYECTOS ORAMON\CÁLCULOS\NESTLE - 753\TECHO K=25.2\SISTEMA

Nº2\PR-753-ACI-CH-001-00.tyc3

Date 12/10/2020 Copyright © 2002-2012 Tyco Fire Protection Products Page 6

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

P9 67.4 25.2 159.4 40 1x(us.Tee-Br)=8 0.67 120 40

77 68.05 159.4 1.61 8 0.7519 -0.3

8.67 6.5

77 68.05 58 65 9.63 120 46.2

76 68.63 217.4 2.469 0 0.1665 -0.3

9.63 1.6

76 68.63 161.7 65 1x(us.90)=6 4.29 120 47.6

75 68.89 379 2.469 6 0.4663 -0.1

10.29 4.8

75 68.89 0 65 1x(us.Tee-Br)=12 2.13 120 52.3

06 66.77 379 2.469 12 0.4663 0.9

14.13 6.6

06 66.77 -168 150 1x(us.90)=14 0.93 120 59.8

05 66.77 211.1 6.065 14 0.002 0

14.93 0.0

05 66.77 0 150 1x(us.90)=14 68.37 120 59.8

04 63.11 211.1 6.065 14 0.002 1.6

82.37 0.2

04 63.11 0 150 0.93 120 61.6

03 63.11 211.1 6.065 0 0.002 0

0.93 0

03 63.11 262.3 150 8.5 120 61.6

18 63.11 473.3 6.065 0 0.0088 0

8.5 0.1

18 63.11 262.7 150 8.98 120 61.6

17 63.11 736 6.065 0 0.02 0

8.98 0.2

17 63.11 263.5 150 1x(us.90)=14 104.25 120 61.8

16 63.11 999.5 6.065 14 0.0353 0

118.25 4.2

16 63.11 0 150 1.41 120 66

15 61.7 999.5 6.065 0 0.0353 0.6

1.41 0.0

15 61.7 -210.3 150 1x(us.90)=14 191.89 120 66.7

14 61.7 789.2 6.065 1x(us.Tee-Br)=30 44 0.0228 0

235.89 5.4

14 61.7 0 150 1x(us.90)=14 107.82 120 72

13 61.7 789.2 6.065 14 0.0228 0

121.82 2.8

13 61.7 0 150 1x(us.Tee-Br)=30 78.42 120 74.8

12 61.7 789.2 6.065 30 0.0228 0

108.42 2.5

12 61.7 1135.9 200 1x(us.90)=18 185.62 120 77.3

31 61.7 1925 8.071 18 0.0295 0

203.62 6

31 61.7 0 200 1x(us.90)=18 94.31 120 83.3

32 61.7 1925 8.071 18 0.0295 0

112.31 3.3

32 61.7 0 200 1x(us.90)=18 40.37 120 86.6

33 21.33 1925 8.071 18 0.0295 17.5

58.37 1.7

33 21.33 0 200 1x(us.90)=18 4.05 120 105.8

34 21.33 1925 8.071 18 0.0295 0

22.05 0.7

34 21.33 0 200 1x(us.90)=18 10.72 120 106.5

35 21.33 1925 8.071 18 0.0295 0

28.72 0.8

© 2006 National Fire Protection Association Page 7

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

35 21.33 0 200 1x(us.90)=18 14.66 120 107.3

36 21.33 1925 8.071 18 0.0295 0

32.66 1

36 21.33 0 200 1x(us.90)=20.98 1.54 120 108.3

37 21.33 1925 8.329 20.98 0.0254 0

22.52 0.6

37 21.33 0 200 1x(us.90)=20.98 19.36 120 108.9

38 1.97 1925 8.329 20.98 0.0254 8.4

40.34 1

38 1.97 0 250 1.98 120 118.3

39 1.97 1925 10.14 0 0.0097 0

1.98 0.0

39 1.97 250 250 1x(us.90)=22 2.34 120 118.3

40 1.97 2175 10.14 22 0.0122 0

24.34 0.3

40 1.97 0 250 1x(us.90)=25.12 19.36 120 118.6

41 21.33 2175 10.42 25.12 0.0107 -8.4

44.48 0.5

41 21.33 0 250 1x(us.90)=25.12 11.72 120 110.7

42 21.33 2175 10.42 25.12 0.0107 0

36.84 0.4

42 21.33 0 250 1x(us.90)=25.12 1.64 120 111.1

43 19.69 2175 10.42 25.12 0.0107 0.7

26.76 0.3

43 19.69 0 250 1x(us.90)=22 4.34 120 112.1

44 19.69 2175 10.14 22 0.0122 0

26.34 0.3

44 19.69 0 250 1x(us.90)=22 3.28 120 112.4

45 16.4 2175 10.14 22 0.0122 1.4

25.28 0.3

45 16.4 0 250 1x(us.90)=25.12 3.22 120 114.1

46 16.4 2175 10.42 25.12 0.0107 0

28.35 0.3

46 16.4 0 250 1x(us.90)=22 29.53 120 114.4

47 45.93 2175 10.14 22 0.0122 -12.8

51.53 0.6

47 45.93 0 250 1x(us.90)=22 3.09 120 102.3

48 45.93 2175 10.14 22 0.0122 0

25.09 0.3

48 45.93 0 250 1x(us.90)=25.12 10.45 120 102.6

49 56.38 2175 10.42 25.12 0.0107 -4.5

35.57 0.4

49 56.38 0 250 1x(us.90)=25.12 35.51 120 98.4

50 56.38 2175 10.42 25.12 0.0107 0

60.63 0.6

50 56.38 0 250 1x(us.90)=25.12 1.53 120 99.1

51 57.91 2175 10.42 25.12 0.0107 -0.7

26.65 0.3

51 57.91 0 250 1x(us.90)=25.12 35.16 120 98.7

52 57.91 2175 10.42 25.12 0.0107 0

60.28 0.6

52 57.91 0 250 1x(us.90)=25.12 1.53 120 99.3

53 56.38 2175 10.42 25.12 0.0107 0.7

26.65 0.3

53 56.38 0 250 1x(us.90)=25.12 26.26 120 100.3

54 56.38 2175 10.42 25.12 0.0107 0

51.38 0.5

© 2006 National Fire Protection Association Page 8

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

54 56.38 0 250 1x(us.90)=22 5.27 120 100.8

55 56.38 2175 10.14 22 0.0122 0

27.27 0.3

55 56.38 0 250 1x(us.90)=22 54.41 120 101.2

56 1.97 2175 10.14 22 0.0122 23.6

76.41 0.9

56 1.97 0 250 1x(us.90)=22 0.99 120 125.7

57 1.97 2175 10.14 22 0.0122 0

22.99 0.3

57 1.97 0 250 1x(us.90)=25.12 299.29 120 125.9

58 1.97 2175 10.42 25.12 0.0107 0

324.41 3.5

58 1.97 0 250 1x(us.90)=25.12 1.31 120 129.4

59 0.66 2175 10.42 25.12 0.0107 0.6

26.43 0.3

59 0.66 0 250 1x(us.90)=25.12 3.78 120 130.3

60 0.66 2175 10.42 25.12 0.0107 0

28.9 0.3

60 0.66 0 250 1x(us.90)=25.12 6.1 120 130.6

61 0.66 2175 10.42 25.12 0.0107 0

31.22 0.3

61 0.66 0 250 1x(us.90)=25.12 1.61 120 130.9

62 0.66 2175 10.42 25.12 0.0107 0

26.73 0.3

62 0.66 0 250 1x(us.90)=25.12 4.59 120 131.2

63 -3.94 2175 10.42 25.12 0.0107 2

29.71 0.3

63 -3.94 0 300 79.26 150 133.5

64 -3.94 2175 12.75 0 0.0026 0

79.26 0.2

64 -3.94 0 300 10.31 150 133.7

65 -3.94 2175 12.75 0 0.0026 0

10.31 0.0

65 -3.94 0 300 24.68 150 133.7

66 -3.94 2175 12.75 0 0.0026 0

24.68 0.1

66 -3.94 0 300 10.34 150 133.8

67 -3.94 2175 12.75 0 0.0026 0

10.34 0.0

67 -3.94 0 300 59.5 150 133.8

68 -3.94 2175 12.75 0 0.0026 0

59.5 0.2

68 -3.94 0 300 1x(us.90)=52.82 2.23 150 134

69 -3.94 2175 12.75 52.82 0.0026 0

55.04 0.1

69 -3.94 0 250 1x(us.90)=25.12 0.66 120 134.1

70 -3.28 2175 10.42 25.12 0.0107 -0.3

25.78 0.3

70 -3.28 0 250 1x(us.90)=25.12 6.12 120 134.1

71 -3.28 2175 10.42 25.12 0.0107 0

31.24 0.3

71 -3.28 0 250 1x(us.90)=25.12 9.84 120 134.4

72 -13.12 2175 10.42 25.12 0.0107 4.3

34.96 0.4

72 -13.12 0 250 18.97 120 139.1

W1 -13.12 2175 10.42 0 0.0107 0

18.97 0.2

© 2006 National Fire Protection Association Page 9

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

P8 67.4 25.2 159.4 40 1x(us.Tee-Br)=8 0.67 120 40

22 68.05 159.4 1.61 8 0.7523 -0.3

8.67 6.5

22 68.05 57.7 65 9.63 120 46.3

23 68.63 217.1 2.469 0 0.1661 -0.3

9.63 1.6

23 68.63 161.7 65 1x(us.90)=6 4.29 120 47.6

24 68.89 378.8 2.469 6 0.4657 -0.1

10.29 4.8

24 68.89 0 65 1x(us.Tee-Br)=12 2.13 120 52.3

07 66.77 378.8 2.469 12 0.4657 0.9

14.13 6.6

07 66.77 168 150 8.98 120 59.8

08 66.77 546.8 6.065 0 0.0115 0

8.98 0.1

08 66.77 378.8 150 1x(us.90)=14 104.23 120 59.9

09 66.77 925.5 6.065 14 0.0306 0

118.23 3.6

09 66.77 0 150 1x(us.Tee-Br)=30 5.07 120 63.5

10 61.7 925.5 6.065 30 0.0306 2.2

35.07 1.1

10 61.7 210.3 150 1x(us.90)=14 27.47 120 66.8

11 61.7 1135.9 6.065 14 0.0447 0

41.47 1.9

11 61.7 0 150 1x(us.Tee-Br)=30 162.98 120 68.6

12 61.7 1135.9 6.065 30 0.0447 0

192.98 8.6

P6 66.8 25.2 159.6 40 1x(us.Tee-Br)=8 0.67 120 40.1

78 67.46 159.6 1.61 8 0.7537 -0.3

8.67 6.5

78 67.46 -58 65 9.33 120 46.4

01 66.9 101.6 2.469 0 0.0407 0.2

9.33 0.4

01 66.9 160.7 65 1x(us.90)=6 35.25 120 47

02 64.77 262.3 2.469 6 0.2357 0.9

41.25 9.7

02 64.77 0 65 1x(us.Tee-Br)=12 1.67 120 57.6

03 63.11 262.3 2.469 12 0.2357 0.7

13.66 3.2

P7 67.4 25.2 159.6 40 1x(us.Tee-Br)=8 0.67 120 40.1

28 68.05 159.6 1.61 8 0.7539 -0.3

8.67 6.5

28 68.05 57.3 65 9.63 120 46.4

29 68.63 216.9 2.469 0 0.1658 -0.3

9.63 1.6

29 68.63 161.9 65 1x(us.90)=6 4.29 120 47.7

30 68.89 378.8 2.469 6 0.4657 -0.1

10.29 4.8

30 68.89 0 65 1x(us.Tee-Br)=12 2.13 120 52.4

08 66.77 378.8 2.469 12 0.4657 0.9

14.13 6.6

P5 66.8 25.2 159.6 40 1x(us.Tee-Br)=8 0.67 120 40.1

21 67.46 159.6 1.61 8 0.7542 -0.3

8.67 6.5

21 67.46 -57.7 65 9.33 120 46.4

20 66.9 102 2.469 0 0.041 0.2

9.33 0.4

© 2006 National Fire Protection Association Page 10

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

20 66.9 160.7 65 1x(us.90)=6 35.25 120 47

19 64.77 262.7 2.469 6 0.2365 0.9

41.25 9.8

19 64.77 0 65 1x(us.Tee-Br)=12 1.67 120 57.7

18 63.11 262.7 2.469 12 0.2365 0.7

13.66 3.2

P4 66.8 25.2 159.8 40 1x(us.Tee-Br)=8 0.67 120 40.2

27 67.46 159.8 1.61 8 0.7558 -0.3

8.67 6.6

27 67.46 -57.3 65 9.33 120 46.5

26 66.9 102.5 2.469 0 0.0414 0.2

9.33 0.4

26 66.9 160.9 65 1x(us.90)=6 35.25 120 47.1

25 64.77 263.5 2.469 6 0.2377 0.9

41.25 9.8

25 64.77 0 65 1x(us.Tee-Br)=12 1.67 120 57.8

17 63.11 263.5 2.469 12 0.2377 0.7

13.66 3.2

P3 66.24 25.2 160.7 40 1x(us.Tee-Br)=8 0.66 120 40.7

01 66.9 160.7 1.61 8 0.7632 -0.3

8.66 6.6

P2 66.24 25.2 160.7 40 1x(us.Tee-Br)=8 0.66 120 40.7

20 66.9 160.7 1.61 8 0.7637 -0.3

8.66 6.6

P1 66.24 25.2 160.9 40 1x(us.Tee-Br)=8 0.66 120 40.8

26 66.9 160.9 1.61 8 0.7654 -0.3

8.66 6.6

P12 67.91 25.2 161.7 40 1x(us.Tee-Br)=8 0.74 120 41.2

76 68.63 161.7 1.61 8 0.7719 -0.3

8.74 6.7

P11 67.91 25.2 161.7 40 1x(us.Tee-Br)=8 0.74 120 41.2

23 68.63 161.7 1.61 8 0.7723 -0.3

8.74 6.8

P10 67.91 25.2 161.9 40 1x(us.Tee-Br)=8 0.74 120 41.3

29 68.63 161.9 1.61 8 0.7739 -0.3

8.74 6.8

his1 21.33 250 100 1x(us.90)=13.17 1.23 120 109

73 21.33 250 4.26 13.17 0.0151 0

14.4 0.2

73 21.33 0 100 1x(us.Tee-Br)=26.33 19.36 120 109.2

39 1.97 250 4.26 26.33 0.0151 8.4

45.69 0.7

06 66.77 0 150 8.5 120 59.8

07 66.77 168 6.065 0 0.0013 0

8.5 0.0

15 61.7 0 150 68.27 120 66.7

10 61.7 210.3 6.065 0 0.002 0

68.27 0.1

78 67.46 0 65 9.86 120 46.4

77 68.05 58 2.469 0 0.0144 -0.3

9.86 0.1

21 67.46 0 65 9.86 120 46.4

22 68.05 57.7 2.469 0 0.0143 -0.3

9.86 0.1

27 67.46 0 65 9.86 120 46.5

28 68.05 57.3 2.469 0 0.0141 -0.3

9.86 0.1

© 2006 National Fire Protection Association Page 11

Job name: NESTLE Sheet number:___________________

PIPE INFORMATION

Node 1 Elev 1 K-Factor 1 Flow added(q)* Nominal ID Fittings L C Factor total (Pt)

Node 2 Elev 2 K-Factor 2 Total flow (Q) Actual ID quantity x (name) = length F Pf per ft elev (Pe) NOTES

T frict (Pf)

(ft) (gpm/psi½) (gpm) (ft) (ft) (psi) (psi)

(in)

* Discharge shown for flowing nodes only

© 2006 National Fire Protection Association Page 12

You might also like

- Fencing and GateDocument16 pagesFencing and Gatemustika05No ratings yet

- Welded Splice Connection-R2Document33 pagesWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- Electrical Design CriteriaDocument45 pagesElectrical Design Criteriamohan babuNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- Wire Rope ConstructionDocument3 pagesWire Rope ConstructionLutfi IsmailNo ratings yet

- Buy Spotify PlaysDocument3 pagesBuy Spotify PlaysBuy Spotify PlaysNo ratings yet

- Calculation Sheets FOR 3P-9171A D/S FOUNDATION Pump: TASNEE Petrochemicals Ethylene Project Al-Jubail, Saudi ArabiaDocument22 pagesCalculation Sheets FOR 3P-9171A D/S FOUNDATION Pump: TASNEE Petrochemicals Ethylene Project Al-Jubail, Saudi ArabiaCarlo BarceloNo ratings yet

- 20PKSA001-LNT-SPV-I-LST-1301 - R4 SCADA IO Signal List (Updated 14.11.22) - ADocument80 pages20PKSA001-LNT-SPV-I-LST-1301 - R4 SCADA IO Signal List (Updated 14.11.22) - ASamkonaya BitomNo ratings yet

- COMPRESSED AIR SYSTEM DESCRIPTION 压缩空气Document20 pagesCOMPRESSED AIR SYSTEM DESCRIPTION 压缩空气کالرو تحریک اتحادNo ratings yet

- SFI Product Description PDFDocument12 pagesSFI Product Description PDFPeng Yao Chen100% (1)

- Paseo Curtain Wall Strutural CalculationDocument79 pagesPaseo Curtain Wall Strutural CalculationVictor Dlreyes100% (1)

- QIPP MPN013 M00 2203 - A - Status2Document5 pagesQIPP MPN013 M00 2203 - A - Status2Ganesh R NairNo ratings yet

- 000 Pe DS 0001Document5 pages000 Pe DS 0001Dar FallNo ratings yet

- Cognizant Putting The Experience in Digital Customer Experience Codex1180 141217233002 Conversion Gate01Document30 pagesCognizant Putting The Experience in Digital Customer Experience Codex1180 141217233002 Conversion Gate01Guillaume TdlcNo ratings yet

- Uplink Capacity Enhancement in WCDMADocument176 pagesUplink Capacity Enhancement in WCDMAAttila KovácsNo ratings yet

- PI Sheet ConfigDocument18 pagesPI Sheet ConfigKaushik BoseNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Supreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeDocument4 pagesSupreme .Co - PVT.LT ': (II) Wind Pressure On Earthwire (Pe) PD X CD X GeGautam KhadkaNo ratings yet

- ES22-ES37 Operation Manual 003Document39 pagesES22-ES37 Operation Manual 003andy habibi100% (1)

- SprinkCALC III ReportDocument17 pagesSprinkCALC III ReportKhronos TempusNo ratings yet

- Export Oriented Unit SchemeDocument4 pagesExport Oriented Unit SchemeinfooncoNo ratings yet

- Calculation Summary: Design AreasDocument10 pagesCalculation Summary: Design AreasSIA PRESUPUESTOSNo ratings yet

- Es 22 002406 Ing Aci CH 001 00Document16 pagesEs 22 002406 Ing Aci CH 001 00Eduardo Serrano AtiroNo ratings yet

- Es 22 002406 Ing Aci CH 002 00Document10 pagesEs 22 002406 Ing Aci CH 002 00Eduardo Serrano AtiroNo ratings yet

- PPIS-660-IT-Y-003 - A - Anexo 12. Bombas Embarque y Cooldown - Constante C AjustadaDocument19 pagesPPIS-660-IT-Y-003 - A - Anexo 12. Bombas Embarque y Cooldown - Constante C AjustadaAnonymous S9qBDVkyNo ratings yet

- Calculation Summary: Design AreasDocument10 pagesCalculation Summary: Design AreasAlexander Alvarez VegaNo ratings yet

- Calculation Summary: Design AreasDocument9 pagesCalculation Summary: Design AreasGuille LRNo ratings yet

- Calculo HidraulicoDocument25 pagesCalculo HidraulicoZlatan PapiNo ratings yet

- CH Británico Arequipa-SemisótanoDocument9 pagesCH Británico Arequipa-SemisótanoAndrea Grados CamarenaNo ratings yet

- System Psychrometrics For CENTREPOINTDocument2 pagesSystem Psychrometrics For CENTREPOINTmechmohsin4745No ratings yet

- Almacen Floxocorte 4 Rack Menos CriticoDocument9 pagesAlmacen Floxocorte 4 Rack Menos CriticoCarlos_MKTRNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- SprinkCALC III Report - Bld7.Riser1Document30 pagesSprinkCALC III Report - Bld7.Riser1Igor CvijovicNo ratings yet

- Hydraulic Calculation New He Line at A4 BuildingDocument24 pagesHydraulic Calculation New He Line at A4 BuildingAob AprilNo ratings yet

- Unit Number: Rft-7-2-2 Location: First Floor Service: Ground FloorDocument21 pagesUnit Number: Rft-7-2-2 Location: First Floor Service: Ground FloorThe Saudi TamizhanNo ratings yet

- Show Room 2Document6 pagesShow Room 2Construction powerNo ratings yet

- Dedicated Outdoor Air System (DOAS) Sizing Summary For FCU-01-02 - RetailDocument4 pagesDedicated Outdoor Air System (DOAS) Sizing Summary For FCU-01-02 - Retailazarin98No ratings yet

- System Psychrometrics For CORRIDOR 4aDocument2 pagesSystem Psychrometrics For CORRIDOR 4amechmohsin4745No ratings yet

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument14 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Figure 1 - Clearance To Pipes: Subject: Clearance Requirements For Cable TraysDocument2 pagesFigure 1 - Clearance To Pipes: Subject: Clearance Requirements For Cable Trayseccos3338No ratings yet

- System Psychrometrics For NIVEL PB - Zona 1Document1 pageSystem Psychrometrics For NIVEL PB - Zona 1Roger PandoNo ratings yet

- Air System Sizing Summary For FF07-OFFICEDocument13 pagesAir System Sizing Summary For FF07-OFFICEThahar ali syedNo ratings yet

- Fast Food - Caffe-01-GFDocument6 pagesFast Food - Caffe-01-GFConstruction powerNo ratings yet

- Sample 01Document20 pagesSample 01Muhammad ElbarbaryNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Show Room 3Document6 pagesShow Room 3Construction powerNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Hydraulic CalDocument22 pagesHydraulic CalSam Hitchens LesenyamotseNo ratings yet

- Office Building 02 FAHU 02Document2 pagesOffice Building 02 FAHU 02Mohanad ElgayarNo ratings yet

- Fast Food - Caffe-01Document6 pagesFast Food - Caffe-01Construction powerNo ratings yet

- Submittal Form: Indoor: Outdoor: Model #Document2 pagesSubmittal Form: Indoor: Outdoor: Model #George H. Gutierrez, PECSANo ratings yet

- System Psychrometrics For AROMA RE MUZNDocument2 pagesSystem Psychrometrics For AROMA RE MUZNmechmohsin4745No ratings yet

- System Psychrometrics For CORRIDOR 1Document2 pagesSystem Psychrometrics For CORRIDOR 1mechmohsin4745No ratings yet

- Zone Sizing Summary For ITR 87-105 Prayer Room: Air System InformationDocument28 pagesZone Sizing Summary For ITR 87-105 Prayer Room: Air System Informationvictor.sNo ratings yet

- ArchiveDocument8 pagesArchiveMahmoud MegahedNo ratings yet

- H-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - CDocument124 pagesH-10207 00 0ea00-001f Da-Cscs Main Equipment Datasheets - Cnguyen rinNo ratings yet

- DBR-Complressed Air System-12.08.2019Document13 pagesDBR-Complressed Air System-12.08.2019raaj bharathNo ratings yet

- Zone Sizing Summary For 3F-Canteen C1: Air System InformationDocument26 pagesZone Sizing Summary For 3F-Canteen C1: Air System InformationKashif MannanNo ratings yet

- 0260-101-01-TR-PVM-U-038-01sizing Calculation FansDocument8 pages0260-101-01-TR-PVM-U-038-01sizing Calculation Fansanil peralaNo ratings yet

- P0116-TAK-P01-0199-01: SGGP Reference NoDocument7 pagesP0116-TAK-P01-0199-01: SGGP Reference NoJabel Oil Services Technical DPTNo ratings yet

- AnnexB Energy Audit ReportDocument25 pagesAnnexB Energy Audit ReportJ-R MERLIN CabatoNo ratings yet

- Air System Sizing Summary For PAU&FCU-TKHUE-SHCDDocument4 pagesAir System Sizing Summary For PAU&FCU-TKHUE-SHCDĐỗ Đức ThànhNo ratings yet

- Informe Técnico 1Document70 pagesInforme Técnico 1amanda17011997No ratings yet

- Lesson Ii Ilmu PemerintahanDocument5 pagesLesson Ii Ilmu PemerintahanMartino AliNo ratings yet

- It Despiece JBMDocument44 pagesIt Despiece JBMcessione attivitàNo ratings yet

- IACO Komponenty 2014Document448 pagesIACO Komponenty 2014Gesiel SoaresNo ratings yet

- 9-0-SP1 Implementing E-Form Support For BPMDocument54 pages9-0-SP1 Implementing E-Form Support For BPMSrinu RayalaNo ratings yet

- SOLiD Technical NoteDocument24 pagesSOLiD Technical NoteJhon GrandezNo ratings yet

- Agregate ErmeticeDocument8 pagesAgregate ErmeticeRusu EugeniuNo ratings yet

- Community Health Worker RoadmapDocument4 pagesCommunity Health Worker RoadmapDEA ANDINI PUTRINo ratings yet

- A Technical Report FORMATDocument3 pagesA Technical Report FORMATOmkarNo ratings yet

- Fair Use ChecklistDocument3 pagesFair Use Checklistapi-280928576No ratings yet

- Introducción A EESDocument97 pagesIntroducción A EESlaura villarroelNo ratings yet

- History of SurveyingDocument2 pagesHistory of SurveyingBrian WafulaNo ratings yet

- SwitchGear Brochure NewDocument12 pagesSwitchGear Brochure NewnetlabindiaNo ratings yet

- Vancouver Convention CentreDocument3 pagesVancouver Convention CentreNabeel AhmedNo ratings yet

- Magcat ITS Data Sheet Update Oct. 2022 1.3b KHDocument2 pagesMagcat ITS Data Sheet Update Oct. 2022 1.3b KHkeshoooNo ratings yet

- Amse PiDocument5 pagesAmse PiNnamdi Celestine NnamdiNo ratings yet

- (SOLUTIONS) Mastering Physics HW37Document4 pages(SOLUTIONS) Mastering Physics HW37cheifXmasterNo ratings yet

- Condenser BRCQ0241BDDocument4 pagesCondenser BRCQ0241BDaligator98No ratings yet

- ADAPT-Builder Concrete Design Suite PDFDocument1 pageADAPT-Builder Concrete Design Suite PDFSuranjan BhanjaNo ratings yet

- Philips DVD DVP630/02Document2 pagesPhilips DVD DVP630/02Zymaflor100% (1)

- SBL2 e Dual Serial To Ethernet Users ManualDocument30 pagesSBL2 e Dual Serial To Ethernet Users Manualsrc.sussi822No ratings yet

- Oscilloscope: 1. DefinitionDocument9 pagesOscilloscope: 1. DefinitionSandi WiarsanaNo ratings yet

- SM9.30 EventServicesDocument140 pagesSM9.30 EventServicesGeorge AnadranistakisNo ratings yet