Professional Documents

Culture Documents

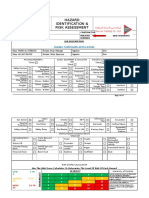

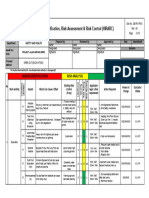

JSA For Oil Pressure For Governor

Uploaded by

Akhli Rohmatuloh0 ratings0% found this document useful (0 votes)

29 views3 pagesThe document is a job hazard analysis for oil pressure governor erection work. It identifies potential hazards such as uneven surfaces, falling materials, and slippery surfaces. Safety measures include preparing appropriate personal protective equipment, restricting access to authorized personnel only, using proper lifting tools, paying attention to the work area and footing, not overexerting when carrying materials, providing absorbents, and preparing communication equipment. The analysis rates the likelihood and consequence of each hazard to determine the risk factors for the different work steps.

Original Description:

milestone trafo manufacturing

Original Title

JSA for Oil Pressure for Governor (1)

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a job hazard analysis for oil pressure governor erection work. It identifies potential hazards such as uneven surfaces, falling materials, and slippery surfaces. Safety measures include preparing appropriate personal protective equipment, restricting access to authorized personnel only, using proper lifting tools, paying attention to the work area and footing, not overexerting when carrying materials, providing absorbents, and preparing communication equipment. The analysis rates the likelihood and consequence of each hazard to determine the risk factors for the different work steps.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views3 pagesJSA For Oil Pressure For Governor

Uploaded by

Akhli RohmatulohThe document is a job hazard analysis for oil pressure governor erection work. It identifies potential hazards such as uneven surfaces, falling materials, and slippery surfaces. Safety measures include preparing appropriate personal protective equipment, restricting access to authorized personnel only, using proper lifting tools, paying attention to the work area and footing, not overexerting when carrying materials, providing absorbents, and preparing communication equipment. The analysis rates the likelihood and consequence of each hazard to determine the risk factors for the different work steps.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

No : JSA-LMB1-001

JOB HAZARD ANALYSIS Rev : 00

Date : Nov 2016

Date : 2019.09.12 JSA no: NAME Sign

Job Title : OIL PRESSURE FOR GOVERNER ERECTION Person in charge :

Location : Power Building / Turbine Floor Originator team :

Standard requirement :

Standard PPE : Safety Helmet Full body harness

Safety glasses Hand glove

Safety Shoes

Special Attention : Review by :

Approved by :

Risk Factor Risk Factor

No. Work Steps Hazard identified Hazard effect Safety Measures & Prevention

L C RF1. Prepare the PPE (helmet, safety glass, dust mask, hand glove, safety shoes,ear plug, body L C RF

1. Uneven surfaces (Permukaan tidak rata) 1. Falling down (Terjatuh) hardness) APD (helem, kaca mata safety, sepatu safety, sarung tangan anti panas, sarung

(Persiapkan

2. Falling material (material terjatuh) 2. Hit by falling material (Tertimpa material jatuh) tangan,

2. Accesspenutup telinga,person

only autorized body hardness)

and only those with permission are allowed to work in the lube oil

3. Slippery surfaces (Permukaan licin) area

Prepare all tool & material to be 4. Spillage of lube oil (Tumpahan oli pelumas) (Hanya yang berwewenang dan memiliki izin diperbolehkan bekerja di area minyak pelumas)

use during working 3.

(Mempersiapkan semua 4. Use

Toolthe

boxappropriate liftingwork

meeting before toolactivity

(Gunakan alat(Tool

begin angkat

boxyang sesuai)

meeting sebelum melakukan pekerjaan

1 peralatan & material yang 3 3 Mod dan sosialisasikan

(Perhatikan dengadan

lokasi kerja PTW)tempat berpijak) 3 2 L

digunakan selama pekerjaan

berlangsung) 6. Do not carry material beyond the capability

(Dilarang

7. Providemengangkat material

sand absorbent melampaui

/ adsorbent kemampuan)

/ bucket

(Sediakan

8. Preparepasir serap / absorban/ember)

communication equipment

(Persiapkan alat komunikasi)

penutup telinga, body hardness)

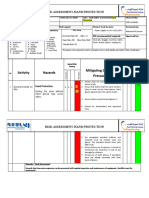

1. Uneven surfaces 1. Falling down (Terjatuh)

(Permukaan

2. Head bangedlicin) 2. Head, hand, fingger injury 2. Access only authorized person and

(Kepala terbentur)

3. Spillage of lube oil (Kepala,

3. tangan,pollution

Environment jari cidera) only

3. Usethose with permission

the appropriate tool are allowed to work in the lube oil tank area

(Tumpahan

4. oli pelumas)

Leakage found during oil filling (Gunakan

4. Tools Boxperalatan

Meetingyang sesuai)

before work aktifity begin (Tools Box Meeting sebelum dimulai pekerjaan

sosialisasikan

5. Provide sandJSA dan PTW)/ adsorbent / bucket

absorbent

2 3 3 (Sediakan

Mod 6. Preparepasir serap / absorban/ember)

communication equipment 3 2 L

(Persiapkan alat komunikasi)

7. Install barricades on lube oil tank area

Loading lube oil into Oil

Pressure tank (Pasang

8. Control the access to well padtangka

barikade disekitar area minyak pelumas)

by watchman

(mengisikan minyak pelumas (Akses untuk

9. Working areafollow

must steamprocedure

harus dikontrol oleh seorang watchman)

kedalam tangka minyak (Bekerja

1. harus susuai dengan prosedur)

pelumas ) 10.Prepare the PPE

See location (helmet,

of the worksafety

and glass,

the dust mask, hand glove, safety shoes,ear plug)

beachhead

(Persiapkan APD (helem,

(Perhatikan lokasi kaca

kerja dan mata safety,

tempat sepatu safety, sarung tangan anti panas, sarung tangan,

berpijak)

penutup telinga, body hardness)

1. Uneven surfaces 1. Falling down (Terjatuh)

(Permukaan

2. Head banged licin) 2. Head, hand, fingger injury 2. Access only authorized person and

(Kepala

3. terbentur)

Suddenly electrical / mechanical energy release (Kepala,

3. tangan,

The spillage of jari

lubecidera)

oil pollutes the environment only

3. Usethose with permission

the appropriate tool are allowed to work in the lube oil tank area

(tiba-tiba

4. Pinchedenergi

fingerslistrik/mekanik lepas) (Tumpahan oli pelumas mencemari lingkungan) (Gunakan

4. Tools Boxperalatan

Meetingyang sesuai)

before work aktifity begin (Tools Box Meeting sebelum dimulai pekerjaan

(Jari terjepit) sosialisasikan

5. Provide sand JSA dan PTW)/ adsorbent / bucket

absorbent

Solo run test (Sediakan

6. Preparepasir serap / absorban/ember)

communication equipment

3 (Test motor tanpa beban) 3 3 Mod (Persiapkan alat komunikasi) 3 2 L

7. Install barricades on lube oil tank area

(Pasang

8. Controlbarikade disekitar

the access to wellarea

padtangka minyak pelumas)

by watchman

(Akses

9. untukmust

Working areafollow

steamprocedure

harus dikontrol oleh seorang watchman)

(Bekerja

10. Applyharus

LOTOsusuai

systemdengan

beforeprosedur)

start working

(Terapkan

11. sistemofLOTO

See location sebelum

the work and memulai pekerjaan)

the beachhead

(Perhatikan lokasi kerja dan tempat berpijak)

1. Prepare the PPE (helmet, safety glass, dust mask, hand glove, safety shoes,ear plug)

(Persiapkan APD (helem, kaca mata safety, sepatu safety, sarung tangan anti panas, sarung tangan,

penutup telinga, body hardness)

1. Uneven surfaces 1. Falling down (Terjatuh)

(Permukaan

2. Head banged licin) 2. Head, hand, fingger injury 2. Access only authorized person and

(Kepala terbentur)

3. Suddenly electrical / mechanical energy release (Kepala, tangan,

3. The spillage of jari

lubecidera)

oil pollutes the environment only

3. Usethose with permission

the appropriate tool are allowed to work in the lube oil tank area

(tiba-tiba

4. Pinchedenergi

fingerslistrik/mekanik lepas) (Tumpahan oli pelumas mencemari lingkungan) (Gunakan

4. Tools Boxperalatan

Meetingyang sesuai)

before work aktifity begin (Tools Box Meeting sebelum dimulai pekerjaan

(Jari terjepit)

5. Found Leakage Hose during oil flushing (Jari terjepit) sosialisasikan

5. Provide sand JSA dan PTW)/ adsorbent / bucket

absorbent

6. Found Pipe Leakage during Oil Flushing (Leakage in welding Joint, Leakage in Flange (Sediakan

6. Preparepasir serap / absorban/ember)

communication equipment

Oil flushing

4 (Flushing minyak pelumas) 3 3 Mod (Persiapkan alat komunikasi)

7. Install barricades on lube oil tank area 3 2 L

(Pasang

8. Controlbarikade disekitar

the access to wellarea

padtangka minyak pelumas)

by watchman

(Akses untukmust

9. Working areafollow

steamprocedure

harus dikontrol oleh seorang watchman)

(Bekerja

10. Applyharus

LOTOsusuai

systemdengan

beforeprosedur)

start working

(Terapkan

11. sistemofLOTO

See location sebelum

the work and memulai pekerjaan)

the beachhead

(Perhatikan

12. Standby lokasi kerjabe

man shall dan tempat

close berpijak)

monitoring during work in confined space

1. Uneven surfaces 1. Falling down (Terjatuh) 2.

1. Prepare

Prepare the PPE meter

oxygen (helmet,

: safety glass, dust mask, hand glove, safety shoes,ear plug)

(Permukaan licin) (Persiapkan

Measure theAPD (helem, kaca

concentration of mata safety,

oxygen andsepatu safety,insarung

toxic gases tangan

the tank anti

before panas,the

starting sarung

job tangan,

2. Head banged 2. Head, hand, fingger injury (Persiapkan

penutup pengukur

telinga, body kandungan

hardness) oksigen

(Kepala

3. terbentur)

Suddenly electrical / mechanical energy release (Kepala,

3. tangan,

The spillage of jari

lubecidera)

oil pollutes the environment Mengukur konsentrasi oksigen dan gas beracun di dalam tangki sebelum memulai pekerjaan)

(tiba-tiba

4. Pinchedenergi

fingerslistrik/mekanik lepas) (Tumpahan oli pelumas mencemari lingkungan)

4. Risk suffocantion 3. Access only authorized person and

(Jari

5. terjepit)

Limited oxygen (Sesak

5. nafas)

Gas poisoning only

4. Usethose with permission

the appropriate tool are allowed to work in the lube oil tank area

Cleaning inside lube oil tank(Oksigen

6. terbatas)

Dust (Debu) (Keracunan

6. gasdue

Dehydration beracun)

to heat (Gunakan

5. Tools Boxperalatan

Meetingyang sesuai)

before work aktifity begin (Tools Box Meeting sebelum dimulai pekerjaan

5 (Membersihkan bagian dalam 7. There is the content of toxic gas (Dehidrasi) 3 3 Mod sosialisasikan

6. Provide sandJSA dan PTW)/ adsorbent / bucket

absorbent 3 2 L

tangki minyak Pelumas) (Terdapat kandungan gas beracun) (Sediakan

8. Dark condition 7. Preparepasir serap / absorban/ember)

communication equipment

(Kondisi

9. gelap) (Kondisi panas)

Hot Condition (Persiapkan alat komunikasi)

8. Install barricades on lube oil tank area

(Pasang barikade disekitar area

9. Prepare the portable lantern andtangka minyak

install light pelumas)

(Persiapkan

10. senter dan lampu

Prepare equipment penerangan)

to supplies fresh air into the pipe (Blower)

(Persiapkan peralatan untuk mesaplai udara segar kedalam tangki)

(Alat Kerja tertinggal dilokasi) penutup telinga, body hardness)

(Tersandung terpeleset) 1. Falling down (Terjatuh)

2. Head, hand, fingger injury 2. Access only authorized person and

3. Sampah berserakan (Trash littered) (Kepala,

3. tangan,

The spillage of jari

lubecidera)

oil pollutes the environment only

3. those

Use with permission

the appropriate tool are allowed to work in the lube oil tank area

Tidy tools and material

(Merapikan Alat Kerja dan 4. Falling material (Tumpahan oli pelumas mencemari lingkungan) (Gunakan

4. peralatan

Tools Box Meetingyang sesuai)

before work aktifity begin (Tools Box Meeting sebelum dimulai pekerjaan

6

Material) (material terjatuh) 3 3 Mod sosialisasikan JSA dan PTW) 3 2 L

5. Provide sand absorbent / adsorbent / bucket

(Sediakan

6. Preparepasir serap / absorban/ember)

communication equipment

(Persiapkan

7. alatmaterial

Do not carry komunikasi)

beyond the capability

(Dilarang

8. mengangkat

Clean the material

work area from melampaui

waste & lube oilkemampuan)

spills

(Bersihkan area kerja dari sampah & tumpahan oli)

Note : * : without control *) : with control

L : likelihood C : consequences

Determined control / Penetapan pengendalian

Risk Factor (RF) Tingkat resiko

Tingkat pengendalian Hierarchi of cotrol

Likelihood X Severity/consequence Keparahan ( C ) =

Score Level

Frequent Sering =5 Cathastrophic (Bencana) =5 14-25 High (H) E = 1+2+3+4+5 1 =eliminasi

Probable Mungkin =4 Major (Utama) =4 11-13 Medium (M) H = 3+4+5 2 =subtitusi

Occasional Sesekali = 3 Moderate/serious (Sedang / Serius) =3 7-10 Moderate(Mo) M = 4+5 3 =engineering control

Unlikely Tidak seper= 2 Minor =2 4 =administrasi

1-6 Low (L) L=5

Improbable Mustahil = 1 Negligible (Dapat diabaikan =1 5 =APD

24 72 864

25 71 852

26 71 852

27 74 888

28 74 888

29 71 852

30 40 480

31 70 840

6516

You might also like

- Jsa MV Cable Pulling, Termination and TestingDocument11 pagesJsa MV Cable Pulling, Termination and TestingMohammad AqilNo ratings yet

- Rebar Lifting Jha 001Document4 pagesRebar Lifting Jha 001Justin JuniorNo ratings yet

- Curing Compound ApplicationDocument12 pagesCuring Compound ApplicationyashNo ratings yet

- Oilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDocument6 pagesOilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDheeraj MenonNo ratings yet

- Conducting Drop Object Inspection - RA-R9-01-017-01Document1 pageConducting Drop Object Inspection - RA-R9-01-017-01cmrig74No ratings yet

- Final HiraDocument39 pagesFinal HiraAnsari HarisNo ratings yet

- Electrical Conduit InstallationDocument10 pagesElectrical Conduit InstallationYahya YusufzayNo ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- RISK ASSESSMENT FOR INSTALLATION OF Mechanical MaintenanceDocument11 pagesRISK ASSESSMENT FOR INSTALLATION OF Mechanical Maintenancevictor100% (1)

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkTigor Gurning100% (1)

- Confined Space - RA-R9-01-002-01Document1 pageConfined Space - RA-R9-01-002-01cmrig74No ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792100% (1)

- Tool Room MGMT GuidebookDocument20 pagesTool Room MGMT GuidebookCarlos MoyaNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisCorrosion FactoryNo ratings yet

- JSA - Low Voltage PanelDocument19 pagesJSA - Low Voltage PanelASLAM MULANINo ratings yet

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkEka100% (1)

- RA (Working at Height)Document4 pagesRA (Working at Height)Yan Naing HtooNo ratings yet

- Ra For Transpo and LiftingDocument5 pagesRa For Transpo and LiftingEdsel RosalesNo ratings yet

- Sample Safe Work Method Statement (SWMS)Document8 pagesSample Safe Work Method Statement (SWMS)Ali RazaNo ratings yet

- JHA For Painting WorkDocument2 pagesJHA For Painting WorkEkaNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- JSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020Document6 pagesJSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020sarge18No ratings yet

- Hirarc - Hazard Identification, Risk Assessment & Risk Control PDFDocument21 pagesHirarc - Hazard Identification, Risk Assessment & Risk Control PDFAhmed GomaaNo ratings yet

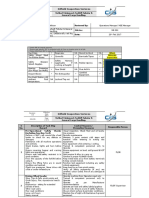

- DOE Handbook Electrical SafetyDocument324 pagesDOE Handbook Electrical Safetyahmd72No ratings yet

- EHS PPT (OHS Our Top Priority)Document27 pagesEHS PPT (OHS Our Top Priority)JonathanNo ratings yet

- Toolbox Talk Register (Yard)Document14 pagesToolbox Talk Register (Yard)jumansyahamid1988No ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- Lesson 1 Health and SafetyDocument52 pagesLesson 1 Health and Safetylarra100% (1)

- Electrical Safety Lesson Plan 6030aDocument5 pagesElectrical Safety Lesson Plan 6030aAyahnya Rizla Atha Rayyan100% (1)

- JSA For Oil Pressure For GovernorDocument1 pageJSA For Oil Pressure For GovernorAkhli RohmatulohNo ratings yet

- Job Safety Analysis Record Sheet: Cause & Effect Metrix TestDocument2 pagesJob Safety Analysis Record Sheet: Cause & Effect Metrix TestFernandoMarquezNo ratings yet

- Inspection RegistersDocument37 pagesInspection RegistersDavid FestusNo ratings yet

- Insulation Works For Heat ExchangerDocument3 pagesInsulation Works For Heat ExchangerVenodaren VelusamyNo ratings yet

- Dry Rework and Wet Rework OkDocument3 pagesDry Rework and Wet Rework OkRinaldyNo ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- Hiradc FormDocument9 pagesHiradc FormBuraku BlackNo ratings yet

- PBSSFTJSA005-Work at HighDocument4 pagesPBSSFTJSA005-Work at HighHSE Pakubumi SemestaNo ratings yet

- Risk Assesment - FormatDocument3 pagesRisk Assesment - FormatSIBINNo ratings yet

- TRA Renovation, Service For Building and Office Construction (Ex Telkom Building) Rev1Document8 pagesTRA Renovation, Service For Building and Office Construction (Ex Telkom Building) Rev1Dol29No ratings yet

- AVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadDocument3 pagesAVN-MAR-PIP-RA-003 - R0 - Installation of Drain Line Below HelipadtaufikNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- DRAFT - HIRARC REGISTER (45637)Document6 pagesDRAFT - HIRARC REGISTER (45637)Leliance Ann BillNo ratings yet

- Job Hazard Analysisb BFDocument2 pagesJob Hazard Analysisb BFCorrosion FactoryNo ratings yet

- 1.0 Acts Hse Form 0001 Jsa 20120405 Rev 1 Company Job Safety Analysis FormDocument3 pages1.0 Acts Hse Form 0001 Jsa 20120405 Rev 1 Company Job Safety Analysis FormPaul BeephanNo ratings yet

- Confined Space Hirarc Taman SeputehDocument3 pagesConfined Space Hirarc Taman SeputehHana SeiadiNo ratings yet

- 23 Risk Assessment Scaffold Erection Dismantling Fire FightingDocument5 pages23 Risk Assessment Scaffold Erection Dismantling Fire FightingBalongNo ratings yet

- 06 ArtDocument2 pages06 ArtEduardoBorquezLNo ratings yet

- Jsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000Document12 pagesJsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000thennarasuNo ratings yet

- HIRA For DAHU - EXH Unit Romp 05Document8 pagesHIRA For DAHU - EXH Unit Romp 05syed khaja misbhuddinNo ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- Jsa EXCAVATIONDocument4 pagesJsa EXCAVATIONHSE Pakubumi SemestaNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- RA Sand BlastingDocument2 pagesRA Sand BlastingAbdus Samad100% (1)

- R1937-JSA-002 Job Safety Analysis For TowingDocument4 pagesR1937-JSA-002 Job Safety Analysis For TowingVineet Agrawal100% (1)

- Risk AssessmentDocument1 pageRisk AssessmentthisbusinesstobusyNo ratings yet

- HIRA FormatDocument7 pagesHIRA Formatvikram.knNo ratings yet

- Riyadh Cargo Terminal Project Zamil SteelDocument41 pagesRiyadh Cargo Terminal Project Zamil SteelGhost RiderNo ratings yet

- 23 Risk Assessment Scaffold Erection Dismantling - HVACDocument5 pages23 Risk Assessment Scaffold Erection Dismantling - HVACBalongNo ratings yet

- Hand Protection RADocument3 pagesHand Protection RAAsif HussainNo ratings yet

- JSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Document3 pagesJSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Ita MonoarfaNo ratings yet

- Aircon Ppe Form - 2Document1 pageAircon Ppe Form - 2Safety 2No ratings yet

- Jsa Demolish of Existing Armor RockDocument2 pagesJsa Demolish of Existing Armor Rockabdan adly TNo ratings yet

- Jsea For Assemble and Disassemble of Hydra EngineDocument14 pagesJsea For Assemble and Disassemble of Hydra EngineMD AbdullahNo ratings yet

- Task Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBDocument2 pagesTask Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBmyo lwinNo ratings yet

- WATER PROOFING-Jan-2019Document2 pagesWATER PROOFING-Jan-2019Hafiz M WaqasNo ratings yet

- Prepared HIRA For Reference, Coke Oven, BPPDocument8 pagesPrepared HIRA For Reference, Coke Oven, BPPvikram.knNo ratings yet

- HSE Risk Assessment (UTM)Document1 pageHSE Risk Assessment (UTM)kamalNo ratings yet

- JohanDocument1 pageJohanEstmarg EstmargNo ratings yet

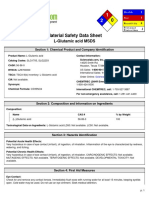

- Material Safety Data Sheet: Effective Date 18.10.2010 According To EC Directive 2001/58/ECDocument7 pagesMaterial Safety Data Sheet: Effective Date 18.10.2010 According To EC Directive 2001/58/ECRey Regaspi TuyayNo ratings yet

- DivocDocument1 pageDivocCarrackNo ratings yet

- PT3 - Grup 3 - Managing Health & Safety Environment RiskDocument55 pagesPT3 - Grup 3 - Managing Health & Safety Environment Riskayu.andiniNo ratings yet

- L-Glutamic Acid MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesL-Glutamic Acid MSDS: Section 1: Chemical Product and Company IdentificationpipitfpuspitaNo ratings yet

- Environmental Engineering Laboratory SEM 1 2017/2018: Dr. HJH Roslinda SeswoyaDocument23 pagesEnvironmental Engineering Laboratory SEM 1 2017/2018: Dr. HJH Roslinda SeswoyaAjimu SulaimanNo ratings yet

- MLL Weekly Inspection CheDocument3 pagesMLL Weekly Inspection CheSyahrudinNo ratings yet

- Material Safety Data Sheet: Phthalic AnhydrideDocument6 pagesMaterial Safety Data Sheet: Phthalic AnhydridefructoraNo ratings yet

- Nitric Acid 60 PR - Safety Data Sheet - EuropeDocument23 pagesNitric Acid 60 PR - Safety Data Sheet - EuropeevinNo ratings yet

- Ammonium Hydroxide MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesAmmonium Hydroxide MSDS: Section 1: Chemical Product and Company IdentificationwindaratlinNo ratings yet

- Oblent Data CardDocument4 pagesOblent Data CardPanchdev KumarNo ratings yet

- Foshan Tian Bao Li Silicone Engineering Technology Co., Ltd. Material Safety Data SheetDocument5 pagesFoshan Tian Bao Li Silicone Engineering Technology Co., Ltd. Material Safety Data SheetShahramNo ratings yet

- DLL For Cot 1 Classroom ObservationDocument6 pagesDLL For Cot 1 Classroom ObservationCatherine Fajardo MesinaNo ratings yet

- Group 5 ScriptDocument2 pagesGroup 5 ScriptMargarette GalangNo ratings yet

- Versachem Mega Grey 85 GRDocument8 pagesVersachem Mega Grey 85 GRpaul heberth areche conovilcaNo ratings yet

- Prepare Material, Tools and Equipment For Nursery Work 2 wk3Document10 pagesPrepare Material, Tools and Equipment For Nursery Work 2 wk3mervin tomasNo ratings yet

- MSDS Shell Tellus S2 VX 22Document19 pagesMSDS Shell Tellus S2 VX 22prilly karmeliaNo ratings yet

- Lesson 9Document28 pagesLesson 9Angel joyce ValenciaNo ratings yet

- 01 WI HSE 001 - Risk Assessment Trail Trench Excavation For Portable Water InstallationDocument5 pages01 WI HSE 001 - Risk Assessment Trail Trench Excavation For Portable Water InstallationMisbah Ul Haq LabeedNo ratings yet

- MSDS SPN 80 - PT Pratama Witta Mandiri (Gianergy)Document4 pagesMSDS SPN 80 - PT Pratama Witta Mandiri (Gianergy)Seftia NurfaNo ratings yet

- Implant Training ReportDocument13 pagesImplant Training ReportAryan.s SuryawanshiNo ratings yet