Professional Documents

Culture Documents

02 Infograph POY FDY en

Uploaded by

anil kapadiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Infograph POY FDY en

Uploaded by

anil kapadiaCopyright:

Available Formats

Oerlikon Barmag Colour Yarn Production for POY and FDY

Why Colouring a Textile is a Real Green Issue

Methods to Bring Colour Into a Textile

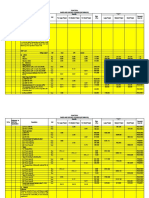

Consumption Per Day assuming a capacity 180 tonnes

Piece Masterbatch Applications for Spun-Dyed

Energy POY and FDY Products

258 MWh 8 MWh

= 20 MWh

= 20 MWh

Wet

Processing Drying Masterbatch

CP or Extrusion Spinning CP or Extrusion Furniture

155 103 8

Thermal Energy ( MWH )

Automotive

220

Electric Energy ( MWH ) Electric Energy ( MWH )

3DD mixing

Spinning 38 8

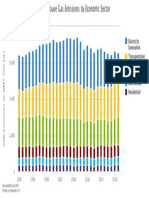

CO2 Emissions

Embroidery

55.000 [ tonnes ] 1.700 [ tonnes ]

CO2 Emissions:

Gas-Based generation ( tonnes )

47.000

CO2 Emissions: CO2 Emissions: Saree

Downstream process India Power Mix ( tonnes ) India Power Mix ( tonnes ) Spinning

8.500 1.700

Water Consumption

& Effluent

1.800 [ m 3

]

- NONE -

= 100 cbm

Lace

Waste

Yarn breaks Yarn breaks

Wear and tear Wear and tear

Piece dyeing Downstream process

Dye Stuff

& Chemicals

13,8 tonnes [ total ]

7,7 tonnes [ dye stuff ] 6,2 tonnes [ dye stuff ] Masterbatch Extruder

6,1 tonnes [ chemicals ]

Flow of Polymer

3

5,2 m [ liquid chemicals (ml/l) ]

3DD Mixer for Masterbatch Dyeing

Masterbatch dyeing is the

environmental friendly solution

to bring colour into a textile.

Coloured

Polymer

We’d love to speak with you about your POY Phone +49 4321 305-353

and FDY production needs. Contact us today sales.neumag@oerlikon.com

to learn how we can help. www.oerlikon.com/manmade-fibers

All indicated values and descriptions in this document are for indicative purposes only and not to be understood as a guarantee. Please note that actual values may differ from any data published in this document.

You might also like

- Scottish Maritime Cluster Babcock LGE Presentation 3rd November 2020Document11 pagesScottish Maritime Cluster Babcock LGE Presentation 3rd November 2020IMECCNo ratings yet

- 18MW Co-Generation system with low emissionsDocument2 pages18MW Co-Generation system with low emissionsfrdnNo ratings yet

- 18MW Co-Generation system with low emissionsDocument2 pages18MW Co-Generation system with low emissionsfrdnNo ratings yet

- SGT-700 Industrial Gas TurbineDocument4 pagesSGT-700 Industrial Gas TurbineDavichín Morató FernandezNo ratings yet

- Iata Steele eDocument31 pagesIata Steele ePabloNo ratings yet

- 16 22 PTKI-i PDFDocument1 page16 22 PTKI-i PDFPrima Jaya Telolet 082233218700No ratings yet

- Greenhouse Gas EmissionsDocument1 pageGreenhouse Gas EmissionsIulia JulieNo ratings yet

- Tesar Cast Resin Product Catalogue en 1499236667Document30 pagesTesar Cast Resin Product Catalogue en 1499236667surda123No ratings yet

- Tu Macc Data Requirements TemplateDocument49 pagesTu Macc Data Requirements TemplateNikhil MohiteNo ratings yet

- Zuari Cement, YerraguntlaDocument26 pagesZuari Cement, YerraguntlaKvnaveen KvnNo ratings yet

- Comparison Between Scenario Main and NuclearCO2Document10 pagesComparison Between Scenario Main and NuclearCO2tania__starNo ratings yet

- Petrochemical IndonesiaDocument43 pagesPetrochemical IndonesiaElfara PuspitaNo ratings yet

- OE Flyer 4000biogas 2 14Document3 pagesOE Flyer 4000biogas 2 14muhammad afrizalNo ratings yet

- Carbon Footprint Report for Kagal-1 and Rajkot PlantsDocument2 pagesCarbon Footprint Report for Kagal-1 and Rajkot PlantsAbhinav DaddeNo ratings yet

- PEF - Nick Sharma - IHS Markit - Panel 1Document13 pagesPEF - Nick Sharma - IHS Markit - Panel 1Nina KonitatNo ratings yet

- Business Opportunity For Coal Upgrading (Briquettes Plant & Power PlantDocument16 pagesBusiness Opportunity For Coal Upgrading (Briquettes Plant & Power PlantSeno BaskoroNo ratings yet

- Cs Distr Steam Methane ReformDocument5 pagesCs Distr Steam Methane ReformJuan Antonio SánchezNo ratings yet

- 9ha Power PlantsDocument2 pages9ha Power PlantsIzzadAfif1990No ratings yet

- 9ha Power Plants PDFDocument2 pages9ha Power Plants PDFmead6356No ratings yet

- MTOE Calculation: Energy Conservation Table and Sample Calculation For Annual Energy Consumption in Terms of MtoeDocument4 pagesMTOE Calculation: Energy Conservation Table and Sample Calculation For Annual Energy Consumption in Terms of MtoeJoydeep PatraNo ratings yet

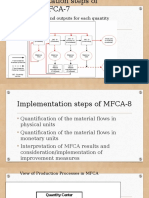

- Steps of Mfca-7 AgesDocument7 pagesSteps of Mfca-7 AgesErlia AgastyaNo ratings yet

- Generation and Reservoirs Statistics in Sri LankaDocument8 pagesGeneration and Reservoirs Statistics in Sri LankaChathura PriyankaNo ratings yet

- 9f Power PlantDocument2 pages9f Power Plantsoccer3_2003No ratings yet

- Lee Filters Poster BookDocument10 pagesLee Filters Poster BookAptaeex ExtremaduraNo ratings yet

- FAW Dump Trucks Brochure Details FD280DT, FD340DT, and HD380DT ModelsDocument3 pagesFAW Dump Trucks Brochure Details FD280DT, FD340DT, and HD380DT ModelsZhang YixingNo ratings yet

- 2035 Razumkov Centre Ukraine Energy StrategyDocument10 pages2035 Razumkov Centre Ukraine Energy StrategyNickNo ratings yet

- CII 18th Excellence in Energy Management Conference HighlightsDocument32 pagesCII 18th Excellence in Energy Management Conference HighlightsBülent BulutNo ratings yet

- Hospet Steels Limited, KoppalDocument21 pagesHospet Steels Limited, KoppalSagar GNo ratings yet

- ASWS Plaza Construction &: ManagementDocument30 pagesASWS Plaza Construction &: ManagementHamza HussainNo ratings yet

- Block Flow Diagram of Biomass Heat Recovery Steam Generation ProcessDocument5 pagesBlock Flow Diagram of Biomass Heat Recovery Steam Generation ProcessLuqman SaidNo ratings yet

- Generation and Reservoirs Statistics: August 6, 2017Document8 pagesGeneration and Reservoirs Statistics: August 6, 2017Chathura PriyankaNo ratings yet

- Key Elements To Revive The Mature Handil FieldDocument12 pagesKey Elements To Revive The Mature Handil Fieldb mNo ratings yet

- FO_CONSUMPTION_TABLE_BF0&4&5 - 20200511 - 15% sea marginDocument3 pagesFO_CONSUMPTION_TABLE_BF0&4&5 - 20200511 - 15% sea marginkosmoz1983No ratings yet

- Current Status of Osaki Coolgen Project: Oxygen-Blown Igcc WithDocument28 pagesCurrent Status of Osaki Coolgen Project: Oxygen-Blown Igcc WithMir MuhammadNo ratings yet

- Net Zero Energy Design PDFDocument72 pagesNet Zero Energy Design PDFshaimaa08100% (1)

- Total Weight of STEEL Structure in TONAGE No of Days: MOBILE CRANE 10 Tons For Assembly Electrode E 7018 ScaffoldingDocument8 pagesTotal Weight of STEEL Structure in TONAGE No of Days: MOBILE CRANE 10 Tons For Assembly Electrode E 7018 ScaffoldingMd Rahul HossainNo ratings yet

- BGR Energy 30-10T CommercialDocument1 pageBGR Energy 30-10T Commercialkarthik RajendranNo ratings yet

- Case Study Inventory and Mitigation-Energy&TransportDocument17 pagesCase Study Inventory and Mitigation-Energy&TransportayyishNo ratings yet

- Gail Pata Daily Progress Report/ गेल पाता दैनिक प्रगनत ररपोर्टDocument1 pageGail Pata Daily Progress Report/ गेल पाता दैनिक प्रगनत ररपोर्टKuls KulsNo ratings yet

- Calculation Sheet Generation 5 - Tissue Paper - Version 5.9Document17 pagesCalculation Sheet Generation 5 - Tissue Paper - Version 5.9HariNo ratings yet

- Fire Fiting System List: Engineering, Procurement & Construction of Sulaimanya (Plastic Recycling Factory)Document1 pageFire Fiting System List: Engineering, Procurement & Construction of Sulaimanya (Plastic Recycling Factory)مممصتبهاNo ratings yet

- Free Guide To ClaimDocument8 pagesFree Guide To ClaimChamara UdayangaNo ratings yet

- MHP MHP: For Harmonious Living With Global EnvironmentDocument2 pagesMHP MHP: For Harmonious Living With Global Environmentvictor siringoNo ratings yet

- Presentation To Analyst On Pata Plant VisitDocument38 pagesPresentation To Analyst On Pata Plant VisitVivek palNo ratings yet

- SETO PTES Workshop Doug Hofer GEDocument7 pagesSETO PTES Workshop Doug Hofer GEIzzadAfif1990No ratings yet

- BAB-7 Pengolahan Limbah Gas - (B)Document49 pagesBAB-7 Pengolahan Limbah Gas - (B)Hafizh tarunaNo ratings yet

- 2014 Mecs Fabricated Metals Energy FootprintDocument2 pages2014 Mecs Fabricated Metals Energy FootprintAbdullah RobbaniNo ratings yet

- CAB - Independent Petrol Station FinancialsDocument32 pagesCAB - Independent Petrol Station FinancialsmenthigaNo ratings yet

- Kobelco SK230SRLC-3 - NaDocument8 pagesKobelco SK230SRLC-3 - NaleonNo ratings yet

- GE Energy: Gas Turbine (60Hz)Document2 pagesGE Energy: Gas Turbine (60Hz)Rolando Antonio Cuenca PironaNo ratings yet

- Jesus Tamang. Philippines. Low Carbon Growth Strategies and ChallengesDocument24 pagesJesus Tamang. Philippines. Low Carbon Growth Strategies and ChallengeslncguevaraNo ratings yet

- Fire Fiting System List: Engineering, Procurement & Construction of Sulaimanya (Plastic Recycling Factory)Document1 pageFire Fiting System List: Engineering, Procurement & Construction of Sulaimanya (Plastic Recycling Factory)مممصتبهاNo ratings yet

- 44 Murali NabinDocument1 page44 Murali NabinNabin MuraliNo ratings yet

- Milling Rate Formate 2019 SDBDocument3 pagesMilling Rate Formate 2019 SDBpraveen kumar sainiNo ratings yet

- Costo de ProducciónDocument1 pageCosto de ProducciónJuan GonzalezNo ratings yet

- Rekapitulasi Tagihan BMJ Ke Mas HamdanDocument2 pagesRekapitulasi Tagihan BMJ Ke Mas HamdansandyNo ratings yet

- Xylowatt Presentation January 2017 1 PDFDocument21 pagesXylowatt Presentation January 2017 1 PDFchoppinNo ratings yet

- 88 Years in The Pump Business enDocument16 pages88 Years in The Pump Business enanil kapadiaNo ratings yet

- 6 - Basic of Polyester - K&Vglobal PDFDocument7 pages6 - Basic of Polyester - K&Vglobal PDFpritam1509No ratings yet

- 2011 Meg PetDocument3 pages2011 Meg PetDiwya ParamarthaNo ratings yet

- Microfibres, Microfilaments & Their Applications: Sandip V. Purane, Narsingh R. PanigrahiDocument11 pagesMicrofibres, Microfilaments & Their Applications: Sandip V. Purane, Narsingh R. Panigrahirosegonca100% (1)

- Fiber Production LineDocument3 pagesFiber Production Lineanil kapadiaNo ratings yet

- Study The Effect of Commingling Parameters On Glass / Polypropylene Hybrid Yarns PropertiesDocument4 pagesStudy The Effect of Commingling Parameters On Glass / Polypropylene Hybrid Yarns Propertiesanil kapadiaNo ratings yet

- 0313e Refinery Future ChallengeDocument16 pages0313e Refinery Future Challengeanil kapadiaNo ratings yet

- Design of A Compounding Extruder by Means of The SIGMA Simulation SoftwareDocument24 pagesDesign of A Compounding Extruder by Means of The SIGMA Simulation SoftwareAnonymous lFvgGOGcuNo ratings yet

- 4010e Polyester Continuous ProcessDocument8 pages4010e Polyester Continuous Processanil kapadiaNo ratings yet

- Pet Flake Conversion 2Document26 pagesPet Flake Conversion 2James NgNo ratings yet

- 4010e Polyester Continuous ProcessDocument8 pages4010e Polyester Continuous Processanil kapadiaNo ratings yet

- Fibretqs Monitoring Poy and FdyDocument2 pagesFibretqs Monitoring Poy and Fdyanil kapadiaNo ratings yet

- (Are You Ready To Evolve?) : Economy FlexibilityDocument1 page(Are You Ready To Evolve?) : Economy Flexibilityanil kapadiaNo ratings yet

- How To Save 630,000 USD Per Year and Produce The Best PolyesterDocument1 pageHow To Save 630,000 USD Per Year and Produce The Best Polyesteranil kapadiaNo ratings yet

- 4 2altunDocument7 pages4 2altunanil kapadiaNo ratings yet

- Synthetic FibersDocument43 pagesSynthetic Fibersprathamesh_aNo ratings yet

- Effect of Process Parameters in SpinningDocument4 pagesEffect of Process Parameters in Spinninganil kapadiaNo ratings yet

- Enhancing Tensile Properties Yarn Strength of Polyester Filament Drawn YarnDocument6 pagesEnhancing Tensile Properties Yarn Strength of Polyester Filament Drawn Yarnanil kapadiaNo ratings yet

- Enhancing Tensile Properties Yarn Strength of Polyester Filament Drawn YarnDocument6 pagesEnhancing Tensile Properties Yarn Strength of Polyester Filament Drawn Yarnanil kapadiaNo ratings yet

- Influence of The Spinning Process Parameters On Strength Characteristics PDFDocument5 pagesInfluence of The Spinning Process Parameters On Strength Characteristics PDFFabia RibeiroNo ratings yet

- Fibretqs Monitoring Poy and FdyDocument2 pagesFibretqs Monitoring Poy and Fdyanil kapadiaNo ratings yet

- Effect of PET Properties on False Twist TexturingDocument22 pagesEffect of PET Properties on False Twist Texturinganil kapadiaNo ratings yet

- Enhancing Tensile Properties Yarn Strength of Polyester Filament Drawn YarnDocument6 pagesEnhancing Tensile Properties Yarn Strength of Polyester Filament Drawn Yarnanil kapadiaNo ratings yet

- Effect of Process Parameters in SpinningDocument4 pagesEffect of Process Parameters in Spinninganil kapadiaNo ratings yet

- Extension Force of Partially Oriented Yarn: Standard Test Method ForDocument6 pagesExtension Force of Partially Oriented Yarn: Standard Test Method ForJuanNo ratings yet

- DL Filament Spinning OBA POY enDocument28 pagesDL Filament Spinning OBA POY enanil kapadiaNo ratings yet

- Enhancing Tensile Properties Yarn Strength of Polyester Filament Drawn YarnDocument6 pagesEnhancing Tensile Properties Yarn Strength of Polyester Filament Drawn Yarnanil kapadiaNo ratings yet

- Effect of PET Properties on False Twist TexturingDocument22 pagesEffect of PET Properties on False Twist Texturinganil kapadiaNo ratings yet

- DL Filament Spinning OBA POY enDocument28 pagesDL Filament Spinning OBA POY enanil kapadiaNo ratings yet

- Biogeochemical Cycles PresentationDocument8 pagesBiogeochemical Cycles PresentationNamish SNNo ratings yet

- Chemistry ProjectDocument15 pagesChemistry ProjectgUD bOiNo ratings yet

- Design of FoundationDocument8 pagesDesign of FoundationRajib BagNo ratings yet

- Identification Study and Mechanical Characterization Clay Stabilized by GumarabicseyalDocument9 pagesIdentification Study and Mechanical Characterization Clay Stabilized by GumarabicseyalIJAR JOURNALNo ratings yet

- Flow Through PipesDocument6 pagesFlow Through PipesammuvijjiNo ratings yet

- Laboratory Report On Diffusion and Sugar Salt SolutionsDocument13 pagesLaboratory Report On Diffusion and Sugar Salt SolutionsJeca InandanNo ratings yet

- Icjephpu 01Document10 pagesIcjephpu 01abhinavdby1008No ratings yet

- Factores de ConversionDocument3 pagesFactores de ConversionDIEGO MARCELO JUELA QUINTUÑANo ratings yet

- Reactor Design and Analysis (MHU)Document164 pagesReactor Design and Analysis (MHU)Chengsi WuNo ratings yet

- Material Science Notes: Brief But Effective Chapter 1. INRODUCTION 1 .1 Historical PerspectiveDocument33 pagesMaterial Science Notes: Brief But Effective Chapter 1. INRODUCTION 1 .1 Historical PerspectivePrathap MulagapakaNo ratings yet

- Specific Heat Lab ReportDocument1 pageSpecific Heat Lab Reportmusu.yanguba932950% (2)

- Green Building Project LifecyclesDocument5 pagesGreen Building Project LifecyclesSwati PriyaNo ratings yet

- HighvocDocument53 pagesHighvocKiran SonawaneNo ratings yet

- 2018 Index IEEE Journal of Photovoltaics Vol. 8Document54 pages2018 Index IEEE Journal of Photovoltaics Vol. 8hakimkorichiNo ratings yet

- GBDocument22 pagesGBNikhil SachdevaNo ratings yet

- Tpss 435: Chapter 6: Cation Exchange ReactionsDocument11 pagesTpss 435: Chapter 6: Cation Exchange ReactionsRonny NguyenNo ratings yet

- An improved model for calculating CO2 solubility in aqueous solutionsDocument9 pagesAn improved model for calculating CO2 solubility in aqueous solutionsNumitor Tor Aten Jil100% (1)

- Earth & Life Science-Q2-M2Document14 pagesEarth & Life Science-Q2-M2Yen SantosNo ratings yet

- IX-Physics WorksheetDocument5 pagesIX-Physics WorksheetPriti KadianNo ratings yet

- Radiacion SolarDocument30 pagesRadiacion SolarMartuchis EstradaNo ratings yet

- Review On Evaporative of Cooling System PDFDocument20 pagesReview On Evaporative of Cooling System PDFMrkoj Amin YahyaZe100% (1)

- Chemistry P-Block ElementDocument38 pagesChemistry P-Block ElementShivanjaliNo ratings yet

- Mind Map DSKP KSSM ScienceDocument9 pagesMind Map DSKP KSSM ScienceNadzirah ZahariNo ratings yet

- Fly Ash Brick TechnologyDocument8 pagesFly Ash Brick TechnologyadagooodNo ratings yet

- Climate Change Adaptation and MitigationDocument39 pagesClimate Change Adaptation and Mitigationldrrm nagaNo ratings yet

- 1 0 IntroDocument2 pages1 0 IntroAnonymous G3DRjDMkNo ratings yet

- The Impact of Geographical PhenomenaDocument6 pagesThe Impact of Geographical PhenomenaKristof Stuven100% (1)

- Sexual vs Asexual ReproductionDocument9 pagesSexual vs Asexual ReproductionChristianJamesCapiz96% (25)

- Mto-2 Oep (30,31,32)Document1 pageMto-2 Oep (30,31,32)Nayan ParmarNo ratings yet

- LAS Science9 MELC 2 Q3 Week-2Document6 pagesLAS Science9 MELC 2 Q3 Week-2Amy VillaNo ratings yet