Professional Documents

Culture Documents

Satr H 1003

Satr H 1003

Uploaded by

Moghal AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Satr H 1003

Satr H 1003

Uploaded by

Moghal AliCopyright:

Available Formats

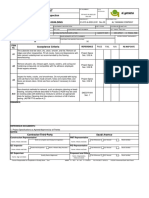

SAUDI ARAMCO ID/PIEU-30-Nov-2018 - Rev. 2018.11.00 (Standards Cutoff - Nov 30,2018) Rev.2018.11.

00 30-Nov-18

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

NBTC-10318-25120-

Concrete Moisture Field Test (For Coating Purposes) SATR-H-1003 27-Jan-19

COAT-0007

Note : SATR-H-1003 forms part of SAIC-H-1003 (Concrete Coatings Pre-Installation Inspection)& other related coating

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

SOUR WATER STRIPPING PROJECT (SWS) 10-1330-001 TR - NBTC

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

EQUIPMENT FOUNDATIONS J78-D-827 Grid A-1, B-1, C-1, D-1

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

RB-158173-001

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

27-DEC-2021 : 11:00 AM 27-DEC-2021 : 11:00 AM SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-H-003-01 3,1

SAUDI ARAMCO INSPECTION LEVEL

H

CONTRACTOR INSPECTION LEVEL

H

Y

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Test Procedures shall be in accordance with (SAES-H-003 Sec. 9.6.9/ ASTM D4263) OR

1- Tape a 4 mil thick (0.1mm), 18"x 18" (450mm x 450mm) of clear plastic sheet to the surface to be coated; tape all around with duct tape.

2- Sheet shall remain in place for a minimum of 16 hours. Indicate number of hours sheet has been in place:_____ hrs.

3- Remove and visually check the underside for moisture.

4- After 16 hours if no moisture is present on the underside of the plastic, the concrete is ready for coating.

5- If droplets of moisture are present, the concrete shall be given more curing time. Pass ¨ Fail ¨ N/A ¨

Alternate Test Procedures shall be in accordance with ( SAES-H-003 Sec. 8.1.4)

1- Drill 2 holes 6mm Diameter, 25mm deep and 150mm apart (holes to be repaired after test)

2- Surface contaminants such as laitance and form oils shall be removed.

3- Insert the Elcometer probes into each hole and seal in place with silicone putty.

4- Wait 24 hours for the effects of the drilling to stabilize.

5- Moisture Content Reading: ____________%

6- Begin coating only if the moisture content reading is less than 4%. Pass ¨ Fail ¨ N/A¨

Repairs During Tests:

Result: Moisture Test Failed ¨ Moisture Test Passed ¨

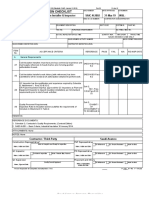

CONCLUSIONS

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Test results are acceptable and in accordance with Saudi Aramco

D1 N/A

Engineering Standards and contractural requirements.

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-H-003 -- Protective Coatings for Industrial Concrete Structures,22 February 2018

2- SAES-H-001 - Coating Selection and Application Requirements for Industrial Plants and Equipment, 21 February 2018

3- SAES-Q-001 -- Criteria for Design and Construction of Concrete Structures, 21 October 2018

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date: FERAS AL SENAN

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

CHRISTOPHER AQUINO RODERICK ACULA

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Anatomy of The SpineDocument83 pagesAnatomy of The SpineUkhti Nur Zannah83% (6)

- Classic Jaguar - April-May 2019 PDFDocument100 pagesClassic Jaguar - April-May 2019 PDFDanilo BuenoNo ratings yet

- Technical SpecificationDocument70 pagesTechnical SpecificationTeuku Rizki Muda KeulanaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- ACLS Test BankDocument13 pagesACLS Test BankSofiaSheikh94% (51)

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Marraige and CompatabilityDocument3 pagesMarraige and CompatabilityRamesh Menon100% (1)

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- 9FB Gas TurbineDocument2 pages9FB Gas TurbineRene GonzalezNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Bandsaw GuidesDocument8 pagesBandsaw GuidesSteeve Loring100% (5)

- Drawn To That Moment: John BergerDocument4 pagesDrawn To That Moment: John BergerJaviera ValienteNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- Carroll - The Philosophy of Motion Pictures PDFDocument250 pagesCarroll - The Philosophy of Motion Pictures PDFMaria Fernanda UgazNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Aramco ChecklistDocument1 pageAramco ChecklistTayyab AchakzaiNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003DipuNo ratings yet

- Saic A 1006Document1 pageSaic A 1006DipuNo ratings yet

- Satr M 1014Document2 pagesSatr M 1014DipuNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Niel TanedoNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation InspectionDocument1 pageAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspectionmoytabura96No ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Saic B 1001Document1 pageSaic B 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatDocument2 pagesSaudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatnasirNo ratings yet

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- Saic G 2018Document1 pageSaic G 2018usmanNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilDocument1 pageSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SAIC-L-2041 Rev 6 Storge & Inspection of ValvesDocument2 pagesSAIC-L-2041 Rev 6 Storge & Inspection of ValvesAhdal NoushadNo ratings yet

- Saic-A-1006 Final Fill InspectionDocument1 pageSaic-A-1006 Final Fill InspectionZia ur RehmanNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ненад КнежевићNo ratings yet

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

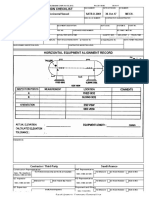

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 22-Jan-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 22-Jan-18 MechaneeshNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Dilshad AhemadNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- Saic M 1043Document1 pageSaic M 1043Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004Ansar Ali VemmullyNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities BuildingDocument6 pagesAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities Buildingmoytabura96No ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechJagdishNo ratings yet

- Saic A 1010Document1 pageSaic A 1010usmanNo ratings yet

- Saic LPT 2010Document4 pagesSaic LPT 2010Arjun RawatNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saic B 2002Document1 pageSaic B 2002usmanNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saic A 1009Document2 pagesSaic A 1009mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic B 2010Document2 pagesSaic B 2010usmanNo ratings yet

- Saic A 1010Document1 pageSaic A 1010mohammadNo ratings yet

- Saudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKDocument2 pagesSaudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKshaikhbwcNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 Mechnadeem shaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Satr D 2001Document2 pagesSatr D 2001Shahzad HussainNo ratings yet

- Saudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalDocument9 pagesSaudi Aramco Typical Inspection Plan: Cement Lining of Pipes & Fittings SATIP-H-002-01 MechanicalMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection Plan: Coating Application On Concrete Surfaces SATIP-H-003 - 01 27-Jan-19Document10 pagesSaudi Aramco Typical Inspection Plan: Coating Application On Concrete Surfaces SATIP-H-003 - 01 27-Jan-19Moghal AliNo ratings yet

- Saudi Aramco Test Report: SATR-H-2011 27-Jan-19 Mech Surface Preparation of Internal Pipe End/Joints For FBE CoatingDocument2 pagesSaudi Aramco Test Report: SATR-H-2011 27-Jan-19 Mech Surface Preparation of Internal Pipe End/Joints For FBE CoatingMoghal AliNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- Apcs 113 - Inorganic ZincDocument11 pagesApcs 113 - Inorganic ZincMoghal AliNo ratings yet

- Interactive Session 6Document3 pagesInteractive Session 6Fiorentina CenaNo ratings yet

- Amansie Central District GhanaDocument10 pagesAmansie Central District GhanaIqra 2000No ratings yet

- GRADE 9 NOTES (1) - PREPARING SANDWICHES #CookeryDocument9 pagesGRADE 9 NOTES (1) - PREPARING SANDWICHES #CookeryRain JannelaNo ratings yet

- Math 201 Spring 2021 SyllabusDocument4 pagesMath 201 Spring 2021 SyllabusPoyraz EmelNo ratings yet

- MIPI/DSI Receiver With HDMI Transmitter: Data SheetDocument12 pagesMIPI/DSI Receiver With HDMI Transmitter: Data SheetRobert GrabekNo ratings yet

- Ac Motor Control Manual gs1m PDFDocument137 pagesAc Motor Control Manual gs1m PDFJuan Francisco Martinez GuerreroNo ratings yet

- NOOK - Precision Screw AssembliesDocument216 pagesNOOK - Precision Screw AssembliesBruv 07No ratings yet

- SSADocument10 pagesSSAAnkush KumarNo ratings yet

- Cambridge IGCSE™ (9-1) : English As A Second Language 9-1 0993/11 May/June 2021Document9 pagesCambridge IGCSE™ (9-1) : English As A Second Language 9-1 0993/11 May/June 2021GhostNo ratings yet

- Bachelor of Architecture-2020Document63 pagesBachelor of Architecture-2020Aditya PatelNo ratings yet

- Civil - SurveyingDocument16 pagesCivil - SurveyingAnurag AnandNo ratings yet

- CONSTRUCTION COMMUNICATIONS PLAN FinVer4Document18 pagesCONSTRUCTION COMMUNICATIONS PLAN FinVer4Mohammed MuzakkirNo ratings yet

- Focus GroupDocument13 pagesFocus GroupPilar VélezNo ratings yet

- Đề Số 9 Section B: Phonetics (5 Pts) : - - - - - - - I am leavingDocument6 pagesĐề Số 9 Section B: Phonetics (5 Pts) : - - - - - - - I am leavingĐỗ LinhNo ratings yet

- Expensive Tissue HypothesisDocument24 pagesExpensive Tissue HypothesisEKNo ratings yet

- SENTRON WL VL Circuit Breakers With Communication Capability PROFIBUS en en-USDocument286 pagesSENTRON WL VL Circuit Breakers With Communication Capability PROFIBUS en en-USkiderilkeNo ratings yet

- Mechanical ProjectDocument7 pagesMechanical ProjectAbi Nesan100% (1)

- Spitz 1990Document11 pagesSpitz 1990Fernando GaliciaNo ratings yet

- Sensor Datasheet 01DT-1..: Type OverviewDocument4 pagesSensor Datasheet 01DT-1..: Type OverviewManashNo ratings yet

- Duck ProductionDocument23 pagesDuck Productionokodi andrewNo ratings yet

- Breech Births & Cesarean Sections - Diana Rose VillamorDocument31 pagesBreech Births & Cesarean Sections - Diana Rose VillamorDaniel TomnobNo ratings yet