Professional Documents

Culture Documents

Effective Stress and Pore Water Pressure

Uploaded by

Di4a AbdelmawlaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effective Stress and Pore Water Pressure

Uploaded by

Di4a AbdelmawlaCopyright:

Available Formats

Geotechnical and Geological Engineering – CVE214

Effective Stress and Pore Water Pressure

The total stress within a mass of soil at any point below a water

table is equal to the sum of two components, which are known as;

effective stress and pore water pressure.

Effective stress is defined as the total force on a cross

section of a soil mass which is transmitted from grain to

grain of the soil, divided by the area of the cross section,

including both solid particles and void spaces. It

sometimes is referred to as inter-granular stress.

Pore water pressure is defined as the unit stress carried by

the water in the soil pores in a cross section.

Effective stress governs soil behavior and can be expressed as:

σ' = σ- u

Where:

σ' = the effective stress in the soil

σ= total (or applied) stress

u = pore water pressure

48 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Soil Strength

One of the most important engineering properties of soil is its

shearing strength, or its ability to resist sliding along internal surfaces

within a given mass. Shear strength is the property that materially

influences the bearing capacity of a foundation soil. The basic

principle is similar in many respects to an object resting on a table.

For example, imagine a brick resting on a table top as shown in above

Figure.The brick is in equilibrium under its own weight and the equal

and opposite reaction force is provided by the table.

Now imagine a horizontal force is applied to the brick near the

table-top. If this horizontal force is small, the brick will remain

at rest, and the applied horizontal force will be balanced by an

equal and opposite force. This resisting force is developed as a

result of the roughness characteristics of the bottom of the brick

and the table surface.

If the applied horizontal force is gradually increased, the

resisting force will also increase, always being equal in

magnitude to the applied force. When the applied force equals or

exceeds the resistance, the brick will slide across the table-top.

The slippage is a shear failure. The applied horizontal force is a

shearing force and the developed force is shear resistance.

49 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

The shear strength is the maximum shear resistance that the materials

are capable of developing.

Shear strength consists of two parts. The first part is the friction

between particles (physical property). The second part is called

cohesion, or no-load shear strength due to a chemical bond

between particles.

1. Angle of Internal Frictionn

The shear strength of a granular soil, such as sands, gravels and

some silts, is closely analogous to the frictional resistance of

solids in contact, as described above and shown in above Figure.

The relationship between the normal stress acting on a plane in

the soil and its shearing strength can be expressed as,

τf = σ tan φ

Where:

τf = the shearing stress at failure, or the shear strength

σ = normal stress acting on the failure plane

φ = friction angle

The internal friction of a given soil mass is related to,

A. The sliding friction between individual soil grains

B. The interlocking of soil particles.

Shear strength attributable to friction requires a normal force (σ),

and the soil material must exhibit friction characteristics, such as

multiple contact areas.

In dense soils, the individual soil grains can interlock, much like

the teeth of two highly irregular gears. For sliding to occur, the

individual grains must be lifted over one another against the

normal stress (σ). Therefore, the force required to overcome

particle interlock is proportional to the normal stress, just the

same as sliding friction is proportional to normal stress. In soil

mechanics φ is designated the angle of internal friction, because

it represents the sum of sliding friction plus interlocking.

The angle of internal friction (φ) is a function of density,

roundness or angularity, and particle size.

50 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

2. Cohesion

When a saturated clay is consolidated, that is, when the

volume of voids decreases as a result of water being squeezed

out of the pores, the shear strength increases with normal

stress.

If the shear strength of clays which have a previous history

of consolidation (i.e. pre-consolidated) is measured, the

relationship between shear strength and normal stress is no

longer a line intersecting the ordinate at zero. The clays

exhibit a memory, or cohesive shear strength.

In other words, the clays remember the pre-consolidation

pressure they were previously subjected to. This means

considerable shear strength is retained by the soil.

Above figure is an example of the relationship between shear

strength and normal stress for a pre-consolidated plastic clay

as derived from a triaxial shear test. The inter-section of the

line at the ordinate is called the cohesion.

51 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Cohesion is associated with fine grain materials such as clays

and some silts. Cohesion is the attraction between soil

particles. It is a function of clay mineralogy, moisture content,

particle orientation (soil structure), and density.

Coulomb Equation for Shear Strength

The equation for shear strength as a linear function of

total stress is called the Coulomb equation because it

was first proposed by C.A. Coulomb in 1773.

τf = c + σ tan φ

In terms of effective stress:

τf = c + (σ - u) tan φ

where:

τf = shear strength

c = cohesion

σ = total stress acting on the failure plane

φ = friction angle

u = pore water pressure

Above two equations are the most widely used equations in

geotechnical engineering, since they approximately describe the shear

strength of any soil under drained conditions. They are the basis for

the bearing capacity equations.

52 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Soil Compaction

Compaction and Objectives

• Many types of earth construction, such as dams, retaining walls,

highways, and airport, require man-placed soil, or fill. To

compact a soil, that is, to place it in a dense state.

• The dense state is achieved through the reduction of the air voids

in the soil, with little or no reduction in the water content. This

process must not be confused with consolidation, in which water

is squeezed out under the action of a continuous static load.

Objectives:

(1) Decrease future settlements

(2) Increase shear strength

(3) Decrease permeability

Compaction - General Principles:

The degree of compaction of soil is measured by its dry unite weight

I.Loose Soils must be compacted to:

a. Increase their unite weights,

b. Increase the strength characteristics of soils, thereby increasing

bearing capacity,

c. Decrease the amount of undesirable settlement, Reduce

compressibility, water absorption and Permeability.

d. Increase Stability of slopes of embankments.

53 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Factors Affecting Compaction:

1. Water content

2. Amount of compaction / Compaction Energy

3. Soil Type

4. Admixtures (calcium chloride acts as soil flocculent, causes slight

increase in the compaction density)

Soil Improvement

1. Compaction

2. Theory of Compaction

3. Properties and Structure of Compacted Fine-Grained Soils

4. Field Compaction Equipment and Procedures

5. Field Compaction Control and Specifications

6. Estimating Performance of Compacted Soils

General Compaction Methods

Comparison-Why?

• In the early days of compaction, because construction equipment

was small and gave relatively low compaction densities, a laboratory

method that used a small amount of compacting energy was required.

As construction equipment and procedures were developed which

gave higher densities, it became necessary to increase the amount of

compacting energy in the laboratory test.

54 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

• The modified test was developed during World War II by the U.S.

Army Corps of Engineering to better represent the compaction

required for airfield to support heavy aircraft. The point is that

increasing the compactive effort tends to increase the maximum dry

density, as expected, but also decrease the optimum water content.

Theory of Compaction (Laboratory Test)

For the similar compacting efforts, the dry unite weight of

compacted soil is increase as the moisture content increases. The

laboratory test generally used to obtained max. dry unite weight of

compaction and the optimum moisture content is called ' Proctor

Compaction test'.

Origin

The fundamentals of compaction of fine-grained soils are relatively

new. R.R. Proctor in the early 1930’s was building dams for the old

Bureau of Waterworks and Supply in Los Angeles, and he developed

the principles of compaction in a series of articles in Engineering

News-Record. In his honor, the standard laboratory compaction test

which he developed is commonly called the proctor test.

Purpose

The purpose of a laboratory compaction test is to determine the proper

amount of mixing water to use when compacting the soil in the field

and the resulting degree of denseness which can be expected from

compaction at this optimum water

Impact compaction

The proctor test is an impact compaction. A hammer is dropped

several times on a soil sample in a mold. The mass of the hammer,

height of drop, number of drops, number of layers of soil, and the

volume of the mold are specified.

55 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Test Equipment

Variables of Compaction

Proctor established that compaction is a function of four variables:

(1) Dry density (d) or dry unit weight d.

(2) Water content w

(3) Compactive effort (energy E)

(4) Soil type (gradation, presence of clay minerals, etc.)

56 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Procedures and Results

Procedures

1. Several samples of the same soil, but at different water contents,

are compacted according to the compaction test specifications.

2. The total or wet density and the actual water content of each

compacted sample are measured.

3. Plot the dry densities d versus water contents w for each

compacted sample. The curve is called as a compaction curve.

Relative Density of Granular

57 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Procedures and Results-Explanation

Procedures and Results-Notes

1. Each data point on the curve represents a single compaction

test, and usually four or five individual compaction tests are

required to completely determine the compaction curve.

2. At least two specimens wet and two specimens dry of

optimum, and water contents varying by about 2%.

3. Optimum water content is typically slightly less than the

plastic limit (ASTM suggestion).

4. Typical values of maximum dry density are around 1.6 to

2.0 Mg/m3 with the maximum range from about 1.3 to 2.4

Mg/m3. Typical optimum water contents are between 10%

and 20%, with an outside maximum range of about 5% to

40%.

58 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Effects of Soil Types on Compaction

The soil type-that is, grain-size distribution, shape of the soil grains,

specific gravity of soil solids, and amount and type of clay minerals

present.

Engineering Properties-Summary

59 Dr. Naema Ali

Geotechnical and Geological Engineering – CVE214

Engineering Properties-Notes

a. Engineers must consider not only the behavior of the soil

as compacted but the behavior of the soil in the

completed structure, especially at the time when the

stability or deformation of the structure is most critical.

b. For example, consider an element of compacted soil in a

dam core. As the height of the dam increases, the total

stresses on the soil element increase. When the dam is

performing its intended function of retaining water, the

percent saturation of the compacted soil element is

increased by the permeating water. Thus the engineer

designing the earth dam must consider not only the

strength and compressibility of the soil element as

compacted, but also its properties after is has been

subjected to increased total stresses and saturated by

permeating water.

Measurement of Field Compaction

Most common methods are:

1) Sand cone method

2) Rubber balloon method

3) Nuclear method

Sand Cone Test

Dry weight of calibrated sand to fill the hole

Volume of the hole

Dry density of calibrated sand

Dry weight of the soil extracted from the hole

dry in the field

Volume of the hole

60 Dr. Naema Ali

You might also like

- BGE Module-4Document38 pagesBGE Module-41JT19CV013 MedheshNo ratings yet

- Gte Assignment 4 SolutionDocument5 pagesGte Assignment 4 Solutionamol bardeNo ratings yet

- 2008 05 DD 41 Manhole FlotationDocument15 pages2008 05 DD 41 Manhole FlotationPedrin Cha Olivos100% (1)

- Module 3 - Geotechengg PDFDocument22 pagesModule 3 - Geotechengg PDFDio LazatinNo ratings yet

- Soil Mehanics II ManualDocument56 pagesSoil Mehanics II ManualPasi C4Siele100% (1)

- Shear Stength of SoilDocument19 pagesShear Stength of SoilRamKrishnaMurtiNo ratings yet

- Ce 364 s2023 Lecture 1 Uyumluluk ModuDocument65 pagesCe 364 s2023 Lecture 1 Uyumluluk Moduenes arikanNo ratings yet

- Effective StressDocument6 pagesEffective StressBaluku BennetNo ratings yet

- (PART I) An Introduction To Retaining Walls DesignDocument12 pages(PART I) An Introduction To Retaining Walls DesignPankaj KapilNo ratings yet

- Soil Mechanics of Large Diameter PilesDocument10 pagesSoil Mechanics of Large Diameter PilesReynaldo FelipeNo ratings yet

- Geotechnical Glossary A-CDocument31 pagesGeotechnical Glossary A-CClaudia SilvaNo ratings yet

- Subsurface Stresses: at A Point Within A Soil Mass, Stresses Will BeDocument24 pagesSubsurface Stresses: at A Point Within A Soil Mass, Stresses Will BegtNo ratings yet

- What Is Consolidation?Document18 pagesWhat Is Consolidation?نور عليNo ratings yet

- Report About: TitleDocument9 pagesReport About: TitleRasti AmediNo ratings yet

- Design of Foundation 1Document9 pagesDesign of Foundation 1LJ ClimacoNo ratings yet

- Shear Strength of Soil Part 1 PDFDocument53 pagesShear Strength of Soil Part 1 PDFVal GallanoNo ratings yet

- Suelos No SaturadosDocument55 pagesSuelos No SaturadosCesar Felipe Jimenez SantiagoNo ratings yet

- Advanced Soil Mechanics Lecture NotesDocument147 pagesAdvanced Soil Mechanics Lecture Notesjayshri bamneNo ratings yet

- Group A Advanced Soil Mechanics CourseworkDocument15 pagesGroup A Advanced Soil Mechanics CourseworkJimmyNo ratings yet

- Mine Waste Stability FactorsDocument5 pagesMine Waste Stability FactorsWalay AllanNo ratings yet

- Compressibility of Soil: Unit 1Document12 pagesCompressibility of Soil: Unit 1Prince AJNo ratings yet

- Chapter 2 (A) - DrRADocument27 pagesChapter 2 (A) - DrRAFareez SedakaNo ratings yet

- Soil Mechanics and Foundation Engineering - SummaryDocument6 pagesSoil Mechanics and Foundation Engineering - Summaryngocbinh8xNo ratings yet

- Phase Relationships of Earth Materials Effective Stress Shear Strength Settlement and ConsolidationDocument19 pagesPhase Relationships of Earth Materials Effective Stress Shear Strength Settlement and ConsolidationAlfonsius ReynaldoNo ratings yet

- The State of The Art Report On Arching Effect: Gholam Moradi, Alireza AbbasnejadDocument14 pagesThe State of The Art Report On Arching Effect: Gholam Moradi, Alireza AbbasnejadG-SamNo ratings yet

- Unit Weight: OverconsolidationDocument2 pagesUnit Weight: OverconsolidationRAYNo ratings yet

- Module 8 of GeotechDocument39 pagesModule 8 of GeotechAnore, Raecel John V.No ratings yet

- Lateral Earth PresDocument36 pagesLateral Earth PresSyed Muhammad Mohsin100% (1)

- GT Guess Paper Solution V Sem PDFDocument98 pagesGT Guess Paper Solution V Sem PDFYogesh PrajapatiNo ratings yet

- W4-Bashir - CompressionDocument55 pagesW4-Bashir - Compression木辛耳总No ratings yet

- 5 (2019) (Scopus)Document17 pages5 (2019) (Scopus)Ismacahyadi Mohamed JaisNo ratings yet

- Lec 1 Settlement Analysis PDFDocument41 pagesLec 1 Settlement Analysis PDFSYED ABDUL WAHAB AHMADNo ratings yet

- Learning Module - 1 - OnlyDocument38 pagesLearning Module - 1 - OnlyJea Escabal MosenabreNo ratings yet

- Shear Strength of SoilsDocument14 pagesShear Strength of SoilsAnkit NagpalNo ratings yet

- Effect of Swelling Soil On Load Carrying Capacity of A Single PileDocument10 pagesEffect of Swelling Soil On Load Carrying Capacity of A Single PileSafwat El RoubyNo ratings yet

- VesicDocument38 pagesVesicLucas de Hollanda100% (1)

- Influence of Soil Structure On The Mechanical RespDocument6 pagesInfluence of Soil Structure On The Mechanical RespCesar Felipe Jimenez SantiagoNo ratings yet

- (FINAL) Direct Shear TestDocument39 pages(FINAL) Direct Shear TestSoumyNayakNo ratings yet

- Dynamic Bearing CapacityDocument62 pagesDynamic Bearing CapacityYasirMahmoodNo ratings yet

- Shear Strength of SoilDocument16 pagesShear Strength of SoilVEERKUMARNo ratings yet

- Soil Mechanics - II - PPTX Day 1Document18 pagesSoil Mechanics - II - PPTX Day 1yareNo ratings yet

- PBL Report GeoTechnical EngineeringDocument39 pagesPBL Report GeoTechnical EngineeringEldren Jamee100% (1)

- 2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimDocument15 pages2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimYoungtae KimNo ratings yet

- Lecture Note - 1 - GeotechDocument19 pagesLecture Note - 1 - GeotechMike MatshonaNo ratings yet

- Settlement Analysis GuideDocument57 pagesSettlement Analysis Guidelance carterNo ratings yet

- Contact Pressure: Elastic Properties of FootingDocument8 pagesContact Pressure: Elastic Properties of FootingdhivyaNo ratings yet

- Geotechnical Foundation Engineering: Bearing Pressure & CapacityDocument89 pagesGeotechnical Foundation Engineering: Bearing Pressure & CapacityTalha.jNo ratings yet

- AssignmentDocument9 pagesAssignmentAlam Mohammad Parvez Saifi100% (1)

- Effective Stress and ConsolidationDocument6 pagesEffective Stress and Consolidationbrandon bernardNo ratings yet

- Arijit Nandi Soil Mechanics-IIDocument4 pagesArijit Nandi Soil Mechanics-IIarijit nandiNo ratings yet

- One-dimensional consolidation of soilDocument7 pagesOne-dimensional consolidation of soilRahul SinhaNo ratings yet

- Soil Mechanics Introduction and DefinitionDocument15 pagesSoil Mechanics Introduction and DefinitionRachel Palma GilNo ratings yet

- Shear StrengthDocument5 pagesShear StrengthsubhashiniNo ratings yet

- COMPRESSIBILITY OF SOIL: FACTORS THAT AFFECT SETTLEMENTDocument93 pagesCOMPRESSIBILITY OF SOIL: FACTORS THAT AFFECT SETTLEMENTjuan camilo corderoNo ratings yet

- 4 - 1 Shallow FoundationsDocument230 pages4 - 1 Shallow FoundationsAnonymous Vx9KTkM8nNo ratings yet

- Lecture39-Seismic Response of PilesDocument34 pagesLecture39-Seismic Response of PilesArun Goyal100% (1)

- WSengara ShearStrengthofSoil HATTI Part2 2021Document57 pagesWSengara ShearStrengthofSoil HATTI Part2 2021Ardyan BadrizaNo ratings yet

- GEOTECH 2 Module 1Document14 pagesGEOTECH 2 Module 1Earl averzosaNo ratings yet

- Foundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsDocument17 pagesFoundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsRobert Prince100% (1)

- RC1 - Sheet # 6 - F19Document1 pageRC1 - Sheet # 6 - F19Di4a AbdelmawlaNo ratings yet

- سيكشن 4 استراكشرDocument3 pagesسيكشن 4 استراكشرDi4a AbdelmawlaNo ratings yet

- سيكشن 3Document4 pagesسيكشن 3Di4a AbdelmawlaNo ratings yet

- سيكشن 5 conjagate beamDocument4 pagesسيكشن 5 conjagate beamDi4a AbdelmawlaNo ratings yet

- CamScanner App Scans Documents EasilyDocument2 pagesCamScanner App Scans Documents EasilyDi4a AbdelmawlaNo ratings yet

- Ex. of Virtual WorkDocument3 pagesEx. of Virtual WorkDi4a AbdelmawlaNo ratings yet

- Geometric Design 4Document8 pagesGeometric Design 4Di4a AbdelmawlaNo ratings yet

- Geometric Design 4Document8 pagesGeometric Design 4Di4a AbdelmawlaNo ratings yet

- DatasheetDocument3 pagesDatasheetzaranrajputNo ratings yet

- Engineering Engineering Engineering Engineering Standard Standard Standard StandardDocument12 pagesEngineering Engineering Engineering Engineering Standard Standard Standard StandardgustavoNo ratings yet

- Acids Bases and Salts 1Document16 pagesAcids Bases and Salts 1nsamba sethNo ratings yet

- Group 14 Element TrendsDocument26 pagesGroup 14 Element TrendsVon JinNo ratings yet

- Paint Additives: Product Guide L-G 1Document16 pagesPaint Additives: Product Guide L-G 1محمد عزتNo ratings yet

- CHEMCON - 2004 - Research PaperDocument17 pagesCHEMCON - 2004 - Research Paperरुद्र प्रताप सिंह ८२No ratings yet

- Activity ZoneDocument4 pagesActivity ZoneSK CreationsNo ratings yet

- Fundamental Financial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument36 pagesFundamental Financial Accounting Concepts 9th Edition Edmonds Solutions Manualalicenhan5bzm2z100% (29)

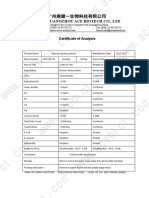

- COA of Siberian Ginseng ExtractDocument1 pageCOA of Siberian Ginseng ExtractPan EmmaNo ratings yet

- Optical and Photovoltaic Properties of Thieno (3,2 B) Thiophenebased Push Pull Organic Dyes With Different Anchoring Groups ForDocument12 pagesOptical and Photovoltaic Properties of Thieno (3,2 B) Thiophenebased Push Pull Organic Dyes With Different Anchoring Groups Forreeshma BegamNo ratings yet

- 2021 Catalog: For CO and Fiber Laser Consumables Replacement Parts Suitable For MazakDocument42 pages2021 Catalog: For CO and Fiber Laser Consumables Replacement Parts Suitable For MazakTayfur AydınNo ratings yet

- General - Chemistry 1 Module 2 AY 2022 2023Document17 pagesGeneral - Chemistry 1 Module 2 AY 2022 2023Yzac Barroga PascualNo ratings yet

- Optimal Cooling of a Tubular ReactorDocument24 pagesOptimal Cooling of a Tubular Reactorkingsley peprahNo ratings yet

- Solute Mass and Solution Concentration CalculationsDocument6 pagesSolute Mass and Solution Concentration CalculationsZinzinNo ratings yet

- EQASDocument55 pagesEQASSHURUQNo ratings yet

- Chemical Kinetics and Reaction Mechanisms - EspensonDocument227 pagesChemical Kinetics and Reaction Mechanisms - EspensonJose Cornejo100% (6)

- Procedure of NDT TestDocument5 pagesProcedure of NDT TestSandeep VarmaNo ratings yet

- 37 MolaritywebDocument10 pages37 MolaritywebpenisNo ratings yet

- ReSouk 2012 Proceedings-FINALDocument819 pagesReSouk 2012 Proceedings-FINALJoaquim Filipe de Castro100% (1)

- Instru Presentation AnumDocument27 pagesInstru Presentation AnumAbdullah DoulaNo ratings yet

- Footing Design (WSD Method) PDFDocument2 pagesFooting Design (WSD Method) PDFFaruque AbdullahNo ratings yet

- Biocharasconstructionmaterial ReviewDocument15 pagesBiocharasconstructionmaterial ReviewAnura BandaraNo ratings yet

- Post Lab DiscussionDocument80 pagesPost Lab DiscussionDan ManaigNo ratings yet

- PartialDocument2 pagesPartialNova RachmadonaNo ratings yet

- Raman Shift Standards For Spectrometer CalibrationDocument11 pagesRaman Shift Standards For Spectrometer CalibrationEric GozzerNo ratings yet

- Review of A Cyclohexane Oxidation Reaction Using Heterogenous CatalystDocument6 pagesReview of A Cyclohexane Oxidation Reaction Using Heterogenous CatalysttatianaNo ratings yet

- Parte1 - Netting - Mat (1) .2Document77 pagesParte1 - Netting - Mat (1) .2LUIS GUSTAVO MIRANDA BRITONo ratings yet

- The Common Ion Effect and Buffer SolutionsDocument11 pagesThe Common Ion Effect and Buffer SolutionsAhmed goldenNo ratings yet

- Sulfur Dioxide Removal: An Overview of Regenerative Flue Gas Desulfurization and Factors Affecting Desulfurization Capacity and Sorbent RegenerationDocument26 pagesSulfur Dioxide Removal: An Overview of Regenerative Flue Gas Desulfurization and Factors Affecting Desulfurization Capacity and Sorbent RegenerationKrittika ChandranNo ratings yet

- 1-6 Chemical Reactions of Alkanes and AlkenesDocument2 pages1-6 Chemical Reactions of Alkanes and AlkenesBryan100% (1)