Professional Documents

Culture Documents

Dme 1 Class Test 2 QP

Uploaded by

Elson Paul VOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dme 1 Class Test 2 QP

Uploaded by

Elson Paul VCopyright:

Available Formats

Roll No……… Name…………………….

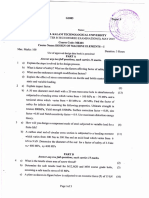

MAR BASELIOS INSTITUTE OF TECHNOLOGY AND SCIENCE [MBITS]

S7 MECHANICAL ENGINEERING

ME401 DESIGN OF MACHINE ELEMENTS 1

CLASS TEST 2 (DECEMBER 2021)

Time: 2 Hrs Answer all questions Max. Marks: 50

Use of approved design data book permitted

Any missed data may suitably be assumed.

Qn.

Questions. Mark CO BL

No.

Answer any FIVE Questions. Each Question carries ten marks

A bolt connects two plates of an assembly whose combined stiffness is 4

times the stiffness of the bolt. The joint is subjected to an external load

which varies from 2 KN to 6 KN. The initial tightening force on the bolt is

1 4KN. The bolt used is M16 Coarse thread and is made of SAE 1025 10 CO3 L3

annealed steel with yield strength 370 MPa. Take A= 1.0, B=0.85, C = 0.9

and fatigue stress concentration factor = 5.0.Determine the factor of safety

used in design.

A Plate as shown in the fig below is subjected to an eccentric force P of 15

KN with an eccentricity of 450 mm from the CG of the bolts. The centre

distance between bolts 1 and 2 is 210 mm and the centre distance between

bolts 1 and 3 is 150 mm. All the bolts are identical. The bolts are made

from plane carbon steel 25C8 and the FOS is 2.5. Find the size of the bolts.

2 10 C03 L3

A sluice gate weighting 500kN is raised at a speed of 6 m/min by two

screw rods with square threads 50 × 8 mm. The two screw rods are driven

3 10 CO3 L3

by bevel gears and motor. Determine (a) torque require to raise the gate; (b)

P.T.O

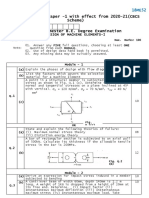

Roll No……… Name…………………….

speed of rotation of the screw rods assuming the thread are triple start; (c)

efficiency of the screw; (d) Length of nuts required to support to load

taking the allowable bearing pressure 12MPa; (e) check for overhaul

Design a triple riveted butt joint with unequal cover plates and chain

riveting to connect two plates 20 mm thick. The allowable tensile stress for

4 the plate is 100 MPa and allowable shear and crushing stress for the plate is 10 CO4 L3

55 MPa and 110 MPa respectively. Sketch the joint and find its efficiency.

A bracket carrying a load of 15 KN as shown below. Find the size of the

weld required if the allowable shear stress is not to exceed 80 MPa.

5 10 CO4 L3

Design a Knuckle joint to transmit 150 KN. The design stress may be taken

6 10 CO4 L3

as 75MPa in tension, 60 MPa in shear and 150 MPa in crushing.

COURSE OUTCOMES (CO)

After completion of the course the students will be able to:

CO3: To study about the stresses induced, modes of failures in various bolted, threaded joints and

power screws

CO4: To study about the stresses induced, modes of failures in various joints

BL-Bloom’s Taxonomy Levels

1-Remembering 2- Understanding 3-Applying 4-Analysing 5- Evaluating 6- Creating

HOD Verified by Prepared by

P.T.O

You might also like

- Analysis of Welded Structures: Residual Stresses, Distortion, and Their ConsequencesFrom EverandAnalysis of Welded Structures: Residual Stresses, Distortion, and Their ConsequencesRating: 5 out of 5 stars5/5 (2)

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocument8 pagesDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekNo ratings yet

- PART-A (10 X 2 20 Marks)Document4 pagesPART-A (10 X 2 20 Marks)Arun R UNo ratings yet

- DMM 1Document9 pagesDMM 1andhracollegesNo ratings yet

- MdId Gtu PaperDocument3 pagesMdId Gtu PaperhukNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- IFS Mechanical Engineering 2015 Part 1Document4 pagesIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajNo ratings yet

- KTU BTech ME 2019scheme 2019Scheme-MinorsDocument114 pagesKTU BTech ME 2019scheme 2019Scheme-MinorsLearn Mechanical EngineeringNo ratings yet

- Avkis: College of Engineering, HassanDocument1 pageAvkis: College of Engineering, HassankiranNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuNo ratings yet

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- DoS ModelDocument2 pagesDoS ModelKrishna KumarNo ratings yet

- Machine Design Question PaperDocument2 pagesMachine Design Question Papersushil.vgi100% (1)

- dmm1 PDFDocument9 pagesdmm1 PDFmohan_rapaka6095No ratings yet

- Design of Prestressed Concrete Structures Jan 2014Document2 pagesDesign of Prestressed Concrete Structures Jan 2014Prasad C MNo ratings yet

- Design of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Document4 pagesDesign of Machine Elements: B.E. (Mechanical Engineering / Power Engineering) Fifth Semester (C.B.S.)Chandani KannakeNo ratings yet

- DME1 Question BankDocument4 pagesDME1 Question BankJinto Joy ManjalyNo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- 07 r05310305 Design of Machine Members IDocument8 pages07 r05310305 Design of Machine Members IandhracollegesNo ratings yet

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- MOM OU Old Question PaperDocument2 pagesMOM OU Old Question PaperAmmineni Syam PrasadNo ratings yet

- DME 1-SupplyDocument3 pagesDME 1-SupplyAmal SNo ratings yet

- CEPC25 Dec 2019Document2 pagesCEPC25 Dec 2019Lokesh Kumar MeenaNo ratings yet

- Assignment 3 IEMDocument1 pageAssignment 3 IEMHareesha N GNo ratings yet

- Som I Iat Ques 2019Document3 pagesSom I Iat Ques 2019Siva RamanNo ratings yet

- Ce401 Design of Steel Structures, January 2023Document2 pagesCe401 Design of Steel Structures, January 2023unni70154No ratings yet

- Internal Assessment Test II, Odd Semester (2016-2017) : Year/Sem: II/III Duration: 1 Hour Max. Marks: 50Document3 pagesInternal Assessment Test II, Odd Semester (2016-2017) : Year/Sem: II/III Duration: 1 Hour Max. Marks: 50Muthukrishnan biherNo ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

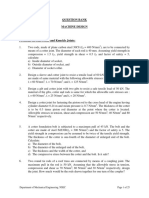

- Model Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationDocument10 pagesModel Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationSharath KotegarNo ratings yet

- 15 PDFDocument2 pages15 PDFKiran KumarNo ratings yet

- Be Winter 2022Document3 pagesBe Winter 2022Karan SheladiyaNo ratings yet

- R7310305-Design of Machine Members-I2Document4 pagesR7310305-Design of Machine Members-I2slv_prasaad100% (1)

- SRM TRP Engineering College, Irungalur, Trichy - 621 105: Co6 L3Ap Co4 L1ReDocument2 pagesSRM TRP Engineering College, Irungalur, Trichy - 621 105: Co6 L3Ap Co4 L1RemyidmaranNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHerat HirparaNo ratings yet

- Dme Gtu PaperDocument5 pagesDme Gtu PaperManav HnNo ratings yet

- Dmm1 Mar2006Document8 pagesDmm1 Mar2006prk74No ratings yet

- Rr310305 Design of Machine Members IDocument8 pagesRr310305 Design of Machine Members ISrinivasa Rao GNo ratings yet

- 9A03504 Design of Machine Elements - IDocument1 page9A03504 Design of Machine Elements - Iprasaad08No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- Design of Machine Members: Part-ADocument4 pagesDesign of Machine Members: Part-ARkrishna ANo ratings yet

- I I I I I I I I I I I: Design of Pre-Stressed Concrete StructuresDocument13 pagesI I I I I I I I I I I: Design of Pre-Stressed Concrete StructuresSuryakant MangajNo ratings yet

- Design: of Steel StructuresDocument2 pagesDesign: of Steel StructureskarthiksampNo ratings yet

- DOME I Set-1 BE P.TDocument3 pagesDOME I Set-1 BE P.TchupchapNo ratings yet

- Hallmark Engineering Classes: "Please Check Whether You Have Got The Right Question Paper."Document2 pagesHallmark Engineering Classes: "Please Check Whether You Have Got The Right Question Paper."Yash DhabaliaNo ratings yet

- Instructions:: No of Pages Course CodeDocument2 pagesInstructions:: No of Pages Course CodeCRAZY PIANO PLAYERNo ratings yet

- Pre Stressed ConcreteDocument8 pagesPre Stressed Concretevamsi_rsNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological UniversityJaineshNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityfeyayel990No ratings yet

- Btech Me 6 Sem Machine Design Kme602 2022Document3 pagesBtech Me 6 Sem Machine Design Kme602 2022thunderstorm8853No ratings yet

- DME Question BankDocument18 pagesDME Question BankAditya PatilNo ratings yet

- 2019 Dec. CE304-F - Ktu QbankDocument2 pages2019 Dec. CE304-F - Ktu QbankAa AaNo ratings yet

- R5310305-Design of Machine Members - IDocument4 pagesR5310305-Design of Machine Members - IsivabharathamurthyNo ratings yet

- Me8593 DmeDocument3 pagesMe8593 DmeSrm EmpirorNo ratings yet

- DME-I Model Paper-3 2Document3 pagesDME-I Model Paper-3 2Srinivas KosuriNo ratings yet

- Prestressed ConcreteDocument8 pagesPrestressed ConcreteYeswanth RaghavendraNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Electrochemical Processes in Biological SystemsFrom EverandElectrochemical Processes in Biological SystemsAndrzej LewenstamNo ratings yet

- Abr Exams GuideDocument10 pagesAbr Exams GuideNelson Appiah-AgyeiNo ratings yet

- Objectives of Chapter Optoelectronic MaterialsDocument36 pagesObjectives of Chapter Optoelectronic MaterialsOriLokisNo ratings yet

- PART 1 - Work, Power and Energy PART 2 - Heat, Work and EnergyDocument4 pagesPART 1 - Work, Power and Energy PART 2 - Heat, Work and EnergyJerizza ParafinaNo ratings yet

- Effects of Silane Functionalization On The Properties of Carbon Nanotube/epoxy NanocompositesDocument8 pagesEffects of Silane Functionalization On The Properties of Carbon Nanotube/epoxy NanocompositespolypolyyNo ratings yet

- Metalworking Tig WeldingDocument11 pagesMetalworking Tig WeldingPutra Pratama100% (8)

- Applied Sciences: A Novel Comprehensive Method For Modeling and Analysis of Mesh StiDocument19 pagesApplied Sciences: A Novel Comprehensive Method For Modeling and Analysis of Mesh StiDiego MascarenhasNo ratings yet

- Balance of Plant Lalpir/Pakgen Made by Mubashir Rasheed Internee GikiDocument1 pageBalance of Plant Lalpir/Pakgen Made by Mubashir Rasheed Internee GikiInaam Ur RehmanNo ratings yet

- Prestressed Post Tensioned Concrete Bridges PDFDocument42 pagesPrestressed Post Tensioned Concrete Bridges PDFMauricioGamboaNo ratings yet

- EY Heet Mathematics: Sec: JR - IIT - COSC (MODEL-B) Date: 03-12-23 Time: 3 Hrs 2019 - P1 Max. Marks: 186Document7 pagesEY Heet Mathematics: Sec: JR - IIT - COSC (MODEL-B) Date: 03-12-23 Time: 3 Hrs 2019 - P1 Max. Marks: 186heroweb970No ratings yet

- SolutionDocument3 pagesSolutionbahast faiqNo ratings yet

- 22 - Fracture Toughness & Toughening MechDocument30 pages22 - Fracture Toughness & Toughening MechMd. Rafiqul IslamNo ratings yet

- FR - Chemical KineticsDocument5 pagesFR - Chemical KineticsKenneth Dionysus SantosNo ratings yet

- MlaDocument6 pagesMlaRodrigo PorcaroNo ratings yet

- Line NumberingDocument2 pagesLine NumberingRafeek ShaikhNo ratings yet

- Spring Mass Couple PDFDocument52 pagesSpring Mass Couple PDFatiqah umairahNo ratings yet

- 1 s2.0 S1296207417307525 MainDocument8 pages1 s2.0 S1296207417307525 MainUdrescu Andreea-IrinaNo ratings yet

- Butterfly Vale LossesDocument12 pagesButterfly Vale LossesNguyễn Thống NhấtNo ratings yet

- Bearing Capacity and Settlement Response of Raft Foundation On Sand Using Standard Penetration Test MethodDocument6 pagesBearing Capacity and Settlement Response of Raft Foundation On Sand Using Standard Penetration Test MethodtasaddaqYounas100% (1)

- DME Unit-3 ProcedureDocument14 pagesDME Unit-3 ProcedureKumaravel SrNo ratings yet

- Introduction To Mec101Document3 pagesIntroduction To Mec101Ericka Mae RuizNo ratings yet

- Hung Ta: Ht-9745 Programmable Temperature and Humidity Walk-In ChamberDocument19 pagesHung Ta: Ht-9745 Programmable Temperature and Humidity Walk-In ChamberRohman AzizNo ratings yet

- Material Nonlinear Analysis OnlyDocument34 pagesMaterial Nonlinear Analysis OnlynargissuhailNo ratings yet

- High Wall Inverter: Yhkf 09 To 24 ZeebmhorxDocument2 pagesHigh Wall Inverter: Yhkf 09 To 24 ZeebmhorxmuratNo ratings yet

- Soil Exploration (Penetration Tests)Document17 pagesSoil Exploration (Penetration Tests)ZakNo ratings yet

- Simple Harmonic MotionDocument18 pagesSimple Harmonic MotionM Shafeeq ManzoorNo ratings yet

- SSP Ii CH 13aDocument12 pagesSSP Ii CH 13aAkil SundarNo ratings yet

- Machine Tool TestingDocument4 pagesMachine Tool Testingnm2007k100% (1)

- Chapter 5 Well Testing (III) : Weibo Sui PH.D, Associate Professor College of Petroleum Engineering, CUPBDocument64 pagesChapter 5 Well Testing (III) : Weibo Sui PH.D, Associate Professor College of Petroleum Engineering, CUPBLyes BouhenikaNo ratings yet

- PDS Stopaq Subsea Intermediate Wrap V3 enDocument1 pagePDS Stopaq Subsea Intermediate Wrap V3 enAndyNo ratings yet

- BT 8800 EnglDocument2 pagesBT 8800 EnglMVTECH CORPNo ratings yet