Professional Documents

Culture Documents

Daily Report Wet Gas K041

Uploaded by

missoum mohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Report Wet Gas K041

Uploaded by

missoum mohamedCopyright:

Available Formats

Customer Name CPECC

Site Name SIDI RZINE ALGERIE REFANERY

Work Scope Start up NEW UNIT

Technology Medium Steam Turbine - SC

Submitted Date

Serial # 1102831

Type of Intervention ON CALL

Site Activity Job # 2875568

This Preliminary Field Service Report is intended to provide you with a preliminary description of the activities performed by our FSEs at site.This

Preliminary Field Service Report is not intended to provide you with recommendations or instructions on future use of your equipment. The purpose

of the preliminary recommendations and/or instructions contained in this report, if any, is to highlight potentially material issues and other

significant information for the operation of your equipment that our FSE has identified. The recommendations and/or instructions included herein

are based solely on the information available to the FSE on site as of the date hereof. Final recommendations and/or instructions on future use

of your machine and equipment, if any, will be issued in the Final Field Service Report. Such Final Field Service Report will be based on our

analysis of all other information available to Baker Hughes, a GE Company. To the extent any recommendation and/or instruction is contained

herein, you should rely on such recommendation and/or instruction only for the interim period until you receive from us the Final Field Service

Report. From that moment on you should rely solely on the recommendation and/or instruction included in the Final Field Service Report. BHGE

assumes no liability in connection with customer’s failure to comply with the above.

BHGE Field Service Representative Customer Representative

Idir MAHREZ

1. GENERAL INFORMATION

1.1 Customer Site Data

Site Address SIDI RZINE BARAKI

Country ALGERIA

Site DUNS Number 2875568

1.2 Customer Representative

Data

Customer Representative

Customer Contact Phone Number 0554 45 67 28

Customer eMail - Required wangyi@cpecc.com.cn

1.3 BH Reference Contact

Project Manager Name Ramdan Ouerd

Field Project Engineer Name

Service/Installation Manager Name Ramdan Oured

Site Manager Name

Report Written by - FSE Name Idir MAHREZ

STRICTLY CONFIDENTIAL (v1.0.2.9301) 1

2. MACHINE DATA

2.1 Equipment Data

Service Hours 0

Starts Number 0

Trip Number 0

Fuel Type(s) Not Applicable

Fuel System Not Applicable

Driven Equipment

Combustion System (if any) Not Applicable

Type of Service/Application

2.2 Machine Status

Status at FSE Arrival On Site Under commissioning

Status at FSE Departure From Site

FSE Arrival Date On Site 25 MARCH 2020

FSE Departure Date From Site

2.3 Outage Service Period

From 25 March 2020

To

2.4 Unit Reference Data

Original Job Number (Manufacturing) 2875568

Cod Date (installation unit date)

GE s/n

Name Plate

Customer Tag # 530-K-041

Related s/n

OEM 1 s/n

OEM 1 Brand

STRICTLY CONFIDENTIAL (v1.0.2.9301) 2

01, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The

pressure was maintained at 0.61 Kg/Cm2 G.

02, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

03, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

04, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

05, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

06, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 3

07, JULY 2020 Day shift

Monitor unit parameters during normal operation.

Monitor the main column receiver pressure and adjust it on process team request. The pressure

was maintained at 0.6 Kg/Cm2 G.

08, JULY 2020 Day shift

Unit stopped on client request; cooldown sequence completed.

Conference call with our Engineering regarding the compressor surge tests and the importance of

gas molecular weight on design surge curves. Gas composition should be stable and aligned with

the design.

Remarks:

Some oil leakage has been identified on Trip Valve Solenoids and need to be fixed (XS-1127 &

XS-1130)

TI-1112 RTD inactive thrust bearing metal temperature will be changed by new one during

shutdown.

12, JULY 2020

Unit in stop condition.

Checked the flow transmitter 530-FI-1161A. Ok done by CPECC/SH

530-XY-1127 & 530-XY-1130 oil leakage to be fixed (in Progress).

Software analyzes according to our engineering taking in consideration the MW.

13, JULY 2020

Software analyzes according to our engineering taking in consideration the MW.

Unit in stop condition.

Checked the flow transmitter 530-FI-1161A. Ok done by CPECC/SH.

530-XY-1127 & 530-XY-1130 oil leakage to be fixed (in Progress).

Replacement of 530-TI-1112 installed on Steam Turbine. (In progress).

14, JULY 2020

Software analyzes according to our engineering taking in consideration the MW and Master

Controller / Load Controller Logics simulation.

Replacement of 530-TI-1112 installed on Steam Turbine (done) by CPECC instrumentation team.

530-XY-1127 & 530-XY-1130 oil leakage to be fixed (in Progress) remain test.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 4

15, JULY 2020

Unit in stop condition.

Checked the flow transmitter 530-FI-1161A. Ok done

Replacement of 530-TI-1112 installed on Steam Turbine. Ok done

Verification & update PLC Software checked the Anti-surge curves and simulate the

Master Controller / Load Controller Logics. In progress

530-XY-1127 & 530-XY-1130 oil leakage, O-rings has been replaced… /in Progress

530-FV-1161: process preparation by the client ongoing in order to check the valve

internally for any probable dirty that could impact the safe operation of the compressor as

recommended by BH engineering… / in progress.

16, JULY 2020

Replacement of 530-TI-1112 installed on Steam Turbine. Ok done

Verification & update PLC Software checked the Anti-surge curves and simulate the

Master Controller / Load Controller Logics. In progress

530-XY-1127 & 530-XY-1130 oil leakage, O-rings has been replaced… /in Progress

530-FV-1161: process preparation by the client ongoing in order to check the valve

internally for any probable dirty that could impact the safe operation of the compressor as

recommended by BH engineering… / in progress.

19, JULY 2020

Verification & update PLC Software checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

530-XY-1127 & 530-XY-1130 oil leakage, O-rings has been replaced… /in Progress

530-FV-1161: process preparation by the client ongoing in order to check the valve internally for any

probable dirty that could impact the safe operation of the compressor as recommended by BH

engineering… / in progress

20, JULY 2020

Verification & update PLC Software checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

530-XY-1127 & 530-XY-1130 oil leakage, O-rings has been replaced… /in Progress

530-FV-1161: process preparation by the client ongoing in order to check the valve internally for any

probable dirty that could impact the safe operation of the compressor as recommended by BH

engineering… / in progress.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 5

21, JULY 2020

Verification & update PLC Software checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

530-XY-1127 & 530-XY-1130 oil leakage, O-rings has been replaced… /in Progress

530-FV-1161: process preparation by the client ongoing in order to check the valve internally for any

probable dirty that could impact the safe operation of the compressor as recommended by BH

engineering… / in progress.

22, JULY 2020

Replacement of 530-TI-1112 installed on Steam Turbine. Ok done

Stroke test of trip valve 530-XV-1102 and HP valve 530-SV-1103 ok, no oil leakage observed on

the solenoids 530-XY-1129/530-XY-1127/530-XY-1130. done

Checked the air booster and Stroke test of the 2nd stage anti-surge valve 530-FV-1161, OK. done

Verification & update PLC Software; checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

23, JULY 2020

Verification & update PLC Software; checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

Conference call with our Engineering team regarding the remain activities for the next startup of

wet gas unit.

26, JULY 2020

Unit in stop condition. Ready for startup

Verification & update PLC Software; checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

27, JULY 2020

Unit in stop condition. Ready for startup

Support customer to check and stroke the process valves PV-0274A/B. ok no issue has been

observed.

Verification & update PLC Software; checked the Anti-surge curves and simulate the Master Controller /

Load Controller Logics. In progress

STRICTLY CONFIDENTIAL (v1.0.2.9301) 6

5, August 2020

Unit in stop condition. Ready for startup

Verification & update PLC Software; checked Anti-surge curves and simulate the Master Controller / Load

Controller Logics. In progress.

6, August 2020

Unit in stop condition.

Checked / reset current Alarms & Trip, the unit is Ready for startup.

Verification & update PLC Software; checked Anti surge curves and simulate the Master Controller / Load

Controller Logics. In progress

Note:

As per the email received on 03Aug2020 from Mr. Ramdane/BH engineering regarding the impact of high

Gas MW on the ASV SLL curves, please provide the data requested by BH engineering in order to get

response from them before next startup of the unit.

10, August 2020

Unit in stop condition /Ready for startup.

Master Controller / Load Controller Logics Tested OK, final tuning will be completed on real condition when

the unit is running.

Update Anti surge 2nd Stage curves. In progress

Note:

As per the email received on 03Aug2020 from Mr. Ramdane/BH engineering regarding the impact of high

Gas MW on the ASV SLL curves, please provide the data requested by BH engineering in order to get

response from them before next startup of the unit.

11, August 2020

Unit in stop condition /Ready for startup.

Master Controller / Load Controller Logics Tested OK, final tuning will be completed on real condition when

the unit is running.

Update Anti surge 2nd Stage curves .. In progress

Note:

As per the email received on 03Aug2020 from Mr. Ramdane/BH engineering regarding the impact of high

Gas MW on the ASV SLL curves, please provide the data requested by BH engineering in order to get

response from them before next startup of the unit.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 7

18, August 2020

Unit in stop condition /Ready for startup.

Master Controller / Load Controller Logics Tested OK, final tuning will be completed on real condition when

the unit is running.

Update Anti surge 2nd Stage SLL curves. New SLL curve has been implemented on the PLC base on the

last surge test data.

The startup of wet gas compressor is planned by the client on 19Aug morning. I’ll be on day shift from

tomorrow.

Note:

As per the email received on 03Aug2020 from Mr. Ramdane/BH engineering regarding the impact of high

Gas MW on the ASV SLL curves, please provide the data requested by BH engineering in order to evaluate

surge protection vs compressor performance.

19, August 2020 day shift

Unit preparation for startup and waiting for Customer process ready.

Auxiliary parameters check (lube oil, steam condenser, baring gear …).

20, August 2020 day shift

Unit preparation for startup and waiting for Customer process ready.

Auxiliary parameters check (lube oil, steam condenser, baring gear …).

21, August 2020 day shift

Unit preparation for startup and waiting for Customer process ready.

Auxiliary parameters check (lube oil, steam condenser, baring gear …).

STRICTLY CONFIDENTIAL (v1.0.2.9301) 8

22, August 2020 day shift

Unit preparation for startup and waiting for Customer process ready.

Auxiliary parameters check (lube oil, steam condenser, baring gear …).

Start the unit after process stabilization from Customer and speed stabilized at 7300tr/min.

23, August 2020 day shift

Unit under operation with main column received pressure maintained at 0.68 KG/CM2.

24, August 2020 day shift

Unit preparation for startup after trip recorded from ESD (N2 seal gas Low pressure).

25, August 2020 day shift

Unit in operation under monitoring process load from Customer 80%.

26, August 2020 day shift

Unit in operation under monitoring process load from Customer 80%.

27, August 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

28, August 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 9

29, August 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

30, August 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

31, August 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

1, September 2020 day shift

Unit in operation under monitoring process load from Customer 100%.

2, September 2020 night shift

Unit in operation under monitoring process load from Customer 100%.

3, September 2020 night shift

Unit in operation under monitoring process load from Customer 65%.

STRICTLY CONFIDENTIAL (v1.0.2.9301) 10

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- MS Traffic Signs Installations (Rev. 01)Document6 pagesMS Traffic Signs Installations (Rev. 01)moytabura96100% (1)

- ASME BPVC 2021 - Key Changes PresentationDocument68 pagesASME BPVC 2021 - Key Changes PresentationOmar Shahin100% (3)

- AA5373.09-MS002 Rev 0 PDFDocument41 pagesAA5373.09-MS002 Rev 0 PDFanisaan100% (2)

- (FBM230231232233) User's GuideDocument240 pages(FBM230231232233) User's Guidemissoum mohamed100% (3)

- MOV EIL Spec 2 PDFDocument134 pagesMOV EIL Spec 2 PDFpl_arunachalam79No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- ASME Code Section 8 Guide for Pressure Vessel Design and ConstructionDocument9 pagesASME Code Section 8 Guide for Pressure Vessel Design and Constructionsnehal.deshmukhNo ratings yet

- 26071-203-V66A-MTFR-20013 - Rev002 - NDE Procedure (PAUT, RT, PT, MT, UT)Document189 pages26071-203-V66A-MTFR-20013 - Rev002 - NDE Procedure (PAUT, RT, PT, MT, UT)randi martaNo ratings yet

- CP Installation ManualDocument14 pagesCP Installation Manualjamal Alawsu100% (1)

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- CF6-80C2 Reliability Scorecards - Monthly - MAR2017-R1 PDFDocument68 pagesCF6-80C2 Reliability Scorecards - Monthly - MAR2017-R1 PDFFaraz Khan100% (1)

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- HGP Insulation ProcedureDocument22 pagesHGP Insulation ProcedureShamas TabraizNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : (To Be Filled in by Originator)Document3 pagesRas Markaz Crude Oil Park Project (Phase1) : (To Be Filled in by Originator)ANIL PLAMOOTTIL100% (1)

- Capex For ATFE Installation For Xylene Distillation QPDocument29 pagesCapex For ATFE Installation For Xylene Distillation QPPrathmesh GujaratiNo ratings yet

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDocument10 pages3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNo ratings yet

- Method of Statement-Pipework Cleaning GuidelinesDocument10 pagesMethod of Statement-Pipework Cleaning Guidelinesmissoum mohamedNo ratings yet

- Project Document No.: VD-MR-007-01-037: Document Title: Site Acceptance Test ProcedureDocument9 pagesProject Document No.: VD-MR-007-01-037: Document Title: Site Acceptance Test ProcedureshahimulkNo ratings yet

- SP 02G 05a 24 27028Document24 pagesSP 02G 05a 24 27028tarek_bouzayaniNo ratings yet

- JAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0Document21 pagesJAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0MedrouaNo ratings yet

- Repair ProceduresDocument5 pagesRepair Proceduresmohd as shahiddin jafriNo ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- 4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control NarrativeDocument47 pages4000046273-PGCA-EA-C09-004 - 5.2 - 1 - Control Narrativerajindo1No ratings yet

- M-33 Diesel Generator Engine ManualDocument847 pagesM-33 Diesel Generator Engine ManualJibu George Thomas100% (7)

- Acd2-Mrl Sur en PDFDocument100 pagesAcd2-Mrl Sur en PDFGutmonarch88% (16)

- LH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageDocument277 pagesLH012-E-CCP-FLS-DM-X-E-001 - RB - A1 - MR For Flare PackageSumantrra Chattopadhyay100% (2)

- FINAL C09145 Scopeofwork-ReportDocument35 pagesFINAL C09145 Scopeofwork-ReportMba Nang Ndong MohamedNo ratings yet

- Preliminary Report Tgm1Document56 pagesPreliminary Report Tgm1SIAD SALIMNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- A Check Format (With New Segmentation) Rev3 02082019Document17 pagesA Check Format (With New Segmentation) Rev3 02082019Anil KumarNo ratings yet

- Siemens MotorDocument7 pagesSiemens MotorsajidkaleemNo ratings yet

- Anant SPG MOM 7-08-18Document4 pagesAnant SPG MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- DRP001-OUF-STC-MTS-E-000-004-001-S3 Electrical Equipment Installation (PCS-T-01180)Document15 pagesDRP001-OUF-STC-MTS-E-000-004-001-S3 Electrical Equipment Installation (PCS-T-01180)Bharathi JNo ratings yet

- Format. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Document3 pagesFormat. No: TSSA - IS - IN - FR - 05 Rev 4 Dated. 15.01.2021Raja KrsNo ratings yet

- XXXXXXXXXXXXXXX - Troubleshooting - Unit DDocument9 pagesXXXXXXXXXXXXXXX - Troubleshooting - Unit DOmar KhaledNo ratings yet

- Technical Bid RFQ 63403e Emd 2Document4 pagesTechnical Bid RFQ 63403e Emd 2wh8tksqjntNo ratings yet

- IGQ0805.100379 - Ultrasonic Examination Per API 6D - Rev2Document12 pagesIGQ0805.100379 - Ultrasonic Examination Per API 6D - Rev2LiliNo ratings yet

- DRM/S T Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No N-539-2-OT-19-20-11 ClosingDocument31 pagesDRM/S T Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No N-539-2-OT-19-20-11 ClosingArmaan MalikNo ratings yet

- 592 R2 Pacific Mall Legaspi Supply, Replacement and Conversion of PCC3201 To Deepsea Controller QSK60 With Esn25281468Document3 pages592 R2 Pacific Mall Legaspi Supply, Replacement and Conversion of PCC3201 To Deepsea Controller QSK60 With Esn25281468kram nievaNo ratings yet

- 1TB03300 300C04 STC Wir Me 0013Document12 pages1TB03300 300C04 STC Wir Me 0013Saud KhanNo ratings yet

- 4.0T TSB Coolant Performance + ThermostatDocument4 pages4.0T TSB Coolant Performance + ThermostatTommy D. SalamiNo ratings yet

- EDM 930 - Installation ManualDocument54 pagesEDM 930 - Installation Manualraisul dianaNo ratings yet

- Technical Service Bulletin: ConditionDocument3 pagesTechnical Service Bulletin: ConditionocnogueiraNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- 22BMJ 045 FEA 03 - Rev 0 - 23.07.05Document14 pages22BMJ 045 FEA 03 - Rev 0 - 23.07.05TEP DesignNo ratings yet

- (Customer) KR - TA - DE08 (136) - INC00369-DE08 (20250210)Document2 pages(Customer) KR - TA - DE08 (136) - INC00369-DE08 (20250210)princesseninouNo ratings yet

- VSD ManualDocument127 pagesVSD Manualvisakhgs0% (1)

- Power Curve v82Document11 pagesPower Curve v82sanjeev kumarNo ratings yet

- Review Presentation: Sahil Karodia Engineer P&FDocument66 pagesReview Presentation: Sahil Karodia Engineer P&FPranayteja.G gottipamulaNo ratings yet

- FWD Engine Mount Shackle Removal ScheduleDocument15 pagesFWD Engine Mount Shackle Removal SchedulePradeep K s100% (1)

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12No ratings yet

- Analisa GMT John Deere PDFDocument8 pagesAnalisa GMT John Deere PDFHidayatNo ratings yet

- Ge Proprietary InformationDocument3 pagesGe Proprietary Informationdavi de laraNo ratings yet

- FAR_ZBN41205Document4 pagesFAR_ZBN41205yeremia kristianNo ratings yet

- Alignment Report PDFDocument4 pagesAlignment Report PDFmohamadhakim.19789No ratings yet

- Transformer rating plate approvalDocument5 pagesTransformer rating plate approvalmayur dhandeNo ratings yet

- DGS-MU-012-R1 Requirements For Manufacturing Data Report For Non-Pressure Vessel EquipmentDocument10 pagesDGS-MU-012-R1 Requirements For Manufacturing Data Report For Non-Pressure Vessel EquipmentHalim KazdarNo ratings yet

- 03 001161 PDFDocument2 pages03 001161 PDFAbid Husain AbidiNo ratings yet

- Wi Opr-E020 Sub-Station System Works (Edit 2)Document13 pagesWi Opr-E020 Sub-Station System Works (Edit 2)Yusuf AlfathonyNo ratings yet

- viewNitPdf 2547183Document19 pagesviewNitPdf 2547183EMJAYNo ratings yet

- Service AgrementDocument36 pagesService AgrementAnnu ThukuranNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Hse Management Plan: Algiers Refinery Rehabilitation and Adaptation ProjectDocument62 pagesHse Management Plan: Algiers Refinery Rehabilitation and Adaptation Projectmissoum mohamedNo ratings yet

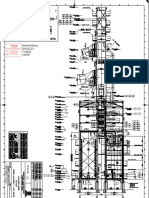

- DWG No. Reference DrawingsDocument1 pageDWG No. Reference Drawingsmissoum mohamedNo ratings yet

- Antonio Navas 2012.07.23 11:58:53 +02'00': Prevaling Wind DirectionDocument1 pageAntonio Navas 2012.07.23 11:58:53 +02'00': Prevaling Wind Directionmissoum mohamedNo ratings yet

- Hse Management Plan: Algiers Refinery Rehabilitation and Adaptation ProjectDocument62 pagesHse Management Plan: Algiers Refinery Rehabilitation and Adaptation Projectmissoum mohamedNo ratings yet

- Algiers Refinery Instrument Tie-In Engineering DossierDocument8 pagesAlgiers Refinery Instrument Tie-In Engineering Dossiermissoum mohamedNo ratings yet

- 1068 S 083 1 CDocument1 page1068 S 083 1 Cmissoum mohamedNo ratings yet

- Fem100 PDFDocument12 pagesFem100 PDFmissoum mohamedNo ratings yet

- PICTURE 2 - Sample FAS Instruments Surface Mounted - IDocument1 pagePICTURE 2 - Sample FAS Instruments Surface Mounted - Imissoum mohamedNo ratings yet

- Gas Extinguishing Description (CAS System Description)Document1 pageGas Extinguishing Description (CAS System Description)missoum mohamedNo ratings yet

- Gate - 2006 PDFDocument13 pagesGate - 2006 PDFRBNo ratings yet

- ZN 375 M PERC - Certificado - 1 PDFDocument2 pagesZN 375 M PERC - Certificado - 1 PDFJosé Luis González MartínezNo ratings yet

- 6.high-Temperature Cl-Induced CorrosionDocument18 pages6.high-Temperature Cl-Induced CorrosionPrakash WarrierNo ratings yet

- KerjaDocument6 pagesKerjaPreetharan RavindranNo ratings yet

- CW - Thompson's Calorimeter - KisaliDocument10 pagesCW - Thompson's Calorimeter - KisaliNADULA RUSIRUNo ratings yet

- Workbook Answers Chapter 5 Asal PhysicsDocument2 pagesWorkbook Answers Chapter 5 Asal PhysicsSaw Lip Xuan JeffNo ratings yet

- EE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenDocument9 pagesEE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenstansilawNo ratings yet

- Solar Cell I-V Characteristic and The Solar Cell I-V CurveDocument5 pagesSolar Cell I-V Characteristic and The Solar Cell I-V CurveMuhammad BalyanNo ratings yet

- Research Paper On Translucent ConcreteDocument8 pagesResearch Paper On Translucent Concretefjluthulg100% (1)

- Tram Anh de Chuyen Ams 2022-2023 8.7.2023Document23 pagesTram Anh de Chuyen Ams 2022-2023 8.7.2023Dothithanh thaoNo ratings yet

- ISO 18436-2 CAT-III Certified Vibration Analyst Hamza AshrafDocument2 pagesISO 18436-2 CAT-III Certified Vibration Analyst Hamza AshrafHamza AshrafNo ratings yet

- Tire explosions from pyrolysisDocument1 pageTire explosions from pyrolysisErere OghomoneNo ratings yet

- EV Design Score Sheet 150pt 2019 002Document8 pagesEV Design Score Sheet 150pt 2019 002Arnob DasNo ratings yet

- Methanol SynthesisDocument6 pagesMethanol SynthesisGaurav BurdeNo ratings yet

- 175 140500Document2 pages175 140500Abu Anas M.SalaheldinNo ratings yet

- Process Pigging SystemDocument22 pagesProcess Pigging SystemAKKI KUMARNo ratings yet

- Exercise - III: (Subjective Problems)Document3 pagesExercise - III: (Subjective Problems)Tejas SalviNo ratings yet

- Photo DiodeDocument3 pagesPhoto DiodeAngga Wijaya KusumaNo ratings yet

- Replacement of Parts - WCS (Water/water)Document48 pagesReplacement of Parts - WCS (Water/water)Klaus BöhmdorferNo ratings yet

- Duplex Stainless Steel 2Document52 pagesDuplex Stainless Steel 2whusada100% (1)

- 03 - Roy Slack - Bore Hole HoistingDocument17 pages03 - Roy Slack - Bore Hole HoistingPabsepulvNo ratings yet

- AGT International Bulk EthyleneDocument10 pagesAGT International Bulk Ethyleneraja duraiNo ratings yet

- Daily Drilling Report 16 Mayo-2013Document2 pagesDaily Drilling Report 16 Mayo-2013Andres RedondoNo ratings yet

- Rate of Reaction 2Document23 pagesRate of Reaction 2brydonsantosNo ratings yet

- Salivary AmylaseDocument43 pagesSalivary Amylasecountdracula9283% (6)

- Danfoss - Compressor Case StudiesDocument5 pagesDanfoss - Compressor Case Studiesgpax42No ratings yet

- BAB 7. Mechanical PropertiesDocument63 pagesBAB 7. Mechanical PropertiesRissaNo ratings yet