Professional Documents

Culture Documents

9D-5 (Temporary Strut) 4

Uploaded by

keaoreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9D-5 (Temporary Strut) 4

Uploaded by

keaoreCopyright:

Available Formats

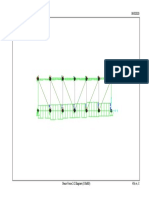

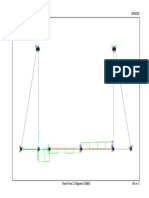

Project: MWA Designed by :

Contract: 9D Checked by :

Section: Temp. Ring beam 2 nd level 9D-5 DATE : 06/1/2022

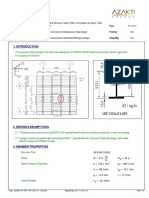

Design Flexural and Axial Member AISC360-10 (LRFD)

Material Properties

member = Temp. Ring beam 2 nd level 9D-5

Steel grade = SM400

yield stress Fy = 235 MPa

tensile stress Fu = 400 MPa

Elastic Modulus ;E = 200000 MPa

selected steel code = 332

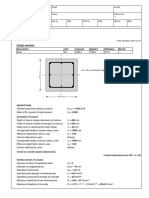

Section Properties

selected section = 1 H 400x400x13x21 L = ANGLE

width = 400 mm LC = LIGHT LIP CHANNEL

depth = 400 mm RT = RECTANGULAR TUBE

thick web = 13 mm ST = SQUARE TUBE

thick flange = 21 mm C = CHANNEL

section area ,A = 21870 mm2 I = I-BEAM

moment of inertia ,Ix = 666,000,000 mm4 H = H-BEAM

moment of inertia ,Iy = 224,000,000 mm5

Elastic section modulus ,Sxb = 3,330,000 mm3

Elastic section modulus ,Sxt = 3,330,000 mm3

Elastic section modulus ,Sy = 1,120,000 mm3

Plastic section modulus ,Zx = 3,600,133 mm3

Plastic section modulus ,Zy = 1,695,126 mm3

radius gyration ,rx = 175 mm

radius gyration ,ry = 101 mm

rts = 112.9 mm

weight ,w = 172 kg/m

Cw = 8.04E+12 mm6

J = 2747154.33 mm4

Length x-x ,Lx = 4620 mm

Length y-y ,Ly = 4620 mm

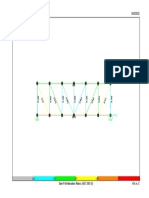

1-Axial strength

1.1 Compression strength

Kx = 1.0 (effective length factor in X-direction)

Ky = 1.0 (effective length factor in y-direction)

λr = 0.56(E/Fy)^0.5 = 16.34 for flanges (Table B4.1a)

λr = 1.49(E/Fy)^0.5 = 43.47 for web (Table B4.1a)

λflanges = 9.52 { Non-slender-section }

λweb = 24.15 { Non-slender-section }

(KL/r)max = 45.74 <= 200 OK

ϕc = 0.9 (E1)

1.1.1 for non-slender section

1.1.1.1 for flexural buckling

Fe = π2E/(KL/r)2 = 943.38 MPa (eq. E3-4)

0.5

(KL/r)max < 4.71*(E/Fy) = 137.40

Fcr = [0.658^(Fy/Fe)]*Fy = 211.73 MPa (eq. E3-2)

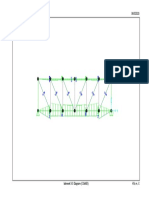

1.1.1.2 for torsional and flexural-torsional buckling

for doubly symmetric members

Fe = [π^2Ecw/(KzL)^2+GJ]*[1/(Ix+Iy)] (eq. E4-4)

= 1073.28 MPa

(KL/r)max > 4.71*(E/Fy)0.5 = 137.40

Fcr = [0.658^(Fy/Fe)]*Fy

= 214.42 MPa (eq. E3-2)

You might also like

- Project: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5Document1 pageProject: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5keaoreNo ratings yet

- Design Flexural and Axial Member: Support Beam SM520Document3 pagesDesign Flexural and Axial Member: Support Beam SM520keaoreNo ratings yet

- AiscDocument13 pagesAiscsteven bianesNo ratings yet

- Slab DesignDocument6 pagesSlab DesignKanchan Raja SinghNo ratings yet

- 009 - Steel Column - Without Top Row FinalDocument4 pages009 - Steel Column - Without Top Row FinalVAIBHAVNo ratings yet

- Calculating steel profile strength and capacityDocument4 pagesCalculating steel profile strength and capacityosman_sultan100% (1)

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Steel Beam Design by KDocument68 pagesSteel Beam Design by KKhandaker Khairul AlamNo ratings yet

- Bottom Chord (B-C)Document2 pagesBottom Chord (B-C)Alex RaiNo ratings yet

- Bottom Chord (A-B)Document2 pagesBottom Chord (A-B)Alex RaiNo ratings yet

- Railing DesignDocument3 pagesRailing Designikanyu79No ratings yet

- Access Stairs (AISC Steel Design-CHS) - 1Document1 pageAccess Stairs (AISC Steel Design-CHS) - 1yolittle shiNo ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- BRP02 Checking PDFDocument4 pagesBRP02 Checking PDFTim T H TingNo ratings yet

- Built Up Column - ChannelDocument18 pagesBuilt Up Column - ChannelSambhav PoddarNo ratings yet

- RPLC DEEP CONVERSION BRACING CONNECTION DESIGNDocument32 pagesRPLC DEEP CONVERSION BRACING CONNECTION DESIGNHeberth SanchezNo ratings yet

- Pier shaft confinement reinforcement optimizationDocument2 pagesPier shaft confinement reinforcement optimizationMayurSoniNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- Baja UTS IrmaDocument69 pagesBaja UTS IrmaArjuna CrewNo ratings yet

- Bajaaisc-SniDocument7 pagesBajaaisc-Sniahmad_prawiraNo ratings yet

- ShortColEC2 - 176 3 Feb 23 - 2Document1 pageShortColEC2 - 176 3 Feb 23 - 2maNo ratings yet

- Design review of arch compression structureDocument3 pagesDesign review of arch compression structurevibishnanNo ratings yet

- c1Document2 pagesc1Erwin MaguideNo ratings yet

- Flange Beam design for first floor beam Grid A, SPAN 6-9Document5 pagesFlange Beam design for first floor beam Grid A, SPAN 6-9James AswaNo ratings yet

- Seafastening Design CalculationsDocument82 pagesSeafastening Design CalculationsInhake AutechreNo ratings yet

- Design column C1 with W12x58 sectionDocument2 pagesDesign column C1 with W12x58 sectionConie CatapanNo ratings yet

- Design of Ss Connection v.2Document68 pagesDesign of Ss Connection v.2markespinoNo ratings yet

- Design steel tubular pile subject to axial & bending loadsDocument5 pagesDesign steel tubular pile subject to axial & bending loadsEdward Albert BañagaNo ratings yet

- 6.3 Design Values of Combined ActionsDocument7 pages6.3 Design Values of Combined Actionsmn4webNo ratings yet

- Design of Column Base PlateDocument12 pagesDesign of Column Base PlateBikal BastakotiNo ratings yet

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaNo ratings yet

- 2-Slab (RoofDeck)Document17 pages2-Slab (RoofDeck)JuNe RaMos JavierNo ratings yet

- Conc Fill CHS To EC4 ExampleDocument2 pagesConc Fill CHS To EC4 ExampleLee CwNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Danh Gia Lien Ket Ban de Chan Cot ThepDocument2 pagesDanh Gia Lien Ket Ban de Chan Cot ThepNguyen Duc CuongNo ratings yet

- GergDocument18 pagesGergOuseppachan AmbookenNo ratings yet

- Design of Steel BeamDocument18 pagesDesign of Steel BeamOuseppachan Ambooken100% (4)

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Larsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PierDocument3 pagesLarsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PiervibishnanNo ratings yet

- Baja 1Document25 pagesBaja 1Ruddy ChoiruddynNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Steel Member DesignDocument41 pagesSteel Member DesignYanfei Jin100% (1)

- Base Plate Design CapacitiesDocument4 pagesBase Plate Design CapacitiesSrishti Project Consultants0% (1)

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Concrete column design parametersDocument3 pagesConcrete column design parametersSuraj de SilvaNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Circular Platform Design AISCDocument32 pagesCircular Platform Design AISCRajveer SinghNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Project Sports Complex Date: V Max ActDocument2 pagesProject Sports Complex Date: V Max ActShanil BussooaNo ratings yet

- Design bending and shear strength of laterally unsupported beamDocument3 pagesDesign bending and shear strength of laterally unsupported beamhema kumarNo ratings yet

- Design steel tubular pile columnDocument5 pagesDesign steel tubular pile columnEdward Albert BañagaNo ratings yet

- Rectangular tank calculation sheet designDocument13 pagesRectangular tank calculation sheet designKamod Rai100% (1)

- Hot-rolled steel beam section properties and classificationDocument19 pagesHot-rolled steel beam section properties and classificationken koemhongNo ratings yet

- B 1Document6 pagesB 1clarkgaguiNo ratings yet

- Bottom Chord (C-D)Document2 pagesBottom Chord (C-D)Alex RaiNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Project: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5Document1 pageProject: MWA Contract: 9D Section: Temp. Ring Beam 1 ST Level 9D-5keaoreNo ratings yet

- 9D-5 (Temporary Strut) 3Document1 page9D-5 (Temporary Strut) 3keaoreNo ratings yet

- 9D-5 (Temporary Strut) 5Document1 page9D-5 (Temporary Strut) 5keaoreNo ratings yet

- 9D-5 (Temporary Strut) 6Document1 page9D-5 (Temporary Strut) 6keaoreNo ratings yet

- 9D-5 (Temporary Strut) 1Document1 page9D-5 (Temporary Strut) 1keaoreNo ratings yet

- 9D-5 (Temporary Strut) 5Document1 page9D-5 (Temporary Strut) 5keaoreNo ratings yet

- GWL Ground Water LevelDocument1 pageGWL Ground Water LevelkeaoreNo ratings yet

- Fig 1. Outline of Working AreaDocument1 pageFig 1. Outline of Working AreakeaoreNo ratings yet

- 9D-5 (Temporary Strut) 5Document1 page9D-5 (Temporary Strut) 5keaoreNo ratings yet

- Organization ChartDocument1 pageOrganization ChartkeaoreNo ratings yet

- RatioDocument1 pageRatiokeaoreNo ratings yet

- BendingDocument1 pageBendingkeaoreNo ratings yet

- SH 01 Layout1Document1 pageSH 01 Layout1keaoreNo ratings yet

- ShearDocument1 pageShearkeaoreNo ratings yet

- 4 Road AlignmentDocument6 pages4 Road Alignmentzpraj09No ratings yet

- Spiral Curves: Iowa Department of Transportation Office of DesignDocument1 pageSpiral Curves: Iowa Department of Transportation Office of DesignkeaoreNo ratings yet

- Shear CROSSDocument1 pageShear CROSSkeaoreNo ratings yet

- Description of CurvesDocument5 pagesDescription of Curvespablo naragNo ratings yet

- Figure 1: Placement of Spiral CurveDocument1 pageFigure 1: Placement of Spiral CurvekeaoreNo ratings yet

- AxialDocument4 pagesAxialkeaoreNo ratings yet

- Formulas: Chapter 2-Alignments SectionDocument1 pageFormulas: Chapter 2-Alignments SectionkeaoreNo ratings yet

- Spiral Curves: Chronology of Changes To Design Manual SectionDocument1 pageSpiral Curves: Chronology of Changes To Design Manual SectionkeaoreNo ratings yet

- Definitions: Section 2A-2 Section 2A-3Document1 pageDefinitions: Section 2A-2 Section 2A-3keaoreNo ratings yet

- M 3Document1 pageM 3keaoreNo ratings yet

- M 5Document1 pageM 5keaoreNo ratings yet

- Spiral Curves On Bridges: Chapter 2-Alignments SectionDocument1 pageSpiral Curves On Bridges: Chapter 2-Alignments SectionkeaoreNo ratings yet

- M 4Document1 pageM 4keaoreNo ratings yet

- M 2Document1 pageM 2keaoreNo ratings yet

- Make A Selection: Choose An Alloy and Correlating Casting ProcessDocument5 pagesMake A Selection: Choose An Alloy and Correlating Casting ProcessSarath ChandraNo ratings yet

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDocument1 page(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNo ratings yet

- RedactedDocument24 pagesRedactedJohn HarrisNo ratings yet

- SilverDocument16 pagesSilversharma_shruti0% (1)

- Mathematical Structures of The UniverseDocument228 pagesMathematical Structures of The UniverseMaki MajomNo ratings yet

- Problem Set 3_Cross-Text ConnectionDocument31 pagesProblem Set 3_Cross-Text Connectiontrinhdat11012010No ratings yet

- Analog Layout Design (Industrial Training)Document10 pagesAnalog Layout Design (Industrial Training)Shivaksh SharmaNo ratings yet

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet

- management of burns readingDocument28 pagesmanagement of burns readinghimanshugupta811997No ratings yet

- 2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFDocument9 pages2011 02 Huijben Spie Why Every Urea Plant Needs A Continuous NC Meter PDFfawadintNo ratings yet

- 3rd Periodic Test in English4Document7 pages3rd Periodic Test in English4Santa Dela Cruz Naluz100% (1)

- LUKAS Product Information-2Document2 pagesLUKAS Product Information-2Flavian ZfmNo ratings yet

- Shadows On The Moon by Zoe Marriott ExtractDocument20 pagesShadows On The Moon by Zoe Marriott ExtractWalker Books100% (1)

- Assignment 12Document7 pagesAssignment 12Anonymous mqIqN5zNo ratings yet

- Surat Kecil Untuk TuhanDocument9 pagesSurat Kecil Untuk TuhanAsgarPurnamaNo ratings yet

- HSB Julian Reyes 4ab 1Document3 pagesHSB Julian Reyes 4ab 1Kéññy RèqüēñåNo ratings yet

- Understanding Revit Architecture - BeginnersDocument56 pagesUnderstanding Revit Architecture - BeginnersBudega100% (95)

- K2N Final Internship ReportDocument55 pagesK2N Final Internship ReportAceZeta0% (1)

- Caelus TT - Caelus Product TrainingDocument93 pagesCaelus TT - Caelus Product TrainingYader Daniel Ortiz CerdaNo ratings yet

- 16 Balance TestDocument15 pages16 Balance Testelga saniNo ratings yet

- ISO 14000 - WikipediaDocument5 pagesISO 14000 - WikipediaalexokorieNo ratings yet

- Subjects Verbs PrepositionsDocument11 pagesSubjects Verbs Prepositionsგუგა ნოსელიძეNo ratings yet

- Theoretical Development of The Brooks-Corey CapillDocument7 pagesTheoretical Development of The Brooks-Corey CapillDiana Vanessa PedrazaNo ratings yet

- Marketing 5 0Document23 pagesMarketing 5 0gmusicestudioNo ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument51 pagesAccepted Manuscript: Process Safety and Environment Protectionimran shaukatNo ratings yet

- 2 1 Flash Klasa 6 Mod 1b Test ExtendedDocument4 pages2 1 Flash Klasa 6 Mod 1b Test ExtendedMonika Ciepłuch-Jarema100% (1)

- CHAPT 12a PDFDocument2 pagesCHAPT 12a PDFindocode100% (1)

- PDM TempDocument2 pagesPDM Tempamit rajputNo ratings yet

- Lightning and Lightning ProtectionDocument5 pagesLightning and Lightning ProtectionrojofreNo ratings yet