Professional Documents

Culture Documents

PT UT Journal Bearing Turbine 1 Ropa #2

Uploaded by

Adjie AzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT UT Journal Bearing Turbine 1 Ropa #2

Uploaded by

Adjie AzaCopyright:

Available Formats

PT PEMBANGKITAN JAWA BALI SERVICE

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Bearing Turbine

Equipment Journal Bearing 1 Mandatory III

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

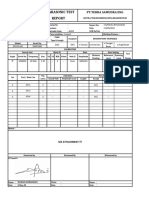

ULTRASONIC TESTING RECORD

Name of Part Journal Shaft Customer PT PLN

Material TIN-CARBON STEEL Quantity 1 Set

Test

Methode test Straight beam Angle Beam

Ultrasonic

instrument EPOCH 1000I Control or Serial No. 170270406

Model No. A109S-RM Dual Probe

Probe

Serial No. 1091346

Couplant Glycerin Machine Oil Grease

Test Piece Test Frequency 5 MHz

Procedure No. Sensitivity

Test Area Babbit Acceptance Std. ISO 4386-3 1992

Place of Test PLTU SUMBAWA BARAT

Time of Test Inspection Date

Rest Result Acceptable

Remark :

Journal bearing 1 Mandatory III tidak ditemukan

adanya indikasi Unbonding

PT.PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbine Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICE

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Bearing Turbine

Equipment Journal Bearing 1 Mandatory II

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

ULTRASONIC TESTING RECORD

Name of Part Journal Shaft Customer PT PLN

Material TIN-CARBON STEEL Quantity 1 Set

Test

Methode test Straight beam Angle Beam

Ultrasonic

instrument EPOCH 1000I Control or Serial No. 170270406

Model No. A109S-RM Dual Probe

Probe

Serial No. 1091346

Couplant Glycerin Machine Oil Grease

Test Piece Test Frequency 5 MHz

Procedure No. Sensitivity

Test Area Babbit Acceptance Std. ISO 4386-3 1992

Place of Test PLTU SUMBAWA BARAT

Time of Test Inspection Date

Rest Result Acceptable

Remark :

Journal bearing 1 Mandatory II tidak ditemukan

adanya indikasi Unbonding

PT.PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbine Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICE

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Bearing Turbine

Equipment Journal Bearing 1 Mandatory I

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

ULTRASONIC TESTING RECORD

Name of Part Journal Shaft Customer PT PLN

Material TIN-CARBON STEEL Quantity 1 Set

Test

Methode test Straight beam Angle Beam

Ultrasonic

instrument EPOCH 1000I Control or Serial No. 170270406

Model No. A109S-RM Dual Probe

Probe

Serial No. 1091346

Couplant Glycerin Machine Oil Grease

Test Piece Test Frequency 5 MHz

Procedure No. Sensitivity

Test Area Babbit Acceptance Std. ISO 4386-3 1992

Place of Test PLTU SUMBAWA BARAT

Time of Test Inspection Date

Rest Result Acceptable

Remark :

Journal bearing 1 Mandatory I tidak ditemukan

adanya indikasi Unbonding

PT.PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbine Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICE

SIAP INTEGRATED MANAGEMENT SYSTEM

JOINT INSPECTION

PLTU ROPA #2 - 2021

Description Bearing Turbine

Equipment Journal Bearing 1

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

ULTRASONIC TESTING RECORD

Name of Part Journal Shaft Customer PT PJB Services

Material TIN-CARBON STEEL Quantity 1 Set

Test

Methode test Straight beam Angle Beam

Ultrasonic

instrument DMS GO UT Control or Serial No. 170270406

Model No. A109S-RM Dual Probe

Probe

Serial No. 1091346

Couplant Glycerin Machine Oil Grease

Test Piece Test Frequency 4 MHz

Procedure No. Sensitivity

Test Area Babbit Acceptance Std. ISO 4386-3 1992

Place of Test PT. JAPA

Time of Test Inspection Date

Rest Result Acceptable

Remark :

Journal bearing 1 tidak ditemukan adanya indikasi

Unbonding

PT. PJB SERVICES

Description

Checked by Inspected by

Signature

Name Adjie Wahyu Sasongko

Position UT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICES

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Journal Bearing

Equipment Journal Bearing 1 Upper Lower Eksisitng

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

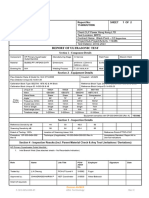

VISIBLE DYE PENETRANT TESTING RECORD

Name of Part Journal Bearing Customer PT. PLN

Material TIN-CARBON STEEL Quantity 1 Set

Thermometer Control /

Product Family Surface Temp. Serial No.

Maker MAGNAFLUX Lot No.

Penetrant SKL-SPL1 OTHER ( ) Penetrant Time 15 - 20 Min

Remover SKC-5 THINNER Developing Time 15 - 20 Min

Developer SKD-S2 OTHER ( )

Penetrant Application Methode Aerosol Cans Brushing Dipping

Developer Application Methode Aerosol Cans

Test Area Babbit Procedure No. ASME SEC V art. 6, 2017

Place of Test PLTU SUMBAWA BARAT Acceptance Std. ASME SEC VIII Div. 1 Apx 8 2017

Time of Test Inspection Date

Test Result Accepted

Remark :

Journal bearing 1 Eksisting upper Lower

tidak ditemukan indikasi crack

RECOMMENDATION ACCEPTED / REWORK / REPLACE

(by Quality Control)

PT. PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbin Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICES

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Journal Bearing

Equipment Journal Bearing 1 Upper Lower Mandatory I

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

VISIBLE DYE PENETRANT TESTING RECORD

Name of Part Journal Bearing Customer PT. PLN

Material TIN-CARBON STEEL Quantity 1 Set

Thermometer Control /

Product Family Surface Temp. Serial No.

Maker MAGNAFLUX Lot No.

Penetrant SKL-SPL1 OTHER ( ) Penetrant Time 15 - 20 Min

Remover SKC-5 THINNER Developing Time 15 - 20 Min

Developer SKD-S2 OTHER ( )

Penetrant Application Methode Aerosol Cans Brushing Dipping

Developer Application Methode Aerosol Cans

Test Area Babbit Procedure No. ASME SEC V art. 6, 2017

Place of Test PLTU SUMBAWA BARAT Acceptance Std. ASME SEC VIII Div. 1 Apx 8 2017

Time of Test Inspection Date

Test Result Accepted

Remark :

Journal bearing 1 Mandatory I upper

Lower tidak ditemukan indikasi crack

RECOMMENDATION ACCEPTED / REWORK / REPLACE

(by Quality Control)

PT. PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbin Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICES

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Journal Bearing

Equipment Journal Bearing 1 Upper Lower Mandatory II

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

VISIBLE DYE PENETRANT TESTING RECORD

Name of Part Journal Bearing Customer PT. PLN

Material TIN-CARBON STEEL Quantity 1 Set

Thermometer Control /

Product Family Surface Temp. Serial No.

Maker MAGNAFLUX Lot No.

Penetrant SKL-SPL1 OTHER ( ) Penetrant Time 15 - 20 Min

Remover SKC-5 THINNER Developing Time 15 - 20 Min

Developer SKD-S2 OTHER ( )

Penetrant Application Methode Aerosol Cans Brushing Dipping

Developer Application Methode Aerosol Cans

Test Area Babbit Procedure No. ASME SEC V art. 6, 2017

Place of Test PLTU SUMBAWA BARAT Acceptance Std. ASME SEC VIII Div. 1 Apx 8 2017

Time of Test Inspection Date

Test Result Accepted

Remark :

Journal bearing 1 Mandatory II upper

Lower tidak ditemukan indikasi crack

RECOMMENDATION ACCEPTED / REWORK / REPLACE

(by Quality Control)

PT. PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbin Area NDT Level II

Approval Date

PT PEMBANGKITAN JAWA BALI SERVICES

SIAP INTEGRATED MANAGEMENT SYSTEM

JOINT INSPECTION

PLTU ROPA #2 - 2021

Description Journal Bearing

Equipment Journal Bearing 1

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

VISIBLE DYE PENETRANT TESTING RECORD

Name of Part Journal Bearing Customer PT. PJB Services

Material TIN-CARBON STEEL Quantity 1 Set

Thermometer Control /

Product Family Surface Temp. Serial No.

Maker MAGNAFLUX Lot No.

Penetrant SKL-SPL1 OTHER ( ) Penetrant Time 15 - 20 Min

Remover SKC-5 THINNER Developing Time 15 - 20 Min

Developer SKD-S2 OTHER ( )

Penetrant Application Methode Aerosol Cans Brushing Dipping

Developer Application Methode Aerosol Cans

Test Area Babbit Procedure No. ASME SEC V art. 6, 2017

Place of Test PT.JAPA Acceptance Std. ASME SEC VIII Div. 1 Apx 8 2017

Time of Test Inspection Date

Test Result Accepted

Remark :

Journal bearing 1 upper Lower tidak

ditemukan indikasi crack

RECOMMENDATION ACCEPTED / REWORK / REPLACE

(by Quality Control)

PT. PJB SERVICES

Description

Checked by Inspected by

Signature

Name Adjie Wahyu Sasongko

Position NDT Level II

Approval Date

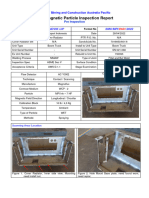

PT PEMBANGKITAN JAWA BALI SERVICES

SIAP INTEGRATED MANAGEMENT SYSTEM

FIRST YEAR INSPECTION UNIT 2

UIW NUSA TENGGARA BARAT

PLTU SUMBAWA - 2021

Description Journal Bearing

Equipment Journal Bearing 1 Lower

TEST SHEET Document Number

Issued

Task No. : Revision : Section : NDT

WO No. : Page : Date :

VISIBLE DYE PENETRANT TESTING RECORD

Name of Part Journal Bearing Customer PT. PLN

Material TIN-CARBON STEEL Quantity 1 Set

Thermometer Control /

Product Family Surface Temp. Serial No.

Maker MAGNAFLUX Lot No.

Penetrant SKL-SPL1 OTHER ( ) Penetrant Time 15 - 20 Min

Remover SKC-5 THINNER Developing Time 15 - 20 Min

Developer SKD-S2 OTHER ( )

Penetrant Application Methode Aerosol Cans Brushing Dipping

Developer Application Methode Aerosol Cans

Test Area Babbit Procedure No. ASME SEC V art. 6, 2017

Place of Test PLTU SUMBAWA BARAT Acceptance Std. ASME SEC VIII Div. 1 Apx 8 2017

Time of Test Inspection Date

Test Result Accepted

Remark :

Journal bearing 1 lower tidak ditemukan

indikasi crack

RECOMMENDATION ACCEPTED / REWORK / REPLACE

(by Quality Control)

PT. PLN PT. PJB SERVICES

Description

Reviewed & Approved by Checked by Inspected by

Signature

Name Gede Prasetyo Adjie Wahyu Sasongko

Position QC Turbin Area NDT Level II

Approval Date

You might also like

- Scheme of Work: Cambridge IGCSE™ / Cambridge IGCSE (9-1) Chemistry 0620 /0971Document97 pagesScheme of Work: Cambridge IGCSE™ / Cambridge IGCSE (9-1) Chemistry 0620 /0971Ala'100% (3)

- ITP Electrical Rev. GenDocument8 pagesITP Electrical Rev. GenAgiesta PradiosNo ratings yet

- Test Sheet: PT Pembangkitan Jawa Bali Services Siap Integrated Management SystemDocument4 pagesTest Sheet: PT Pembangkitan Jawa Bali Services Siap Integrated Management SystemAdjie AzaNo ratings yet

- PT PLN Nusantara Power Integrated Management System Form Uji Visual InspectionDocument4 pagesPT PLN Nusantara Power Integrated Management System Form Uji Visual InspectionDidit Gencar LaksanaNo ratings yet

- Int Aim 231787 PT 14 1302&03Document1 pageInt Aim 231787 PT 14 1302&03Joshua ClaytonNo ratings yet

- VT - S13 Dan Screen TubeDocument9 pagesVT - S13 Dan Screen TubeDidit Gencar LaksanaNo ratings yet

- 2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338Document1 page2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338wahyuNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Ut & Mpi ProcedureDocument23 pagesUt & Mpi ProcedurePRASHANT100% (2)

- PT - ReportDocument3 pagesPT - ReportNaveen KumarNo ratings yet

- Turbine Generator PDocument26 pagesTurbine Generator PSandal Jepit100% (1)

- F-10 DPTDocument2 pagesF-10 DPTHimanshu SinghNo ratings yet

- Mpi D212Document1 pageMpi D212K.s. Raghavendra KumarNo ratings yet

- Int-Aim-231887 PT 06-15-23Document2 pagesInt-Aim-231887 PT 06-15-23Joshua ClaytonNo ratings yet

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- Modul GE F35 MultilinDocument8 pagesModul GE F35 MultilinMr IlchamNo ratings yet

- UT PLTU BTG Turbine 1-DikonversiDocument2 pagesUT PLTU BTG Turbine 1-DikonversiWawan KurniawanNo ratings yet

- Ultrasonic Laminations Test Report BatamDocument2 pagesUltrasonic Laminations Test Report Batamvinsensius rasaNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- REPORTDocument65 pagesREPORTAnoop VermaNo ratings yet

- RT ProcedureDocument12 pagesRT ProcedurePRASHANTNo ratings yet

- Hasil Pengujian Metalografi Dan Hardness: Assessment Boiler Pltu Jeranjang Unit 3 2022Document6 pagesHasil Pengujian Metalografi Dan Hardness: Assessment Boiler Pltu Jeranjang Unit 3 2022mochbimNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Pacific Twelve - LPT - Propeller ShaftDocument8 pagesPacific Twelve - LPT - Propeller ShaftDolok Joko KenconoNo ratings yet

- LG (67) - G3-1009-Fan (Turbo) G v.2Document9 pagesLG (67) - G3-1009-Fan (Turbo) G v.2Anonymous Lta32Ta9No ratings yet

- MRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintDocument3 pagesMRR NO.021 Jetec PO 962922446 PT. Multitek Electrical Pressure Switch PrintSuhendrik Abi NayaNo ratings yet

- Circulating Water Pump System ADocument6 pagesCirculating Water Pump System AMusachatib UmarNo ratings yet

- FO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentDocument1 pageFO-InD-HAL-PR-001 - Inspection Work Order Form - RevG - 2019!11!01 - PHE Oses Frac EquipmentRico100% (1)

- WO 2707 - PO 4504247285 - Change Out Fastline Sheave - NDT Inspection - PGCDocument22 pagesWO 2707 - PO 4504247285 - Change Out Fastline Sheave - NDT Inspection - PGCMatheus Fabrício TeixeiraNo ratings yet

- Tis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Document10 pagesTis-Gti-Aosi-Epf-Itp-001 Inspection Test Plan (Itp)Raka PriaNo ratings yet

- Rfi-1274 - FF Non Critical-Hc-Tpsk FormDocument2 pagesRfi-1274 - FF Non Critical-Hc-Tpsk FormLong Nhật PhanNo ratings yet

- QCS EP UTT 01 Rev02 GeneralDocument8 pagesQCS EP UTT 01 Rev02 Generalm_armoutiNo ratings yet

- SATRDocument1 pageSATRAhmed BoraeyNo ratings yet

- Pacific Twelve - LPT - Propeller BladeDocument8 pagesPacific Twelve - LPT - Propeller BladeDolok Joko KenconoNo ratings yet

- WO2652 - PO - 4504214604 - Drill Stop PGA (Archer) .Document119 pagesWO2652 - PO - 4504214604 - Drill Stop PGA (Archer) .Matheus Fabrício TeixeiraNo ratings yet

- DPT Report MBBR U-BDocument15 pagesDPT Report MBBR U-BMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- NDT Test Report NTP PDFDocument6 pagesNDT Test Report NTP PDFwawan kusnandar100% (1)

- MT - Area Wall Reheat - Paiton 9 - Rev3Document3 pagesMT - Area Wall Reheat - Paiton 9 - Rev3Lexo SitompulNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Ut Test ReportDocument1 pageUt Test ReportManish KumarNo ratings yet

- 114486-UT-006 HP Primary Superheater Outlet ManifoldDocument2 pages114486-UT-006 HP Primary Superheater Outlet ManifoldDave CheungNo ratings yet

- EQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Document6 pagesEQUIPMENT: Tube Bundle For Shell &tube HX Titile: Inspection Test Plan Item: 6112-E-02Khalilahmad KhatriNo ratings yet

- RED-NDT-MT-00001 Rev ADocument11 pagesRED-NDT-MT-00001 Rev ATadaya KasaharaNo ratings yet

- Work Order: VN 23515383 6 - MiscellaneousDocument2 pagesWork Order: VN 23515383 6 - MiscellaneoushungphanNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraNo ratings yet

- PT Pembangkitan Jawa Bali Services Siap Integrated Management System Boiler Inspection Unit 1 Pltu Banjarsari 2021 Inspection SheetDocument4 pagesPT Pembangkitan Jawa Bali Services Siap Integrated Management System Boiler Inspection Unit 1 Pltu Banjarsari 2021 Inspection SheetMusachatib UmarNo ratings yet

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- Modul GE G60 MultilinDocument27 pagesModul GE G60 MultilinMr IlchamNo ratings yet

- Hydrogen Seal Ring (AS GS)Document6 pagesHydrogen Seal Ring (AS GS)Dave CheungNo ratings yet

- U3PO2019 - Inspection Sheet - Mech - ElectDocument16 pagesU3PO2019 - Inspection Sheet - Mech - Electachmad khumaidiNo ratings yet

- Inspection and Test Plan: Technip France Abu Dhabi ASME B31.3 Ed 2008 Abbreviations UsedDocument4 pagesInspection and Test Plan: Technip France Abu Dhabi ASME B31.3 Ed 2008 Abbreviations UsedattaullaNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul RajNo ratings yet

- 4.1i Inspection &test PlanDocument8 pages4.1i Inspection &test PlanISAACNo ratings yet

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pages109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Komparasi IRIS M Motion AmplificationDocument4 pagesKomparasi IRIS M Motion AmplificationAdjie AzaNo ratings yet

- Siui Smartor UTDocument6 pagesSiui Smartor UTJohn Choquemaque Mendoza100% (2)

- Brocure Sonodur 3Document8 pagesBrocure Sonodur 3Novianto RachmadNo ratings yet

- Data Operasi Data Manual Book: Temperature ASME b31.1Document16 pagesData Operasi Data Manual Book: Temperature ASME b31.1Adjie AzaNo ratings yet

- Article - Non-Basal Slip Systems in HCP Metals and Alloys SourcemechanismsDocument6 pagesArticle - Non-Basal Slip Systems in HCP Metals and Alloys SourcemechanismsAmilton CardosoNo ratings yet

- H BR H H 1 2 1 2 (A, E) Cis-1,2-Dibromocyclohexane BR H H BR H BR 1 2 1 2 (A, A) Trans-1,2-Dibromocyclohexane BR BR BR HDocument19 pagesH BR H H 1 2 1 2 (A, E) Cis-1,2-Dibromocyclohexane BR H H BR H BR 1 2 1 2 (A, A) Trans-1,2-Dibromocyclohexane BR BR BR HVIGHNESH BALKRISHNA LOKARENo ratings yet

- PKLPPC300N Operating ManualDocument231 pagesPKLPPC300N Operating ManualLonCin123No ratings yet

- Unit 3&4 Exercises Biochemistry 17.11.20Document36 pagesUnit 3&4 Exercises Biochemistry 17.11.20Nguyen Bao TranNo ratings yet

- Antiprotozoarios 2013Document10 pagesAntiprotozoarios 2013angelaparasitoNo ratings yet

- Astm b858 1995Document6 pagesAstm b858 1995rensieoviNo ratings yet

- How To Formulate UV PDFDocument16 pagesHow To Formulate UV PDFMOHAMEDNo ratings yet

- Chapter 2 Alloys - 2012 - Applied Welding EngineeringDocument5 pagesChapter 2 Alloys - 2012 - Applied Welding EngineeringJames LeonNo ratings yet

- 5.36 Biochemistry Laboratory: Mit OpencoursewareDocument11 pages5.36 Biochemistry Laboratory: Mit OpencoursewareNeenu RajputNo ratings yet

- Carbohydrates (Class 4)Document19 pagesCarbohydrates (Class 4)Swetank SahaiNo ratings yet

- Data Produk & Vendor E-Catalog LKPP - KursiDocument55 pagesData Produk & Vendor E-Catalog LKPP - KursiAndi Ramdan HamdaniNo ratings yet

- Water ProofingDocument2 pagesWater Proofingraghuram prasad100% (2)

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22Tilawat KhanNo ratings yet

- Chem I (EM) BLM 2021-22Document66 pagesChem I (EM) BLM 2021-22Tanzeela Hashmi75% (8)

- ARQ - Chemical KineticsDocument5 pagesARQ - Chemical Kineticskabir singhNo ratings yet

- 2009 a تأثير ملوحة ماء الري الممغنط في صفات النمو الخضري لنبات الجربيراDocument12 pages2009 a تأثير ملوحة ماء الري الممغنط في صفات النمو الخضري لنبات الجربيراMUHAMMED ALSUVAİDNo ratings yet

- ASTM D5386 Standard Test Method For Color of Liquids Using Tristimulus ColorimetryDocument3 pagesASTM D5386 Standard Test Method For Color of Liquids Using Tristimulus Colorimetryk.v.bogacheNo ratings yet

- Presentation 1Document20 pagesPresentation 1Muhammad UmarNo ratings yet

- Determination of Tolterodine Tartrate in Bulk and Formulation by Extractive Colorimetric Method Using Tropaeolin OOO-1Document7 pagesDetermination of Tolterodine Tartrate in Bulk and Formulation by Extractive Colorimetric Method Using Tropaeolin OOO-1sadafNo ratings yet

- WT ch1Document20 pagesWT ch1አድሜ ልስልሱNo ratings yet

- Acquaintance With Different Equipments Used in Fish Processing LaboratoryDocument2 pagesAcquaintance With Different Equipments Used in Fish Processing LaboratoryBadrul HassanNo ratings yet

- Basic Principles and Practice of Clinical Chemistry Part 1Document34 pagesBasic Principles and Practice of Clinical Chemistry Part 1Mohamed MidoNo ratings yet

- Performance and Emissions Characteristics of C.I. Engine Fueled With Palm Oil/palm Oil Methyl Ester Blended With Diesel FuelDocument6 pagesPerformance and Emissions Characteristics of C.I. Engine Fueled With Palm Oil/palm Oil Methyl Ester Blended With Diesel Fuelmohamed aliNo ratings yet

- C 05 SupplementDocument13 pagesC 05 SupplementVivekananda NandamNo ratings yet

- Determining Integrity of Seals For Medical Packaging by Visual InspectionDocument4 pagesDetermining Integrity of Seals For Medical Packaging by Visual Inspectionรอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- Voltatex t050 Cleaning Agent - DatasheetDocument2 pagesVoltatex t050 Cleaning Agent - DatasheetAlexandru CanturNo ratings yet

- Panelex DataDocument1 pagePanelex DataTimothy GordonNo ratings yet

- Solve Solids Handling Problems by Retrofitting: Also: San Luis Obispo, CA - Toronto, Canada - Viña Del Mar, ChileDocument20 pagesSolve Solids Handling Problems by Retrofitting: Also: San Luis Obispo, CA - Toronto, Canada - Viña Del Mar, ChilefvassisNo ratings yet

- R.O Chemical Cleaning ProcedureDocument4 pagesR.O Chemical Cleaning ProcedureAbu Bakar Hamada100% (2)