Professional Documents

Culture Documents

Fabric Aesthetics Evaluation

Fabric Aesthetics Evaluation

Uploaded by

Popper JohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabric Aesthetics Evaluation

Fabric Aesthetics Evaluation

Uploaded by

Popper JohnCopyright:

Available Formats

Fabric Aesthetics Evaluation

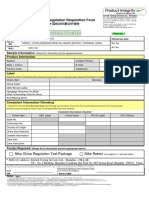

Authorized By: Scott Crump

Sr. Director Global Apparel &

FAS05506R2.4 Fabric

Equipment Product Integrity

Aesthetics Evaluation Approved By: Lois Wang

Effective Date: OCT 2011 Revision # 2.4 Revision Date: DD-MAR-2013 Owner: Vicky Yang

Fabric Aesthetics Evaluation

The purpose of this document is to provide additional details related to the Nike Fabric

Aesthetics Test Method.

Background

This test method was developed to support the following scenarios:

• to provide a common method that allows different people at different times to evaluate

certain fabric aesthetic properties such as texture, stretch, and recovery;

• to assist in training of evaluators to detect and distinguish differences in certain fabric

aesthetic properties;

• to provide a more consistent and objective method for monitoring bulk fabric

production.

To develop the method, a Nike Standards Committee conducted the following activities:

• Developed a draft test method based largely on AATCC Evaluation Procedure 5 “Fabric

Hand: Guidelines for the Subjective Evaluation of” and conducted a series of

experiments to determine the repeatability and reliability of each evaluation technique;

• Following the initial experiments, the methods were adjusted and documented by

recording a series of video tutorials compiled in the Nike Fabric Aesthetics Test Method;

• A pilot was conducted at several Nike vendors to evaluate the method in a production

environment and based on the feedback from the pilot vendors, additional adjustments

to the method were made.

2 CONTROLLED DOCUMENT FINAL_FAS05506R2.4 Fabric Aesthetics Evaluation_VYang_DDMAR2013

Nike Confidential

Authorized By: Scott Crump

Sr. Director Global Apparel &

FAS05506R2.4 Fabric

Equipment Product Integrity

Aesthetics Evaluation Approved By: Lois Wang

Effective Date: OCT 2011 Revision # 2.4 Revision Date: DD-MAR-2013 Owner: Vicky Yang

Test Method Details

1. Swatch Size & Evaluation Location

a. The recommended swatch size is 30cm x 30cm (12” x 12”)

b. Swatches should be taken at least 15cm (6”) away from the selvage

c. The central portion of the swatch should be used for evaluation purposes as

shown below:

Central portion of swatch circled in red

30cm

30cm

2. Surface Appearance: Texture and Sheen

Placing the sample swatch and approved standard on a flat surface and conducting the

evaluation in a light box can improve the consistency of the evaluation. NOTE: this is an

optional improvement to the method and can be implemented at the vendor’s

discretion or used only when a more thorough evaluation is required.

Photos: Courtesy of Y.R.C. Textile Co. Ltd (Thailand)

3 CONTROLLED DOCUMENT FINAL_FAS05506R2.4 Fabric Aesthetics Evaluation_VYang_DDMAR2013

Nike Confidential

Authorized By: Scott Crump

Sr. Director Global Apparel &

FAS05506R2.4 Fabric

Equipment Product Integrity

Aesthetics Evaluation Approved By: Lois Wang

Effective Date: OCT 2011 Revision # 2.4 Revision Date: DD-MAR-2013 Owner: Vicky Yang

3. Opacity

Use of a “light table” can improve the ability of the evaluator to compare the opacity of

the sample swatch to the approved standard. Opacity can vary with colour so only major

differences should be noted and only if they affect the fabric hand or performance

properties (e.g.: moisture management) of the fabric. NOTE: this is an optional

improvement to the method and can be implemented at the vendor’s discretion or used

only when a more thorough evaluation is required.

Evaluating opacity using a light table

Photos: Courtesy of Y.R.C. Textile Co. Ltd (Thailand)

4. Drape

The test method for drape is intended to compare the stiffness/limpness of a fabric. The

manual method indicated by Nike is simple to conduct but has limitations with

repeatability. Similar to surface appearance and opacity, more advanced techniques can

be employed if there are difficulties in assessing this property. One example is to use the

fabric properties measured via a 3D modeling tool such as V-Stitcher.

Photos: Courtesy of Y.R.C. Textile Co. Ltd (Thailand)

4 CONTROLLED DOCUMENT FINAL_FAS05506R2.4 Fabric Aesthetics Evaluation_VYang_DDMAR2013

Nike Confidential

Authorized By: Scott Crump

Sr. Director Global Apparel &

FAS05506R2.4 Fabric

Equipment Product Integrity

Aesthetics Evaluation Approved By: Lois Wang

Effective Date: OCT 2011 Revision # 2.4 Revision Date: DD-MAR-2013 Owner: Vicky Yang

5. Stretch and Recovery

Similar to drape, this method is designed to be simple and easy to implement without

the use of advanced equipment such as a tensile tester. The main objective is to

compare the sample swatch to the approved standard and to note any differences. For

example, more or less force may be required to stretch the sample to a similar distance

as compared to the approved standard. We are also interested in how quickly the fabric

returns to a relaxed state noting any noticeable difference between the two swatches.

6. Continuity Cards

The concept of continuity cards is to provide a convenient method for reviewing the lot

to lot consistency of a process by storing physical samples of each lot in an organized

manner. Similar to continuity cards used to monitor colour consistency, this process can

also be applied to monitor the lot to lot variation in fabric aesthetics. It is recommended

that continuity cards for fabric aesthetics be kept for the current and previous season to

assist with maintaining consistency from one season to another.

7. Maintaining a technical roll / Approved sample yardage

The primary purpose of this requirement is to ensure that an approved sample always be

available to conduct the fabric aesthetics evaluation. This can be achieved by maintaining

a “technical roll’ of fabric (e.g.: 25-75 yards) so that cuttings can be taken from the

technical roll when a new approved standard is needed. Sample yardage can also be

taken from bulk production provided that the yardage match all of the fabric aesthetic

properties to the current approved standard. It is up to the vendor’s discretion to

determine a logical process to maintain sufficient yardage of an approved standard.

8. Approved sample replacement

After repeated use during fabric aesthetic evaluations, the approved sample swatch will

become worn and will need replacement. Sample fatigue will vary from fabric to fabric

and it is up to the vendor to determine when to replace the approved sample with a new

swatch prior to the sample becoming worn.

5 CONTROLLED DOCUMENT FINAL_FAS05506R2.4 Fabric Aesthetics Evaluation_VYang_DDMAR2013

Nike Confidential

Authorized By: Scott Crump

Sr. Director Global Apparel &

FAS05506R2.4 Fabric

Equipment Product Integrity

Aesthetics Evaluation Approved By: Lois Wang

Effective Date: OCT 2011 Revision # 2.4 Revision Date: DD-MAR-2013 Owner: Vicky Yang

Revision History

Revision Date Revision# Description of changes Revised by Approved by

12-JUN-2015 R2.0 Revision history detail is unavailable. Annette Shabat Shelly Silvana Reagan

12-JUN-2015 R2.1 Updated headers and footers + added revision Annette Shabat Shelly Silvana Reagan

history

12-JUN-2015 R2.2 Revised document ID # Annette Shabat Shelly Joey Osborne Robinson

From: FA05506R2.1 To: FAS05506R2.2 Silvana Reagan

Revised “Approved By”

From: Carol Quimby

To: Tom Young

28-NOV-2016 R2.3 Renamed titled Annette Shabat Shelly Vicky Yang

From: Jamie Ueda

Fabric Aesthetics Test Method Details Silvana Reagan

To: Fabric Aesthetics Evaluation

Updated document owner to Jaime Ueda and

Vicky Yang

Added title page

Updated logo

28-JUL-2017 R2.4 Removed Jamie Ueda as a document owner Annette Shabat Shelly Silvana Reagan

Vicky Yang

6 CONTROLLED DOCUMENT FINAL_FAS05506R2.4 Fabric Aesthetics Evaluation_VYang_DDMAR2013

Nike Confidential

You might also like

- Injection Moulding Lab ReportDocument27 pagesInjection Moulding Lab ReportErnie Yana IINo ratings yet

- Belt Conveyors: Learner GuideDocument62 pagesBelt Conveyors: Learner GuideRobson DE Freitas WerlingNo ratings yet

- Azantee Yazmie Abdul Wahab Dept. of Obstetrics & Gynaecology Kulliyyah of Medicine IIUM KuantanDocument51 pagesAzantee Yazmie Abdul Wahab Dept. of Obstetrics & Gynaecology Kulliyyah of Medicine IIUM KuantanNur ShafilaNo ratings yet

- A Marketing Plan of Jack Fruites JuiceDocument25 pagesA Marketing Plan of Jack Fruites JuiceNazrul Islam100% (3)

- System Verification: Proving the Design Solution Satisfies the RequirementsFrom EverandSystem Verification: Proving the Design Solution Satisfies the RequirementsRating: 1 out of 5 stars1/5 (2)

- BROUWER: Guitar Music, Vol. 2 - Decameron Negro (El) : Preludios EpigramaticosDocument2 pagesBROUWER: Guitar Music, Vol. 2 - Decameron Negro (El) : Preludios EpigramaticosSteven ThachukNo ratings yet

- Sop For Destruction of Sample After Analysis.Document5 pagesSop For Destruction of Sample After Analysis.vasant ugaleNo ratings yet

- D 3740 - 04 Minimum Requirements For AgenciesDocument7 pagesD 3740 - 04 Minimum Requirements For AgenciesEdvin Neil Huamanguillas ParavecinoNo ratings yet

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Group Members - : Utkarsh Sharma Rahul Chauhan Sony Raghvendram Saumya Katiyar Shreya MahaurDocument31 pagesGroup Members - : Utkarsh Sharma Rahul Chauhan Sony Raghvendram Saumya Katiyar Shreya MahaurSNEHA SHARMANo ratings yet

- 1790 Visual Inspection of InjectionsDocument20 pages1790 Visual Inspection of InjectionsAbdelkarim Belkebir100% (2)

- Geo CreteDocument80 pagesGeo CreteRichard OonNo ratings yet

- Examen Extraordinario de Ingles IiDocument7 pagesExamen Extraordinario de Ingles Iimorto009No ratings yet

- 2018 AATCC Laundering MethodsDocument48 pages2018 AATCC Laundering MethodsWarlie Suwarlie67% (3)

- BS en 12385-1-2002+a1 - 2009Document24 pagesBS en 12385-1-2002+a1 - 2009Qiu RitaNo ratings yet

- 15 Andrulonis Advanced Fiber Reinforced PolymerDocument31 pages15 Andrulonis Advanced Fiber Reinforced PolymersengozkNo ratings yet

- Final Assignment: Textile Testing & Quality Control-IIDocument11 pagesFinal Assignment: Textile Testing & Quality Control-IINoman ahmedNo ratings yet

- Test Plan V1Document14 pagesTest Plan V1Trupti zureNo ratings yet

- Trinseo - Papercon 2022 - Barrier Coating TestDocument20 pagesTrinseo - Papercon 2022 - Barrier Coating TestD.B. CooperNo ratings yet

- Attachment 0Document10 pagesAttachment 0Nasaii AhmadNo ratings yet

- Control of Materials Properties IIDocument11 pagesControl of Materials Properties IIK HNo ratings yet

- Student Assessment Record - Phase IIIDocument9 pagesStudent Assessment Record - Phase IIIS U R Y A S U R Y ANo ratings yet

- Functional Testing Plan: For Accenture PhilippinesDocument19 pagesFunctional Testing Plan: For Accenture PhilippinesLight YagamiNo ratings yet

- Notepad TestplanDocument11 pagesNotepad TestplanPratiksha Jadhav50% (2)

- 08 News 280605 A New Approach To TestingDocument12 pages08 News 280605 A New Approach To TestingKashif ZulfiqarNo ratings yet

- Web Based Quality Assessment of Customer Reviews Using Quartile MeasureDocument7 pagesWeb Based Quality Assessment of Customer Reviews Using Quartile MeasuremmmmNo ratings yet

- Cmats Experiment 7Document4 pagesCmats Experiment 7Jenevive TumacderNo ratings yet

- Optimising The Manufacture in Composites Materials of A Box Shaped Geometry Through Ergonomics and Human Factor AssessmentsDocument3 pagesOptimising The Manufacture in Composites Materials of A Box Shaped Geometry Through Ergonomics and Human Factor AssessmentsEric AinslieNo ratings yet

- Lecture 1 Introduction To Textile TestingDocument10 pagesLecture 1 Introduction To Textile TestingRaji AbdulwasiuNo ratings yet

- Experiment 7 - Concrete Mix DesignDocument3 pagesExperiment 7 - Concrete Mix DesignhazelmariedmNo ratings yet

- Project Name: "New Arrivals": FNA Test PlanDocument6 pagesProject Name: "New Arrivals": FNA Test PlanNusrat HasanNo ratings yet

- Qualitycontrol 140803081747 Phpapp01Document72 pagesQualitycontrol 140803081747 Phpapp01ShivamNo ratings yet

- Experiment No. VI Los Angeles Abrasion Test 1. Objective(s)Document6 pagesExperiment No. VI Los Angeles Abrasion Test 1. Objective(s)Jar stormiNo ratings yet

- TCC NonwovensDocument21 pagesTCC Nonwovensjothi vel muruganNo ratings yet

- Technical and Business WritingDocument3 pagesTechnical and Business Writingashfaq ahmadNo ratings yet

- Vastram ExportsDocument40 pagesVastram ExportsHarsha DuraiNo ratings yet

- Ce401 Laboratory Experiment No. 1Document8 pagesCe401 Laboratory Experiment No. 1Angeline SisonNo ratings yet

- FhhingDocument4 pagesFhhingMohamed SelimNo ratings yet

- AATCC-American Association of Textile Chemists and ColoristsDocument4 pagesAATCC-American Association of Textile Chemists and ColoristsRidhima TripathiNo ratings yet

- Ste SwaDocument14 pagesSte Swakamblepiyush426No ratings yet

- StepUsersGuide 09Document51 pagesStepUsersGuide 09Yixuan ZhongNo ratings yet

- Laboratory Activity 3.1 Sieve Analysis of Fine and Coarse AggregatesDocument5 pagesLaboratory Activity 3.1 Sieve Analysis of Fine and Coarse AggregatesJennifer AdvientoNo ratings yet

- Software Testing Outline Performances and MeasurementsDocument2 pagesSoftware Testing Outline Performances and MeasurementsEditor IJTSRDNo ratings yet

- Final AssignmentDocument19 pagesFinal Assignmentshahid rizwanNo ratings yet

- Module 1: Control of Material PropertiesDocument9 pagesModule 1: Control of Material PropertiesLiz Gaviola PescoNo ratings yet

- Jobdesc Quality AssuranceDocument3 pagesJobdesc Quality Assuranceaden duniatexNo ratings yet

- Course Presentation Group 5Document7 pagesCourse Presentation Group 5byansi edrineNo ratings yet

- Format For Group Work No. 3-ToTALQMDocument1 pageFormat For Group Work No. 3-ToTALQMHolly AlexanderNo ratings yet

- Module 1Document9 pagesModule 1mylappiee2023No ratings yet

- Apply Quality StandardsDocument18 pagesApply Quality StandardsCamelle DichosoNo ratings yet

- Experiment 2 Sieve AnalysisDocument7 pagesExperiment 2 Sieve AnalysisBambi San GabrielNo ratings yet

- S A I P C A N S: Participant Module PEW-105.04Document143 pagesS A I P C A N S: Participant Module PEW-105.04shakeelahmadjsrNo ratings yet

- Jayashree TextileDocument29 pagesJayashree TextilePayal ParidaNo ratings yet

- 5SAMPLING - Printed VersionDocument12 pages5SAMPLING - Printed Version6f67crt5cpNo ratings yet

- FYP Test PlanDocument5 pagesFYP Test PlanMuhammad AbdullahNo ratings yet

- 4.0 Static Testing 4.1 OverviewDocument14 pages4.0 Static Testing 4.1 OverviewnithiananthiNo ratings yet

- Review On Software TestingDocument20 pagesReview On Software Testingmarilou ranoyNo ratings yet

- CAG-014 Final 04012022 SignedDocument19 pagesCAG-014 Final 04012022 SignedAzeddine LANo ratings yet

- Common 4.2 1Document7 pagesCommon 4.2 1Meiyuketachi banaNo ratings yet

- Machine Health Evaluation SheetDocument4 pagesMachine Health Evaluation SheetVarun MehrotraNo ratings yet

- CV AshrafDocument4 pagesCV AshrafAshraf Ali75% (8)

- Learning OutcomeDocument32 pagesLearning OutcomeAbhinav KumarNo ratings yet

- PAPER Employee Performance Appraisal at Sri Veerabhadreshwar Motors BidarDocument13 pagesPAPER Employee Performance Appraisal at Sri Veerabhadreshwar Motors BidarDr Bhadrappa HaralayyaNo ratings yet

- Software Testing and Quality Assurance: Week - 8Document9 pagesSoftware Testing and Quality Assurance: Week - 8xofalavejeNo ratings yet

- Six Sigma Analysis of Sopura Silk MillsDocument14 pagesSix Sigma Analysis of Sopura Silk MillsAsif AhmadNo ratings yet

- Shen 2012Document15 pagesShen 2012Danti DantiNo ratings yet

- DWC03225R6.0 Drawstrings, Functional Cords, and Decorative CordsDocument12 pagesDWC03225R6.0 Drawstrings, Functional Cords, and Decorative CordsPopper JohnNo ratings yet

- Product ID Pad Printing ProcessDocument10 pagesProduct ID Pad Printing ProcessPopper JohnNo ratings yet

- Consumer Product Safety Improvement Act (CPSIA) : Implementation Guide For Nike & Affiliates - February, 2012 UpdateDocument2 pagesConsumer Product Safety Improvement Act (CPSIA) : Implementation Guide For Nike & Affiliates - February, 2012 UpdatePopper JohnNo ratings yet

- MRK032051R1.2 The CE Marking Process: Sr. Director Global Apparel & Equipment Product IntegrityDocument2 pagesMRK032051R1.2 The CE Marking Process: Sr. Director Global Apparel & Equipment Product IntegrityPopper JohnNo ratings yet

- China Domestic Style Test ProcessDocument2 pagesChina Domestic Style Test ProcessPopper JohnNo ratings yet

- China Import Style Test ProcessDocument2 pagesChina Import Style Test ProcessPopper JohnNo ratings yet

- Its SH Test Submit FormDocument2 pagesIts SH Test Submit FormPopper JohnNo ratings yet

- China Buy Equipment Socks List China Buy Apparel Socks ListDocument2 pagesChina Buy Equipment Socks List China Buy Apparel Socks ListPopper JohnNo ratings yet

- Apparel China Import Quarantine (CIQ) Material Pre-Qualification ProcessDocument2 pagesApparel China Import Quarantine (CIQ) Material Pre-Qualification ProcessPopper JohnNo ratings yet

- China Regulation Product Testing Checklist (ITS-SH) - 20181018Document1 pageChina Regulation Product Testing Checklist (ITS-SH) - 20181018Popper JohnNo ratings yet

- CHR08011R2.1 Golf China Style Test Process: Sr. Director Global Apparel & Equipment Product IntegrityDocument2 pagesCHR08011R2.1 Golf China Style Test Process: Sr. Director Global Apparel & Equipment Product IntegrityPopper JohnNo ratings yet

- Artigo JardelDocument20 pagesArtigo JardelOlavonazareno CostaNo ratings yet

- Learning Activity #2 Heritage Mapping Community: Sarrat, Ilocos Norte Place With Cultural Significance Cultural Significance Impact To The SelfDocument4 pagesLearning Activity #2 Heritage Mapping Community: Sarrat, Ilocos Norte Place With Cultural Significance Cultural Significance Impact To The SelfRomeoNo ratings yet

- Yamaha Rx-V800 Service ManualDocument75 pagesYamaha Rx-V800 Service ManualTheoniusNo ratings yet

- Tutorial 1. Deflection of Beam (Part-A)Document2 pagesTutorial 1. Deflection of Beam (Part-A)akash_solanki_7100% (1)

- Biological Molecule (Nucleid Acids) ObjDocument5 pagesBiological Molecule (Nucleid Acids) ObjYing ShuangNo ratings yet

- Module 1 - Functions, Limits & Continuity, DerivativesDocument14 pagesModule 1 - Functions, Limits & Continuity, DerivativesSteve RogersNo ratings yet

- Innovative Teaching Manual: Submitted byDocument7 pagesInnovative Teaching Manual: Submitted byPrasant NatarajanNo ratings yet

- Evolving Your View of Thermodilution: Volumeview SetDocument4 pagesEvolving Your View of Thermodilution: Volumeview Setalejandro sanche mejoradaNo ratings yet

- Grade 4 - Text TypesDocument17 pagesGrade 4 - Text TypesladyNo ratings yet

- Loose Bodies Tips PearlsDocument10 pagesLoose Bodies Tips PearlsGus AbellaNo ratings yet

- P3F30 en M C004 WebDocument368 pagesP3F30 en M C004 WebdyjimenezNo ratings yet

- 25 - Gas CalcsDocument36 pages25 - Gas CalcsChinmiholicNo ratings yet

- VA-01 Orientation To Voacabulary - QuestionsDocument10 pagesVA-01 Orientation To Voacabulary - QuestionsShubham PadwalNo ratings yet

- Slit RollingDocument16 pagesSlit Rollingreichfuhrer100% (1)

- Grade 9 JARIS Chapter # 1: SECTION 2 Accuracy and PrecisionDocument23 pagesGrade 9 JARIS Chapter # 1: SECTION 2 Accuracy and PrecisionzeyadNo ratings yet

- Notes Quranic PassagesDocument17 pagesNotes Quranic PassagesRazan Ali60% (5)

- Stories of Love and AdventureDocument24 pagesStories of Love and AdventureMargie HernandezNo ratings yet

- 623 Epm Mobile TransceiverDocument4 pages623 Epm Mobile TransceiverPhuc HoangNo ratings yet

- Kims Chart: Key Word Information Memory Clue SentenceDocument2 pagesKims Chart: Key Word Information Memory Clue SentenceJoshua WhiteNo ratings yet

- Acid Gas Comp 120 MMSCFD 3 Mol% H2SDocument1 pageAcid Gas Comp 120 MMSCFD 3 Mol% H2SGreg EverettNo ratings yet

- Toxicology of The Skin (Target Organ Toxicology Series) (PDFDrive)Document377 pagesToxicology of The Skin (Target Organ Toxicology Series) (PDFDrive)Shefira TashaNo ratings yet

- What Is Government Procurement LawDocument15 pagesWhat Is Government Procurement LawJohn Rey BallesterosNo ratings yet