Professional Documents

Culture Documents

Procedure Sheet For 11.4

Uploaded by

mauryapiaeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Sheet For 11.4

Uploaded by

mauryapiaeCopyright:

Available Formats

CARVER TRAINING AND SERVICES PVT. LTD.

Approved by

Quality Manager

3rd Floor, Vidya-Corner Building Pencil Chowk, MIDC, Baramati Carver Training

District-Pune State-Maharashtra Country-India Pin Code-413133 and Services Pvt.

Ltd

01. Understanding of layout and components of pressurizing

system .

Ref.Doc. MODULE 11A BOOK

1. Safety Precaution:

1. Refer manufacturer manual before working.

2. Outflow valve is always open on the ground.

3. Cabin altitude is never more than aircraft altitude.

4. Differential pressure should be within limit.

2. Tools & Equipment/Consumables: -

Tools & Equipment Consumables

General tools oil

Barometer grease

Leak test equipment N/A

Socket and wrench N/A

3. Task Details:

Understanding of layout of pressurization system.

Understanding of components of pressurization system.

4. Procedure:

PRESSURIZATION TERMS :

1. Cabin altitude - given the air pressure inside the cabin, the altitude on a standard day that has the

same pressure as that in the cabin. Rather than saying the pressure inside the cabin is 10.92 psi, it can

be said that the cabin altitude is 8 000 feet (MSL).

2. Cabin differential pressure - the difference between the air pressure inside the cabin and the air

pressure outside the cabin. Cabin pressure (psi) - ambient pressure (psi) = cabin differential pressure

(psid or ? psi).

3. Cabin rate of climb - the rate of change of air pressure inside the cabin, expressed in feet per minute

(fpm) of cabin altitude change.

PRESSURIZING SYSTEM :

1. Pressurizing an aircraft cabin assists in making flight possible in the hostile environment of the upper

atmosphere.

2. The degree of pressurization and the operating altitude of any aircraft are limited by critical design

factors.

3. A cabin pressurization system must accomplish several functions if it is to ensure adequate passenger

comfort and safety.

4. It must be capable of maintaining a cabin pressure altitude of approximately 8 000 feet or lower

regardless of the cruising altitude of the aircraft.

5. This is to ensure that passengers and crew have enough oxygen present at sufficient pressure to

facilitate full blood saturation.

6. A pressurization system must also be designed to prevent rapid changes of cabin pressure, which can

be uncomfortable or injurious to passengers and crew.

DOCUMENT S.NO ISSUE REVISION TOTAL PAGE

CTSPL/M11B/11.4/PS-1 ISSUE NO: 00 REVISION NO: 00 Page 1 of 4

DATE OF ISSUE: NOV 2018 REVISION DATE:00

(Cat-B1.2) REVISION PAGE: 00

CARVER TRAINING AND SERVICES PVT. LTD. Approved by

Quality Manager

3rd Floor, Vidya-Corner Building Pencil Chowk, MIDC, Baramati Carver Training

District-Pune State-Maharashtra Country-India Pin Code-413133 and Services Pvt.

Ltd

01. Understanding of layout and components of pressurizing

system .

Ref.Doc. MODULE 11A BOOK

7. Additionally, a pressurization system should circulate air from inside the cabin to the outside at a rate

that quickly eliminates odors and to remove stale air.

8. Cabin air most also be heated or cooled on pressurized aircraft.

9. Typically, these functions are incorporated into the pressurization source.

10. To pressurize, a portion of the aircraft designed to contain air at a pressure higher than outside

atmospheric pressure must be sealed.

11. A wide variety of materials facilitate this compressible seals around doors combine with various

other seals, grommets, and sealants to essentially establish an air tight pressure vessel.

12. This usually includes the cabin, flight compartment, and the baggage compartments.

13. Air is then pumped into this area at a constant rate sufficient to raise the pressure slightly above that

which is needed.

14. Control is maintained by adjusting the rate at which the air is allowed to flow out of the aircraft.

15. A key factor in pressurization is the ability of the fuselage to withstand the forces associated with the

increase in pressure inside the structure versus the ambient pressure outside.

16. This differential pressure can range from 3.5 psi for a single engine reciprocating aircraft, to

approximately 9 psi on high performance.

DOCUMENT S.NO ISSUE REVISION TOTAL PAGE

CTSPL/M11B/11.4/PS-1 ISSUE NO: 00 REVISION NO: 00 Page 2 of 4

DATE OF ISSUE: NOV 2018 REVISION DATE:00

(Cat-B1.2) REVISION PAGE: 00

CARVER TRAINING AND SERVICES PVT. LTD. Approved by

Quality Manager

3rd Floor, Vidya-Corner Building Pencil Chowk, MIDC, Baramati Carver Training

District-Pune State-Maharashtra Country-India Pin Code-413133 and Services Pvt.

Ltd

01. Understanding of layout and components of pressurizing

system .

Ref.Doc. MODULE 11A BOOK

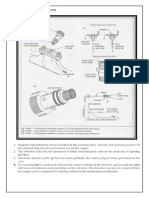

Fig. pressurization system

DOCUMENT S.NO ISSUE REVISION TOTAL PAGE

CTSPL/M11B/11.4/PS-1 ISSUE NO: 00 REVISION NO: 00 Page 3 of 4

DATE OF ISSUE: NOV 2018 REVISION DATE:00

(Cat-B1.2) REVISION PAGE: 00

CARVER TRAINING AND SERVICES PVT. LTD. Approved by

Quality Manager

3rd Floor, Vidya-Corner Building Pencil Chowk, MIDC, Baramati Carver Training

District-Pune State-Maharashtra Country-India Pin Code-413133 and Services Pvt.

Ltd

01. Understanding of layout and components of pressurizing

system .

Ref.Doc. MODULE 11A BOOK

Fig. pressurization system

Sign of Instructor Sign of Training Manager Approved by Quality

Manager

DOCUMENT S.NO ISSUE REVISION TOTAL PAGE

CTSPL/M11B/11.4/PS-1 ISSUE NO: 00 REVISION NO: 00 Page 4 of 4

DATE OF ISSUE: NOV 2018 REVISION DATE:00

(Cat-B1.2) REVISION PAGE: 00

You might also like

- Ref: Module 11 A Level: TOPIC - 11.7 Equipment and FurnishingsDocument6 pagesRef: Module 11 A Level: TOPIC - 11.7 Equipment and FurnishingsmauryapiaeNo ratings yet

- Ref: Module 11 A Level: Carver Training and Services Pvt. LTDDocument5 pagesRef: Module 11 A Level: Carver Training and Services Pvt. LTDmauryapiaeNo ratings yet

- Ref - Doc.: Carver Training and Services Pvt. LTDDocument2 pagesRef - Doc.: Carver Training and Services Pvt. LTDShiv Chatrapati clanNo ratings yet

- RSMQCM FJ3D503LDocument60 pagesRSMQCM FJ3D503LMohd Ridzuan Abdul Aziz100% (1)

- 9.1 General: Carver Training and Services Pvt. LTDDocument8 pages9.1 General: Carver Training and Services Pvt. LTDmauryapiaeNo ratings yet

- Method Statement For Pressure Switch 2019Document6 pagesMethod Statement For Pressure Switch 2019Trí Đức Minh CôngNo ratings yet

- Reliability Meeting Agenda RM 2016 002Document8 pagesReliability Meeting Agenda RM 2016 002Bibek BaralNo ratings yet

- Force InductionDocument17 pagesForce InductionMuhammad Aznan ZakariaNo ratings yet

- Ops MD 003 - V4.1Document16 pagesOps MD 003 - V4.1Mohamed OuheibiNo ratings yet

- 03 - Revised MOS - AIR BALANCINGDocument8 pages03 - Revised MOS - AIR BALANCINGEditor EditorNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- Mpaps 6028Document3 pagesMpaps 6028PANKAJ CHAUHANNo ratings yet

- DMI-BD-10-001-A4 Process Operating and Control PhilosophyDocument14 pagesDMI-BD-10-001-A4 Process Operating and Control Philosophykemas100% (2)

- Amman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MADocument11 pagesAmman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MAAbd Al Rahman OmaryNo ratings yet

- TOFD Procedure For VesselDocument12 pagesTOFD Procedure For Vesselmohanraj67% (3)

- MoeDocument214 pagesMoemahmud517No ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- RSQCM PDFDocument1,087 pagesRSQCM PDFDavid Lopez100% (1)

- Cover Page PPM Far142Document51 pagesCover Page PPM Far142Idham ZawawiNo ratings yet

- TM 55 4940 353 13 and PDocument43 pagesTM 55 4940 353 13 and PaburizqiNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- MSFC STD 246eDocument91 pagesMSFC STD 246eJoseph DavidNo ratings yet

- Complete ELP Manual 3 July 2022Document70 pagesComplete ELP Manual 3 July 2022Bhupinder Pal SinghNo ratings yet

- SHE-ECP-09-017 Motorize Equipment Procedure Rev02Document7 pagesSHE-ECP-09-017 Motorize Equipment Procedure Rev02grantNo ratings yet

- TASK 12!13!79-610-011-A Check Oil Level and ReplenishDocument6 pagesTASK 12!13!79-610-011-A Check Oil Level and ReplenishSatishReddyNo ratings yet

- Adjusting Suction Press & Speed C-2650Document12 pagesAdjusting Suction Press & Speed C-2650adi SaputraNo ratings yet

- Module 07.20Document47 pagesModule 07.20AddienNo ratings yet

- Remove and Install Turbine To Engine 18Document19 pagesRemove and Install Turbine To Engine 18RahmatNo ratings yet

- Aircraft Maintenance ProgramsDocument58 pagesAircraft Maintenance ProgramsJaydip Singh100% (1)

- Component Maintenance Manual With Illustrated Part ListDocument19 pagesComponent Maintenance Manual With Illustrated Part ListVeritec DocsNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeDocument16 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Lubricated Plug Valves - Inverted TypeXmanyeyNo ratings yet

- FCTP A321 R04 10may17Document137 pagesFCTP A321 R04 10may17GermanTobon100% (2)

- Attachment 19-Exterran Pneumatic Pressure Testing SpecificationDocument10 pagesAttachment 19-Exterran Pneumatic Pressure Testing Specificationum erNo ratings yet

- Checklist For RatingsDocument4 pagesChecklist For RatingsOILER GABRIOLA, MARK GREGORY IIINo ratings yet

- RDSO 2008 CG 06 Rev-1Document15 pagesRDSO 2008 CG 06 Rev-1Shiv PandeyNo ratings yet

- SP 1246part 4 2003 Pdo Painting SpecDocument38 pagesSP 1246part 4 2003 Pdo Painting SpecMuthu KumaranNo ratings yet

- 10 KG Weighing Balance (XL-WH-WB-01) ... URSDocument7 pages10 KG Weighing Balance (XL-WH-WB-01) ... URSAshok Lenka100% (4)

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Document5 pagesGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanNo ratings yet

- M & e MST - 036 Rev. 0Document3 pagesM & e MST - 036 Rev. 0Anonymous 3eHGEDbxNo ratings yet

- 30 ML Moulded Vial Filling OQDocument15 pages30 ML Moulded Vial Filling OQSubhash NaiduNo ratings yet

- PTL APM FebriDocument34 pagesPTL APM FebriFebri Kurnia SandyNo ratings yet

- DMI-DB-10-013-A4 CONTROL SAFEGUARD PHILOSOPHY Rev.0Document12 pagesDMI-DB-10-013-A4 CONTROL SAFEGUARD PHILOSOPHY Rev.0Kemas Muhandis M.100% (2)

- DQ Ahu G01Document24 pagesDQ Ahu G01santosh yadavNo ratings yet

- Manual Compressor Cloro Siemmens BAYERDocument53 pagesManual Compressor Cloro Siemmens BAYERJoao Carlos PereiraNo ratings yet

- Template For An Industry Training Program Description: NEI 06-13A (Revision 1)Document34 pagesTemplate For An Industry Training Program Description: NEI 06-13A (Revision 1)aki ferNo ratings yet

- PDR 5 Ems 002 R00Document110 pagesPDR 5 Ems 002 R00wan haffizNo ratings yet

- SOP UT ThicknessDocument12 pagesSOP UT ThicknessPT PUTRA SETIAWAN PRIMANo ratings yet

- Afa InstrementDocument71 pagesAfa Instrementcod modernwarfareNo ratings yet

- DQ Ahu G19Document23 pagesDQ Ahu G19santosh yadavNo ratings yet

- Kertas Tugasan: Institut Teknologi Perak E-3-10, Greentown Square, Jalan Dato' Seri Ahmad Said, 30450, IPOH, PERAKDocument4 pagesKertas Tugasan: Institut Teknologi Perak E-3-10, Greentown Square, Jalan Dato' Seri Ahmad Said, 30450, IPOH, PERAKMuhammad ZuhairiNo ratings yet

- Swaraj 744 FEDocument15 pagesSwaraj 744 FESaradhi PkmNo ratings yet

- Index of Worksheets (Issued Jun'2014) - SoftDocument200 pagesIndex of Worksheets (Issued Jun'2014) - Softsan2inNo ratings yet

- Ops MD 004 - V4.1Document22 pagesOps MD 004 - V4.1Mohamed OuheibiNo ratings yet

- Manual On Station Level Training For Acquiring Rating NEWDocument45 pagesManual On Station Level Training For Acquiring Rating NEWBiplav KumarNo ratings yet

- Service Description - ClouddeskDocument15 pagesService Description - ClouddeskhgergesNo ratings yet

- Quality Manual Atr A.8!1!45Document34 pagesQuality Manual Atr A.8!1!45John KevinNo ratings yet

- MD 04 MT Rssta CH 501Document11 pagesMD 04 MT Rssta CH 501Nguyễn Đặng LâmNo ratings yet

- 05 00 00 inDocument8 pages05 00 00 inÜmit KazanNo ratings yet

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- LP 3Document1 pageLP 3mauryapiaeNo ratings yet

- LP 190Document1 pageLP 190mauryapiaeNo ratings yet

- Carver Training and Services Pvt. Ltd. Baramati: 15.13 Starting and Ignition SystemDocument30 pagesCarver Training and Services Pvt. Ltd. Baramati: 15.13 Starting and Ignition SystemmauryapiaeNo ratings yet

- Reff: Charles Otis Page No.-2.3Document12 pagesReff: Charles Otis Page No.-2.3mauryapiaeNo ratings yet

- WWW - Dgcaquestionpapers.In (CT June 2013) : Download Our Mobile App From Play Store @dgca Question PapersDocument9 pagesWWW - Dgcaquestionpapers.In (CT June 2013) : Download Our Mobile App From Play Store @dgca Question PapersmauryapiaeNo ratings yet

- Procedures and Training ManualDocument170 pagesProcedures and Training ManualmauryapiaeNo ratings yet

- CAR 21 Presentation 20 Jun 2011Document63 pagesCAR 21 Presentation 20 Jun 2011mauryapiaeNo ratings yet

- A-P Technician-Airframe-Faa-Airmen-Knowledge-Test-Guide PDFDocument312 pagesA-P Technician-Airframe-Faa-Airmen-Knowledge-Test-Guide PDFmauryapiae100% (2)

- Account Statement From 9 Jul 2019 To 9 Jan 2020: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument4 pagesAccount Statement From 9 Jul 2019 To 9 Jan 2020: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancemauryapiaeNo ratings yet

- BOOKSDocument1 pageBOOKSmauryapiaeNo ratings yet

- PA-30 Maintenance ManualDocument863 pagesPA-30 Maintenance Manualmauryapiae100% (2)

- Listening: Mcgraw-Hill/Irwin ©2007, The Mcgraw-Hill Companies, All Rights ReservedDocument6 pagesListening: Mcgraw-Hill/Irwin ©2007, The Mcgraw-Hill Companies, All Rights ReservedmauryapiaeNo ratings yet

- Oil Tank: Figure A Oil System Basic Schematic CFM 56 - 5A1 / 5A5Document1 pageOil Tank: Figure A Oil System Basic Schematic CFM 56 - 5A1 / 5A5mauryapiaeNo ratings yet

- Unit Test-1 SEM.-I: Subjects - Aerodynamic Batech-06Document7 pagesUnit Test-1 SEM.-I: Subjects - Aerodynamic Batech-06mauryapiaeNo ratings yet

- Mo Dule 1 7A - 02 Propeller: PropellerconstructionDocument41 pagesMo Dule 1 7A - 02 Propeller: PropellerconstructionmauryapiaeNo ratings yet

- High SpeedDocument48 pagesHigh SpeedmauryapiaeNo ratings yet

- Ac 65-12a PDFDocument503 pagesAc 65-12a PDFmauryapiaeNo ratings yet

- Urea EPC ScheduleDocument45 pagesUrea EPC Schedulevishal_madhukar100% (1)

- RQ - RP - RPT & FBNDocument35 pagesRQ - RP - RPT & FBNSlim.B100% (2)

- Month Wise Checklist For Submission of Various ReturnsDocument3 pagesMonth Wise Checklist For Submission of Various Returnsadith24No ratings yet

- 3VM Interruptores Caja Moldeada MCCB 3VM 2015Document92 pages3VM Interruptores Caja Moldeada MCCB 3VM 2015AG CarlosNo ratings yet

- Dimmesdale Parris PaperDocument9 pagesDimmesdale Parris Paperjustinenguyen8No ratings yet

- Indiana Contract With ID - MeDocument23 pagesIndiana Contract With ID - MeWTHR80% (5)

- One Point Acupressure Treatment - Acupressure Research, Training and Treatment Sansthan - AllahabadDocument22 pagesOne Point Acupressure Treatment - Acupressure Research, Training and Treatment Sansthan - AllahabadShrini100083% (24)

- The Economic Infrastructure: Task 1a. VocabularyDocument5 pagesThe Economic Infrastructure: Task 1a. VocabularyPolina Nalistia IrawanNo ratings yet

- Chapter 1, Unit 2, Human Anatomy and Physiology 1, B Pharmacy 1st Sem, Carewell PharmaDocument5 pagesChapter 1, Unit 2, Human Anatomy and Physiology 1, B Pharmacy 1st Sem, Carewell Pharmatambreen18No ratings yet

- Hatchery MNGT PresentationDocument16 pagesHatchery MNGT PresentationKarl KiwisNo ratings yet

- SimulationDocument2 pagesSimulationVin Mamuric Meneses100% (1)

- Lesson 3 The Ideal Gasq PDFDocument4 pagesLesson 3 The Ideal Gasq PDFireneNo ratings yet

- UTM SlideDocument231 pagesUTM SlideAlly RaxaNo ratings yet

- The Human Aura: Manual Compiled by DR Gaynor Du PerezDocument33 pagesThe Human Aura: Manual Compiled by DR Gaynor Du Perezdorcas7342100% (2)

- NAME: Sonwalkar Pratik Rohidas Class: 12 R1 Subject: Biology TOPIC: Detailed Study On Infertility Its Causes and TreatmentDocument27 pagesNAME: Sonwalkar Pratik Rohidas Class: 12 R1 Subject: Biology TOPIC: Detailed Study On Infertility Its Causes and TreatmentPratik Sonwalkar0% (1)

- IGCSE Biology NotesDocument21 pagesIGCSE Biology NotesalfaazmcsNo ratings yet

- Jurnal Case Control UTS (Idrus) 5Document8 pagesJurnal Case Control UTS (Idrus) 5Reny NapitupuluNo ratings yet

- Exam Year Questions and AnswersDocument8 pagesExam Year Questions and AnswersArdianto SuhendarNo ratings yet

- Schools of CriminologyDocument38 pagesSchools of Criminologykongthei100% (1)

- Analyst Validation Protocol PCR No.: Avalon Cosmetics PVT LTD ACPL/QA/AV/002 Page: 1 of 13Document13 pagesAnalyst Validation Protocol PCR No.: Avalon Cosmetics PVT LTD ACPL/QA/AV/002 Page: 1 of 13Sankar ChinnathambiNo ratings yet

- Nilai ResistivitasDocument3 pagesNilai ResistivitasHana Azizah RakhmanNo ratings yet

- LVTSL004 Grundfos - Peerless VT Pump BrochureDocument5 pagesLVTSL004 Grundfos - Peerless VT Pump BrochuredanilobossuNo ratings yet

- BEKS - Annual Report - 2017 - Revisi PDFDocument596 pagesBEKS - Annual Report - 2017 - Revisi PDFWilliam WongNo ratings yet

- Diode Characteristics LabDocument5 pagesDiode Characteristics LabShuvodip Das100% (2)

- Final Annual Report 2018Document31 pagesFinal Annual Report 2018Nirmal Kumar SharmaNo ratings yet

- Lancet BFseriespaper1Document17 pagesLancet BFseriespaper1nosh.rose95No ratings yet

- Jewish Standard, February 26, 1016Document56 pagesJewish Standard, February 26, 1016New Jersey Jewish StandardNo ratings yet

- Pregnancy and Birth in Denmark - April 2023Document4 pagesPregnancy and Birth in Denmark - April 2023valckefranNo ratings yet

- Argumentative Essay ExamplesDocument4 pagesArgumentative Essay ExamplesAdinda Thalita AuliaNo ratings yet

- Detailed Lesson Plan in Health Grade 1Document12 pagesDetailed Lesson Plan in Health Grade 1Grace Ma AyNo ratings yet