Professional Documents

Culture Documents

Schlumberger Pressure Pumping Daily Report 21 Nov 2021

Uploaded by

hans vatriolisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schlumberger Pressure Pumping Daily Report 21 Nov 2021

Uploaded by

hans vatriolisCopyright:

Available Formats

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Felix/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

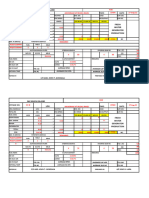

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 8 -Oct-2021 FROM TO TIME TIME REMARKS

Function Test circulation with C-Pump

Mixing FRW 300 bbl

Fresh Water : 100 bbl

FRW : 12.6 gal

Support CT Baker for flushing and purging production well Tree Cap (B10)

Transfer Soda Ash to third tank 20 bbl

Support P/T X tree needle valve at Well B10 to 300/3000 PSI for 5/10 min 07:00 8:00

Support depressurizing and flushing X tree at Well B 10 08:00 8:30

P/T against MCV to 300/3000 Psi for 5/10 min 08:30 9:00

Mixing FRW 100 bbl :

Fresh Water : 100 bbl 09:00 10:00

FRW : 8.4 Gal

Install Rate sensor Baker to SLB pump unit 10:00 11:00

Circulate water at Batch mixer 11:00 13:00

Rig up low pressure hose from water tank 360 bbl to C pump serva 13:00 15:00

Sampling physical treatment (circulation) for h2s content on water tapping

15 minutes : >60ppm

30 minutes: 28 ppm

15:30 17:30

45 minutes: 18 ppm

60 minutes: 1.8 ppm

90 minutes: ~0ppm

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Felix/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 9 -Oct-2021 FROM TO TIME TIME REMARKS

Start circulation test, h2s content on water 112 ppm

- 30 min 450 ppm

00:20 1:50

- 1 hr 450 ppm

- 1 hr 30 min >500 ppm

Observe h2s content after circulation

- 1 hr 215 ppm

01:50 4:50

- 2 hr 74 ppm

- 3 hr 34 ppm

Start circulation water from water tank 05:20 7:00

Re arrange low pressure hose for cleanout operation 07:30 9:30

Take water sample from water tapping, run test with analyzer for water treatment using safe scav with 2 gal/100 bbl, 2.5

09:30 12:00

gal /100 bbl, and 3 gal/100 bbl

Simulate water treatment: 50 bbl water sample directly from water tapping with 1.75 gal safe scav (3.5 gal/100 bbl),

mixed on GBS using circulation for 10 minutes

13:30 14:00

result: 0 ppm h2s found

Check water+frw sample on 180 bbl tank, 160 bbl tank, 250 bbl tank, and 270 bbl tank with total volume of 440 bbl 14:30 16:00

Transfer fresh water 6 bbl to sand skip Expro 16:00 16:30

Mixing 100 bbl FRW with treated fresh water h2s 0 ppm

16:30 17:00

- frw = 8.4 gal

Circulate 100 bbl of water on GBS to reduce H2S Content 17:00 18:30

Pre Job Safety Meeting 19:00 21:00

Mixing 100 bbl FRW with treated fresh water h2s 0 ppm

21:00 21:30

- frw = 8.4 gal

Circulate 100 bbl of water on GBS to reduce H2S Content, start tapping water from water injection well 21:30 22:30

Take Sample from 180 bbl tank, 160 bbl tank, 250 bbl tank, 270 bbl tank, Batch Mixer 1 and Batch Mixer 2

22:30 23:00

Sample 175ml ; 25 ml NaOH

Mixing 100 bbl FRW with treated fresh water h2s 0 ppm

23:15 23:45

- frw = 8.4 gal

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Felix/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 10 -Oct-2021 FROM TO TIME TIME REMARKS

Mixing 100 bbl FRW 8.4 gal 01:00 1:20

Function test pump rate with baker, pump rate 4 need to be rechecked 01:20 2:40

Function test rotojet

0.3 bpm - 70 psi

0.5 bpm - 150 psi

0.75 bpm - 390 psi

02:40 3:10

1 bpm - 650 psi

1.3 bpm - 1080 psi

1.5 bpm - 1400 psi

1.7 bpm - 1650 psi

2.1 bpm - 2300 psi

Fill up lubricator 03:10 3:20

Pressure test lubricator 300 psi 5min/2200 psi 15 min, while mixing FRW 50 bbl 4.2 gal, soda ash 50 bbl

03:20 4:00

soda ash = 7.5 sx

Circulate 100 bbl water from water tank 04:00 5:30

Mixing Chronox 10 bbl 04:15 4:50

Pressure test stripper 300 psi 5 min/ 2200 psi 15 min 04:50 5:00

Circulate water tank 160 bbl, check h2s level, result 174.5 ppm 7:30 10:00

Pressure up CT Line to 2200 psi, bled off, pressure up to 200 psi 9:30 10:00

Continue circulate water tank 160 bbl, check h2s level , safe scav 1st, 2nd, 3rd 11:00 12:00

Standby while Flow back simulation 12:00 18:00

Mixing FRW 100 bbl 8.4 gal safe

15:00 16:00

scav 4th and 5th

Transfer soda ash to expro 3.3 bbl 19:35 19:45

Pump chronox 0.3 bbl, parallel with transfer water to expro 19:45 20:45

pump chronox 0.3 bbl 20:45 21:10

Circulate 50 bbl water from frac tank on batch mixer (safe scav 5th) 21:10 21:25

Circulate 50 bbl water from frac tank on batch mixer (safe scav 6th) 21:25 21:45

Pump chronox 0.3 bbl and mixing FRW 100 bbl 8.4 gal 21:45 22:14

Circulate 100 bb water add safe scav 7th and 8th 3.5 gal safe scav 22:14 22:45

Pump chronox 0.3 bbl 22:45 22:50

Mixing FRW 100 bbl 8.4 gal 22:50 23:10

Circulate 100 bbl wter from frac tank, add safe scav 9th and 10th, 3.5 gal safe scav 23:10 23:20

Increase pump rate to 2.2 bpm 23:20 23:45

Pump chronox 0.3 bbl, while mixing 100 FRW 23:45

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Felix/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 11 -Oct-2021 FROM TO TIME TIME REMARKS

Circulate 100 bbl water from water tank+ safe scav 3.5 gal 00:15 0:45

Pump chronox 0.3 bbl while mixing frw 100 bbl + 8.4 gal 00:45 1:10

Circulate 100 bbl water from water tank+ safe scav 3.5 gal 01:10 1:45

Pump 0.3 bbl chronox while mixing 100 bbl + 8.4 gal 01:45 2:20

Circulate 100 bbl water from water tank+ safe scav 3.5 gal 02:20 2:45

Pump 0.3 bbl chronox while mixing 100 bbl + 8.4 gal 02:45 3:00

Mixing Acid 10 bbl 03:00 3:45

Pump 0.3 bbl chronox while mixing 100 bbl + 8.4 gal 03:45 4:35

Pump acid 1 bbl 04:35 4:40

Mix 50 bbl FRW with 4.2 gal 04:40 4:44

Circulate water 50 bbl with safe scav 1.75 04:44 4:45

Pump 0.3 bbl chronox 04:45 5:03

Pump 1 bbl acid 05:03 5:10

Pump 1 bbl acid 05:10 5:32

Circulate water 50 bbl with safe scav 3.5 gal 05:32 5:45

Pump 0.3 bbl chronox 05:45 6:42

Mix 50 bbl FRW with 4.2 gal 06:42 6:45

Pump 0.3 bbl chronox 06:45 6:50

50 bbl water + 4.2 gal frw + safe scav 1.75 gal 07:30 8:00

50 bbl water + 4.2 gal frw + safe scav 1.75 gal 08:00 8:34

50 bbl water + 4.2 gal frw + safe scav 1.75 gal 08:34 9:00

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 09:00 9:05

Pumping acid 1 bbl 09:05 9:15

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 09:15 9:40

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 09:40 10:00

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 10:00 11:12

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 11:12 11:22

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 11:22 11:42

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 11:42 12:01

50 bbl water + 4.2 gal frw + safe scav 3.5 gal 12:01 13:00

Pumping fresh water , total pump frw 2296 bbl 13:00 13:22

50 bbl water + safe scav 3.5 gal 13:22 14:16

Pumping acid 3 bbl 14:16 14:25

Pumpin acid 3 bbl 14:25 14:35

50 bbl water + safe scav 3.5 gal 14:35 14:50

PPLi take 7 sax @ 55 lbs soda ash for neutralize acid @ iso tank 14:50 15:14

Stop pumping, total pump frw = 2296 bbl, total pump fresh water 259 bbl, total pump acid 10 bbl 15:14 17:00

50 bbl water + safe scav 3.5 gal 17:00 17:45

Support CT Baker flushing soda ash and fresh water to lubricator 17:45 18:10

Support CTU, Pumping 5 bbl soda ash and 20 bbl water to CT Reel 18:10 19:00

Take Sample from batch mixer, send to Exxon lab 19:00 19:45

Circulate 100 bbl with safe scav 3.5 gal 19:45 20:15

Pilot test

1.75 gal/50 bbl

20:15 21:30

2 gal/50 bbl

2.5 gal / 50 bbl

Transfer soda ash 3 bbl to PPLI Lugger box 21:30 22:50

Mixing 3.5 bbl Chronox, diesel 385

22:50 23:00

liter, chronox 44.1 gal

Pilot test

2.25 gal/50 bbl 23:00 23:50

2.5 gal/50bbl

Circulate 100 bbl, safe scav 3.5 gal 23:50

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Felix/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 12 -Oct-2021 FROM TO TIME TIME REMARKS

Check sample water on batch mixers (result 3 ppm h2s and 5 ppm h2s) 01:00 1:45

Pilot Test from 3 ppm h2s content water sample

1.75 gal/50 bbl 01:45 2:00

2 gal/50 bbl

2.25 gal/50 bbl

Function test rotojet

0.5 bpm 112 psi

0.75 bpm 330 psi 03:35 4:00

1 bpm 550 psi

1.25 860 psi

Pressure Test stripper 300 psi 5min/2200 psi 10 min 04:00 4:10

Mixing Solvent 100 bbl - 0.5 hour

Fresh Water 89.81 bbl 04:10 4:40

U066 Mutual Solvent 7.6 drum

Safe Scav 8 gal

Mixing Acid 15% 360 bbl

Fresh Water 7424 gal

F103 31 gal

W054 46 gal

L041 756 lb 09:00 13:00

L058 76 lb

A284 152 gal

A270 152 gal

A201 605 gal

HCl 6600 gal

Start pumping 0.3 bbl chronox, rate 0.3 bpm, repeat every 7.5 bbl water pumped 09:30 11:00

Start pumping fresh water 2.1 bpm 11:00 11:20

Decreasing rate to 0.3 bbpm 11:20 13:45

Injectivity test on depth

0.5 bpm - 230 psi

1 bpm - 690 psi 13:45 14:00

1.5 bpm - 1200 psi

2 bpm - 2200 psi

2.5 bpm - 3100 psi

Pumping chronox 0.3 bbl 14:00 14:08

Pumping solvent @ 2.5 bpm 14:08 14:36

Stop pumping, transit point 14:36 14:37

Continue pumping solvent @ 2.5 bpm 14:37 14:45

Switch to acid @ 2.5 bpm, total solvent pumped 88 bbl 14:45 15:01

Stop pumping, transit point 15:01 15:03

Continue pumping acid @ 2.5 bpm 15:03 15:39

Stop pumping, transit point 15:39 15:40

Continue pumping acid @ 2.5 bpm 15:40 16:23

Stop pumping, transit point 16:23 16:24

Continue pumping acid @ 2.5 bpm 16:24 17:30

Switch to water @ 2.5 bpm, total acid pumped 360 bbl 17:30 18:26

Decreasing rate to 0.3 bbpm 18:26

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 13 -Oct-2021 FROM TO TIME TIME REMARKS

Pressure Test Stripper 1 & 2 02:40 3:50

Mixing Inhibitor for 4 bbl acid

- A270 = 2 bbl 05:00 6:00

- A201 = 7 bbl

- A284 = 2 bbl

Check line up to donor well and pressure up to 300 psi 06:10 7:00

Pumping 0.5 bpm water 07:40 7:45

Pump 1 bpm water 07:45 7:46

Pump 2 bpm water 07:46 7:48

Pump 3 bpm water 07:48 7:52

Pump acid 1 bpm 07:52 7:53

Switch to water 07:53 7:58

Step rate 1 bpm 07:58 7:59

Step rate 2 bpm 07:59 8:01

Step rate 3 bpm 08:01 8:07

Pumping 0.5 bpm, production choke 10% 08:07 8:17

Pump acid 2 bbl rate 0.5 bpm 08:17 8:25

Stop pumping, close production choke to 10% 08:25

Pressure line to Expro and wellstack 400 psi 10:04 10:05

Offloading 16 drum safe scav 16:30 17:00

Mixing soda ash 50 bbl (7.5 sx) 19:45 20:05

Mixing soda ash 35 bbl (4.5 sx) 21:35 21:55

Clean up displacement tank on both pump 22:00 22:30

Fill up batch mixer with water

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 14 -Oct-2021 FROM TO TIME TIME REMARKS

Housekeeping and arranging chemical for next acid wash operation 02:00 4:30

Start circulating water on frac tank 360 bbl with total volume of 320 bbl 09:00 9:30

Mixing first batch of 100 bbl water from frac tank with 4 gal of safe scav on batch mixer, ensure h2s is zero before re transferred to frac tank 09:30 10:00

Flush Expro line with 7 bbl soda ash and 13 bbl water 10:00 10:30

Mixing second batch of 100 bbl water from frac tank with 4 gal of safe scav on batch mixer, ensure h2s is zero before re transferred to frac tank 10:30 11:30

Connect Datascribe from pump acquisition system to Baker Cabin 11:00 11:30

Mixing third batch of 100 bbl water from frac tank with 4 gal of safe scav on batch mixer, ensure h2s is zero before re transferred to frac tank 11:30 12:00

Check for h2s content on frac tank water after circulating and chemical treatment, result 0 ppm h2s found 13:00 13:30

Transfer water from PPLI vacuum truck to Batch Mixer 14:00 14:30

Survey for treating line requirement on next well 20:00 20:30

Housekeeping on pumping and mixing area 20:30 23:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 14 -Oct-2021 FROM TO TIME TIME REMARKS

Re-rigup downstream 2 inch treating line 01:15 2:00

Hazard hunt and continue housekeeping night shift 02:00 4:30

Housekeeping and hazard hunt for day shift 08:30 10:00

Neutralize acid 26 bbl on Acid Tank 270 bbl using Soda Ash 24 sx, circulating using air hose 14:00 16:00

Survey Wellpad C with other Serco prior to interpad mobilization 17:00 17:40

Flushing lubricator and support CT Baker 17:45 18:30

Continue flushing with soda ash 50 psi and water 50 psi 19:00 20:00

Check sample on acid tank, PH = 2, mix 4 sack soda ash 20:00 20:10

Rig down 4 inch low pressure hose 20:10 21:30

Check sample on acid tank PH = 4 continue circulate 22:00 22:10

Continue Rig down 4 inch low pressure hose 22:10 23:10

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 14 -Oct-2021 FROM TO TIME TIME REMARKS

Mixing 6 sack and circulating 270 bbl acid tank 00:30 1:00

Check sample on tank 270 bbl, result pH 7 01:00 2:30

Transfer fluid from acid tank 270 bbl = 100 bbl to iso tank 02:30 4:00

Continue rig down 4" low pressure hose 04:00 5:00

Housekeeping pumping area, prepare chemical for interpad mobilization 08:00 11:00

Mobilize 18 drum of H032 to WPC, loading another 18 drums to Trailer, to be sent tomorrow 13:00 17:00

Rigup treating line to Donor Well and install manifold for flushing and purging 21:30 22:15

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 17 -Oct-2021 FROM TO TIME TIME REMARKS

Slack Management 00:00 1:45

Pressure test treating line to donor well, pressure test against PV 2x2 01:45 2:10

Rig Down treating line to CT 02:10 3:10

Rig Down pumping line to water tapping well 03:10 4:30

Pressure test against MCV and Tree Cap 300 psi 5min / 2500 psi 10 min 04:30 5:30

Mobilize 18 Palette H032 to WPC 09:00 10:00

Mobilize Salt D044 8 Bag and Lighting Tower PGX 2 ea to WPC 10:00 11:00

Mobilize Lab Cabin Expro, D151 6 ea, and D044 Salt 5 Bag to WPC 13:00 14:00

Mobilize H032 Acid 12 Palet and HDPE Liner PPLi 1 set to WPC 14:00 14:30

Mobilize H032 Acid 14 Palet to WPC 14:30 15:00

Rig Down Donor Well B02 16:30 18:30

Pressure Test Tree Cap on B02 300 psi for 5 min and 3000 psi for 10 min 19:00 19:30

Rig down treating line to Donor Well and Iso Tank and loading chemical to CKB Trailer 19:20 21:00

Continue Rig Down treating line, loading chemical and emtying Batch Mixer, Acid Tank 270 bbl and Displacement Tank 21:20 23:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 18 -Oct-2021 FROM TO TIME TIME REMARKS

Packing treating line and fsr to pallette and rig down CPS and air manifold 01:00 2:30

Mobilize to WPC

- Formic Acid A201 8 Palet + 1 drum

- H032 Acid HCl 8 palet

- W054 1 drum

- U066 2 Palet 1 drum

- A284 5 drum

- A270 2 Palet 7 can 02:30 3:00

- L041 3 Sack

- L058 2 carton box

- F103 1 drum

- FRW 1 Palet

- M290 1 IBC

-Safe SCAV 3 Palet

- J512 1 Palet

Reposition chemical liner 03:00 3:30

Backload chemical from flat bed 03:30 4:30

Rig down CPS Rooftop 08:30 9:30

Packing chemical and mobilize to WPC

- D151 4 Box

- D047 1 Pallet

- D044 5 Bag

- Saraline 1 IBC

- Chronox 1 Palette 09:30 14:30

- L041 1 Box

- U066 2 Palette

- Transqua 1 Palette

- M303 & Radiagreen 1 Palette

- J512 1 Palette

- M003 2 Pallet

Loading Chemical

- Safe Scav 1 Pallete

- FRW 1 Pallete

- Chronox 4 Pallete (14 drm)

19:00 20:00

- Oil Basket

- Genset

Loading Equipment

- Acid Tank 270 bbl

- Acid Tank 250 bbl

20:00 22:00

- Genset

- Storage Tank 140 bbl

- C-pump Portable

Loading Equipment

- Tower Light 2ea

22:00 23:30

- Treating Iron 4 Pallete

- Fuel Tank

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD B

Mobil Cepu Limited 4.5" Cased Hole

(Well B10)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE:

0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 19 -Oct-2021 FROM TO TIME TIME REMARKS

Mobilize Chemical and Unit to WPC

- Safe Scav

- FRW

- Chronox

- Oil Basket

- Genset 01:00 5:30

- Compressor

- Cables

- Tower light

- Treating Line

- Tote tank

Mobilize Unit to WPC

- CPS Serva

- CPS GD

- Batch Mixer

- Acid tank 270

- acid tank 250

- solvent tank 140

- genset 2 ea

07:30 17:30

- compressor

- tool container

- treating iron basket

- hose basket

- tower light 2 out of 4

- chemical fully mobilized

- CPump portable

- Chronox tank

Reposition Storage Tank tool container and hose basket. Install tent on CPS 19:00 21:00

Emptying Soda ash with PPLi at WPB

Loading Unit on WPB

- Soda ash tank

- Treating Iron on Pallet 4ea

21:30 0:00

- Water Tank 160 bbl

- Fuel Tank CPS

- Nitrogen bottle on cradle

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 20 -Oct-2021 FROM TO TIME TIME REMARKS

Reposition and check layout on pumping area 00:00 3:00

Rigup Treating iron manifold 03:00 6:00

Mobilize Water Tank 180 bbl and Light Tower to WPC 08:30 10:00

Rig Up Low Pressure Hose to Tanks 11:00 13:00

Mobilize Frac Tank 360 bbl to WPC

13:00 14:00

(Mobilization 100 %)

Rig Up Treating line up to plug valves before Water Tapping well 14:30 17:30

Offloading Water Tank 360 bbl 19:30 20:30

Rig up low pressure hose and water

20:30 21:00

tapping hose to tank

Function test pump and fill up water to displacement tank 21:20 22:10

Rig up treating line on iso tank and 22:10 23:00

Pressure Test Treating Iron manifold 23:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 21 -Oct-2021 FROM TO TIME TIME REMARKS

Pressure test manifold on pump 00:00 0:30

Continue pressure test manifold on pump 01:15 3:00

Pressure test water tapping line againts plug valve on ground 03:30 4:30

Mixing 50 bbl soda ash 8 sack 08:30 9:30

Rig up treating line up to iso tank 09:30 11:30

Survey to WPA 13:00 14:00

Continue Rig up treating line up to iso tank 14:00 16:30

Fill Up Coiled Tubing and pressure test 300 psi/5min and 6000 psi/15min 16:30 17:30

Continue rig up treating line from pumping to ISO tank and install safety line 19:30 20:30

Move some additive chemical to mixing area 20:30 21:30

Mixing FRW 300 bbl and prepare hoses and connection for rigup on water tapping well 21:30 23:00

Pressure test line to Iso Tank (not done) 23:00 23:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 22 -Oct-2021 FROM TO TIME TIME REMARKS

Continue pressure test line to Iso Tank 00:30 2:00

08:30 9:00

Prepare to rig up to water tapping well 08:30 9:00

Rig up to water tapping well, pressure test 300 psi/5min and 3000 psi 15 min

09:30 11:00

Found issue on crown valve, not holding pressure above 2500 psi

Waiting on greasing team to grease

13:00 14:00

the crown valve

Continue pressure test, still found leak while pressure testing above 2500 psi against the crown valve 14:30 17:30

Waiting on PGX Genset for supply power to bulk blower 19:00 20:00

Purging water tapping well with N2, H2S 0 ppm

20:00 21:45

Continue rig up pump-in sub and stand pipe in water tapping well while transferring water from 160 bbl and 180 bbl tank to 360 bbl tank

Pressure Test Stand pipe and pump-in sub againts MCV 300 psi for 5 min and 2250 psi for 10 min 21:45 23:00

Transfer 4 bbl water to Expro 4 bbl while fill up 160 bbl tank by PPLi with dearated water 23:00 23:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 23 -Oct-2021 FROM TO TIME TIME REMARKS

Re-arrangement chemical (acid and formic acid) to mixing area 01:00 2:30

Donor well C9 rig up preparation 02:30 3:20

Breaking containment on Donor well C9 03:20 8:00

Rig up donor well and pressure test 300 psi/5min 3000 psi/15 min 08:30 11:00

Mixing acid for pickling

- H032 = 238 Gal

14:00 15:30

- A270 = 5 Gal

- L058 = 4 KG

- F103 = 4 Gal

Mixing soda ash 50 bbl 8 sack 15:30 16:00

Flushing and pressure test tree cap

17:00 19:00

C09 to support CT Baker

Continue pressure test tree cap C9 to support CT Baker 19:00 20:00

Waiting on greasing team (leak on MCV) 20:00 21:00

Continue pressure test tree cap C9 to support CT Baker 21:00 22:00

Pickling CT, pump 20 bbl acid, 5 bbl water, 15 bbl soda ash, 25 bbl water 22:30 23:45

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 24 -Oct-2021 FROM TO TIME TIME REMARKS

Support Pressure Test on C9 01:00 5:00

Hazard hunt and housekeeping pumping area 08:30 10:00

Transfer soda ash to Expro 13:30 14:00

Support CT Baker to flushing and pressure test tree cap 14:00 17:00

Housekeeping Pumping area 19:00 20:45

Function test pump rate with CT Baker 21:00 22:00

Pressure Test Isolation Valve Baker 22:30 23:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 25 -Oct-2021 FROM TO TIME TIME REMARKS

Hazard Hunt 01:00 3:00

Function check pump condition and preparation unit 03:00 5:00

Housekeeping pumping area 08:30 10:00

Mixing soda ash 16 sax with 5 bbl water for ISO Tank Acid Neutralization 10:00 11:30

Switch the leaking check valve with new one and pressure tested 300 psi/5 min, 4500 psi/10 min 13:30 14:30

Transfer soda ash to vacuum truck PPLi 14:30 15:30

Greasing plug valves and re-function check check valve 19:30 21:30

Housekeeping pumping area 22:00 23:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Adiraka / Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 26 -Oct-2021 FROM TO TIME TIME REMARKS

Function Test RotoJet 03:00 3:55

Pressure Test Stripper 1 & 2 ; 300 psi / 5min and 2300 psi / 15 min 03:55 5:00

Displace CT with FRW 05:00 5:45

Prepare unit for flow back 08:30 10:00

PJSM for flow test C09 12:00 12:30

Standby on flow test 13:00 15:00

Mixing chronox 6 bbl - 75 gal 15:30 16:00

Flushing and depressurizing

16:30 17:30

lubricator C09

Function Test RotoJet 21:30 22:30

Pressure Test Lubricator 22:30 23:30

PJSM for flow test C09 23:30 0:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Restu/ Biki FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Rudy V. / Antonius Dwi/ Rahadian DF

A : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 27 -Oct-2021 FROM TO TIME TIME REMARKS

00:00

Continue pumping for scale clean out 07:30 8:00

Pumping chronox 0.3 bbl 08:00 8:15

Pumping chronox 0.3 bbl 09:00 9:15

Pumping chronox 0.3 bbl 10:00 10:15

Pumping chronox 0.3 bbl 11:00 11:15

Pumping chronox 0.3 bbl 12:00 12:15

Pumping chronox 0.3 bbl 13:00 13:15

Pumping chronox 0.3 bbl 14:00 14:15

Pumping chronox 0.3 bbl 15:00 15:15

Pumping chronox 0.3 bbl 16:00 16:15

Coiled Tubing on Surface, bleed off pressure 16:30 17:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 28 -Oct-2021 FROM TO TIME TIME REMARKS

Mixing Solvent 56.9 bbl 01:00 2:00

Flushing soda ash 50 psi to lubricator CTU and followed by flushing water 50 psi to CTU 02:00 3:10

Transfer soda ash 3 bbl and water 5 bbl to expro 03:10 3:30

Prepare additives for acid wash job 03:30 4:35

Fill up coil 18.7 bbl 04:35 5:05

Function Test Roto Jet with below result:

0.3 bpm 362 psi

0.5 bpm 370 psi

0.7 bpm 430 psi

1 bpm 720 psi

1.2 bpm 970 psi

05:05 5:45

1.5 bpm 1300 psi

1.7 bpm 1630 psi

2 bpm 2160 psi

2.2 bpm 2590 psi

2.3 bpm 2730 psi

2.5 bpm 3280 psi

Pressure Test Stripper 05:45 6:30

CT Start RIH 08:15

Start Mixing Additives for Acid 70 bbl 08:26 8:50

Pumping Fresh Water 0.3 bpm while CTU Baker RIH 08:50

CT at depth 5216 ft, PJSM prior acid wash job as per pumping schedule 11:47 12:00

Perform Injectivity Test with below result:

0.5 bpm 470 psi

1 bpm 870 psi

12:00 12:25

1.5 bpm 1570 psi

2 bpm 2750 psi

2.5 bpm 3500 psi

Pumping chronox 0.3 bbl 12:25 12:29

Start Pumping Solvent for 56.9 bbl at 2.5 bpm 12:29 12:50

Start pumping acid at 2.5 bpm 12:50 13:00

Decrease pumping acid rate to 0.3 bpm 13:00 13:05

Increase pumping acid rate back to 2.5 bpm 13:05 13:28

Acid pumped 70 bbl, switch to fresh water at 2.5 bpm 13:28 13:38

Stop pumping fresh water, CTU Baker POOH to 1500 ft 13:38 15:35

Start pumping fresh water 125 bbl to overdisplace 15:35 16:25

Stop pumping fresh water, CTU Baker POOH to surface 16:25 18:00

Flush soda ash and fresh water prior opening Baker QTS 18:00 19:00

transfer fresh water 4 bbls to expro 19:00 19:30

Flush Batch mixer with 10 bbls of soda ash solution (mix 440 lbs of soda ash) and dump to ISO tank 19:30 20:30

Baker to break QTS and change BHA to unload BHA (contingency) 20:30 21:30

Flush coiled tubing with 15 bbls soda ash and 25 bbls water 21:30 22:30

Pressure test Stripper 22:30 0:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 29 -Oct-2021 FROM TO TIME TIME REMARKS

continue pressure test stripper and DFCV 00:00 0:30

Pressure up Expro Line u p to 800 psi 00:30 1:00

Standby waiting on Expro to flowback 01:00 6:00

Flush soda ash and fresh water prior opening QTS 06:00 6:15

Standby waiting on decision and prepare permit for rig down water tapping line and rig down donor well 06:00 8:00

Dismantle Low pressure hoses in pumping area 08:00 12:00

Reposition empty chemical drum from pumping area to Yellow Cage area 13:00 14:00

Continue Housekeeping 14:00 16:00

SWA due to heavy rain and wind 16:00 17:30

Flush soda ash 4 bbls and fresh water 4 bbls to Expro thru CT flow cross 19:00 19:30

Housekeeping pumping area 19:30 21:00

standby to start R/D water tapping well after Baker finished R/D C-09 21:00 0:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 30 -Oct-2021 FROM TO TIME TIME REMARKS

standby to start R/D water tapping well after Baker finished R/D C-09 00:00 3:30

Flush well C09 and pressure test tree cap 03:30 4:30

Rig Down Water tapping line, purge with nitrogen, nipple down line and FSR , and nipple up tree cap 04:30 7:00

Pressure test tree cap 300 psi for 5 minutes and 3000 psi for 10 minutes 07:00 7:30

Prepare to rig down high pressure line from donor well 07:30 8:00

Flushing SLB pumping line to test separator 3 bbl 08:00 8:30

Flush line with soda ash to neutralize 08:30 9:00

purging donor well tree cap with Nitrogen and perform sniffing H2S 09:30 10:30

Rig Down high pressure line and flange adaptor from donor well C08 10:30 12:00

Rig up flange tree cap to donor well C-08 12:00 12:30

Pressure test donor well 300 psi 5 minutes and 3000 psi for 10 minutes 12:30 13:30

continue dismantle SLB pumping hoses, reposition chemical to yellow cage, rig down safety shower 13:30 14:30

SWA due to heavy rain and wind 14:30 15:30

continue to pack treating iron low pressure hoses to basket 15:30 17:30

R/D high pressure line to ISO tanks, loading 1 flat bed with chemicals 19:00 20:00

House keeping and preparation for interpad move 20:00 21:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 31 -Oct-2021 FROM TO TIME TIME REMARKS

Receive 14 pallets of chemical (HCl Acid) from WPC and spot it in WPA 08:00 11:00

Receive another 14 pallets of chemical (HCl Acid) from WPC and spot it in WPA 13:00 14:00

Standby waiting on trucks to mob equipment from WPC to WPA 14:00 16:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 1-Nov-2021 FROM TO TIME TIME REMARKS

Waiting on SLB trucks to arrive to wellpad C 08:00 12:00

SWA due to heavy rain 12:00 13:00

Loading water tank 270 bbl and chronox tank to high bed 13:00 14:00

loading acid tank 250 bbl to low bed 14:00 14:30

Loading 120 bbl water tank to high bed, portable C-Pump, and tote tank for fuel 14:30 15:00

spotting water tank 270 bbl, chronox tank, acid tank 250 bbl , and 120 bbl water tank, chronox tank, portable C-Pump and tote tank in WPA 15:00 16:00

loading 160 bbl water tank, CPS-361 fluid pump to high bed and low bed 16:00 16:45

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 2 -Nov-2021 FROM TO TIME TIME REMARKS

Loading 160 bbl tank and pallet of hoses from Wellpad C and spot it in Wellpad A 08:00 9:30

Loading treating iron pallet and lightning tower and spot in Wellpad A 09:30 11:00

Loading 360 bbl tank, treating iron basket, and hose basket and spot in Wellpad A 11:00 13:00

Loading GBS batch mixer, lightning tower and spot in Wellpad A 13:00 14:30

Loading CPS-361 Fluid pump from wellpad C and spot in Wellpad A 14:30 15:30

Loading CPS-361 back up fluid pump from wellpad C to Wellpad A 15:30 16:00

Loading 18 pallets of chemical in Wellpad C 16:00 16:45

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 3 -Nov-2021 FROM TO TIME TIME REMARKS

Loading HCl 18 pallet and spot it to Wellpad A, meanwhile in Wellpad A start to spot pumping equipment (batch mixer, fluid pump, and tanks) 09:00 10:30

Loading HCl 15 pallet and U066 1 pallet, meanwhile in Wellpad A start to rig up line and low pressure hoses 10:30 12:00

Loading the rest chemicals and spot to Wellpad A (Total 103 pallets chemicals moved to Wellpad A) 13:00 15:00

Continue to rig up fluid pump in wellpad A 15:00 16:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 4 -Nov-2021 FROM TO TIME TIME REMARKS

Rig up pumping line to iso tank 08:00 10:30

Fill up fresh water to SLB PP water tank 10;30 11:00

Rig up pumping line to water tapping well 11:00 12:00

mix 16 pallets of soda ash with 100 bbl of fresh water, will transfer 40 bbls of mixed soda ash to PPLI iso tank 2 ea (20 bbls each tank, the rest will be stored in SLB PP tanks) 13:00 14:00

Function test CPS-361 fluid pump , reposition safety shower, install FSR on pumping line 14:00 16:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 5 -Nov-2021 FROM TO TIME TIME REMARKS

Priming fluid pump, check sensor and acquisition, and perform Pressure test line to water tapping well 300 psi low pressure and 3000 psi high pressure 08:00 10:30

Flushing line to iso tank 3 bbls prior pressure test 10:30 11:00

Pressure test line to water tapping well 300 psi low pressure and 3000 psi high pressure 11:00 12:00

Transfer soda ash 40 bbl to 2 PPLI iso tank and 8 bbl to lugger box 13:00 14:00

Fill up CTU Baker's CT String, perform pressure test Coil to 5000 psi and slack management 14:00 17:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 6 -Nov-2021 FROM TO TIME TIME REMARKS

Transfer soda ash 4 bbl to PPLI lugger box (2 bbl each lugger box) 09:00 10:00

Fill up coil prior pressure test 10:00 11:00

Support CTU Baker to Pressure Test Coil up to 5000 psi 13:00 14:00

Mixing Acid 15% 20 bbls for pickling 14:00 14:15

Pressure test water tapping well tree cap prior dismantle 14:30 14:40

Dismantle water tapping tree cap 14:50 15:15

R/U water tapping well X-over 15:15 15:45

R/U rest of pumping line to X-Over water tapping well 15:45 16:15

Pressure test water tapping well tree cap after installed 16:15 16:45

Pumping acid 20 bbl for pickling process then continue to flush with water and soda ash 15 bbl 16:45 18:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 7 -Nov-2021 FROM TO TIME TIME REMARKS

While waiting for ICC Donor well, perform small maintenance on both fluid pump 08:00 11:00

perform weekly checking on SLB PP equipment 13:00 16:00

Flushing line to donor well with soda ash up to 50 psi 16:00 16:10

Flushing line to donor well with water up to 50 psi 16:10 16:40

Prepare to perform pressure test tree cap donor well 16:40 16:45

Pressure test tree cap donor well 300 psi 16:45 16:55

Pressure test tree cap donor well 3000 psi 16:55 17:10

Start to dismantle tree cap donor well 17:10 17:30

install donor well Pump in Sub 17:30 17:45

Pressure test against crown valve to 300 psi 17:48 18:00

pressure test against crown valve to 3000 psi 18:00 18:45

Pressure test against Expro's low torque 300 psi 18:45 19:00

Pressure test against Expro's low torque 3000 psi 19:00 19:20

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 8 -Nov-2021 FROM TO TIME TIME REMARKS

Pressure test tree cap A10 Well 06:30 7:30

Repair and greasing leaking low torque valves 2x2 07:30 9:30

Pressure test against repaired low torque valve 2x2 09:30 11:00

Pressure test against line to water tapping after repair leaking valves 13:30 14:00

Mixing FRW 250 bbl (4.2 gal per 50 bbl) 14:30 15:00

Mixing soda ash 4 sacks with 10 bbls fresh water 15:00 15:20

Transfer soda ash to PPLI iso tank 15:50 16:00

Fill up water in GBS batch mixer 100 bbl 16:00 16:30

Mixing FRW 250 bbl (4.2 gal per 50 bbl) 20:00 22:00

Mixing soda ash 12 sacks with 10 bbls fresh water 22:00 22:30

Continue to fill up water by SPIE water trucks 22:30 0:00

xxc

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 9 -Nov-2021 FROM TO TIME TIME REMARKS

Support Expro for Pressure test 01:00 1:30

Transfer soda ash 6 bbl to PPLI iso tank 01:30 2:00

Pressure test bleed off line instrument 03:00 3:30

Fill up water to water tank 03:30 4:30

Standby waiting on baker 04:30 8:30

Fill up fuel tank and chronox tank with diesel 08:30 9:00

Mixing Chronox solution 6 bbl (76 gal Chronox + 670 liter diesel) 09:00 9:30

Support CTU Baker to perform slack management (total 43 bbl pumped) 10:00 10:45

Fill up CT String 12:55 13:20

Pressure test CTU Baker stripper 13:20 14:00

Support CTU Baker to perform negative pressure test for check valve 14:00 14:35

Function test rotojet with below result (total 15.5 bbl FRW pumped)

0.5 bpm 374 psi

0.75 bpm 625 psi

14:35 14:55

1 bpm 1052 psi

1.5 bpm 2517 psi

2.1 bpm 3700 psi

Fill up Baker Line to manifold expro prior pressure test 15:30 16:00

Prepare to introduce hydrocarbon by Expro 16:00 16:30

Introduce Hydrocarbon 16:30 21:00

PJM prior to RIH CT 21:00 21:15

transfer soda ash 15 bbls to ISO tank 3 21:15 21:30

Start pumping 0.3 bbls Chronox followed by FRW as per @0.5 bpm 21:30 21:45

continue to pump or stop pumping as per instruction from CT cabin 21:45 0:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 10 -Nov-2021 FROM TO TIME TIME REMARKS

Support Flushing 01:00 1:30

Waiting on CTU Baker 01:30 6:00

Prepare to P/T BOP CTU Baker 06:50 8:00

Support P/T Stripper CTU Baker 08:00 8:45

Prepare to RIH 09:25

Pump Chronox 0.3 bbl 09:45 10:00

CT at 230 ft, continue pumping FRW at 0.3 bpm 10:00 11:20

Pump Chronox 0.3 bbl 11:45 11:50

Pump Chronox 0.3 bbl 13:50 14:00

Top up FRW 300 bbls (12.6 gal FRW with 300 bbls fresh water) 14:00 14:30

Increase rate to 2.1 bpm 14:30 15:00

Decreae rate back to 0.3 bpm 15:00 15:05

Pump Chronox 0.3 bbl 15:05 15:10

Increase rate to 2.1 bpm 15:15 15:30

CT @TD, continue circulate for 5 hrs using FRW 16:45

Pump Chronox 0.3 bbl 18:45

Pump Chronox 0.3 bbl 20:45

CT start to POOH, continue pump 2.1 bpm FRW 21:00

switch to fresh water , total FRW pumped 1100 bbls (decrease N2 rate) 22:00

Pump Chronox 0.3 bbl 22:45

continue to pump fresh water as per CT cabin instruction 22:50 0:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 11 -Nov-2021 FROM TO TIME TIME REMARKS

CT at surface, continue to perform flowback by Expro, SLB PP Waiting 01:00

Perform maintenance on both fluid pump while waiting on flowback well 07:00 13:00

Transfer soda ash 5 bbl and water 8 bbl to lugger box Expro 13:00 13:30

Continue to perform maintenance while waiting on flowback well 13:30 17:00

Rig Down low pressure hose 19:30 20:00

Flushing soda ash 50 psi approx 1 bbl and water 50 psi approx 1 bbl to CT Baker Wellhead Stack 20:00 20:30

Flushing water 5 bbl to separator via donor well 20:30 21:00

Flushing soda ash 5 bbl and water 5 bbl to iso tank 21:00 21:30

Transfer FRW from 250 tank and 270 tank to Vacuum Truck 22:00 22:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 12 -Nov-2021 FROM TO TIME TIME REMARKS

01:00

Waiting to rig down high pressure line from donor well 06:00 10:00

Flushing high pressure line to separator 2 bbl with water 10:00 10:20

Purging pump in sub donor well with nitrogen 10:20 10:40

Dismantle Pump in sub from donor well 10:40 11:00

Install tree cap to donor well A03 11:00 11:30

Pressure test tree cap donor well A03 11:30 12:00

Waiting on CTU Baker to install tree cap at well A10 13:00 15:00

Support pressure test tree cap well A10 to 3000 psi 15:00 16:10

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 13 -Nov-2021 FROM TO TIME TIME REMARKS

Dismantle remaining treating line near pumping area 08:00 10:00

PJSM prior rig down high pressure line from water tapping well 14:00 14:15

Purging X-Over Donor well with nitrogen and bleed off to lubricator then perform H2S sniffing 14:15 15:00

Dismantle X-Over from donor well and install tree cap 15:00 15:30

Pressure test tree cap donor well 300 psi and 2500 psi 15:30 16:00

Rig Down Line from donor well to pumping unit 16:00 17:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 14 -Nov-2021 FROM TO TIME TIME REMARKS

Received 2 pallets of soda ash (80 sacks) and demob portable C-Pump 10:00 11:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 15 -Nov-2021 FROM TO TIME TIME REMARKS

Loading 18 pallets of Salt (killing fluid chemical) from wellpad A and mob to wellpad C 10:00 11:00

Loading 18 pallets of chemical (HCl) from wellpad A and mob to Wellpad C 13:00 14:00

Loading 18 pallets of chemical from wellpad A to trailer and mob to Wellpad C 14:00 15:00

Loading 360 bbl tank to trailer 15:00 15:30

Loading 160 bbl tank 15:30 16:00

Loading 140 & 120 bbl tank 16:00 16:15

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 16 -Nov-2021 FROM TO TIME TIME REMARKS

Move 140, 120 bbl, 160 bbl, and 350 bbl tank to wellpad C 08:00 9:45

Loading 9 pallets of chemical, 4 lightning tower, 1 genset, 1 compressor and move to wellpad C 09:45 10:30

Loading CPS-361 fluid pump from wellpad A to Wellpad C 10:30 11:15

Loading Hose Basket and Iron Basket and move to wellpad C 11:15 11:45

Loading GBS Batch mixer, Oil Basket, and fuel tank to wellpad C 11:45 12:30

Loading 270 bbl stainless tank to wellpad C 14:50 15:30

Continue to receive and spot equipment from wellpad A 15:30 16:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 17 -Nov-2021 FROM TO TIME TIME REMARKS

Loading Tool Container, Fuel Tank, and treating iron pallet to WPC 08:20 8:40

Loading Genset, Compressor, Treating Iron, Nitrogen Bottle to WPC 08:40 9:00

Loading 250 bbl tanks and demobilize to Jakarta 09:00 10:00

Loading CPS-361 fluid pump to Jakarta 10:00 10:30

Loading 10 pallets of chemical and demobilize to Jakarta 15:00 15:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Afiff/Antonius/Rudy V DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 18 -Nov-2021 FROM TO TIME TIME REMARKS

Perform maintenance unit in wellpad C and lay down treating line 09:00 13:00

Loading 18 pallets of chemical to trailer and demobilized to SLB base 13:00 13:30

Loading 18 pallets of chemica to trailer and demobilized to SLB base 13:30 14:00

Loading 18 pallets of chemica to trailer and demobilized to SLB base 15:00 16:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Rudy V/Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 19 -Nov-2021 FROM TO TIME TIME REMARKS

Rig Up Line to front of water tapping well 09:00 10:30

Rig up Line from isotank to front of C09 well 13:00 14:00

Function test Fluid Pump and pressure test pump manifold 14:00 15:00

Perform maintenance checklist on all Schlumberger Pressure Pumping equipment 15:00 16:00

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Rudy V/Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 20 -Nov-2021 FROM TO TIME TIME REMARKS

Function test pumping unit 09:00 10:30

Function test batch mixer 13:00 14:00

Mixing soda ash 50 bbl (8 sacks or 440 lbs) in GBS batch mixer 14:00 15:00

Continue to rig up line and install Safety Restraint 15:00 16:00

Pressure testing line from schlumberger pump to front of C09 well 16:00 16:30

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

BANYU URIP WELLPAD C

Mobil Cepu Limited 4.5" Cased Hole

(Well C09)

ExxonMobil Witness : Slamoedding/Felix FIELD : Production MW & TYPE: 0.78 g/cc

Reservoir Engineer/Subsurface Engineer (s): RIG : Rigless RM :

No measured due to not run RES log

STIMULATION ENGINEER: Antonius/Rudy V/Maulana DF : 171.8 RMF : No measured due to not run RES log

CONTRACTOR: Schlumberger GL 137.8 RMC : No measured due to not run RES log

LOG / OPERATIONS TIMING TOTAL LOST MISCELLANEOUS

DATE: 21 -Nov-2021 FROM TO TIME TIME REMARKS

Purging water tapping well CW 10 with nitrogen prior dismantle and perform sniffing H2S by Fergaco 13:20 13:50

Pressure test line to water tapping tree cap 300 psi for 5 minutes and 2500 psi for 10 minutes 13:50 14:30

Dismantle tree cap and install pump-in-sub to water tapping well CW 10 14:30 15:00

Connect remaining line to pump - in-sub 15:00 15:10

Pressure test line to pump-in-sub 300 psi for 5 minutes and 2500 psi for 10 minutes 15:10 15:30

Pressure test line to iso tank 16:10 16:50

OPERATION TIME : CUMULATIVE LOST TIME : Nil

TOTAL RECORDING TIME : WIPER TRIPS TIME : Nil

TOTAL TIME : FISHING TIME : Nil

You might also like

- 9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)Document7 pages9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)engr anharNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- FR-8x Editor Eng01 WDocument8 pagesFR-8x Editor Eng01 WRadulian Daniel100% (1)

- Aux Engine Hyundai-Man-B-W-8l2832h PDFDocument1,044 pagesAux Engine Hyundai-Man-B-W-8l2832h PDFDimitris KNo ratings yet

- Daily Agustus 2022Document11 pagesDaily Agustus 2022Unda HariNo ratings yet

- Data SheetsDocument5 pagesData Sheetshector cano moraNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Bridge-Plug Installation ProgramDocument2 pagesBridge-Plug Installation Programgben11No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Pre-Stowage Plan-Maputo 01 23 02 2022Document1 pagePre-Stowage Plan-Maputo 01 23 02 2022Zb ZbNo ratings yet

- History File - CTU2 - 03-March-2020Document21 pagesHistory File - CTU2 - 03-March-2020Chinmoyee SharmaNo ratings yet

- Sand Screen Hangoff Draft Well ProgramDocument3 pagesSand Screen Hangoff Draft Well Programgben11No ratings yet

- Form Swab ReportDocument1 pageForm Swab ReportimampranadipaNo ratings yet

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- Va Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedDocument1 pageVa Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedRamKS80100% (1)

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Hydraulic Oil Test DescriptionDocument24 pagesHydraulic Oil Test Descriptionjondutta189No ratings yet

- 20th Sept 2023Document9 pages20th Sept 2023jondutta189No ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Results Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgeDocument7 pagesResults Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgewillyNo ratings yet

- Inverter Green Energy Mini Splits SpecsDocument1 pageInverter Green Energy Mini Splits Specsnikalah45No ratings yet

- Amal-18 Sta DDR#8 19-02-2020Document30 pagesAmal-18 Sta DDR#8 19-02-2020eng7mohamed7hashimNo ratings yet

- Squeeze Cement LabreportDocument2 pagesSqueeze Cement LabreportThem Bui XuanNo ratings yet

- ALS InglésDocument26 pagesALS Inglésjose belloNo ratings yet

- Book1 by JR MillanesDocument1 pageBook1 by JR Millanesa36948512No ratings yet

- 15.1. As Built Drawing - KML Route (A3) - MTI Cepu - XL GenengDocument9 pages15.1. As Built Drawing - KML Route (A3) - MTI Cepu - XL GenengmamassanjayaNo ratings yet

- Interchangeable Products Rlpwm12 1250 PCB PW12Document1 pageInterchangeable Products Rlpwm12 1250 PCB PW12produccion multipackNo ratings yet

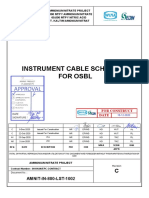

- AMNIT-IN-800-LST-1002 Cable Schedule Rev C-1 (2) 1912Document4 pagesAMNIT-IN-800-LST-1002 Cable Schedule Rev C-1 (2) 1912zaraki kenpachiNo ratings yet

- Lo 2019Document2 pagesLo 2019024Lita LucianaNo ratings yet

- Interconnecting Piping For Hook Up New Wells at Guebiba ClusterDocument1 pageInterconnecting Piping For Hook Up New Wells at Guebiba ClusterCss SfaxienNo ratings yet

- 20kg-P&id (Sheet 2 of 3)Document1 page20kg-P&id (Sheet 2 of 3)naurizsultanov.fxNo ratings yet

- Daily Drilling Fluid Report (041A) - 01 April 16-1Document1 pageDaily Drilling Fluid Report (041A) - 01 April 16-1Lenin FontanaNo ratings yet

- WFT-0005 (2378695) Jan 02 Ico-Corp-Mpt-5002 MpiDocument1 pageWFT-0005 (2378695) Jan 02 Ico-Corp-Mpt-5002 MpiApichai ZankerNo ratings yet

- DMR-019 - Louisiana - A-2-D - 07 - Oct-18Document5 pagesDMR-019 - Louisiana - A-2-D - 07 - Oct-18Aziz AndriyantoNo ratings yet

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Document30 pagesPetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoNo ratings yet

- BWT 9000 SCDocument1 pageBWT 9000 SCMehdi AcilNo ratings yet

- BMBS-APM Working SystemDocument5 pagesBMBS-APM Working SystemSrinivas AvutapalliNo ratings yet

- EEPNL Drill Bits and Services - ITT Part 3 Attach 2 - NCDMB Commercial TemplateDocument8 pagesEEPNL Drill Bits and Services - ITT Part 3 Attach 2 - NCDMB Commercial TemplateDORNU SIMEON NGBAANo ratings yet

- Fel AmarilloDocument31 pagesFel AmarilloGermán Alberto CifuentesNo ratings yet

- CC Schedule HEGDocument16 pagesCC Schedule HEGvomicih221No ratings yet

- WFT-0001 (2378680) Jan 02 Ico-Corp-Mpt-5002 MpiDocument1 pageWFT-0001 (2378680) Jan 02 Ico-Corp-Mpt-5002 MpiApichai ZankerNo ratings yet

- Eq Das 8020 0001Document10 pagesEq Das 8020 0001pradeep yadavNo ratings yet

- ACS GW 24 001 AR030 Gose Neck ThreadDocument1 pageACS GW 24 001 AR030 Gose Neck Threadarehmanmirza1990No ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- TM - 5ce - 2016Document48 pagesTM - 5ce - 2016Jf OngNo ratings yet

- New Itpl Construction of Masonary Walls For Lub Oil RoomDocument2 pagesNew Itpl Construction of Masonary Walls For Lub Oil RoomAndile CeleNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- Ep Wells Daily Operations Report: Event SummaryDocument5 pagesEp Wells Daily Operations Report: Event Summarymohamed gadallahNo ratings yet

- SLB COSL 223 Morning Report 12-Jul-2020) REV.01Document2 pagesSLB COSL 223 Morning Report 12-Jul-2020) REV.01Jusman Van SitohangNo ratings yet

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- DBR TGL 05 Feb 2024Document2 pagesDBR TGL 05 Feb 2024edibagus401No ratings yet

- 005 15 1-2'' String Stabilzer Am-Pt-Sstb-15120013 (12-12-21) PmiDocument1 page005 15 1-2'' String Stabilzer Am-Pt-Sstb-15120013 (12-12-21) PmiAboozar FathinejadNo ratings yet

- Programa de Perforación XA-32 LateralDocument1 pagePrograma de Perforación XA-32 LateralcarlosNo ratings yet

- Field Report T-901Document1 pageField Report T-901Tahir Iqbal. Kharpa RehanNo ratings yet

- Test Report Englisch BlancoDocument3 pagesTest Report Englisch BlancoElio DiazNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- Job Safety & Environmental Analysis (Jsea) : Schlumberger CTSDocument4 pagesJob Safety & Environmental Analysis (Jsea) : Schlumberger CTShans vatriolisNo ratings yet

- Wandi Muslim: Schlumberger, 2014 PT. BNSP, 2016 Samson Tiara, 2017Document5 pagesWandi Muslim: Schlumberger, 2014 PT. BNSP, 2016 Samson Tiara, 2017hans vatriolisNo ratings yet

- Wandi Muslim: TrainingDocument6 pagesWandi Muslim: Traininghans vatriolisNo ratings yet

- Hose Inventory: No Length Qty RemarksDocument2 pagesHose Inventory: No Length Qty Remarkshans vatriolisNo ratings yet

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateDocument6 pagesHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisNo ratings yet

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateDocument2 pagesHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisNo ratings yet

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateDocument6 pagesHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisNo ratings yet

- Hazard Analysis and Risk Control Record: Schlumberger-PrivateDocument6 pagesHazard Analysis and Risk Control Record: Schlumberger-Privatehans vatriolisNo ratings yet

- Electro Magnetic Induction PDFDocument28 pagesElectro Magnetic Induction PDFPuran BistaNo ratings yet

- C12200Document3 pagesC12200xgiorg100% (1)

- Quality ControlDocument10 pagesQuality ControlSabbir AhmedNo ratings yet

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDocument12 pagesComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNo ratings yet

- 25252525Document38 pages25252525Ivan GonzalezNo ratings yet

- 85GDocument4 pages85GBeny StephenNo ratings yet