Professional Documents

Culture Documents

Preventive Maintenance Checklist Es Ceramics Technology

Uploaded by

navinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preventive Maintenance Checklist Es Ceramics Technology

Uploaded by

navinCopyright:

Available Formats

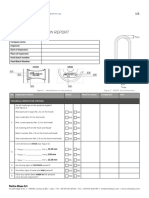

PREVENTIVE MAINTENANCE CHECKLIST ES Ceramics Technology

Machine Name: LPG Work Order No: MONTH

Type/I.D No: Plant:

Location: YEAR 2020

Note: Please tick [ √ ] if found o.k and tick [ X ] and note remark if found not ok. Note [ NA ] for Not Applicable.

Item 1 Robot Act Requirement Standard Status Remarks

1.1 Check all the Signboard/ Marking condition I Good condition Visible

1.2 Visually Inspect Security Protection I Good condition No damage

1.3 Tank Fitting Condition I No leak No wear and tear

1.4 Vaporiser Fitting Condition I No leak No wear and tear Bar:

1.5 Oil Separator Fitting Condition I No leak No wear and tear

1.6 Safety relief valve Fitting Condition I No leak No wear and tear

Requirement Standard

1.7 Fire Extinguisher Fitting Condition I Good condition No wear and tear

1.8 Vapour Line pipe condition I Good condition No wear and tear

1.9 Oil Separator Line pipe condition I Good condition No wear and tear

2.1 Thread Joint pipe condition I Good condition No wear and tear

2.2 Flange Joint pipe condition I Good condition No wear and tear

Requirement Standard

2.5 Operation Pressure on pipe I

2.6 Check the Vaporiser temperature I Within range ( 45°c - 50°c)

2.7 Drain out oil from the oil separator I Clean No clog

2.8 Pressure Gauge 1 I Within range

2.9 Pressure Gauge 2 I Within range

3.1 Pressure Gauge 3 I Within range

3.2 Pressure Gauge 4 I Within range

3.3 Pressure Gauge 5 I Within range

3.4 Pressure Gauge 6 I Within range

3.5 Tank temperature 1 I Within range

3.6 Open the Y strainer to clean the filter Mesh. Clean No clog

Report if additional work carried out : * Switch OFF the machine before work

* Be aware on slip hazards Check by

* Be aware of sharp edges Sign:

* Be aware of pinch points and crushing hazards.

* Do not remove any hydraulic fitting if still have pressure in the line. Date:

* Use LOTO procedure

Action Note:C = Cleaning, G = Greasing, I = Inspection, L = Lubricate, T = Test Run. Verify by:

Navin

You might also like

- Chemistry: Inorganic Qualitative Analysis in the LaboratoryFrom EverandChemistry: Inorganic Qualitative Analysis in the LaboratoryRating: 5 out of 5 stars5/5 (1)

- Preventive Maintenance Checklist Es Ceramics TechnologyDocument1 pagePreventive Maintenance Checklist Es Ceramics TechnologynavinNo ratings yet

- Preventive Maintenance Checklist Es Ceramics TechnologyDocument1 pagePreventive Maintenance Checklist Es Ceramics TechnologynavinNo ratings yet

- Preventive Maintenance Checklist Es Ceramics TechnologyDocument1 pagePreventive Maintenance Checklist Es Ceramics TechnologynavinNo ratings yet

- PM - AircompDocument3 pagesPM - AircompNavin RobertNo ratings yet

- 9.checklist Electric Fire PumpDocument1 page9.checklist Electric Fire Pumpdwi armadaNo ratings yet

- Health Alert PMI and CAL Cert 03.03.22Document6 pagesHealth Alert PMI and CAL Cert 03.03.22Webb PalangNo ratings yet

- Compartive Test and MNTC WayDocument4 pagesCompartive Test and MNTC WayAnonymous axyNzhNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

- Copy of TA 12 English - Generator Set 2Document6 pagesCopy of TA 12 English - Generator Set 2Eddie UnivoNo ratings yet

- Swivel & Main ShaftDocument2 pagesSwivel & Main ShaftmhmdtrainingNo ratings yet

- Petrol Station Checklist AuditDocument10 pagesPetrol Station Checklist AuditrizamryNo ratings yet

- Work Standar Lube Oil PurifierDocument4 pagesWork Standar Lube Oil Purifierasri elektronikNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Sop For Oil Purification SystemDocument8 pagesSop For Oil Purification SystemSonrat100% (1)

- Operation of Winding Machine 03Document2 pagesOperation of Winding Machine 03Aris PurnamaNo ratings yet

- MAINTENANCEDocument6 pagesMAINTENANCEshaktiNo ratings yet

- Sepremium English Web 10 2017Document10 pagesSepremium English Web 10 2017Andreas BayNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- CltiDocument53 pagesCltiGURMUKH SINGH100% (1)

- RM 1301 Service ReportDocument1 pageRM 1301 Service ReportshaktiNo ratings yet

- Split-UnitDocument6 pagesSplit-UnitKhairul AnwarNo ratings yet

- Formulir Checklist Preventive MaintenanceDocument1 pageFormulir Checklist Preventive Maintenanceimam siregarNo ratings yet

- Group 2 Hydraulic and Mechanical SystemDocument20 pagesGroup 2 Hydraulic and Mechanical SystemMarcelino chiritoNo ratings yet

- TA1 English - Hydraulic HammerDocument11 pagesTA1 English - Hydraulic Hammercarlos angelNo ratings yet

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- B737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFDocument604 pagesB737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFMe Keen100% (1)

- GS-F34 - Generator Set System (Off Load Test)Document2 pagesGS-F34 - Generator Set System (Off Load Test)Mohamed Firdaus Bin ZakariaNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - FinalrambihariNo ratings yet

- 11 5K 5K Annular BOPDocument4 pages11 5K 5K Annular BOPEdwin MP0% (1)

- Multi Mill SOPDocument14 pagesMulti Mill SOPDilraj KohliNo ratings yet

- Daily Maintenance Check SheetDocument5 pagesDaily Maintenance Check SheetPearlsgodNo ratings yet

- Mobile Equipment Inspection Checklist 1687755981 Part8Document1 pageMobile Equipment Inspection Checklist 1687755981 Part8nellaika puspa dewiNo ratings yet

- Air CompressorDocument1 pageAir Compressornellaika puspa dewiNo ratings yet

- Ga2 28:6:23Document1 pageGa2 28:6:23john HuntNo ratings yet

- Group 2 Hydraulic and Mechanical SystemDocument20 pagesGroup 2 Hydraulic and Mechanical Systemdeniden2013No ratings yet

- Ink Jet PrinterDocument1 pageInk Jet Printerkashifurrahaman8No ratings yet

- Ga2 27:6:23Document1 pageGa2 27:6:23john HuntNo ratings yet

- Sample Transformer Life Assessment SheetDocument10 pagesSample Transformer Life Assessment SheetMuhammed Zubair NNo ratings yet

- Commissioning Report Generator - SAMPLEDocument5 pagesCommissioning Report Generator - SAMPLEMax JohnNo ratings yet

- R330Hydraulic and MechnanicalDocument20 pagesR330Hydraulic and MechnanicalkrisnantoNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Coating PanDocument2 pagesCoating Pankashifurrahaman8No ratings yet

- Risk AssessmentDocument2 pagesRisk Assessmentnirmal krisnaNo ratings yet

- Inspection Report: Wheel LoadersDocument5 pagesInspection Report: Wheel LoadersLacatusu MirceaNo ratings yet

- WASPL - Yearly Inspection Report - enDocument2 pagesWASPL - Yearly Inspection Report - enMayara WolffNo ratings yet

- 5b. STP Weekly Log BookDocument1 page5b. STP Weekly Log BookNISHANTH GANESHNo ratings yet

- Self Maintenance ChecklistDocument19 pagesSelf Maintenance Checklistgrapher05No ratings yet

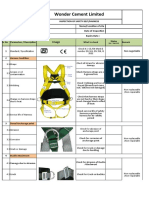

- Safety Harness ChecklistDocument2 pagesSafety Harness ChecklistTilak RajNo ratings yet

- RIU Maldives: Chiller Plant Control AlgorithmDocument12 pagesRIU Maldives: Chiller Plant Control AlgorithmThilina SarangaNo ratings yet

- Name of Building Time Commenced Model / EL No. Time Completed Checked by DateDocument7 pagesName of Building Time Commenced Model / EL No. Time Completed Checked by Dateangela15900% (1)

- QCV Test CertificatesDocument1 pageQCV Test CertificatesShashank RajputNo ratings yet

- Owner's: L'HinDocument114 pagesOwner's: L'HinxistormanexNo ratings yet

- 2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Document80 pages2 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (086-165)Lala CéspedesNo ratings yet

- I-Beam: Operations and Maintenance Periodic IAQ MaintenanceDocument13 pagesI-Beam: Operations and Maintenance Periodic IAQ MaintenanceKhalid ImamNo ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Overhauling of Ray Roll 33Kv Circuit Breaker: Presented By: Asset Management - Transformer & Work Shop StaffDocument26 pagesOverhauling of Ray Roll 33Kv Circuit Breaker: Presented By: Asset Management - Transformer & Work Shop Staffమాచర్ల రవీంద్ర నాథ్No ratings yet

- Jishu Hozen by Sudhansu Bhushan Mohapatra TPM Consultant - IIPM E-Mail: Sbm@iipm - Ac.inDocument64 pagesJishu Hozen by Sudhansu Bhushan Mohapatra TPM Consultant - IIPM E-Mail: Sbm@iipm - Ac.insudhansu_cvrce100% (9)

- F WalnutLane Nasser Oct081Document5 pagesF WalnutLane Nasser Oct081Sergiomar IsraelNo ratings yet

- Spatial Separations 2010Document3 pagesSpatial Separations 2010ARTURONo ratings yet

- Astm A501 PDFDocument2 pagesAstm A501 PDFgamin100% (1)

- Hvac Zona 2 - Edif ADocument8 pagesHvac Zona 2 - Edif AFranklin Cisneros PradoNo ratings yet

- Design of Piles in London Clay Revised GuideDocument16 pagesDesign of Piles in London Clay Revised GuideLaurentiu TarbucNo ratings yet

- Attempt ALL Questions.: Nepal Engineering CollegeDocument2 pagesAttempt ALL Questions.: Nepal Engineering CollegeSubodh AdhikariNo ratings yet

- Terminal DesignDocument28 pagesTerminal DesignMarwa HassanNo ratings yet

- Whirlpool Washing Machine Use & Care Guide-W10860705-RevBDocument36 pagesWhirlpool Washing Machine Use & Care Guide-W10860705-RevBCarter AtkinsonNo ratings yet

- Folded Plate AnalysisDocument9 pagesFolded Plate AnalysisxvNo ratings yet

- 7251 - 08 - 104 Rock Chute (Standard)Document1 page7251 - 08 - 104 Rock Chute (Standard)Barrasons Engineers TeamNo ratings yet

- New Government Accounting SystemDocument65 pagesNew Government Accounting SystemRuel Villanueva100% (1)

- The Evolution of Glass Façades - Aleksander T. ŚwiątekDocument10 pagesThe Evolution of Glass Façades - Aleksander T. ŚwiątekAlexSaszaNo ratings yet

- Design and Construction of Large Diameter Circular Shafts: T.T. Aye, M.S.Y. Tong, K.H. Yi, E. ArunasorubanDocument14 pagesDesign and Construction of Large Diameter Circular Shafts: T.T. Aye, M.S.Y. Tong, K.H. Yi, E. ArunasorubanAdam FredrikssonNo ratings yet

- Equipment Preservation Plan: Report No. 000-PR-R-002Document17 pagesEquipment Preservation Plan: Report No. 000-PR-R-002Richard BertoniNo ratings yet

- NEOM Presentation Sustainability - R0 PDFDocument2 pagesNEOM Presentation Sustainability - R0 PDFMohamad HssanNo ratings yet

- Valvula Mariposa Con Volante Ranura 250LBS Mech D381X4Document1 pageValvula Mariposa Con Volante Ranura 250LBS Mech D381X4almacen911listoNo ratings yet

- Concrete Pavement Design & Construction: Course Overview (2 Days)Document2 pagesConcrete Pavement Design & Construction: Course Overview (2 Days)Besim QelajNo ratings yet

- LysaghtRoofingWallingInstallationManualJul2015 PDFDocument68 pagesLysaghtRoofingWallingInstallationManualJul2015 PDFthailan100% (1)

- DWV Fittings List Price: Effective May 23,2022Document20 pagesDWV Fittings List Price: Effective May 23,2022Robert SmyserNo ratings yet

- Build Operate Transfer (BOT)Document25 pagesBuild Operate Transfer (BOT)Jim Juan OsmanNo ratings yet

- Geotechnical ManualDocument546 pagesGeotechnical Manualdavid gonzalez50% (2)

- Berkeley Glass PavillionDocument9 pagesBerkeley Glass PavillionFernando Rodríguez GonzálezNo ratings yet

- Shear WallDocument6 pagesShear WallAnantPawar100% (1)

- Colt ShaftDocument1 pageColt ShaftPJNo ratings yet

- Mci 2005Document3 pagesMci 2005Christos LeptokaridisNo ratings yet

- Scaffold Inspection Checklist 03 PDFDocument3 pagesScaffold Inspection Checklist 03 PDFTahir KhanNo ratings yet

- IRS Steel Bridge CodeDocument25 pagesIRS Steel Bridge Codeviv99844No ratings yet

- Q3 Competitive Price Is A Very Important Criteria To Win A Tender. A Tenderer Will HaveDocument2 pagesQ3 Competitive Price Is A Very Important Criteria To Win A Tender. A Tenderer Will HaveShunjie OoiNo ratings yet

- Road LabDocument298 pagesRoad LabAzmi BazazouNo ratings yet

- Guide To Lighting and Power Cables - The Engineering Mindset - Reader ViewDocument5 pagesGuide To Lighting and Power Cables - The Engineering Mindset - Reader ViewDenish SebastianNo ratings yet