Professional Documents

Culture Documents

Fan Motor Noise, Fan Impeller Turning: Source of Noise How/Why Noise Arises

Uploaded by

tood0 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

00521967

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageFan Motor Noise, Fan Impeller Turning: Source of Noise How/Why Noise Arises

Uploaded by

toodCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

key to figure

(a) cooking area

(b) cooker hood/canopy Cartridge filters

(c) grease filters Installed horizontally, cartridge filters comprise a high velocity slot opening on to a

(d) coarse pre-filter series of baffles which cause air to change direction four times compared to only

(e) fine pre-filter twice in a conventional baffle filter. The cartridge filters are installed over the full

(f) activated carbon filters length of the extract plenum and should be sloped to allow trapped grease to fall

(g) fan/motor unit through a drain to a grease drawer. These filters are intended for heavy grease

(h) lagging loads. Having a higher velocity enables lower air volumes to be used. Air balancing

(i) anti- vibration mounting is required to prevent carry over of grease.

(j) noise attenuator (best located within the building)

(k) exhaust flue/stack Fine filtration;

A basic filtration system can be used to deal with a low intensity odour problem, but

Source of Noise How/Why Noise Arises more usually will form a protective pre-treatment step before an activated carbon

Extract/supply fan step.

Fan motor noise, Fan impeller turning

Typical problems encountered with commercial kitchen Recommendations for maintenance of odour control system

ventilation systems; For a system employing fine filtration and carbon filtration;

netcen, with the assistance of the cieh, contacted a number of local authorities to review • Change fine filters every two weeks

the types of problems encountered by council officers when dealing with odour and noise • Change carbon filters every 4 to 6 months

situations. a summary of this information gathering exercise is given in annex a. For a system employing ESP and other in line abatement systems:

responses were received from metropolitan and rural authorities. authorities from • Clean every 2-6 months

england, northern ireland, scotland and wales have been consulted

Noise reduction methods for various noise sources and

Ventilation systems are used; transmission paths;

linear extract method: each linear meter of active filter length is assigned a Reflected sound from walls, ceiling, and

vent rate depending on the vent canopy type. walls.Direct sound can be controlled only by

Recommended canopy type; selecting quiet equipment. Reflected

sound is controlled by adding sound

Canopy type Light duty Medium duty Heavy duty Extra heavy duty absorption to room and to location of

Wall mounted 0.23-0.31 (m3/s) 0.31-0.46(m3/s) 0.31-0.62 (m3/s) >0.54 (m3/s) equipment.

Noise reduction methods for various noise ources and

The dimensions of a canopy are dictated by the size of the catering equipment that it is

transmission paths

serving. the two criteria that have the most influence on the amount of air required for

effective ventilation are the plan dimensions and height. Description Noise reduction method

unless restricted by walls etc., the plan dimensions of the canopy should always exceed

the plan dimensions of the catering equipment by a minimum of 200mm on each free side Direct sound radiated from sound source Direct sound can be controlled only by

and by 300mm at the front and rear. dimensions at the side may needto be increased to ear. selecting quiet equipment. Reflected sound is

where high output equipment is located at the end of the cooking line-up. Reflected sound from walls, ceiling, and controlled by adding sound absorption to

walls. room and to location of equipment.

Where combination steamer and certain types of baking ovens are used, the

overhang at the front should be 600mm to cope with steam or fumes that arise when

the doors of the appliance are opened. Stack

Inadequate height of the discharge stack is one of the main reasons the emissions

The height of the canopy is governed by the height of the ceiling and the underside of the from a kitchen gives rise to odour nuisance. The stack design is paramount to

canopy should be located between 2000 and 2100 mm above the finished floor level. the achieving good dispersion. Good stack dispersion requires:

efficiency of canopies less than 400mm high are less than normal because the collection • The effective stack height (discharge height plus plume rise) must be high

volume is reduced. in these situations, the face velocity may need to be increased to enough to ensure that adequate dilution takes place before the plume interacts

0.5m/s to compensate. where the ideal flow rate cannot be achieved the size of the canopy with a receptor.

may be increased to aid capture. the ideal distance between the lowest edge of the grease • Discharge velocity influences the plume rise and therefore the effective stack

filter and the top of the cooking surface should be between 450mm to 1350mm. this is to height. The effective stack height can be estimated from:

avoid the risk of excessive temperatures or fire in the filter that could cause the extracted ÄH = 3W.d/U

grease to where,

vaporise and pass through to the ductwork. this dimension will vary with the type of W (m/s) is the efflux speed at the chimney top

cooking appliance and can be reduced where fire suppression equipment is installed, but U (m/s) is the wind speed at the height of the stack

should never be below 1350mm where mesh filters are installed. d (m) is the internal diameter of the stack

Ideally W/U should be greater than 4. If W/V is less than 1.5, then down wash

types of system are available: will occur resulting in a reduced effective stack height.

cassette system: is an integrated system incorporating partitioned or

dedicated extract and partitioned or dedicated supply. the systems are • The discharge to be outside the wake of nearby buildings. Discharging ventilation

modular and contain a number of cassettes of proprietary design, which air below a roof ridge may result in excessive entrainment within building down

filter and separate grease from the air prior to its exhaust. the grease is wash. In certain situations, the use of high velocity discharge systems can force

normally collected in a non-drip integral or perimeter trough for removal and the discharging plume out of the building wake.

cleaning. • The flow to be unimpeded. Cowls can increase the static pressure, noise,

materials of construction of canopy; potential down draught and risk of re-entry of the exhaust back into the building.

the food safety (general food hygiene) regulations[20] requires that in food Alternative stack terminals are available and include:

preparation areas: • terminals without integral drains e.g. reducing cone, solid top cones; and

'ceilings and overhead fixtures must be designed, constructed and finished to • terminals with integral drains e.g. open top cone and drain, induction types and

prevent the accumulation of dirt and reduce condensation, the growth of sleeve type.

undesirable moulds and the shedding of particles.' in relation to canopies, it is best • Straight and vertical discharge.

practice to use stainless steel especially if the relevant surface comes directly into contact Figure 4.5 shows examples of best stack design.

with food. typically canopies and other Guidance on stack requirements for commercial kitchens varies between Local

overhead fixtures are fabricated using ultra fine-grained stainless steel (grade 304). Authorities. The range of guidance issued by Local Authorities is summarised below:

higher grades of stainless steel may also be specified. • Guidance on the minimum stack height ranges from:

• 1 m above the eaves of the premises and/or above any dormer window;

Other best practice guidelines include: • 1 m above ridge height of any building within 15 m; and

where air must be equalised within a supply plenum of a canopy 0.8 mm • low level discharge should be avoided.

perforated stainless steel sheet should be used. in addition, care should be • The height of external ground level should be taken into account when setting

taken to ensure that the face velocity is about 0.7 m/s. noise generation stack height. This is particularly important on rising ground where houses may be

increases when velocities of 0.9 m/s are exceeded. located above the discharge.

• discharge grills on make-up air system should be fabricated with 1mm • A stack should be positioned to be as far as possible from the nearest residential

perforated stainless steel sheet. accommodation.

• condensation should be avoided in canopies that are provided with supply • A stack discharging into a semi-enclosed area such as a courtyard or the area

plenum. where insulation is used it should: between back additions should be avoided.

• be a rigid foil faced non fibrous slab, with a class 1 spread of flame; and • Use of Chinaman's hats or other cowls is not recommended.

• not be fibre based as this could contaminate food. • The prevailing wind direction should also be considered in the ducting positioning.

Fan; • The ducting should be rigid in construction and resiliently mounted.

kitchen ventilation systems often have relatively high resistance against which a fan • Large section ducts may need bracing or stiffeners to prevent drumming.

has to operate. therefore, fans need to be sized to cope with a design pressure of a In certain instances restriction on stack height might arise, for example:

minimum additional 10% pressure margin. care must to be taken: • Where an A3 premises is a listed building and a visible stack is prohibited;

• to ensure operational changes e.g. build up of dirt on mesh filters are taken into • Where an A3 premises is located within a conservation area and a visible stack is

account; and prohibited; and

• if changes are made to the ventilation system that may alter the operating • Operators of the A3 premises do not have legal right to attach a stack to upper

pressure. floors of building.

to overcome such changes variable speed control or balancing dampers may be

used. a range of impeller designs is available as follows: Motor Frame Size and type;

• backward curved centrifugal, mixed flow or axial flow impellers are preferred as

they are less prone to imbalance and are easier to clean and maintain due to Code Speed Max. Pitch Motor Motor Full Load Starting Efficiency Power

their open construction. rev/min Angle (°) Rating (kW) Current (A) Current d.o.l. (A) % Factor cos Ø

• fixed or adjustable metal impellers are recommended.

• lightweight multi-vane or plastic-type impellers can warp and are prone to 50JM.BIF/20/4/6 1440 20 DA71MAC 0.37 1.1 4.9 69 0.71

collecting grease. although plastic bladed fans can be used in non-grease, low

temperature situation.

the fan must be able to operate at between 40o and 60o at 95% relative humidity.

motors should be rated to ip55. where fan motors sit within warm moist air streams,

they should be upgraded to withstand more onerous conditions. to avoid excessive

temperature build-up, temperature detectors should be fitted.

drain holes should be provided at the lowest point in the fan housing to remove

condensation. care needs to be taken to ensure that the drain hole does not

downgrade the index of protection (ip) of the motor.

dual or variable speed regulation are widely used. the fan must always operate at its

design duty, especially when grease is being produced. a minimum extract level

should be set within the speed regulator to ensure that, even at low speed, an

adequate rate of ventilation is maintained. speed regulation should be applied to both

make-up air and extraction air. speed regulation cannot be employed with water

wash/cartridge systems as flow rates are fixed.

make-up and extract fan operation should be interlocked with gas supply, so that gas K

supply is switched off if the fans fail. fans should be isolated when fire a

FAN/ MOTOR UNIT

suppression system is activated. EXHAUST FLUE/STACK

SIMPLE PHASE CENTRIFUGAL FAN

the connection between ductwork and fan housing should be suitable for use in NOISE ATTENUATOR

(RD 2854,

152KW,1120 RPM, 2000 CFM, 1.6

grease-laden atmospheres and at duct temperature. joints must be clamped or (BEST LOCATED WITHIN J WG) IN ACOUSTIC BOX x 45 DBA

bonded to prevent air leakage. under fire conditions the material should have a THEBUILDING) WIHT FLEXIBLE

ISOLATOR UNITS TO DUCT COARSE PRE-FILTER

minimum integrity of at least 15 minutes. CONNECTIONS

FINE PRE-FILTER

ANTI-VIBRATION GREASE FILTERS

H

Fan type Advantages Disadvantages MOUNTING

I

G F E D

Roof Extract Good temp range when motor is Temperature limitations, but C

COOKER HOOD/

Fans (Vertical Jet Discharge outside of air stream suitable for kitchen use. ACTIVATED CARBON B CANOPY

DRAINAGE LAGGING

with Centrifugal Impellers) Easy removal for cleaning and Requires good roof access for OULET FILTERS

maintenance maintenance

No space restrictions More expensive than inline/ COOKING AREA

A

Good external appearance axial models

No discharge ductwork required

SCHEMATIC DIAGRAM OF A TYPICAL KITCHEN

Coarse or Grease filtration

VENTILAION SYSTEM

Filter type Recommended Face Velocity Typical Advantages Disadvantages

(m/s) Efficiency

Cartridge 4.5-5.5 90-95% Higher efficiency High pressure

(at entry) Non-overloading drop Special

pressure drop plenum

fabrication required

You might also like

- CatalogueDocument6 pagesCatalogueRakesh RanjanNo ratings yet

- Noise Control ArticleDocument4 pagesNoise Control ArticleDavid JayNo ratings yet

- HVAC Silencer GuideDocument7 pagesHVAC Silencer GuideSelva Kumar Selva KumarNo ratings yet

- KITCHEN EXHAUST ISSUES AND SOLUTIONSDocument3 pagesKITCHEN EXHAUST ISSUES AND SOLUTIONSkktayNo ratings yet

- Sound ReductionDocument11 pagesSound ReductionWilliam GrecoNo ratings yet

- Control Design For Steam Vent Noise in Refineries (HP)Document2 pagesControl Design For Steam Vent Noise in Refineries (HP)jdgh1986No ratings yet

- 20 Kitchen Canopy Fan SolutionsDocument2 pages20 Kitchen Canopy Fan SolutionsImranAtheeqNo ratings yet

- Placa Acustica SiniatDocument4 pagesPlaca Acustica SiniatWilliams InquillaNo ratings yet

- 893 Low Noise Solutions For Turbine Bypass To Air Cooled CondensersDocument10 pages893 Low Noise Solutions For Turbine Bypass To Air Cooled CondensersfelramNo ratings yet

- Noise Reduction Barriers for Mechanical EquipmentDocument33 pagesNoise Reduction Barriers for Mechanical EquipmentAditha Varma RajaNo ratings yet

- Silencing Blower Noise with Proper Silencer SelectionDocument3 pagesSilencing Blower Noise with Proper Silencer Selectionkanito1No ratings yet

- Gas Cleaning TechnologyDocument6 pagesGas Cleaning TechnologyKaneNo ratings yet

- Design DuctsDocument15 pagesDesign DuctsAbdul WahabNo ratings yet

- FCU Acoustic Guide Nov09 PDFDocument18 pagesFCU Acoustic Guide Nov09 PDFprasathinusaNo ratings yet

- Air-Inlet Grille FlowGrid enDocument8 pagesAir-Inlet Grille FlowGrid enspscribd1No ratings yet

- Leaflet Vent Eng RGBDocument2 pagesLeaflet Vent Eng RGBEmrah MertyürekNo ratings yet

- AeroPac BrochureDocument4 pagesAeroPac BrochureRenzo ArangoNo ratings yet

- Catalogue Valve Silencers Valvulas NacionalDocument4 pagesCatalogue Valve Silencers Valvulas Nacionaltiffanyyy00No ratings yet

- Guia para Diseño de VentilacionDocument1 pageGuia para Diseño de VentilacionNelson VargasNo ratings yet

- Project Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al UlaDocument2 pagesProject Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al Ulathahar ali syedNo ratings yet

- Noise PredictionDocument34 pagesNoise Predictionfabyano100% (1)

- Duct TypesDocument4 pagesDuct Typeschathura buddhikaNo ratings yet

- DBlue Brochure - Under SlabDocument12 pagesDBlue Brochure - Under SlabbcsmurthyNo ratings yet

- B3636-1 PDS Vacuload-1 AUDocument1 pageB3636-1 PDS Vacuload-1 AUwanfaroukNo ratings yet

- AstroPure 1700V BrochureDocument2 pagesAstroPure 1700V Brochurem.indrajayaNo ratings yet

- AW240 190 Gaggenau Specifications SheetDocument2 pagesAW240 190 Gaggenau Specifications SheetFrederick CooryNo ratings yet

- Air Filters - at Inlet SideDocument7 pagesAir Filters - at Inlet SideSudeep SNo ratings yet

- Recent Advances Turbine BypassDocument4 pagesRecent Advances Turbine BypassretrogradesNo ratings yet

- Acouistics 1Document10 pagesAcouistics 1mohamedmustafa.1422No ratings yet

- TROX Sound and SenseDocument18 pagesTROX Sound and SenseDemir DökenNo ratings yet

- Two Types of Silencers and Their Acoustic PerformanceDocument6 pagesTwo Types of Silencers and Their Acoustic PerformanceShiva KrishnanNo ratings yet

- Low Noise Solutions For Turbine Bypass To Air-Cooled CondensersDocument10 pagesLow Noise Solutions For Turbine Bypass To Air-Cooled CondensersElavarasan Ramalingam100% (1)

- UNIT - Air Distribution SystemDocument33 pagesUNIT - Air Distribution SystemSumit KumarNo ratings yet

- Esco Pharmacon Downflow Booth, Model DFB-1.5S1-1-CDocument4 pagesEsco Pharmacon Downflow Booth, Model DFB-1.5S1-1-Caqeel1970No ratings yet

- Part 3 - Radiated SoundDocument4 pagesPart 3 - Radiated Soundsamir rabiaNo ratings yet

- Laminar Air FlowDocument9 pagesLaminar Air FlowsserzadNo ratings yet

- Kitchen Exhaust Filtration Unit: The Revolution in Air FiltrationDocument12 pagesKitchen Exhaust Filtration Unit: The Revolution in Air FiltrationMohammad SadikNo ratings yet

- IAC Duct SilencersDocument88 pagesIAC Duct SilencersPornlert Wana.No ratings yet

- Axminster 03 - Dust Extraction & Wood Waste - p109-p126Document18 pagesAxminster 03 - Dust Extraction & Wood Waste - p109-p126Pierre799esNo ratings yet

- Kitchen VentilationDocument45 pagesKitchen VentilationMyo Kyaw KyawNo ratings yet

- Presentationlu 180126221936 PDFDocument20 pagesPresentationlu 180126221936 PDFhaptoorNo ratings yet

- Enhance Mixing & Reduce Smoke from Flare StacksDocument20 pagesEnhance Mixing & Reduce Smoke from Flare Stacks12mchc07No ratings yet

- Pag 5, Tjernlund - Clothes - Dryer - Duct - Booster - Reference - Guide - 8500303Document8 pagesPag 5, Tjernlund - Clothes - Dryer - Duct - Booster - Reference - Guide - 8500303josebolis6550No ratings yet

- D296 - Barreira LinearDocument12 pagesD296 - Barreira LinearEvandro Eduardo Jr. CarvalhalNo ratings yet

- Callidus Flares Brochure PDFDocument5 pagesCallidus Flares Brochure PDFNurul Atiqah Ahmad KamalNo ratings yet

- 25 Important Design Considerations For A BlastroomDocument28 pages25 Important Design Considerations For A BlastroomVinay KUMAR N100% (1)

- Delham Engineering's Flare Package GuideDocument6 pagesDelham Engineering's Flare Package Guidesujaysarkar85No ratings yet

- Flare SystemsDocument38 pagesFlare Systemsanu malikNo ratings yet

- VENCO Articles Jet Fan System in Closed Car ParksDocument9 pagesVENCO Articles Jet Fan System in Closed Car ParksRuben AugustoNo ratings yet

- Tunnel Ventilation Design SolutionDocument27 pagesTunnel Ventilation Design SolutionRitesh Singh100% (1)

- Fire Rated Duct PDFDocument6 pagesFire Rated Duct PDFa.m.zainNo ratings yet

- Vibration Isolation For Noise Control in Residential Condensing UnitsDocument7 pagesVibration Isolation For Noise Control in Residential Condensing Unitsshank100No ratings yet

- Bag Filters Remove 99% of ParticulatesDocument5 pagesBag Filters Remove 99% of ParticulatesselamitspNo ratings yet

- HVAC NoiseDocument41 pagesHVAC Noisesp su100% (3)

- LIGNO Compact-Filter EnglischDocument6 pagesLIGNO Compact-Filter EnglischMagdalenaNo ratings yet

- Packed Bed Tower ScrubbersDocument8 pagesPacked Bed Tower ScrubbersDota NgNo ratings yet

- Enclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameDocument4 pagesEnclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameT. LimNo ratings yet

- 9.6.3 Execution: Schedule 3 020 Technical SpecificationsDocument1 page9.6.3 Execution: Schedule 3 020 Technical SpecificationstoodNo ratings yet

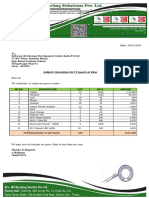

- Quotation.: Asiathai Engineering Co., LTDDocument4 pagesQuotation.: Asiathai Engineering Co., LTDtoodNo ratings yet

- NIH Local Exhaust Ventilation Testing ProtocolsDocument18 pagesNIH Local Exhaust Ventilation Testing ProtocolsEmmanuel WinfulNo ratings yet

- Guidelines For Kitchen Exhaust HoodsDocument6 pagesGuidelines For Kitchen Exhaust Hoodssirius64No ratings yet

- Extraction Canopy CalculationsDocument1 pageExtraction Canopy CalculationstoodNo ratings yet

- AV 18 C6 Unmarked DrawingDocument1 pageAV 18 C6 Unmarked DrawingtoodNo ratings yet

- AV 18 C6 Unmarked DrawingDocument1 pageAV 18 C6 Unmarked DrawingtoodNo ratings yet

- (2a8d70ee) Root Ais Playbox V2 APK 2019-2020 (Latest Version) - Updated 16 November 2021Document2 pages(2a8d70ee) Root Ais Playbox V2 APK 2019-2020 (Latest Version) - Updated 16 November 2021toodNo ratings yet

- Hood Design Data - Range of Capture VelocitiesDocument3 pagesHood Design Data - Range of Capture VelocitieszshehadehNo ratings yet

- AV 18 C6 Unmarked DrawingDocument1 pageAV 18 C6 Unmarked DrawingtoodNo ratings yet

- AV 18 C6 Unmarked DrawingDocument1 pageAV 18 C6 Unmarked DrawingtoodNo ratings yet

- Toshiba LCD TV-DVD 17HLV85 - SVMDocument134 pagesToshiba LCD TV-DVD 17HLV85 - SVMJose Angel Coronel SanchezNo ratings yet

- Cioks DC7Document2 pagesCioks DC7Mac MiñaNo ratings yet

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- Quantel Optimis II Service Manual 11 20Document10 pagesQuantel Optimis II Service Manual 11 20Vladimir LevchenkoNo ratings yet

- Student's ReflectionDocument2 pagesStudent's ReflectionRex MagsipocNo ratings yet

- Resume of Jhune Perez RTDocument2 pagesResume of Jhune Perez RTByahe Ni GeloNo ratings yet

- 3 - MT 103 - 202 Base Procedure For Receiver Review and Comments AoDocument4 pages3 - MT 103 - 202 Base Procedure For Receiver Review and Comments Aouink wowNo ratings yet

- Blank Letterhead..... PDF - 20240120 - 143356 - 0000Document1 pageBlank Letterhead..... PDF - 20240120 - 143356 - 0000jrsrecyclingltdNo ratings yet

- 21290f PDFDocument40 pages21290f PDFАндрій БілявськийNo ratings yet

- Numerical Methods Project TemplateDocument14 pagesNumerical Methods Project TemplateMikaela Dela CruzNo ratings yet

- BT5 - Wall Panel SystemsDocument5 pagesBT5 - Wall Panel SystemsJansen RosillaNo ratings yet

- Energy Hakan Aygun MakaleDocument18 pagesEnergy Hakan Aygun MakaleIsmail EkmekciNo ratings yet

- Panasonic VP-7721A Audio Analyzer Instruction ManualDocument74 pagesPanasonic VP-7721A Audio Analyzer Instruction ManualLY ChinNo ratings yet

- Give at Least 10 Advantages Aasdnd 10 Disadvantages of Steel As A Structural MaterialDocument4 pagesGive at Least 10 Advantages Aasdnd 10 Disadvantages of Steel As A Structural MaterialAdvincula Jericson79% (14)

- Native Instruments Guitar Rig TutorialsDocument12 pagesNative Instruments Guitar Rig TutorialsEmre AlaçayırNo ratings yet

- TLC Online Learning Packs Brochure 2020Document20 pagesTLC Online Learning Packs Brochure 2020trongnvtNo ratings yet

- Power System Protection Lab: Department of Electrical EngineeringDocument33 pagesPower System Protection Lab: Department of Electrical EngineeringBharat Kumar PrajapatiNo ratings yet

- Alcatel Phones T76 Spec Sheet ENDocument2 pagesAlcatel Phones T76 Spec Sheet ENissam hmirouNo ratings yet

- Electric Application Solution ExpertDocument21 pagesElectric Application Solution ExpertChonticha ChobsonNo ratings yet

- Excel CheatsheetDocument1 pageExcel CheatsheetBoring BlandNo ratings yet

- Example of 500 Word EssayDocument8 pagesExample of 500 Word Essaylud0b1jiwom3100% (2)

- RamchanderRaoKrishnamraj SAPABAP HyderabapDocument5 pagesRamchanderRaoKrishnamraj SAPABAP HyderabapAmit MahajanNo ratings yet

- Eee421: Power Electronics: Power Semiconductor Devices: MOSFETDocument9 pagesEee421: Power Electronics: Power Semiconductor Devices: MOSFETRafat ShamsNo ratings yet

- Standby Leakage Power Reduction in Digital CircuitsDocument4 pagesStandby Leakage Power Reduction in Digital CircuitsmadhuNo ratings yet

- PC400 8 1Document549 pagesPC400 8 1Eka Anwar100% (1)

- Computer Science (2210) Sample Paper For O Level 2Document9 pagesComputer Science (2210) Sample Paper For O Level 2Mehwish TahirNo ratings yet

- Combined Assignment For Supply Chain Operations ManagementDocument22 pagesCombined Assignment For Supply Chain Operations ManagementAbood Thekrallah100% (2)

- Kandi. Sai Pavan Kumar: Career ObjectiveDocument2 pagesKandi. Sai Pavan Kumar: Career ObjectiveSai PavanNo ratings yet

- Rcra Online: Howdoiuse Advanced Search?Document2 pagesRcra Online: Howdoiuse Advanced Search?Franklin Crespo AmoresNo ratings yet

- Clone WarsDocument30 pagesClone Warsapi-652369770No ratings yet