Professional Documents

Culture Documents

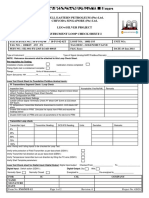

Ip Control Valve Calibration Form

Ip Control Valve Calibration Form

Uploaded by

MGHIRBI HAYKEL0 ratings0% found this document useful (0 votes)

5 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageIp Control Valve Calibration Form

Ip Control Valve Calibration Form

Uploaded by

MGHIRBI HAYKELCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Project No:

INSPECTION & TEST RECORD

INSTRUMENT Project Name:

CALIBRATION

Document No:

(CONTROL VALVE)

1 Tag Number: System:

2

3 Manufacturer: Data Sheet No:

4

5 Model Number: P&ID No:

6

7 Range: Eng Unit: Layout Drawing No:

8

9

10 PUNCH

ITEMS OK N/A

11 ITEM

12 INSPECTION CHECKLIST

13 Check Instrument tagplate details against data sheet

14 Check Instrument has no physical damage

15 Check no water ingress/condensation

16 CALIBRATION

17 Operate the valve by stroking 0, 25, 50, 75, 100, 75, 50, 25% of travel

18 Check valve fail position against instrument data sheet by removing electrical signal

19

20 Check valve fail position by isolating instrument air/hydraullics source to valve

21 Check control valve accessories for condition and correct operation such as positioner, limit

22 switch, air filter regulator, solenoid valve, etc

23

24 Valve supply pressure Bench set pressure

25

26 Positioner or I/P transducer supply pressure Valve travel

27

28 Test medium Electrical Power Suppy

29

30 Fail Close/Fail Open Fail position time

31

32 Accessories operation Positioner

33

34 Air Filter Regulator

35

36 Limit Switch

37

38 Others Solenoid Valve

39

40

41

Rising (%) Falling (%)

42

43 0 25 50 75 100 75 50 25 0

44 input mA

45

46 valve position

47

48

Completed By Witnessed By Accepted By

Name

Sign

Date

You might also like

- Mission Control Center Familiarization ManualDocument159 pagesMission Control Center Familiarization ManualBob AndrepontNo ratings yet

- Subsea 8 Important PDFDocument64 pagesSubsea 8 Important PDFKester NdabaiNo ratings yet

- Problem Solving Basic 7 QC ToolsDocument53 pagesProblem Solving Basic 7 QC Toolsshukumar_24100% (4)

- Calibration Format ReportDocument3 pagesCalibration Format ReportNugraha Munthe100% (1)

- Pressure Gauge Calibration & Inspection Checklist: AbnormalityDocument2 pagesPressure Gauge Calibration & Inspection Checklist: Abnormalityelisha100% (1)

- 2d Auto Cad Tutorial PemulaDocument342 pages2d Auto Cad Tutorial PemulaNur KhoirNo ratings yet

- Pressure Calibration Application Selection Guide UsdDocument32 pagesPressure Calibration Application Selection Guide UsdAli ElsgheirNo ratings yet

- Loop Test Sheet PDFDocument1 pageLoop Test Sheet PDFTrí NguyễnNo ratings yet

- LoopCheckProcedure E1Document3 pagesLoopCheckProcedure E1mc_prayer50% (2)

- Instrument Calibration ChecklistDocument11 pagesInstrument Calibration ChecklistMohd A IshakNo ratings yet

- How To Calibrate VEGA LT PDFDocument4 pagesHow To Calibrate VEGA LT PDFDeny SafariNo ratings yet

- Isolation Valve Check ListDocument2 pagesIsolation Valve Check ListAhmed KhairiNo ratings yet

- Calibration Techniques and Process: Abdul Latif, Pe H (NI)Document69 pagesCalibration Techniques and Process: Abdul Latif, Pe H (NI)Engr Umair AzizNo ratings yet

- Check List Junction BoxDocument9 pagesCheck List Junction BoxAldeline SungahidNo ratings yet

- Method Statement For Instrument CalibrationDocument14 pagesMethod Statement For Instrument CalibrationFredric Tun100% (2)

- Instrument Calibration Test Report FormatDocument8 pagesInstrument Calibration Test Report FormatRaj Kiran100% (9)

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiNo ratings yet

- A Simple Pressure Safety Valve Calibration ProcedureDocument5 pagesA Simple Pressure Safety Valve Calibration ProcedureBaran Shafqat0% (1)

- Check List Instrument - NewDocument1 pageCheck List Instrument - NewAldeline SungahidNo ratings yet

- Calibration of Pressure GaugeDocument2 pagesCalibration of Pressure GaugeLugabalugaNo ratings yet

- Chapter 5Document55 pagesChapter 5Arjun Kumar100% (1)

- Ip Transmitter Calibration FormDocument1 pageIp Transmitter Calibration Formعماد صدقيNo ratings yet

- French LanguageDocument16 pagesFrench LanguageKester NdabaiNo ratings yet

- Calibration of Smart TransmittersDocument4 pagesCalibration of Smart TransmittersLugabalugaNo ratings yet

- Basic Principles of Instrument CalibrationDocument6 pagesBasic Principles of Instrument CalibrationLugabaluga100% (1)

- Instr Loop CheckDocument3 pagesInstr Loop CheckMiko Quijano100% (1)

- Control Valve Calibration Procedure (Fisher HC6010)Document14 pagesControl Valve Calibration Procedure (Fisher HC6010)Karen Cain93% (15)

- Loop Checking Basic ProcedureDocument4 pagesLoop Checking Basic ProcedureHamada Elsharawy100% (1)

- Calibration All PDFDocument42 pagesCalibration All PDFMubasher92% (13)

- Procedures For Lube Oil CommissioningDocument3 pagesProcedures For Lube Oil Commissioningavciay100% (1)

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Loop Test ReportDocument7 pagesLoop Test ReportAldeline Sungahid100% (1)

- Interview Questions InstrumentationDocument22 pagesInterview Questions Instrumentationeeyo_ken80% (5)

- Instrumentation TestingDocument24 pagesInstrumentation Testingaugur886No ratings yet

- SATR-J-6512 - Rev 0 PDFDocument5 pagesSATR-J-6512 - Rev 0 PDFAdel KlkNo ratings yet

- Instrument Check ListDocument19 pagesInstrument Check ListFarhan KhanNo ratings yet

- Flow & Level Calibration Notes: Differential Pressure Transmitter CalibrationDocument9 pagesFlow & Level Calibration Notes: Differential Pressure Transmitter Calibrationterio16100% (1)

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- Calibration Procedure of A Control ValveDocument12 pagesCalibration Procedure of A Control ValveAbdNo ratings yet

- 2 - ARM Cotex-M3 - IntroductionDocument124 pages2 - ARM Cotex-M3 - IntroductionNghĩa VũNo ratings yet

- Feasibility Study For Small Scaling Flywheel-Energy-Storage Systems in Energy Harvesting SystemsDocument9 pagesFeasibility Study For Small Scaling Flywheel-Energy-Storage Systems in Energy Harvesting SystemsshawnleegabrielNo ratings yet

- Instrumentation Switch ChecklistDocument5 pagesInstrumentation Switch Checklistrenjithv_4No ratings yet

- Instrumentation Job Interview Preparation GuideDocument11 pagesInstrumentation Job Interview Preparation GuideJignesh Banava100% (1)

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Ip Control Valve Calibration FormDocument1 pageIp Control Valve Calibration FormKester Ndabai50% (2)

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (2)

- 9.9 Differential Pressure TransmittersDocument99 pages9.9 Differential Pressure TransmittersorazioconiglioNo ratings yet

- Yokogawa Differential Pressure TransmitterDocument18 pagesYokogawa Differential Pressure Transmitterprasanna1990No ratings yet

- The Pastoral EpistlesDocument8 pagesThe Pastoral EpistlesKester Ndabai100% (1)

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- 5W 7H 7Z DMS Service D5W-40-025 Rev.ØDocument426 pages5W 7H 7Z DMS Service D5W-40-025 Rev.ØRubén DíazNo ratings yet

- Calibration of Absolute Pressure TransmitterDocument4 pagesCalibration of Absolute Pressure Transmitterget_engineer05No ratings yet

- Calibration ReportDocument13 pagesCalibration ReportAldeline SungahidNo ratings yet

- Functional Test ProcedureDocument5 pagesFunctional Test ProcedureKhalilahmad Khatri33% (3)

- I-004 Control Valve Calibration RecordDocument1 pageI-004 Control Valve Calibration RecordAr RahmanNo ratings yet

- BeneviewT8 Service ManualDocument228 pagesBeneviewT8 Service Manualjavier_valdivia_42No ratings yet

- Control Valve CalibrationDocument3 pagesControl Valve CalibrationsujitNo ratings yet

- PLGC II Manual - Board Rev 1bDocument113 pagesPLGC II Manual - Board Rev 1bEka Pramudia Santoso100% (2)

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakNo ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- 03.QSP-QC-003-Transmitter Calibration Procedure With RTD & TCDocument2 pages03.QSP-QC-003-Transmitter Calibration Procedure With RTD & TCMangesh MohiteNo ratings yet

- 4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The ComplexDocument5 pages4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The Complexkirandevi1981No ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Unit Num # Title Page #: Technical InformationDocument5 pagesUnit Num # Title Page #: Technical InformationJamil WarrenNo ratings yet

- Information and Inspection: Type of Test: Service Test / Leak TestDocument2 pagesInformation and Inspection: Type of Test: Service Test / Leak TestNorman MoralesNo ratings yet

- Pressure IndicatorDocument8 pagesPressure Indicatorabi ridwan davidsNo ratings yet

- Appendix G - All FTPDocument81 pagesAppendix G - All FTPRaja AntonyNo ratings yet

- Power Generation Service Checklist: # Items To Be Check Procedure Initials RemarksDocument1 pagePower Generation Service Checklist: # Items To Be Check Procedure Initials RemarkstorjaniceNo ratings yet

- 19dk - IOMDocument42 pages19dk - IOMPraveesh ThomasNo ratings yet

- Case StudyDocument11 pagesCase StudyKester NdabaiNo ratings yet

- Parker Alok Bible (Web)Document220 pagesParker Alok Bible (Web)Kester NdabaiNo ratings yet

- Design and Simulation of 60kWp Solar On-Grid System For Rural Area in Uttar-Pradesh by "PVsyst"Document13 pagesDesign and Simulation of 60kWp Solar On-Grid System For Rural Area in Uttar-Pradesh by "PVsyst"fatemeh mohammadiNo ratings yet

- 4.trends in HDLDocument13 pages4.trends in HDLRamesh NairNo ratings yet

- William Stallings Computer Organization and Architecture 6 EditionDocument52 pagesWilliam Stallings Computer Organization and Architecture 6 EditionRahmat RafliNo ratings yet

- BK4811B Datasheet V1.2Document37 pagesBK4811B Datasheet V1.2BradMorse50% (2)

- 7 Watt Class-A Audio Amplifier - RED - Page177Document3 pages7 Watt Class-A Audio Amplifier - RED - Page177Antonio José Montaña Pérez de CristoNo ratings yet

- Gujarat Technological University: Electronics and Communication Engineering Subject Code: B.E. 8 SemesterDocument4 pagesGujarat Technological University: Electronics and Communication Engineering Subject Code: B.E. 8 Semestermehul03ecNo ratings yet

- Differential Characteristic Test: DescriptionDocument2 pagesDifferential Characteristic Test: DescriptionCorey PorterNo ratings yet

- Hc-E098t OspDocument18 pagesHc-E098t OspĐỗ BìnhNo ratings yet

- Sacredsun Manual BookDocument36 pagesSacredsun Manual BookRandy RNo ratings yet

- Revolutionary Triangular Patch Antenna With Dumbbell-Shaped Defected Ground Structure For 5G at 3.7 GHZ: A Disruptive Design InnovationDocument6 pagesRevolutionary Triangular Patch Antenna With Dumbbell-Shaped Defected Ground Structure For 5G at 3.7 GHZ: A Disruptive Design InnovationMohd Azlishah OthmanNo ratings yet

- 857 Um001 - en P PDFDocument504 pages857 Um001 - en P PDFdhairyashil_dspNo ratings yet

- Ethernet: Outline Multiple Access and Ethernet Intro Ethernet Framing CSMA/CD Protocol Exponential BackoffDocument25 pagesEthernet: Outline Multiple Access and Ethernet Intro Ethernet Framing CSMA/CD Protocol Exponential BackoffcheckNo ratings yet

- Haier Y11B User GuideDocument27 pagesHaier Y11B User GuideSbykyNo ratings yet

- ATmega 8Document96 pagesATmega 8Narendra Kumar KommineniNo ratings yet

- A 106 NW 10 B 80 Ks/s SAR ADC With Duty-Cycled Reference Generation in 65 NM CMOSDocument11 pagesA 106 NW 10 B 80 Ks/s SAR ADC With Duty-Cycled Reference Generation in 65 NM CMOSSilpa VelagaletiNo ratings yet

- Titan Spec Sheet PDFDocument2 pagesTitan Spec Sheet PDFFreddy Javier ManzanaresNo ratings yet

- Copie de Tarif - ABB - KAUFEL - 2019 - 02 - v3Document207 pagesCopie de Tarif - ABB - KAUFEL - 2019 - 02 - v3ABELWALIDNo ratings yet

- DANEO 400: Hybrid Signal Analyzer For Power Utility Automation SystemsDocument16 pagesDANEO 400: Hybrid Signal Analyzer For Power Utility Automation SystemsAndrew SetiawanNo ratings yet

- LinkedIn Group Technical DiscussionsDocument5 pagesLinkedIn Group Technical DiscussionsVitthal PatnechaNo ratings yet

- Electricity and Magnetism by MIT For Edx CourseDocument57 pagesElectricity and Magnetism by MIT For Edx CourseHarsh JaiswalNo ratings yet

- Ac Fundamentals: by Nagaling GuravDocument31 pagesAc Fundamentals: by Nagaling GuravNagalingNo ratings yet

- Chaitanya Prasad ResumeDocument3 pagesChaitanya Prasad ResumeChaitanya PrasadNo ratings yet

- Course Name: Digital Electronics Circuits Course Code: EC (EE) 302 Credit: 3Document7 pagesCourse Name: Digital Electronics Circuits Course Code: EC (EE) 302 Credit: 3Naimul HasanNo ratings yet

- Cat Sensor 242Document42 pagesCat Sensor 242Ramesh KrishnamoorthyNo ratings yet

- WorkshopDocument5 pagesWorkshopgopalgeniusNo ratings yet