Professional Documents

Culture Documents

MDNQT1017 - SQA PPAP Checklist

Uploaded by

krds chidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDNQT1017 - SQA PPAP Checklist

Uploaded by

krds chidCopyright:

Available Formats

Supplier Quality Assurance

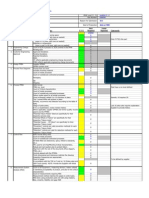

Production Part Approval Process (PPAP) Submission Checklist

Part Number: Part Description:

Vendor Code: Supplier:

Drawing Number: Revision:

Tool/Cavity #

Date Reviewed: Reviewed By:

Check Box as

PPAP LEVEL

Appropriate Reason for Submission:

LEVEL 1 (Sections 1 & 2 only) NOTICE: PPAP submission is to be made according to the AIAG Production Part Approval Process (PPAP) manual. Refer to Retention/Submission requirements table 4.2 in AIAG

LEVEL 2 (Sections 1-8) PPAP manual section for detailed submission requirements for each level. This document should be used as a reference guide only and does not supersede the requirements set

forth in the AIAG PPAP manual.

LEVEL 3 (All Sections)

LEVEL 4 (As defined)

* Please allow a minimum of one week for processing. Ensure you have adequate inventory to support shipment until the PPAP is processed and approved.

LEVEL 5 (All Sections)

Documentation Evaluation Criteria: If that specific evaluation criteria is highlighted in yellow and the supplier's results are not acceptable, this constitutes as a PPAP REJECTION. A limited/interim approval will not be authorized. It will be at the Supplier

Quality Engineer's direction as to whether the remaining items constitute a rejection or limited/interim approval.

SECTION 1 - WARRANT FORM

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

1.1 There is a supplier Part Submission Warrant Form included in the submission.

1.2 Current revision of the AIAG warrant form is used

1.3 The heading is accurately & fully completed. Include multiple buyer & application information if available.

1.4 The “Results” and “Declaration” are properly completed (e.g. all applicable blocks must be check marked) and

the form is signed and dated. Electronic submissions require an authorized signature.

1.5 Identifies applicable tool/cavity number

SECTION 2 – INTERNATIONAL MATERIAL DATA SYSTEM (IMDS)

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

2.1 ID version number from IMDS system and printed report detailing tree specifics is included in the package.

SECTION 3 - APPEARANCE APPROVAL REPORT (AAR)

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

3.1 If part is an appearance item, there is an AAR included in the package and includes the following:

a. Tool Source b. Type of Tool Steel c. No. Tools d. No. of Cavities

e. Texture Type f. Texture Source g. Gloss h. Material

i. Material Spec j. Paint Spec k. Performance Spec l. Painter (if outsourced)

Location and Doc.#: file:///conversion/tmp/activity_task_scratch/579376411.xls

Sheet: MDNQT1017

Attachment to AWI 3-15-SQA-007

Form Rev. Date: 4/6/10

Page 1 of 5

SECTION 4 – SAMPLES

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

4.1 There are two samples of each process stream and/or cavity which represent the production part Quality

capabilities (unless otherwise directed by the appropriate Magna Mirrors SQA representative). These samples must

be properly identified in the package (e.g. tagged or marked with Magna Mirrors part number, revision level, cavity

number, etc.).

4.2 Samples provided are not visually different when compared to the previous level or supplied component.

4.3 A sufficient number of samples have been run through Newaygo’s assembly operation in a Manufacturing Line

Trial with no issues or concerns. (Magna Mirrors use only)

SECTION 5 - CHECKED DRAWINGS OR SKETCHES

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

5.1 A Magna Mirrors approved drawing (i.e. as stated on P.O.) which matches the Magna Mirrors Engineering

release level is included in the package. All Dimensions, characteristics, and notes are numbered for use with the

inspection reports. (If the drawing does not match the part revision level of the submission reference Section 6).

SECTION 6 - CHANGE DOCUMENTS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

6.1 If drawing is “marked up” to a part revision level different than the submission level it must be signed by a

Magna Mirrors Project Engineer and include the Magna Mirrors Engineering Change Order number (EO#). A copy

of the approved EO should be included in the submission.

SECTION 7 – DIMENSIONAL RESULTS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

7.1 There is a signed and dated Dimensional Inspection Report included in the submission. Use of the AIAG format

is recommended.

7.2 The heading is accurately & fully completed.

7.3 All dimensions on the appropriate blueprint are listed exactly as stated (i.e. in the metric system) under

“Dimension/Specification”. All notes must be included. Reference and basic dimensions do not need to be listed

on the report.

7.4 Results for all dimensions are reported on 3 to 6 parts per cavity as agreed upon with the appropriate Magna

Mirrors SQA representative.

7.5 All dimensions meet print requirements or change documents per section 5.

7.6 The supplier’s results are consistent with Magna Mirrors' findings. (Magna Mirrors' use only)

SECTION 8 – CHECKING AIDS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

8.1 If checking aids (fixtures, etc.) were requested by the appropriate Magna Donnelly SQA representative, they are

included with submission package.

8.2 Gage certification is provided if requested by the appropriate Magna Mirrors SQA representative.

Location and Doc.#: file:///conversion/tmp/activity_task_scratch/579376411.xls

Sheet: MDNQT1017

Attachment to AWI 3-15-SQA-007

Form Rev. Date: 4/6/10

Page 2 of 5

SECTION 9 – LABORATORY/FUNCTIONAL RESULTS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

9.1 There are actual test results for all chemical, physical, metallurgical, and performance requirements as

specified on the print provided on a signed and dated report, unless otherwise agreed upon with the appropriate

Magna Mirrors SQA representative. All applicable notes and specifications must be included in the report as well.

9.2 Supplier will summarize material and performance test results utilizing the forms as found in appendix D and

appendix E of the AIAG PPAP manual. A copy of the specification is to be included in the PPAP package and each

section of the specification is to be ballooned to match each line item as indicated on the results form.

9.3 The results are from an “Accredited”, TS 16949 or QS 9000 compliant Laboratory” (evidence may be required).

9.4 The results from a commercial laboratory shall be submitted on the laboratory’s letterhead, or on the normal

laboratory report format.

9.5 All laboratory and test results are less than one year old.

9.6 For all heat treated components, a CQI 9 audit form is completed and shows compliance to the Heat Treat

System Survey Guidelines. A copy of the CQI-9 Ford Specific Requirements must also be completed for all Ford

heat treated components, to ensure compliance to Ford's Heat Treat Specification W-HTX. The audits must be

uploaded onto Supplier Connection and updated on an annual basis. If supplier does not meet the requirements,

all nonconformances are documented and action plans are in place. To reduce the risk of embrittlement, heat-

treated steel components are required to conform with Ford material specification WSS-M99A3-A.

9.7 For all plated components, a CQI 11 audit form has been completed and shows compliance to the Plating

System Survey Guidelines. The supplier survey must be uploaded onto supplier connection and updated on an

annual basis. All nonconformances are documented and action plans are in place.

9.8 For all coated and painted components, a CQI 12 audit form has been completed and shows compliance to the

Coating System Survey Guidelines. The supplier survey must be uploaded onto supplier connection and updated

on an annual basis. All nonconformances are documented and action plans are in place.

9.9 All sub-suppliers of base materials and finishings (heat treat, plating, coating, etc.) must be on the approved

supplier list for the appropriate OEM.

SECTION 10 - PROCESS FLOW DIAGRAM

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

10.1 There is a Process Flow Diagram included in the submission.

10.2 The heading is accurately & fully completed. Should conform to the AIAG format.

10.3 Based on the blueprint and parts, the operation descriptions are clear & the process steps are all there &

follow a logical sequence.

10.4 Operation/Process steps correlate with PFMEA & Control Plan.

10.5 If PPAP is for transfer of part to new supplier or same supplier producing at a different location, SQE has

reviewed old and new process flow to ensure critical processes and characteristics have been considered.

(Magna Mirrors use only)

Location and Doc.#: file:///conversion/tmp/activity_task_scratch/579376411.xls

Sheet: MDNQT1017

Attachment to AWI 3-15-SQA-007

Form Rev. Date: 4/6/10

Page 3 of 5

SECTION 11 - FAILURE MODE AND EFFECTS ANALYSIS (FMEA)

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

11.1 There is a PFMEA (and Design FMEA if supplier has design responsibility) included in the submission which

conforms to the AIAG requirements, rating scales, etc.

11.2 All areas listed in the supplier’s Process Flow Diagram are included for failure analysis.

11.3 The heading is accurately & fully completed.

11.4 When the severity of a failure mode is 9 or 10, special attention must be given to ensure that the risk is

addressed through existing design actions/controls or process preventive/correction action(s), regardless of the

RPN. Once all severity rankings are lowered, then the supplier team should address other failure mode rankings in

occurrence, then detection.

11.5 All of the Magna Mirrors Safety and Critical Characteristics (MDS/MDC) identified on the drawing have been

listed on the FMEA.

11.6 If PPAP is for transfer of part to new supplier or same supplier producing at a different location, SQE has

reviewed old and new FMEA to ensure critical processes and characteristics have been considered. (Magna Mirrors

use only)

11.7 PFMEA Ratings for severities match the DFMEA. If the DFMEA is not available, ensure that all MDS and MDC

characteristics are scored appropriately (reference section 11.4). Ratings for occurences and detection may be

reduced through actions taken. Ratings for severities can not be reduced unless a failure mode is eliminated

through a design change.

SECTION 12 – PROCESS CONTROL PLAN

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

12.1 A process control plan is included in the submission.

12.2 The heading is accurately & fully completed. Should conform to the AIAG Advanced Product Quality Planning

and Control Plan Reference Manual

12.3 All of the Magna Mirrors Safety and Critical Characteristics (MDS/MDC) identified on the drawing have been

listed on the Control Plan.

12.4 All columns are completed for each item.

12.5 The type and frequency of controls are adequate to ensure product quality.

12.6 The Control Plan covers all parts of the process from receiving inspection through processing/assembly

including final packaging and any required annual validation.

12.7 If PPAP is for transfer of part to new supplier or same supplier producing at a different location, SQE has

reviewed old and new process flow to ensure critical processes and characteristics have been considered. (Magna

Mirrors use only)

12.8 All specification requirements are included on the control plan, and are checked at a minimum, on an annual

basis.

SECTION 13 – PROCESS PERFORMANCE CAPABILITY RESULTS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

13.1 Process Potential Studies have been performed for all agreed-upon Magna Donnelly Safety and Critical

Characteristics (MDS/MDC). The parts studied must be from production tooling, gauging, process, materials and

operators at the production intended site.

13.2 Unless otherwise approved by the appropriate Magna Mirrors SQA representative, a 100 part minimum study

has been conducted with at least 25 subgroups containing consecutively produced parts from a 300-piece or larger

run. Each subgroup should be consecutive or at short intervals & the time-order relationship maintained. This

applies per process stream (i.e. cavity).

13.3 (Variable Studies) The studies have all been properly displayed on a Control Chart and demonstrate process

control.

13.4 (Variable Studies) Process Potential has been calculated correctly for each study. Process Control is

demonstrated and Ppk > 1.67.

13.5 (Variable Studies) For each study not in control or with a Ppk < 1.67 a Corrective Action Plan with timing has

been submitted and approved by Magna Mirrors SQA.

13.6 (Attribute Studies) Attribute studies showing a defect percent >0 must be approved with the appropriate

Magna Mirrors SQA representative.

Location and Doc.#: file:///conversion/tmp/activity_task_scratch/579376411.xls

Sheet: MDNQT1017

Attachment to AWI 3-15-SQA-007

Form Rev. Date: 4/6/10

Page 4 of 5

SECTION 14 – MEASUREMENT SYSTEM STUDIES (R&R)

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

14.1 A repeatability and reproducibility (R & R) study has been performed for all control items identified on the

Control Plan.

14.2 Methods conform to those described in the AIAG Measurement Systems Analysis Reference Manual.

For variable gage studies, the ANOVA method must be used. (10 parts, 3 operators, and 3 trials).

Attribute gage studies should utilize 50 parts, 3 operators, and 3 trials.

14.3 Gauge error is less than or equal to 10%. Gauge error over 10% must be approved by the appropriate Magna

Donnelly SQA representative.

SECTION 15 – MISCELLANEOUS MAGNA MIRRORS SPECIFICS

Acceptable Not Acceptable Not Required

DOCUMENTATION EVALUATION CRITERIA COMMENTS

(YES) (LPA or REJ) (N/R)

15.1 A completed Team Feasibility Form is included to the proper revision level. All areas are completed, and are

feasible.

15.2 A completed and approved Magna Mirrors Newaygo packaging declaration is included. Weight, size, and

quantity information is completed. Sign off from the appropriate parties is included.

15.3 Box barcode labels are included in the package and include scannable bar codes for the part number,

quantity, and lot information. The part revision level is included on the label. Reference the Magna Mirrors

Packaging & Shipping Requirements Manual for further details.

15.4 A completed run @ rate form is submitted. If the OEM utilizes a specified format (Chrysler Process Sign-Off,

General Motors Run-at-Rate, Honda Are-You-Ready, etc.), supplier will submit the run @ rate utilizing this format. If

the OEM does not specify a format, the Magna Mirrors of America Run-at-Rate form will be utilized. A link to the

Magna Mirrors of America Run-at-Rate format is provided in Appendix A of the SQR manual or electronically via

Supplier Connection.

PPAP Status: Resubmission Due Date:

Acceptable Not Acceptable Not Acceptable

(YES) (LPA) (REJ) PPCA Number:

PPCA Expiration Date:

A Production Parts Change Authorization (PPCA) allows shipment of parts, at or above the quality level of the parts reviewed for this PPAP submission, until the expiration date as listed above. Any

parts shipped after this date will require an approved PSW or an additional deviation from Magna Mirrors. IF A PPCA IS ISSUED, IT MUST BE REFERENCED ON EACH CONTAINER UNTIL THE PPAP IS

APPROVED OR A NEW DEVIATION IS ISSUED.

LPA = With Magna Mirrors approved corrective action plan, a "Limited Production Approval" may be issued allowing temporary production shipment.

REJ = The Submission is rejected & production shipments are not authorized until corrective action is implemented.

Location and Doc.#: file:///conversion/tmp/activity_task_scratch/579376411.xls

Sheet: MDNQT1017

Attachment to AWI 3-15-SQA-007

Form Rev. Date: 4/6/10

Page 5 of 5

You might also like

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- PPAP Risk: MediumDocument8 pagesPPAP Risk: Mediumrajesh sharmaNo ratings yet

- PPAP Approval RequestDocument1 pagePPAP Approval RequestJosué PérezNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- Instructions for First Article ProcedureDocument13 pagesInstructions for First Article ProcedureConstantin PrecupNo ratings yet

- Ppap ChecklistDocument61 pagesPpap Checklistravindra erabatti100% (1)

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- Index: Spreeadshet Description PPAP Requirements of The AIAG Fourth Edition ManualDocument45 pagesIndex: Spreeadshet Description PPAP Requirements of The AIAG Fourth Edition ManualdanoninoNo ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- Bulk Material/Part Ppap Process Checklist / Approval: Required?Document32 pagesBulk Material/Part Ppap Process Checklist / Approval: Required?krds chidNo ratings yet

- Fs-Qual-006 PpapDocument15 pagesFs-Qual-006 PpapSchioppa Rodas e RodíziosNo ratings yet

- RO-RG80-00031 - Rev H, JPPAP Templates (Jabil Production Part Approval Process)Document38 pagesRO-RG80-00031 - Rev H, JPPAP Templates (Jabil Production Part Approval Process)KM MuiNo ratings yet

- L - FA - Niel T. - wk#06 - Contractors Monitoring & Measuring DeviceDocument1 pageL - FA - Niel T. - wk#06 - Contractors Monitoring & Measuring DeviceNIEL TANEDONo ratings yet

- APQP Documentation ChecklistsDocument67 pagesAPQP Documentation ChecklistsNeumar NeumannNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- Annex 1 PQ WB ProduksiDocument2 pagesAnnex 1 PQ WB ProduksirikoNo ratings yet

- Part Submission Warrant FMEADocument16 pagesPart Submission Warrant FMEASchioppa Rodas e RodíziosNo ratings yet

- Apqp FormsDocument32 pagesApqp FormsAnonymous A2jnZ5MNPxNo ratings yet

- Project Handover Check List: Page 1 of 5Document5 pagesProject Handover Check List: Page 1 of 5Mohammed Al DissoukyNo ratings yet

- VALVE TAG INDEXDocument3 pagesVALVE TAG INDEXSAKHIRAMNo ratings yet

- AC7114-4 Rev M Final EDITORIAL 2DECDocument60 pagesAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneNo ratings yet

- QA/QC Process DocumentationDocument1 pageQA/QC Process DocumentationChiheb GNo ratings yet

- NPD Procedure & Apqp FormatDocument132 pagesNPD Procedure & Apqp FormatKaramjit Singh100% (2)

- PPAP Review ChecklistDocument3 pagesPPAP Review ChecklistGeovanny HernándezNo ratings yet

- Core Tools Forms V5cDocument118 pagesCore Tools Forms V5ciocephNo ratings yet

- Copy of Docsity Formatos de Apqp Para Su Llenado y Aplicado 1Document64 pagesCopy of Docsity Formatos de Apqp Para Su Llenado y Aplicado 1Alejandro Martinez OrtegaNo ratings yet

- 4020-001A-VD-004 Rev 1 - Inspection & Test Plan (ITP) - Code1Document5 pages4020-001A-VD-004 Rev 1 - Inspection & Test Plan (ITP) - Code1BUDI HARIANTONo ratings yet

- SRG Global PPAP ChecklistDocument61 pagesSRG Global PPAP Checklistanamika tripathiNo ratings yet

- Control Plan Training GuideDocument20 pagesControl Plan Training GuidelittlekheongNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Control Plan TrainingDocument20 pagesControl Plan TrainingAbi Parilla100% (2)

- Control Plan TrainingDocument20 pagesControl Plan TrainingGAURAV SHARMANo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- APQP FormatosDocument15 pagesAPQP FormatoseddiefloresNo ratings yet

- Research Designs & Standards Organization: 1.0 Amendment HistoryDocument8 pagesResearch Designs & Standards Organization: 1.0 Amendment Historynvnrajesh123No ratings yet

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlieNo ratings yet

- Api RP 8B / Astm E709Document1 pageApi RP 8B / Astm E709engmuhmudNo ratings yet

- ITPDocument1 pageITPmaani7zeroNo ratings yet

- Internal audit checklist for hot shop operationsDocument36 pagesInternal audit checklist for hot shop operationsDhinakaran100% (1)

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- Needs and Expectations, Turtle ChartDocument1 pageNeeds and Expectations, Turtle ChartCHANDRUNo ratings yet

- 2 - 685 - PPAP PSW Submission+checklist - instructions+FAU F SPG 2430 EN 4Document8 pages2 - 685 - PPAP PSW Submission+checklist - instructions+FAU F SPG 2430 EN 4Helton MotaNo ratings yet

- Inspection Report (IR) : Key Point(s)Document3 pagesInspection Report (IR) : Key Point(s)nathan pagotoNo ratings yet

- 15.4 GPSPE CC QUA 005 Template Site Quality documentation ProcedureDocument11 pages15.4 GPSPE CC QUA 005 Template Site Quality documentation ProcedureH2gen ProjectNo ratings yet

- PS - APQP Check ListDocument15 pagesPS - APQP Check ListKristof MCNo ratings yet

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- EMD Supplier Product Approval Process (SPAPDocument14 pagesEMD Supplier Product Approval Process (SPAPDEVIKA PHULENo ratings yet

- PR0013 Rev FDocument1 pagePR0013 Rev Fkrds chidNo ratings yet

- Manufacturing Process Audit Report SummaryDocument1 pageManufacturing Process Audit Report SummaryNaresh kumarNo ratings yet

- AQPP Check List NewDocument17 pagesAQPP Check List NewSuresh KumarNo ratings yet

- Only Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Document4 pagesOnly Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Rahmat BasukiNo ratings yet

- Control Plan TRANINGDocument18 pagesControl Plan TRANINGqualityNo ratings yet

- Functional Specification: LCNC Report For MaterialDocument7 pagesFunctional Specification: LCNC Report For MaterialSUBHOJIT BANERJEENo ratings yet

- IATF ChecksheetDocument37 pagesIATF ChecksheetDhinakaran67% (3)

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- en 30 - PSWDocument1 pageen 30 - PSWBESNo ratings yet

- Api 1Document19 pagesApi 1Siddheshwarr JabagoudarNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- E9. Non-Conformity Report NCRDocument2 pagesE9. Non-Conformity Report NCRPeter IyereNo ratings yet

- Balanceo y Calculo de OperadoresDocument3 pagesBalanceo y Calculo de Operadoreskrds chidNo ratings yet

- Layered Audit Checklist ExampleDocument9 pagesLayered Audit Checklist ExampleR JNo ratings yet

- Cost Model for Data Management Center (DMCDocument63 pagesCost Model for Data Management Center (DMCkrds chidNo ratings yet

- Part Submission Warrant: Organization Manufacturing Information Customer Submittal InformationDocument1 pagePart Submission Warrant: Organization Manufacturing Information Customer Submittal Informationkrds chidNo ratings yet

- Control Plan AIAGDocument1 pageControl Plan AIAGAhmad Firdaus100% (1)

- PR0013 Rev FDocument1 pagePR0013 Rev Fkrds chidNo ratings yet

- Bulk Material/Part Ppap Process Checklist / Approval: Required?Document32 pagesBulk Material/Part Ppap Process Checklist / Approval: Required?krds chidNo ratings yet

- Dot ImageVIEWDocument61 pagesDot ImageVIEWravindra erabattiNo ratings yet

- Bulk Material Interim Approval Form: STATUS: (NR - Not Required, A - Approved, I - Interim)Document1 pageBulk Material Interim Approval Form: STATUS: (NR - Not Required, A - Approved, I - Interim)krds chidNo ratings yet

- Supplier APQP Process Training (In-Depth)Document142 pagesSupplier APQP Process Training (In-Depth)A MNo ratings yet

- Bulk Materials Requirements Checklist: Product Design and Development VerificationDocument1 pageBulk Materials Requirements Checklist: Product Design and Development Verificationkrds chidNo ratings yet

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- Bulk Materials Checklist Project RequirementsDocument1 pageBulk Materials Checklist Project RequirementsGeovanny HernándezNo ratings yet

- No. User No. Vendor Divisi ON: RefaccionesDocument42 pagesNo. User No. Vendor Divisi ON: Refaccioneskrds chidNo ratings yet

- SQD-025 PPAP ChecklistDocument7 pagesSQD-025 PPAP ChecklistMadhan RajNo ratings yet

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- Schedule and Prepare for DPAR MeetingDocument15 pagesSchedule and Prepare for DPAR Meetingkrds chidNo ratings yet

- CQI-15 Welding ProcessDocument52 pagesCQI-15 Welding ProcessAwdhesh Singh Bhadoriya100% (7)

- Schedule and Prepare for DPAR MeetingDocument15 pagesSchedule and Prepare for DPAR Meetingkrds chidNo ratings yet

- U1 VocabularyDocument6 pagesU1 VocabularyMinitaNo ratings yet

- Schedule and Prepare for DPAR MeetingDocument15 pagesSchedule and Prepare for DPAR Meetingkrds chidNo ratings yet

- SABS Standards and Their Relevance to Conveyor SpecificationsDocument17 pagesSABS Standards and Their Relevance to Conveyor SpecificationsRobert Nicodemus Pelupessy0% (1)

- GPS InspectionDocument48 pagesGPS InspectionAhmed AluoshNo ratings yet

- Lanco Solar EPC leaderDocument19 pagesLanco Solar EPC leaderShabir TrambooNo ratings yet

- SC Project Closeout Report v6Document27 pagesSC Project Closeout Report v6SateeshIngoleNo ratings yet

- RD 5000 CalibracionDocument5 pagesRD 5000 Calibracionfran reyNo ratings yet

- PassionForProcesse en 04-13Document20 pagesPassionForProcesse en 04-13Mutas MattaNo ratings yet

- Universiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603Document4 pagesUniversiti Teknologi Mara Odl Test 1: Confidential 1 EM/ MAY 2020/MEM603000No ratings yet

- Gen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFDocument18 pagesGen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFMGrace P. VergaraNo ratings yet

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- Management Science PDFDocument131 pagesManagement Science PDFAngela Lei SanJuan BucadNo ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- ERA News Mar 23 - Final - 0Document10 pagesERA News Mar 23 - Final - 0Băltoiu Son AlisaNo ratings yet

- Filipinism 3Document3 pagesFilipinism 3Shahani Cel MananayNo ratings yet

- DNV OS-B101 Metallic MaterialsDocument48 pagesDNV OS-B101 Metallic MaterialsBoni Luck100% (1)

- RK271007 AN RXSF 1Document2 pagesRK271007 AN RXSF 1Ahmed FaragNo ratings yet

- Dur - Ernakulam ReportDocument141 pagesDur - Ernakulam ReportArun SasiNo ratings yet

- Bee Unit-IiDocument98 pagesBee Unit-IiHemant Ingale100% (1)

- Huawei Technologies Network Router B681Document12 pagesHuawei Technologies Network Router B681Eduardo Vaz RibeiroNo ratings yet

- Creative Commons Attribution-Noncommercial-Share Alike 3.0 LicenseDocument4 pagesCreative Commons Attribution-Noncommercial-Share Alike 3.0 LicenseAnindito W WicaksonoNo ratings yet

- SMAN52730 - Wiring Diagram B11RaDocument58 pagesSMAN52730 - Wiring Diagram B11RaJonathan Nuñez100% (1)

- Abdul Jabbar (Mechanical Engineer) AGROFEED KSADocument4 pagesAbdul Jabbar (Mechanical Engineer) AGROFEED KSAftimum1No ratings yet

- Identifying The Orders of AR and MA Terms in An ARIMA ModelDocument11 pagesIdentifying The Orders of AR and MA Terms in An ARIMA ModelNeha GillNo ratings yet

- HYDRAULICSDocument1 pageHYDRAULICSOrland Son FactorNo ratings yet

- LPDocument5 pagesLPHeizyl ann VelascoNo ratings yet

- Jhamuna Tower Design DataDocument15 pagesJhamuna Tower Design DataArindam RoyNo ratings yet

- Günter Fella: Head of Purchasing AutomotiveDocument2 pagesGünter Fella: Head of Purchasing AutomotiveHeart Touching VideosNo ratings yet

- Certificate of Incorporation Phlips India LimitedDocument1 pageCertificate of Incorporation Phlips India LimitedRam AgarwalNo ratings yet

- Surveying - Mcqs On Unit I - SJMDocument6 pagesSurveying - Mcqs On Unit I - SJMKalyani ingole100% (1)

- Madd Powerpoint 1Document17 pagesMadd Powerpoint 1api-457366947No ratings yet

- ouchureIC 7000Document4 pagesouchureIC 7000iti_na8567No ratings yet