100% found this document useful (2 votes)

3K views20 pagesControl Plan Training

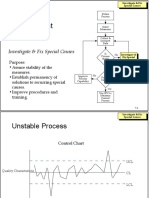

The document discusses control plans, which are used to control risks identified in a Process FMEA by defining control methods for process and product characteristics. An objective of the training is to understand how to develop a control plan by linking each step, such as defining specifications, measurement techniques, and reaction plans, to the relevant FMEA. A control plan is a systematic way to control a process and verify that defined steps are followed.

Uploaded by

littlekheongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

3K views20 pagesControl Plan Training

The document discusses control plans, which are used to control risks identified in a Process FMEA by defining control methods for process and product characteristics. An objective of the training is to understand how to develop a control plan by linking each step, such as defining specifications, measurement techniques, and reaction plans, to the relevant FMEA. A control plan is a systematic way to control a process and verify that defined steps are followed.

Uploaded by

littlekheongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd