Professional Documents

Culture Documents

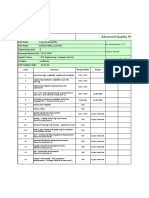

PR0013 Rev F

Uploaded by

krds chidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PR0013 Rev F

Uploaded by

krds chidCopyright:

Available Formats

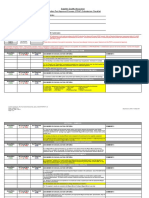

PPAP REQUIREMENT CHECKLIST

All items must comply with latest applicable AIAG manual editions unless specifically listed below.

Part Number / Revision: SDE:

Design Record / Revision: Location:

Date: Phone / Email:

Submission Level: 1 2 3 4 5 PPAP Due Date:

Submission

Required

Requirement Quantity and Instructions Special Requirement Check-Off

if checked

Date

1. Warrant Letter

2. Bulk Material Checklist

3. Design Record Ballooned SDI/Daicel drawing.

Include RFA for items not meeting specification. RFA

4. Engineering Change Documents

should be submitted prior to PPAP submission.

5. Customer Engineering Approval

6. DFMEA

7. Process Flow

8. PFMEA

9. Control Plan

At a minimum, shall represent all critical and major

10. Measurement Systems Analysis

characteristics.

Minimum of five (5) parts. All dimensions and notes shall

be measured and show compliance, including measurement

11. Dimensional Results method used. If the part is from more than one cavity, mold,

tool, die, or production process (line, cell, machine, etc.),

data shall be taken on two parts from each.

Certificate of analysis showing compliance to material

12. Material and Performance Test

specification on drawing. Should be less than one year.

Results

Provide explanation if older than one year.

Shall be from an ISO 17025 approved lab (or registered to

ISO 9001:2008/ISO TS 16949:2002 or later with lab scope).

13. Qualified Laboratory

Should show requirement and actual results. Should be less

Documentation than one year and not expired. Provide explanation if older

than one year.

100 samples minimum unless otherwise specified.

14. Initial Process (Capability) Studies Must include data, charts and Ppk/Cpk results per

SQAM at a minimum.

15. Appearance Approval Report

16. Sample Product Refer to quantity requested on PO.

Four serialized parts, two retained at supplier and two sent to

SDI with dimensional data (see #11). If a more than one

cavity, mold, tool, die, or production process is used, one

17. Master Samples part per each is retained at the supplier and one part per each

sent to SDI. Dimensional parts can be used if measurements

were not destructive.

18. Checking Aids Drawing and MSA are required.

Description of packaging (type, quantity, etc.). Sample

19. Packaging / Sample Barcode Label

barcode label per SQAM.

20. Lot Definition and Traceability Supplier to provide definition of lot and traceability

Information system.

Submit via IMDS prior to PPAP and include approval

21. Reportable and Restricted Materials

with PPAP.

Submit for all special processes used (includes

22. AIAG Special Process Assessments

suppliers). Must be less than one year old.

23. Conflict Mineral Reporting Submit using cfsi reporting template (http://www.conflictfreesourcing.org/conflict-minerals-reporting-template/)

24. Other

Attn:

Ship parts to:

APD-PR0013 Rev. F Page 1 of 1

You might also like

- PPAP ChecklistDocument2 pagesPPAP ChecklistSudhagarNo ratings yet

- PPAP Audit Check SheetDocument12 pagesPPAP Audit Check Sheetmahesh100% (1)

- Bulk Material/Part Ppap Process Checklist / Approval: Required?Document32 pagesBulk Material/Part Ppap Process Checklist / Approval: Required?krds chidNo ratings yet

- Index: Spreeadshet Description PPAP Requirements of The AIAG Fourth Edition ManualDocument45 pagesIndex: Spreeadshet Description PPAP Requirements of The AIAG Fourth Edition ManualdanoninoNo ratings yet

- Global Supplier Quality Manual PPAP RequirementsDocument36 pagesGlobal Supplier Quality Manual PPAP Requirementsmandeep.singh0009No ratings yet

- AQPP Check List NewDocument17 pagesAQPP Check List NewSuresh KumarNo ratings yet

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- Tenneco PPAP Guidelines 2017-11-13Document50 pagesTenneco PPAP Guidelines 2017-11-13tuan mai vanNo ratings yet

- PPAP TrainingDocument40 pagesPPAP TrainingfranciscoNo ratings yet

- PPAP ChecklistDocument2 pagesPPAP ChecklistN.Palaniappan50% (2)

- Corp Sqadoc 004Document84 pagesCorp Sqadoc 004Geovanny HernándezNo ratings yet

- PPAP Sign Off Checklist (3rd Ed) : Product Submission Warrant (PSW)Document1 pagePPAP Sign Off Checklist (3rd Ed) : Product Submission Warrant (PSW)SudhaNo ratings yet

- 2 PpapDocument32 pages2 PpapVIPIN YADAVNo ratings yet

- NASCO Supplier PPAP Submission Checklist: Purpose/Special Notes: Level: 1 2 3 4 5Document7 pagesNASCO Supplier PPAP Submission Checklist: Purpose/Special Notes: Level: 1 2 3 4 5amr ahmedNo ratings yet

- Ppap Material PDFDocument7 pagesPpap Material PDFHariharan PNo ratings yet

- Number: Weight (KG)Document2 pagesNumber: Weight (KG)secretNo ratings yet

- AS9102 FormsDocument4 pagesAS9102 Formstongai100% (1)

- PPAP Review Checklist: (Reference AIAG PPAP Manual)Document3 pagesPPAP Review Checklist: (Reference AIAG PPAP Manual)Geovanny HernándezNo ratings yet

- Sr. No. Requirements: Ppap Check ListDocument3 pagesSr. No. Requirements: Ppap Check Listkamlesh kuchekarNo ratings yet

- PPAP Explained - 2021 GuideDocument12 pagesPPAP Explained - 2021 GuideMiguel RiusNo ratings yet

- This Check List Must Be Submitted To FCSD STA Before Submitting A PPAP PackageDocument2 pagesThis Check List Must Be Submitted To FCSD STA Before Submitting A PPAP Packageankit kumarNo ratings yet

- Ppap Review ChecklistDocument8 pagesPpap Review ChecklistVipin RanaNo ratings yet

- Ford Supplier PPAP ChecklistDocument5 pagesFord Supplier PPAP ChecklistRaju.PalNo ratings yet

- Ppap ChecklistDocument61 pagesPpap Checklistravindra erabatti100% (1)

- Ppap ClassDocument20 pagesPpap ClassrjzepfelNo ratings yet

- APQP Progress Report - CoversheetDocument3 pagesAPQP Progress Report - CoversheetAman AwachatNo ratings yet

- Apqp Progress Report CoversheetDocument3 pagesApqp Progress Report Coversheetponrajan1979No ratings yet

- Supplier Engagement GuidelinesDocument5 pagesSupplier Engagement GuidelinesffppxxzzNo ratings yet

- Apqp Ppap FormatsDocument66 pagesApqp Ppap Formatsjuande6940% (5)

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarNo ratings yet

- Action Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableDocument39 pagesAction Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableSanjay KumarNo ratings yet

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- Apqp Critical Supplier Status ReportDocument8 pagesApqp Critical Supplier Status ReportNeumar NeumannNo ratings yet

- Advanced Quality Planning: S.No Activities Responsibility Target Progress UpdateDocument18 pagesAdvanced Quality Planning: S.No Activities Responsibility Target Progress UpdateamrikNo ratings yet

- PPAP Checklist GenericDocument9 pagesPPAP Checklist Genericamr ahmedNo ratings yet

- Pressure Safety Valves SDRL Rev 1Document3 pagesPressure Safety Valves SDRL Rev 1salesNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- SRG Global PPAP ChecklistDocument61 pagesSRG Global PPAP Checklistanamika tripathiNo ratings yet

- Ppap WorkbookDocument80 pagesPpap WorkbookalyankaNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- Apqp Stages AIAG-1Document49 pagesApqp Stages AIAG-1Jose Antonio Santoyo RayaNo ratings yet

- PPAP FormatDocument24 pagesPPAP Formatsyisyi87No ratings yet

- F1021 PPAP Check List Instructions 04JN18Document9 pagesF1021 PPAP Check List Instructions 04JN18Sharmad TamhaneNo ratings yet

- DR Documents - Rev 7 UpdatedDocument171 pagesDR Documents - Rev 7 UpdatedRakesh SNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- NPD Procedure & Apqp FormatDocument132 pagesNPD Procedure & Apqp FormatKaramjit Singh100% (2)

- Apqp Status LogDocument1 pageApqp Status Logsathyabalaraman67% (3)

- Guideline Release Procedure-SQPDocument19 pagesGuideline Release Procedure-SQPfraspaNo ratings yet

- PPAP Check ListDocument1 pagePPAP Check Listhello2er.ajayNo ratings yet

- PPAP Requirement TrainingDocument30 pagesPPAP Requirement TrainingsarfrajNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- F Qa 48 Ppap Readiness Sheet For 0.7lDocument4 pagesF Qa 48 Ppap Readiness Sheet For 0.7lVikas RaiNo ratings yet

- Phased Ps Wwith P Pap Tracking FormDocument3 pagesPhased Ps Wwith P Pap Tracking FormKurt FinkNo ratings yet

- PIP PCDPS001-2018 Packaged Equipment Instrumentation Documentation Requirements Sheet and InstructionsDocument10 pagesPIP PCDPS001-2018 Packaged Equipment Instrumentation Documentation Requirements Sheet and Instructions刘旭No ratings yet

- ANPQP 2.1 - ChangesDocument25 pagesANPQP 2.1 - ChangeskoalaboiNo ratings yet

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Document26 pagesTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNo ratings yet

- Cooper Industries PPAP Quick ReferenceDocument1 pageCooper Industries PPAP Quick ReferenceMoraru CiprianNo ratings yet

- PS - Copy of Supplier PSODocument11 pagesPS - Copy of Supplier PSODesmond MahadeoNo ratings yet

- MDNQT1017 - SQA PPAP ChecklistDocument5 pagesMDNQT1017 - SQA PPAP Checklistkrds chidNo ratings yet

- Cost Model For Data Management Center (DMC) Main MenuDocument63 pagesCost Model For Data Management Center (DMC) Main Menukrds chidNo ratings yet

- Bulk Material Interim Approval Form: STATUS: (NR - Not Required, A - Approved, I - Interim)Document1 pageBulk Material Interim Approval Form: STATUS: (NR - Not Required, A - Approved, I - Interim)krds chidNo ratings yet

- Bulk Materials Requirements Checklist: Product Design and Development VerificationDocument1 pageBulk Materials Requirements Checklist: Product Design and Development Verificationkrds chidNo ratings yet

- No. User No. Vendor Divisi ON: RefaccionesDocument42 pagesNo. User No. Vendor Divisi ON: Refaccioneskrds chidNo ratings yet

- GP Template DPAR1Document15 pagesGP Template DPAR1krds chidNo ratings yet

- Production Part Approval Process (Ppap) Tracker - ChecklistDocument4 pagesProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidNo ratings yet

- Aida Model With ExamplesDocument9 pagesAida Model With ExamplesNaveed AhmadNo ratings yet

- Coal Geology Research ProgressDocument255 pagesCoal Geology Research ProgressTRI NOPIYANTINo ratings yet

- Lauren Gantz On - The Palm Wine Drinkard - E3W Review of BooksDocument2 pagesLauren Gantz On - The Palm Wine Drinkard - E3W Review of BooksjayasriniNo ratings yet

- Pedagogical Approachesin Teaching MAPEHDocument15 pagesPedagogical Approachesin Teaching MAPEHEhya AbetriaNo ratings yet

- 01 Right On 3 - Test 1A - Mod 1Document6 pages01 Right On 3 - Test 1A - Mod 1Biljana Nestorovska75% (12)

- Booth ProposalDocument3 pagesBooth ProposalChristian ResustaNo ratings yet

- Automatic Control - ExercisesDocument140 pagesAutomatic Control - Exerciseshasan bishNo ratings yet

- Rademacher Dropout: An Adaptive Dropout For Deep Neural Network Via Optimizing Generalization GapDocument11 pagesRademacher Dropout: An Adaptive Dropout For Deep Neural Network Via Optimizing Generalization Gapbob aaNo ratings yet

- The Enchanted StorksDocument7 pagesThe Enchanted StorksAnonymous 7Qvpgy63oNo ratings yet

- David CarpenterDocument2 pagesDavid CarpenterbobblobNo ratings yet

- HRD Multiple Choice QuestionDocument29 pagesHRD Multiple Choice QuestionHayat TarrarNo ratings yet

- Gerunds and Infinitives Exercise 28 - ENGLISH PAGEDocument2 pagesGerunds and Infinitives Exercise 28 - ENGLISH PAGEgustavo orueNo ratings yet

- 1984 Novel StudyDocument2 pages1984 Novel StudyYaxuan ZhuNo ratings yet

- QUIZ: Encircle The Letter of The Correct AnswerDocument3 pagesQUIZ: Encircle The Letter of The Correct AnswerShy Adamtreasuremaker100% (1)

- Chararacteristics of LanguageDocument2 pagesChararacteristics of LanguageMariz EntodNo ratings yet

- AcknowledgementDocument13 pagesAcknowledgementDeepak VermaNo ratings yet

- Personal Pov On StudentsDocument2 pagesPersonal Pov On Students7xnc4st2g8No ratings yet

- Book Review Assignment Book: The Da Vinci Code Group Members: Sadia Jabeen World LiteratureDocument5 pagesBook Review Assignment Book: The Da Vinci Code Group Members: Sadia Jabeen World LiteratureZone MusicNo ratings yet

- Coulmas 2009Document13 pagesCoulmas 2009Katie Bernstein0% (1)

- Module 8 Quiz Fundamentals of Global Health ResearchDocument11 pagesModule 8 Quiz Fundamentals of Global Health ResearchMohamed Abdel-AzizNo ratings yet

- CompDocument4 pagesCompAmeer JoshuaNo ratings yet

- Liste Provizorii PompieriDocument11 pagesListe Provizorii Pompieridica1041No ratings yet

- 2012 Fall IPG General Trade CatalogDocument268 pages2012 Fall IPG General Trade CatalogIndependent Publishers GroupNo ratings yet

- Material For BTS3900&BTS5900 Node Performance Counter Changes (V100R015C10SPC080 Vs V100R015C10)Document14 pagesMaterial For BTS3900&BTS5900 Node Performance Counter Changes (V100R015C10SPC080 Vs V100R015C10)klajdiNo ratings yet

- Mou (Nickel)Document16 pagesMou (Nickel)MANOJ PANNASENo ratings yet

- Cantelang Vs Medina 1979 PDFDocument5 pagesCantelang Vs Medina 1979 PDFMark Christian B. ApordoNo ratings yet

- K E-HistoryDocument3 pagesK E-HistoryLovely ReyesNo ratings yet

- Consumer Behaviour Towards Readymade Garments With Reference To ITC - Consumer Behaviour - MarketingDocument134 pagesConsumer Behaviour Towards Readymade Garments With Reference To ITC - Consumer Behaviour - MarketingarthanariNo ratings yet

- Application - For - Adjunct Faculty - COEPDocument7 pagesApplication - For - Adjunct Faculty - COEPSwapnilMahajanNo ratings yet

- Amber Gilbert Sped856 Running Assignment 1 OriginalDocument5 pagesAmber Gilbert Sped856 Running Assignment 1 Originalapi-324975660No ratings yet