100% found this document useful (1 vote)

2K views3 pagesPPAP Process for SRI Vigneshwara Forge

This document outlines Sri Vigneshwara Cold Forge's product part approval process (PAP). The PAP is required for new parts, design changes, process changes, material changes, supplier changes, and parts inactive for over 24 months. The process involves forming a cross-functional team, reviewing customer requirements, preparing and running production, recording production details, conducting process capability studies, addressing any issues, compiling the PAP package, obtaining approval signatures, and updating records. The goal is to ensure products meet customer requirements before production and delivery.

Uploaded by

rajaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views3 pagesPPAP Process for SRI Vigneshwara Forge

This document outlines Sri Vigneshwara Cold Forge's product part approval process (PAP). The PAP is required for new parts, design changes, process changes, material changes, supplier changes, and parts inactive for over 24 months. The process involves forming a cross-functional team, reviewing customer requirements, preparing and running production, recording production details, conducting process capability studies, addressing any issues, compiling the PAP package, obtaining approval signatures, and updating records. The goal is to ensure products meet customer requirements before production and delivery.

Uploaded by

rajaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

- Product Approval Procedure: Details the specific steps and responsibilities involved in the product part approval procedure.

- Product Approval Process Introduction: Introduces the purpose, scope, and references for the product part approval process, outlining criteria and guidelines.

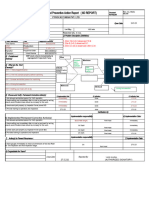

- Detailed Process Flow: Describes each step of the flowchart in detail, focusing on actions required for successful completion.

- Flow Chart Overview: Illustrates the procedural flow of the approval process through a visual flowchart, incorporating decision points and actions.