Professional Documents

Culture Documents

Ch3 SI Solution

Uploaded by

عبدالمحسن العنزيCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ch3 SI Solution

Uploaded by

عبدالمحسن العنزيCopyright:

Available Formats

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

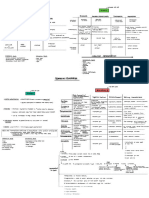

•3–1. A concrete

•8–1. concrete cylinder

cylinderhaving

havinga adiameter

diameter of of

6.00 in.mm

150 and

Load

Load (kip) Contraction

(kN) Contraction(mm)

(in.)

gauge

and length

gauge of 12of

length in.300

is tested

mm isin tested

compression. The results

in compression. of

The

the testof

results arethe

reported

test areinreported

the tableinasthe

loadtable

versus

as contraction.

load versus 00 00

Draw the stress–strain

contraction. Draw thediagram using scales

stress-strain diagram in. = 0.5

of 1 using ksi

scales 25.05.0 0.0150

0.0006

and101mm

of 2 MPa-3and

in. == 0.2110 2 in.>in. From

10 mm = 0.1(10 –3

the diagram,

) mm/mm.determine

From 47.59.5 0.0012

0.0300

approximately

the the modulusapproximately

diagram, determine of elasticity. the modulus of 82.516.5 0.0020

0.0500

elasticity. 20.5 0.0026

102.5 0.0650

25.5 0.0034

Stress and Strain: 127.530.0 0.0850

0.0040

Stress and Strain: 150.034.5 0.1000

0.0045

P dL 172.538.5 0.1125

0.0050

s5 = P (MPa)

(ksi) ee=5 dL(in./in.)

s A L (mm/mm) 192.546.5 0.0062

0.1250

A L 50.0 0.0070

232.5 0.1750

0 0 53.0 0.0075

0 0 250.0 0.1850

0.177 0.00005 265.0

1.41 0.00005

0.336

2.69 0.00010

0.00010

0.584

4.67 0.000167

0.000167

5.80

0.725 0.000217

0.000217

7.22

0.902 0.000283

0.000283

8.49 0.000333

1.061 0.000333

9.76 0.000375

1.220 0.000375

10.89 0.000417

1.362 0.000417

13.16 0.000517

1.645

14.15 0.000517

0.000583

1.768

15.00 0.000583

0.000625

1.874 0.000625

Modulus of Elasticity: From the stress–strain diagram

8.0 – -

1.31 0 0

=

Eapprox 5 = 3.275 A310

= 26.67(10 3

) MPaB ksi= 26.67 GPa Ans.

0.0003 –-0 0

0.0004

s (MPa)

16

12

(mm/mm)

92

507

SM_CH08.indd 507 4/11/11 9:54:20 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

3–2. Data taken from a stress–strain test for a ceramic are

8–2.

S(MPa)

(ksi) eP (mm/mm)

(in./in.)

given in the table. The curve is linear between the origin and

the first point. Plot the diagram, and determine the modulus 00 0 0

of elasticity and the modulus of resilience. 232.4

33.2 0.0006

0.0006

45.5

318.5 0.0010

0.0010

Modulus of Elasticity: From the stress–strain diagram 49.4

345.8 0.0014

0.0014

51.5 0.0018

360.5 0.0018

53.4 0.0022

33.2 –-00

232.4 373.8 0.0022

=

E5 55.3 A 103)3 BMPa

5 =387.3(10 ksi = 387.3 GPa Ans.

0.0006 –-0 0

0.0006

Modulus of Resilience: The modulus of resilience is equal to the area under the

420

linear portion of the stress–strain diagram (shown shaded).

1 N1 mmlb in. #

3 in lb

ut = (232.4)a b a0.0006

ut = 2(33.2) A 103 B ¢ 2b≤=¢0.0697

0.0006 N · ≤mm/mm

= 9.96 = 0.0697 MJ/m3 Ans. 350

2 mm2 mm in in. in3

280

232.4

210

140

70

e (mm/mm)

8–3.

3–3. Data taken from a stress–strain test for a ceramic are

(MPa)

S (ksi) e P(mm/mm)

(in./in.)

given in the table. The curve is linear between the origin

and the first point. Plot the diagram, and determine 00 0 0

approximately the modulus of toughness. The rupture stress 232.4

33.2 0.0006

0.0006

is sr = 53.4

373.8ksi.

MPa 318.5

45.5 0.0010

0.0010

49.4

345.8 0.0014

0.0014

51.5

360.5 0.0018

0.0018

Modulus of Toughness: The modulus of toughness is equal to the area under the

53.4 0.0022

stress–strain diagram (shown shaded). 373.8 0.0022

11 N lb mm in.

(33.2) A 103 B 2¢b(0.0004

(ut)approx == (232.4)a 2 ≤ (0.0004 + 0.0010) ¢b ≤

+ 0.0010)a

22 mm in mm in. s (MPa)

420

N lb mmin.

+ 45.5 A 103 B ¢2 b(0.0012)a

+ 318.5 a ≤ (0.0012) ¢ b ≤ 373.8

mm in2 mmin.

350

11 N lb mm in. 318.5

(7.90) A 103 B2¢b(0.0012)a

+ (55.3)a

+ ≤ (0.0012) ¢b ≤

22 mm in2 mm in. 280

232.4

11 N lb mm in.

+ (12.3) A 103 B2¢b(0.0004)a

+ (86.1)a ≤ (0.0004) ¢b ≤ 210

22 mm in2 mm in.

N #·lb

= 0.595in mm/mm3 140

= 85.0 3

Ans.

in

= 0.595 MJ/m3

70

e (mm/mm)

93

508

SM_CH08.indd 508 4/11/11 9:54:20 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

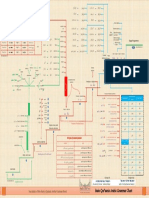

*8–4. A tension test was performed on a specimen having

*3–4. Load (kN) Elongation (mm)

an original diameter of 12.5 mm and a gauge length of

50 mm. The data are listed in the table. Plot the stress–strain 0 0

diagram, and determine approximately the modulus of 11.1 0.0175

elasticity, the ultimate stress, and the fracture stress. Use a 31.9 0.0600

37.8 0.1020

scale of 20 mm = 50 MPa and 20 mm = 0.05 mm>mm. 40.9 0.1650

Redraw the linear-elastic region, using the same stress scale 43.6 0.2490

but a strain scale of 20 mm = 0.001 mm>mm. 53.4 1.0160

62.3 3.0480

64.5 6.3500

Stress and Strain:

62.3 8.8900

58.8 11.9380

P dL

s = (MPa) e = (mm/mm)

A L

0 0

90.45 0.00035

259.9 0.00120

308.0 0.00204

333.3 0.00330

355.3 0.00498

435.1 0.02032

507.7 0.06096

525.6 0.12700

507.7 0.17780

479.1 0.23876

Modulus of Elasticity: From the stress–strain diagram

228.75(106) - 0

(E)approx = = 229 GPa Ans.

0.001 - 0

Ultimate and Fracture Stress: From the stress–strain diagram

(sm)approx = 528 MPa Ans.

(sf)approx = 479 MPa Ans.

94

509

SM_CH08.indd 509 4/11/11 9:54:21 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•8–5.

3–5. A tension test was performed on a steel specimen

Load (kN) Elongation (mm)

having an original diameter of 12.5 mm and gauge length

of 50 mm. Using the data listed in the table, plot the 0 0

stress–strain diagram, and determine approximately the 11.1 0.0175

modulus of toughness. Use a scale of 20 mm = 50 MPa and 31.9 0.0600

37.8 0.1020

20 mm = 0.05 mm>mm.

40.9 0.1650

43.6 0.2490

Stress and Strain: 53.4 1.0160

62.3 3.0480

P dL 64.5 6.3500

s = (MPa) e = (mm/mm) 62.3 8.8900

A L 58.8 11.9380

0 0

90.45 0.00035

259.9 0.00120

308.0 0.00204

333.3 0.00330

355.3 0.00498

435.1 0.02032

507.7 0.06096

525.6 0.12700

507.7 0.17780

479.1 0.23876

Modulus of Toughness: The modulus of toughness is equal to the

total area under the stress–strain diagram and can be

approximated by counting the number of squares. The total

number of squares is 187.

N m

(ut)approx = 187(25) A 106 B ¢ 2≤

a 0.025 b = 117 MJ>m3 Ans.

m m

95

510

SM_CH08.indd 510 4/11/11 9:54:21 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

3–6. A specimen

8–6. specimen isisoriginally

originally3001 ftmm

long, hashas

long, a diameter

a diameterof

0.5 12

of in.,mm,

and isandsubjected to a force

is subjected to aofforce

500 lb.

ofWhen

2.5 kN.theWhen

force

is increased

the from 500 lb

force is increased to 1800

from lb, the

2.5 kN to 9specimen

kN,, the elongates

specimen

0.009 in. 0.225

elongates Determine the modulus

mm. Determine of elasticity

the modulus for the

of elasticity for

material

the if it if

material remains linear

it remains elastic.

linear elastic.

P dL

Normal Stress and Strain: Applying s = and e = .

A L

0.5003)

2.5(10

=

s1 5 pp = 2.546 ksi

2 5 22.10 MPa

44(0.5

(12)2)

1.80

9(10 3

)

= pp

s2 5 5=79.58

9.167MPa

ksi

(0.522))

44(12

0.009

¢e = 0.225 5

∆e 5 = 0.000750

0.000750 mm/mm

in.>in.

12

300

Modulus of Elasticity:

¢s 9.167 –-22.10

79.58 2.546

E = = 8.83 A 1033) BMPa

5=76.64(10 ksi = 76.64 GPa Ans.

¢e 0.000750

0.000750

8–7.

3–7. A structural member in a nuclear reactor is made of a

zirconium alloy. If an

an axial

axial load

load ofof20 kN is to be supported

4 kip

by the member, determine its required cross-sectional area.

Use a factor of safety of 3 relative to yielding. What is the

load on the

the member

member ifif itit is

is 13 m

ft long and its elongation is

3

0.02mm?

0.5 Ezrzr = 14(10

in.? E ) ksi,sYsY= =400

100 GPa, 57.5 ksi.The

MPa. The material

material has

elastic behavior.

Allowable Normal Stress:

sy

F.S. =

sallow

57.5

400

3 =

sallow

sallow = 19.17

133.33ksi

MPa

P

sallow =

A

4

20(10 3

)

=

19.17 5

133.33

AA

2 2

A == 150

0.2087

mmin = 0.209 in2 Ans.

Stress–Strain Relationship: Applying Hooke’s law with

d 0.02

0.5

e = = 3

== 0.0005 mm/mm

0.000555 in.>in.

L 3 (12)

1(10 )

s == Ee 14 A 10

Ee==100(10 33

B (0.000555)

)(0.0005) = 50 MPa

= 7.778 ksi

P

Normal Force: Applying equation s = .

A

P ==sA

P sA= =50(150) = 7500 N== 1.62

7.778 (0.2087) kip

7.5 kN Ans.

96

511

SM_CH08.indd 511 4/11/11 9:54:21 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

*3–8.

*8–8. The strut is supported by a pin at C and an A-36

the wire

AB. If the

steel guy wire AB. wire has

has aa diameter

diameter of

of 0.2

5 mm,

in.,

determine how much it stretches when the distributed load A

acts on the strut.

60�

60

200 lb/ft

3.4 kN/m

B

Here, we are only interested in determining the force in wire AB. C

9 ftm

2.7

11

a + ©MC = 0; AB cos

FAB 60°(9) -– (3.4)(2.7)(0.9)

cos 60°(2.7) (200)(9)(3) = 0= 0 F AB ==3.06

FAB 600kN

lb

22

The normal stress the wire is

FAB 600 3)

3.06(10 3

sAB = = p p 22 ==19.10(10 ) psi = 19.10 ksi

155.84 MPa

4 (0.2

4 (5 ))

AAB

Since sAB 6 sy = 36

250ksi

MPa, Hooke’s

, Hooke’s Lawcan

Law canbe

beapplied

applied to determine

determine the

thestrain

strain

in wire.

sAB = EPAB; 155.84 =

19.10 200(1033)e

= 29.0(10 )PAB

AB

PeAB = 0.7792(10–3

- 3) mm/mm

AB = 0.6586(10 ) in>in

9(12)3)

2.7(10

The unstretched length of the wire is LAB = == 124.71 inThus,

3117.69. . Thus,

thethe wire

wire

sin

sin 60°

60°

stretches

dAB = PAB LAB = 0.6586(10 -3

0.7792(10–3)(3117.69)

)(124.71)

2.429 mm

= 0.0821 in. Ans.

1

(3.4)(2.7) kN

2

0.9 m 1.8 m

97

512

SM_CH08.indd 512 4/11/11 9:54:22 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

•3–9. The s– P diagram for a collagen fiber bundle from

•8–9. ss(MPa)

(ksi)

which a human tendon is composed is shown. If a segment

31.50

4.50

of the Achilles

Achilles tendon

tendon at

atAAhas

hasaalength

lengthofof165

6.5mm

in. and an A

approximate cross-sectional area of 145 mm

0.229 in2, determine its 26.25

3.75

elongation if the foot supports a load of 125

625 lb,

N, which causes 21.00

3.00

a tension in the tendon of 1718.75 N.

343.75 lb. 15.75

2.25

10.50

1.50

343.75

PP 1718.75 625

=

s5 == 5= 11.85 MPa

1.50 ksi 5.25

0.75 125 N

lb

AA 0.229

145

P (mm/mm)

(in./in.)

0.05 0.10

From the graph e == 0.035

0.035mm/mm

in.>in.

d = eL = 0.035(6.5)

0.035(165) = 5.775

0.228 mm

in. Ans.

8–10 The

3–10. The stress-strain

stress–strain diagram

diagram forfor aa metal alloy having

metal alloy having an

an s (ksi)

original diameter of 0.5 in. and a gauge length of 2 in. is givenis

original diameter of 12 mm and a gauge length of 50 mm

given 105

in theinfigure.

the figure. Determine

Determine approximately

approximately the the modulus

modulus of

of elasticity for the material, the load on the specimen that

elasticity for the material, the load on the specimen that causes 90

causes yielding,

yielding, and theload

and the ultimate ultimate load the

the specimen willspecimen

support. will 75

support.

60

From the stress–strain diagram, Fig. a,

45

E 290 MPa- –00

60 ksi

== ; ; EE== 30.0(10

290 GPa3

) ksi Ans. 30

1 0.001 -

0.002 – 00

15

sy ==290 MPa su>t

60 ksi su/t==100

550ksi

GPa 0 P (in./in.)

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35

0 0.001 0.002 0.003 0.004 0.005 0.006 0.007

Thus,

604C(12

p 2 2

)] )=D 32.80(10

= 11.783kip

p

PYY ==ss

YA

YA 290[

== 4 (0.5 ) N == 32.80 kN

11.8 kip Ans.

u>t ==ss

Pu/t AA

u/tu>t = 500[

p p2

= 100

4 (12 C

4 (0.5 D

)] =262.20(103

) = 19.63 )N

kip

= = 19.6kN

62.20 kip Ans.

(MPa)

500

A

400

300

y = 290

200

E

100

1

B

0 (mm/m)

0 0.05/ 0.08/ 0.15/ 0.20/ 0.25/ 0.30/ 0.35/

0.001 0.002 0.003 0.004 0.005 0.006 0.007

Elastic Recovery

p

(a)

98

513

SM_CH08.indd 513 4/11/11 9:54:23 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

8–11.

3–11. The stress–strain diagram for a steel alloy having an s (ksi)

original diameter of 12 0.5mm and aa gauge

in. and gauge length of 50 mm

2 in. is

105

is given

given in inthe

thefigure.

figure.If Ifthe

thespecimen

specimenisisloaded

loaded until

until itit is

stressed to

to 500 MPa,determine

90 ksi, determinethe theapproximate

approximate amount

amount of 90

elastic recovery and the increase in the gauge length after it 75

is unloaded.

60

45

30

15

0 P (in./in.)

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35

0 0.001 0.002 0.003 0.004 0.005 0.006 0.007

From the stress–strain diagram Fig. a, the modulus of elasticity for the steel alloy is

E 290 MPa- –00

60 ksi

== ; EE =

= 290 GPa3) ksi

30.0(10

1 0.001 -

0.002 – 00

when the specimen is unloaded, its normal strain recovered along line AB, Fig. a,

which has a gradient of E. Thus

50090 500 90

MPa ksi

Elastic Recovery = = =

Elastic Recovery 3 3

= 0.001724 mm/mm

= 0.003 in>in Ans.

30.0(10

E E 290(10 ) MPa) ksi

Amount ofset

Thus, the permanent Elastic

is Recovery = 0.001724(50 mm) = 0.0862 mm Ans.

PP = 0.05 -

Thus, the permanent set0.003

is = 0.047 in>in

Then, the increase in gauge length is – 0.001724 = 0.078276 mm/mm

eP = 0.08

Then, the ¢L = PPL

increase = 0.047(2)

in gauge length= is0.094 in Ans.

∆L = ePL = 0.078276(50 mm) = 3.91379 mm Ans.

(MPa)

500

A

400

300

200

E

100

1

B

0 (mm/mm)

0 0.05/ 0.08/ 0.15/ 0.20/ 0.25/ 0.30/ 0.35/

0.001 0.002 0.003 0.004 0.005 0.006 0.007

Elastic Recovery

p

(a)

99

514

SM_CH08.indd 514 4/11/11 9:54:24 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

*8–12. The stress–strain diagram for a steel alloy having an

*3–12.

original diameter

diameter ofof 12

0.5mm

in. and

and aagauge

gaugelength

lengthofof502mm

in.

is given in the figure. Determine approximately the modulus

of resilience and the modulus of toughness for the material.

The Modulus of resilience is equal to the area under the stress–strain diagram up to

the proportional limit.

sPL == 290 MPa PPL

60 ksi ePL= =0.002

0.001in>in.

mm/mm

Thus,

1 1 in # lb

(ui)r = C 60(103) D (0.002)

s P = [(290)](0.001) = 0.145 MPa 3

= 60.0 Ans.

2 PL PL 2 in

The modulus of toughness is equal to the area under the entire stress–strain

diagram. This area can be approximated by counting the number of squares. The

total number is 33.

38. Thus.

Thus,

lb in mm in # lb

C (ui)t D approx[(u

= i)38

t]approx

3

= 33[100

c 15(10 ) 2 d MPa]a0.04

a 0.05 b = 28.5(103

b = 132 ) MPa3 Ans.

in in mm in

s (ksi) (MPa)

105 500

90 A

400

75

60 300

PL = 290

45

200

30

E

15 100

1

B

0 P (in./in.)

0 0.050 00.100.05/ 0.200.15/

0.150.08/ 0.250.20/ 0.350.30/ 0.35/ (mm/m)

0.300.25/

0 0.001 0.002 0.003 0.004 0.005 0.006 0.007

0.001 0.002 0.003 0.004 0.005 0.006 0.007

(a)

100

515

SM_CH08.indd 515 4/11/11 9:54:24 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•8–13. A bar having a length

•3–13. A bar having a length of of

5 in.125

andmm and cross-

cross-sectional

2

sectional

area of 0.7area ofsubjected

in2 is 437.5 mmto isan

subjected

axial forceto an axial lb.

of 8000 force of

If the 8000

40 kNlb 8000

40 kNlb

40 kN. If the bar stretches 0.05 mm, determine the modulus

bar stretches 0.002 in., determine the modulus of elasticity 5 in.

125 mm

of elasticity

of the of the

material. Thematerial.

material The material has behavior.

has linear-elastic linear-elastic

behavior.

Normal Stress and Strain:

8.003)

P 40(10

P

=

s5 == =511.43

95.81ksi

MPa

0.7

A 437.5

A

dL 0.05

dL 0.002

=

e5 == = 0.000400

5 0.000400 in.>in.

mm/mm

L

L 1255

Modulus of Elasticity:

s

s 11.43

95.81 3 3

=

E5 == 5=239.525 ) ksi

28.6(10(10 ) MPa = 239.5 GPa Ans.

0.000400

ee 0.000400

3–14.

8–14. The rigid pipe is supported by a pin at A and an

A-36 steel guy wire BD. If the wire has a diameter of B

60.25

mm,in.,determine

determinehow howmuch

muchitit stretches

stretches when

when aa load

load of

P ==3600

kN acts onon

lb acts thethe

pipe.

pipe.

Here, we are only interested in determining the force in wire BD. Referring 1.2

4 ftm P

to the FBD in Fig. a

a + ©MA = 0; FBD A 45 B (0.9)

(3) -–600(6)

3(1.8) == 0

0 FFBD= =

BD 7.51500

kN lb A D

C

The normal stress developed in the wire is

0.9

3 ftm 0.9

3 ftm

3

FBD 7.5(10

1500 )

sBD = = p p 2 2 5=265.3 MPa3) psi = 30.56 ksi

30.56(10

4 (6 ) )

(0.25

ABD 4

Since sBD 6 sy = 36

250ksi , Hooke’s

MPa, Law

Hooke’s cancan

Law bebe

applied totodetermine

applied determinethe

thestrain

straininin

the wire.

sBD = EPBD; 265.3 =

30.56 29.0(103)e

= 200(10 3

)PAB

BD

- 3–3

eBD= =1.054(10

PBD 1.3265(10 ) )in.>in.

mm/mm

0.922 ++ 14.222==5ft

The unstretched length of the wire is LBD = 23 1.5=m.60

Thus, the the

in. Thus,

wire stretches

1.054(10 -–3

dBD = PBD LBD = 1.3265(10 3

)(1.5)(103)

)(60)

= 1.98975

0.0632 inmm Ans.

3 kN

0.9 m 0.9 m

101

516

SM_CH08.indd 516 4/11/11 9:54:25 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

8–15. The rigid pipe is supported by a pin at A and an

3–15.

A-36 guy wire BD. If the

BD. If the wire

wire has

hasaadiameter

diameterofof0.25

6 mm,

in., B

determine the load

load PP ifif the

the end

end CCisisdisplaced

displaced1.875

0.075mmin.

downward.

4 ftm

1.2 P

A D

C

3 ftm

0.9 3 ftm

0.9

Here, we are only interested in determining the force in wire BD. Referring to the

FBD in Fig. a

a + ©MA = 0; FBD A 45 B (0.9)

(3) -–P(6)

P(1.8)= =0 0 FBD = 2.50 P

The unstretched length for wire BD is LBD = 23 0.922 ++ 14.222==51.5 = 60

ft m. in. From

From the the

geometry shown in Fig. b, the stretched length of wire BD is

15002 2++ 0.075

LBD¿ = 260 1.87522 -− 22(60)(0.075)

(1500)(1.875)cos 143.13°==60.060017

cos143.13° 1501.500 mm

Thus, the normal strain is

LBD¿ - LBD 1501.500 – -

60.060017 1500

60

PBD = = 1.0003(10–3- )3)mm/mm

= 1.0000(10

5 in.>in.

LBD 1500

60

Then, the normal stress can be obtain by applying Hooke’s Law.

29(103)3C)[1.0000(10

sBD = EPBD = 200(10 1.0003(10 -–3

3

))]D = 200 MPa

29.01 ksi

Since sBD 6 sy = 250 MPa,

36 ksi , thethe result

result is valid.

is valid.

FBD 2.50P 2.50 P

sBD = ; 200 5 p 3) 2 = p

29.01(10 2

ABD 4 (6 ) 4 (0.25 )

P ==2261.9

569.57Nlb= =2.26

570kN

lb Ans.

LBD = 1.5 m

0.9 m 0.9 m

1.875 mm

102

517

SM_CH08.indd 517 4/11/11 9:54:26 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

*3–16. Determine the elongation of the square hollow bar

*8–16. s (MPa)

when it is subjected to the axial force P = 100 kN. If this 500

axial force is increased to P = 360 kN and released, find

the permanent elongation of the bar. The bar is made of a 600 mm

metal alloy having a stress–strain diagram which can be P

250 50 mm

approximated as shown.

5 mm

P (mm/mm)

0.00125 0.05 P

50 mm 5 mm

Normal Stress and Strain: The cross-sectional area of the hollow bar is

A = 0.052 - 0.042 = 0.9(10 - 3)m2. When P = 100 kN,

P 100(103)

s1 = = = 111.11 MPa

A 0.9(10 - 3)

From the stress–strain diagram shown in Fig. a, the slope of the straight line OA

which represents the modulus of elasticity of the metal alloy is

250(106) - 0

E = = 200 GPa

0.00125 - 0

Since s1 6 250 MPa, Hooke’s Law can be applied. Thus

s1 = Ee1; 111.11(106) = 200(109)e1

e1 = 0.5556(10 - 3) mm>mm

Thus, the elongation of the bar is

d1 = e1L = 0.5556(10 - 3)(600) = 0.333 mm Ans.

When P = 360 kN,

P 360(103)

s2 = = = 400 MPa

A 0.9(10 - 3)

From the geometry of the stress–strain diagram, Fig. a,

e2 - 0.00125 0.05 - 0.00125

= e2 = 0.0305 mm>mm

400 - 250 500 - 250

When P = 360 kN is removed, the strain recovers linearly along line BC, Fig. a,

parallel to OA. Thus, the elastic recovery of strain is given by

s2 = Eer; 400(106) = 200(109)er

er = 0.002 mm>mm

The permanent set is

eP = e2 - er = 0.0305 - 0.002 = 0.0285 mm>mm

Thus, the permanent elongation of the bar is

dP = ePL = 0.0285(600) = 17.1 mm Ans.

103

518

SM_CH08.indd 518 4/11/11 9:54:26 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

8–16.

3–16. Continued

104

519

SM_CH08.indd 519 4/11/11 9:54:26 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•8–17.

3–17. A tension test was performed on an aluminum s (ksi)

(MPa)

2014-T6 alloy specimen. The resulting stress–strain diagram

is shown in the figure. Estimate (a) the proportional limit, 70

490

(b) the modulus of elasticity, and (c) the yield strength

60

420

based on a 0.2% strain offset method.

50

350

40

280

30

210

20

140

10

70

00 PP (mm/mm)

(in./in.)

0.02

0.02 0.04

0.04 0.06

0.06 0.08

0.08 0.10

0.10

0.002

0.002 0.004

0.004 0.006

0.006 0.008

0.008 0.010

0.010

Proportional Limit and Yield Strength: From the stress–strain diagram, Fig. a,

spl ==308

44 ksi

MPa Ans.

sYY ==420

60 ksi

MPa Ans.

Modulus of Elasticity: From the stress–strain diagram, the corresponding strain for

sPL == 308

44 ksi

MPa eplepl= =0.004

is is 0.004in.>in.

mm/mm. Thus,

Thus,

44 –- 00

308 33

=

E5 5=77.0(10

11.0(10) )MPa

ksi = 77.0 GPa Ans.

0.004 –-00

0.004

Modulus of Resilience: The modulus of resilience is equal to the area under the

s (MPa)

490

420

350

280

210

140

70

e (mm/mm)

105

520

SM_CH08.indd 520 4/11/11 9:54:27 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

3–18.

8–18. A tension test was performed on an aluminum (ksi)

ss(MPa)

2014-T6 alloy specimen. The resulting stress–strain

diagram is shown in the figure. Estimate (a) the modulus of 70

490

resilience; and (b) modulus of toughness.

60

420

50

350

40

280

30

210

20

140

10

70

0 PP(mm/mm)

(in./in.)

0.02 0.04 0.06 0.08 0.10

0.002 0.004 0.006 0.008 0.010

stress–strain diagram up to the proportional limit. From the stress–strain diagram,

spl ==308

44 ksi

MPa e pl == 0.004

0.004mm/mm

in.>in.

Thus,

1 1 in # lb

A Ui B r = splepl = (308)(0.004)

(44)(103)(0.004) MJ/m33

= 88

= 0.616 Ans.

2 2 in

Modulus of Toughness: The modulus of toughness is equal to the area under the

entire stress–strain diagram. This area can be approximated by counting the number

of squares. The total number of squares is 65. Thus,

lb mm in. in # lb

C A Ui B t D approx = 65[70

65 B 10(103

MPa] 2R

) c 0.01 c 0.01 d = MJ/m

d = 45.5 3 3

6.50(10 ) Ans.

in mm in. in3

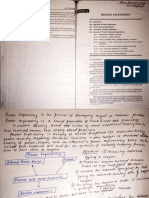

The stress–strain diagram for a bone is shown, and can be described by the equation

3–19.

8–19. The stress–strain diagram for a bone is shown, and P

can be described by the equation P = 0.45110-62 s �

0.36110-122 s3, where s is in kPa. Determine the yield s

strength assuming a 0.3% offset.

P � 0.45(10�6)s + 0.36(10�12)s3

P P

e = 0.45(10-6)s + 0.36(10-12)s3,

dP = A 0.45(10-6) + 1.08(10-12) s2 B ds

ds 1

E = 2 = = 2.22 MPa Ans.

dP 0.45(10 - 6)

s=0

106

521

SM_CH08.indd 521 4/11/11 9:54:27 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

*3–20.

*8–20. The stress–strain diagram for a bone is shown and P

can be described by the equation P = 0.45110-62 s �

0.36110-122 s3, where s is in kPa. Determine the modulus s

of toughness and the amount of elongation of a 200-mm-

long region just before it fractures if failure occurs at

P = 0.12 mm>mm .

P � 0.45(10�6)s + 0.36(10�12)s3

P P

When e = 0.12

120(103) = 0.45 s + 0.36(10-6)s3

Solving for the real root:

s = 6873.52 kPa

6873.52

LA L0

ut = dA = (0.12 - e)ds

6873.52

L0

ut = (0.12 - 0.45(10-6)s - 0.36(10-12)s3)ds

6873.52

= 0.12 s - 0.225(10-6)s2 - 0.09(10-12)s4|0

= 613 kJ>m3 Ans.

d = eL = 0.12(200) = 24 mm Ans.

107

522

SM_CH08.indd 522 4/11/11 9:54:27 AM

n = 2.73 Ans.

-6

k = 4.23(10

© 2011 Pearson Education, Inc., Upper ) NJ. All rights reserved. This materialAns.

Saddle River, is protected under all copyright laws as they currently

exist. No portion of this material may be reproduced, in any form or by any means, without permission in writing from the publisher.

•3–25. The acrylic plastic rod is 200 mm long and 15 mm in

•8–21.

diameter. If an axial load of 300 N is applied to it, determine 300 N 300 N

the change in its length and the change in its diameter.

200 mm

Ep = 2.70 GPa, np = 0.4.

P 300

s = = p 2

= 1.697 MPa

4 (0.015)

A

s 1.697(106)

elong = = = 0.0006288

E 2.70(109)

d = elong L = 0.0006288 (200) = 0.126 mm Ans.

elat = -Velong = - 0.4(0.0006288) = - 0.0002515

¢d = elatd = - 0.0002515 (15) = - 0.00377 mm Ans.

110

523

SM_CH08.indd 523 4/11/11 9:54:28 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

3–26. The short cylindrical block of 2014-T6 aluminum,

8–22. 800 lb

4 kN 800 lb

4 kN

having an

anoriginal

originaldiameter

diameterofof120.5

mm in.and

anda alength ofof

length 37.5

1.5mm,

in.,

is placed in the smooth jaws of a vise and squeezed until the

axial load applied is

is 800

4 kN.

lb.Determine

Determine(a) (a) the

the decrease

decrease in its

length and (b) its new diameter.

a)

3

PP 4(10 800 )

=

s5 == pp 2 2 5= 35.3678

4074.37MPa

psi

AA 44(12 )

(0.5)

- 4074.37

ss –35.3678

=

elong 5 == = - 0.0003844

6 5 –0.00004838

10.6(10)6)

E 73.1(10

E

= eelong

d5 L 5= –0.0004838(37.5)

long L - 0.0003844 (1.5)5=–0.0181 (10 - 3) in.

- 0.577mm Ans.

b)

-elat

y =

V = 0.35

elong

elat = -0.35 (–0.0004838)

( - 0.0003844)==0.00016933

0.00013453

¢d = elat d = 0.00013453 (0.5)= =0.002032

0.00016933(12) 0.00006727

mm

d¿ = d + ¢d = 12.002032

0.5000673 mm

in. Ans.

8–23.

3–27. The elastic portion of the stress–strain diagram for a s(MPa)

steel alloy is shown in the figure. The specimen from which

it was obtained had an original diameter of 13 mm and a 400

gauge length of 50 mm. When the applied load on the

specimen is 50 kN, the diameter is 12.99265 mm. Determine

Poisson’s ratio for the material.

Normal Stress:

P 50(103)

s = = = 376.70 Mpa

A p

(0.0132) P(mm/mm)

4 0.002

Normal Strain: From the stress–strain diagram, the modulus of elasticity

400(106)

E = = 200 GPa. Applying Hooke’s law

0.002

s 376.70(106)

elong = = = 1.8835 A 10 - 3 B mm>mm

E 200(104)

d - d0 12.99265 - 13

elat = = = - 0.56538 A 10 - 3 B mm>mm

d0 13

Poisson’s Ratio: The lateral and longitudinal strain can be related using Poisson’s

ratio.

elat - 0.56538(10 - 3)

V = - = - = 0.300 Ans.

elong 1.8835(10 - 3)

111

524

SM_CH08.indd 524 4/11/11 9:54:29 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

*8–24. The elastic portion of the stress–strain diagram for

*3–28. s(MPa)

a steel alloy is shown in the figure. The specimen from

which it was obtained had an original diameter of 13 mm 400

and a gauge length of 50 mm. If a load of P = 20 kN is

applied to the specimen, determine its diameter and gauge

length. Take n = 0.4.

Normal Stress:

P 20(103)

s = = = 150.68Mpa P(mm/mm)

A p

4 (0.0132) 0.002

Normal Strain: From the Stress–Strain diagram, the modulus of elasticity

400(106)

E = = 200 GPa. Applying Hooke’s Law

0.002

s 150.68(106)

elong = = = 0.7534 A 10 - 3 B mm>mm

E 200(109)

Thus,

dL = elong L0 = 0.7534 A 10 - 3 B (50) = 0.03767 mm

L = L0 + dL = 50 + 0.03767 = 50.0377 mm Ans.

Poisson’s Ratio: The lateral and longitudinal can be related using poisson’s ratio.

elat = - velong = - 0.4(0.7534) A 10 - 3 B

= - 0.3014 A 10 - 3 B mm>mm

dd = elat d = - 0.3014 A 10 - 3 B (13) = - 0.003918 mm

d = d0 + dd = 13 + ( -0.003918) = 12.99608 mm Ans.

•3–29. The aluminum block has a rectangular cross

•8–25. 37.51.5

mm in.

section and is subjected to an axial compressive force of 2 in.

408kN

kip 50 mm

840kip.

kN.If

If the 37.5-mm sidechanged

1.5-in. side changeditsitslength

lengthto

to 1.500132

37.5033 mm,

in.,

determine Poisson’s ratioratio and

andthe

thenewnewlength

lengthofof

thethe

502-in.

mm 8 kip

40 kN

3) ksi.

al =

side. Eal �7010(10

GPa.

753mm

in.

P

P 8 3)

40(10

=

s5 == = 21.33 ksi

5 2.667 MPa

A (50)(37.5)

A (2)(1.5)

ss –21.33

- 2.667

=

elong 5 == 3 3 5=–0.00030476

- 0.0002667

EE 70(10

10(10 ))

- 1.5

1.500132– 37.5

37.5033

=

elat 5 5=0.0000880

0.0000880

1.5

37.5

-0.0000880

–0.0000880

=

v5 = 0.289

5 0.330 Ans.

- 0.0002667

–0.00030476

h¿ = 50

h9 5 2 ++ 0.0000880(50) 50.0044 mm

0.0000880(2) =52.000176 in. Ans.

112

525

SM_CH08.indd 525 4/11/11 9:54:34 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

3–30. The block is made of titanium Ti-6A1-4V and is

8–26. y

subjected to a compression of 1.5

0.06mm along the

in. along the y axis, and its

shape is given a tilt of u = 89.7°. Determine Px, Py, and gxy.

Normal Strain:

1004mm

in. u

dLy -0.06

–1.5

ey = = 5 =–0.0150

- 0.0150 in.>in.

mm/mm Ans.

Ly 4

100

x

Poisson’s Ratio: The lateral and longitudinal strain can be related using Poisson’s ratio. 5 in.

125 mm

ex = - vey = - 0.36( - 0.0150)

= 0.00540 in. >in.

mm/mm Ans.

Shear Strain:

b = 180° - 89.7° = 90.3° = 1.576032 rad

p p

gxy = - b = - 1.576032 = - 0.00524 rad Ans.

2 2

3–31. The shear stress–strain diagram for a steel alloy is

8–27.

P P/2

shown in the figure. If a bolt having aa diameter

diameter of

of 0.75

20 mmin. P/2

is made of this material and used in the double lap joint,

determine the modulus of elasticity E and the force P

t(MPa)

t(ksi)

required to cause the material to yield. Take n = 0.3.

420

60

The shear force developed on the shear planes of the bolt can be determined by

considering the equilibrium of the FBD shown in Fig. a

g(rad)

:

+ ©F = 0; P P 0.00545

x V + V - P = 0 V = =

2 2

From the shear stress–strain diagram, the yield stress is ty = 60

420ksi . Thus,

MPa. Thus,

Vy P>2

P/2

ty = ; 60 =5

420

A pp (202)2

A

4 0.75

4 B

P == 263893.8

53.01 kipN== 53.0 kipkN

263.89 Ans.

From the shear stress–strain diagram, the shear modulus is

420

60 ksi

=

G5 5 11.01(1033))ksi

= 77.064(10 MPa 5 77.064 GPa

0.00545

0.00545

Thus, the modulus of elasticity is

E 3 E

G = ; 11.01(10

77.064) =

2(1 + y) 2(1 + 0.3)

5 200.43)GPa

E =E 28.6(10 ksi Ans.

113

526

SM_CH08.indd 526 4/11/11 9:54:38 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

*8–28.

*3–32. A shear spring is made by bonding the rubber P

annulus to a rigid fixed ring and a plug. When an axial load

P is placed on the plug, show that the slope at point y in

the rubber is dy>dr = - tan g = - tan1P>12phGr22. For small

angles we can write dy>dr = - P>12phGr2. Integrate this h

expression and evaluate the constant of integration using

the condition that y = 0 at r = ro. From the result compute

y

the deflection y = d of the plug. d

ro ri

r

y

P

Shear Stress–Strain Relationship: Applying Hooke’s law with tA = .

2p r h

tA P

g = =

G 2p h G r

dy P

= - tan g = - tan a b (Q.E.D)

dr 2p h G r

If g is small, then tan g = g. Therefore,

dy P

= -

dr 2p h G r

2p h G L r

P dr

y = -

P

y = - ln r + C

2p h G

At r = ro, y = 0

P

0 = - ln ro + C

2p h G

P

C = ln ro

2p h G

P ro

Then, y = ln

2p h G r

At r = ri, y = d

P ro

d = ln Ans.

2p h G ri

114

527

SM_CH08.indd 527 4/11/11 9:54:39 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•3–33. The support consists of three rigid plates, which

•8–29.

are connected together using two symmetrically placed

rubber pads. If a vertical force of 5 N is applied to plate

A, determine the approximate vertical displacement of C B

this plate due to shear strains in the rubber. Each pad

has cross-sectional dimensions of 30 mm and 20 mm.

Gr = 0.20 MPa. 40 mm 40 mm

V 2.5

tavg = = = 4166.7 Pa 5N

A (0.03)(0.02)

t 4166.7

g = = = 0.02083 rad

G 0.2(106)

d = 40(0.02083) = 0.833 mm Ans.

8–30.

3–34. A shear spring is made from two blocks of rubber, P

each having a height h, width b, and thickness a. The d

A

blocks are bonded to three plates as shown. If the plates

are rigid and the shear modulus of the rubber is G,

determine the displacement of plate A if a vertical load P is

applied to this plate. Assume that the displacement is small

so that d = a tan g L ag. h

P a a

Average Shear Stress: The rubber block is subjected to a shear force of V = .

2

P

V 2 P

t = = =

A bh 2bh

Shear Strain: Applying Hooke’s law for shear

P

t 2bh P

g = = =

G G 2bhG

Thus,

Pa

d = ag = = Ans.

2bhG

115

528

SM_CH08.indd 528 4/11/11 9:54:40 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

3–35. The elastic portion of the tension stress–strain

8–31. (MPa)

s (ksi)

diagram for an aluminum alloy is shown in the figure. The

specimen used for the test test has

has aa gauge

gauge length

lengthof

of50 mm

2 in. and

and a 500

70

a diameterofof0.5

diameter 12.5

in. mm.

When When the applied

the applied loadload is 45the

is 9 kip, kN,new

the

new diameter

diameter of the of specimen

the specimen is 12.48375

is 0.49935 mm. Compute

in. Compute the

the shear

shear modulus

modulus Gal forGtheal for the aluminum.

aluminum.

P (mm/mm)

(in./in.)

From the stress–strain diagram, 0.00614

s

s 500

70

=

Eal 5 =

5 11400.653ksi

5=81.433(10 ) MPa

ee 0.00614

0.00614

When specimen is loaded with a 945-kN

- kip load,

P 45(10

P 9 3)

=

s5 5= pp = 366.69

5 45.84 ksi

MPa

(0.5)2

A 44(12.5)

A

ss 45.84

366.69

=

elong 5 =

5 = 0.0040208 in.>in.

3 5 0.0045030 mm/mm

EE 11400.65

81.433(10 )

d9 0.49935–-12.5

d¿ –-d d 12.48375 0.5

=

elat 5 5= 5= –0.0013

- 0.0013 in.>in.

mm/mm

dd 0.5

12.5

- 0.0013

elatelat –0.0013

= e- 5 = -

V5 = 0.32332

5 0.28870

0.0040208

elong 0.0045030

long

EEatat 11.4(1033))

81.433(10

=

Galal 5 = = 4.31(103 3) ksi Ans.

2(1 ++ v)

2(1 5 0.32332)5 31.60(10 ) MPa 5 31.60 GPa

2(1++0.28870)

v) 2(1

*8–32. The elastic portion of the tension stress–strain

*3–36. (MPa)

s (ksi)

diagram for an aluminum alloy is shown in the figure. The

specimen used forfor the

thetest

testhas

hasaagauge

gaugelength

lengthofof

502mm

in. and a 500

70

diameter of 12.5 mm.

0.5 in. If If

thetheapplied

appliedload

loadisis10

50kip,

kN, determine

the new diameter of the specimen. The shear modulus is

Gal == 28 GPa.32 ksi.

3.8110

P (mm/mm)

(in./in.)

10 3) 0.00614

PP 50(10

= 5= pp

s5 = 407.44

5 50.9296MPa

ksi

A (0.5)22

A 44(12.5)

stress–strain diagram

From the stress-strain diagram

70

500

=

E5 11400.653ksi

5= 81.433(10 ) MPa

0.00614

0.00614

ss 407.44

50.9296

=

elong 5 == =50.0044673

0.0050033in.>in.

mm/mm

E 11400.653)

E 81.433(10

3

EE 11400.65

81.433(10 )

=

G5 ; ; 28(10 3

)5 3) =

3.8(10 v = 0.500

; v; 5 0.45416

2(1 ++v)v) + v)+ v)

2(12(1

= –ve

elat 5 - ve

long 5=–0.45416(0.0050033)

long - 0.500(0.0044673) 5= –0.002272

- 0.002234 in.>in.

¢d5= eelatlatdd5=–0.002272(12.5)

∆d - 0.002234(0.5)5=–0.0284

- 0.001117

mm in.

d9 = dd++∆d¢d

d¿ 5 5= 0.5– -

12.5 0.001117

0.0284 = 0.4989

5 12.4716 mmin. Ans.

116

529

SM_CH08.indd 529 4/11/11 9:54:41 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•8–33.

3–37. The s –P diagram for elastic fibers that make up s(psi)

s(MPa)

human skin and muscle is shown. Determine the modulus

of elasticity of the fibers and estimate their modulus of 55

385

toughness and modulus of resilience.

11

77

P(in./in.)

P(mm/mm)

1 2 2.25

77

11

38.5

E al=5 =55.5 psiMPa Ans.

22

11 11

= (2)(77)

utt 5 (2)(11)++ (385

(55++77)(2.25

11)(2.25– 2)

- 52) 134.75 psi 3

MJ/m

= 19.25 Ans.

22 22

11

= (2)(77)

utt 5 (2)(11)5= 77 psi 3

11MJ/m Ans.

22

8–34. A short cylindrical block of 6061-T6 aluminum,

3–38.

having an original diameter of 20 mm and a length of

75 mm, is placed in a compression machine and squeezed

until the axial load applied is 5 kN. Determine (a) the

decrease in its length and (b) its new diameter.

P -5(103)

a) s = = p 2

= - 15.915 MPa

4 (0.02)

A

s = E elong ; - 15.915(106) = 68.9(109) elong

elong = - 0.0002310 mm>mm

d = elong L = - 0.0002310(75) = - 0.0173 mm Ans.

elat elat

b) v = - ; 0.35 = -

elong - 0.0002310

elat = 0.00008085 mm>mm

¢d = elat d = 0.00008085(20) = 0.0016 mm

d¿ = d + ¢d = 20 + 0.0016 = 20.0016 mm Ans.

117

530

SM_CH08.indd 530 4/11/11 9:54:42 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

3–39. The rigid beam rests in the horizontal position on

8–35. 80 kN

two 2014-T6 aluminum cylinders having the unloaded lengths

x

shown. If each cylinder has a diameter of 30 mm, determine

the placement x of the applied 80-kN load so that the beam

remains horizontal. What is the new diameter of cylinder A A B

after the load is applied? nal = 0.35. 220 mm 210 mm

80x 3m

a + ©MA = 0; FB(3) - 80(x) = 0; FB = (1)

3

80(3 - x)

a + ©MB = 0; - FA(3) + 80(3 - x) = 0; FA = (2)

3

Since the beam is held horizontally, dA = dB

P

P s A

s = ; e = =

A E E

P

A PL

d = eL = a bL =

E AE

80(3 - x) 80x

3 (220) 3 (210)

dA = dB ; =

AE AE

80(3 - x)(220) = 80x(210)

x = 1.53 m Ans.

From Eq. (2),

FA = 39.07 kN

FA 39.07(103)

sA = = p 2

= 55.27 MPa

4 (0.03 )

A

sA 55.27(106)

elong = = - = - 0.000756

E 73.1(109)

elat = -velong = - 0.35( -0.000756) = 0.0002646

œ

dA = dA + d elat = 30 + 30(0.0002646) = 30.008 mm Ans.

*3–40.

*8–36. The head H is connected to the cylinder of a

compressor using six steel bolts. If the clamping force in

each bolt

bolt isis4 800

kN, lb, determine

determine the the

normalnormalstrainstrain

in theinbolts.

the L

C

3

bolts.

Each Each

bolt has bolta has a diameter

diameter of 5 of

mm.16 in.

If s If s

Y Y= =

280 40 ksi

MPa and H

3

Est ==200

29110

GPa, 2 ksi,

whatwhat is strain

is the the strain in each

in each bolt when

bolt when the

the nut is

nut is unscrewed

unscrewed so thatsothe

that the clamping

clamping force isforce is released?

released?

Normal Stress:

3

P 4(10

P 800)

=

s5 5= pp 3 2 5=203.72 MPa6< sgg 5

28.97 ksi = 280

40 ksi

MPa

A

A (5)

4 A B2

4 16

Normal Strain: Since s 6 sg, Hooke’s law is still valid.

ss 203.72

28.97

=

e5 5= 33

= 0.0010186

5 mm/mm

0.000999 in.>in. Ans.

EE 200(10)

29(10 )

If the nut is unscrewed, the load is zero. Therefore, the strain e = 0 Ans.

118

531

SM_CH08.indd 531 4/11/11 9:54:42 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

•3–41. The stone has a mass of 800 kg and center of gravity

•8–37.

P

at G. It rests on a pad at A and a roller at B. The pad is fixed 0.4 m G 0.3 m

to the ground and has a compressed height of 30 mm, a

width of 140 mm, and a length of 150 mm. If the coefficient

of static friction between the pad and the stone is ms = 0.8, B 1.25 m 1.5 m A

determine the approximate horizontal displacement of the

stone, caused by the shear strains in the pad, before the

stone begins to slip. Assume the normal force at A acts

1.5 m from G as shown. The pad is made from a material

having E = 4 MPa and n = 0.35.

Equations of Equilibrium:

a + ©MB = 0; FA(2.75) - 7848(1.25) - P(0.3) = 0 [1]

:

+ ©F = 0;

x P - F = 0 [2]

Note: The normal force at A does not act exactly at A. It has to shift due to friction.

Friction Equation:

F = ms FA = 0.8 FA [3]

Solving Eqs. [1], [2] and [3] yields:

FA = 3908.37 N F = P = 3126.69 N

Average Shear Stress: The pad is subjected to a shear force of V = F = 3126.69 N.

V 3126.69

t = = = 148.89 kPa

A (0.14)(0.15)

Modulus of Rigidity:

E 4

G = = = 1.481 MPa

2(1 + v) 2(1 + 0.35)

Shear Strain: Applying Hooke’s law for shear

t 148.89(103)

g = = = 0.1005 rad

G 1.481(106)

Thus,

dh = hg = 30(0.1005) = 3.02 mm Ans.

119

532

SM_CH08.indd 532 4/11/11 9:54:43 AM

©©2011

2010Pearson

PearsonEducation,

Education,Inc.,

Inc.,Upper

UpperSaddle

SaddleRiver,

River,NJ.

NJ.All

Allrights

rightsreserved.

reserved.This

Thismaterial

materialis isprotected

protectedunder

underallallcopyright

copyrightlaws

lawsasasthey

theycurrently

currently

exist.

exist.No

Noportion

portionofofthis

thismaterial

materialmay

maybebereproduced,

reproduced,ininany

anyform

formororbybyany

anymeans,

means,without

withoutpermission

permissionininwriting

writingfrom

fromthe

thepublisher.

publisher.

8–38.

3–42. The bar DA is rigid and is originally held in the

horizontal position when the weight W is supported from C. E

If the weight causes B to

causes B tobe

bedisplaced

displaceddownward

downward0.625

0.025mm,

in.,

determine the strain in wires DE and BC. Also, if the wires 0.93 m

ft

are made of A-36 steel and have a cross-sectional area of

in22, ,determine

1.25 mm

0.002 determinethe

theweight

weightW.

W. 2 ftm

0.6 3 ftm

0.9

D B A

0.9

3 1.5

5

==

0.025

0.625 dd

4 ftm

1.2

d == 1.04167 mm

0.0417 in

dd 0.0417

1.04167 C

eDE == == ==0.00116

0.0011574 mm/mm

in.>in. Ans.

LL 0.9(1000)

3(12)

W

sDE == Ee

EeDE 29(1033)(0.0011574)

DE==200(10 )(0.00116) ==33.56 ksiMPa

231.48

0.6 m 0.9 m

DE ==ss

FDE DEAA

DE DE= =

DE 33.56 (0.002)

231.48(1.25) = 0.0672

= 289.35 N kip

1.04167

0.625

a + ©MA = 0; –(289.35)(1.5) + 0.9(W)

- (0.0672) (5) + 3(W) == 00

W ==482.25 N = 112 lb

0.112 kip Ans. FDE = 289.35 N

W 482.25

s

sBC = W = 0.112==385.8 MPa

BC = ABC = 1.25 55.94 ksi 0.6 m 0.9 m

ABC 0.002

s BC 385.8

55.94 = 0.00193 mm/mm

eeBC == sBC = Ans.

BC E =200(103)3 = 0.00193 in.>in.

E 29 (10 )

3–43. The 8-mm-diameter bolt is made of an aluminum

8–39.

alloy. It fits through a magnesium sleeve that has an inner

diameter of 12 mm and an outer diameter of 20 mm. If the

original lengths of the bolt and sleeve are 80 mm and

50 mm

50 mm, respectively, determine the strains in the sleeve and

the bolt if the nut on the bolt is tightened so that the tension A

in the bolt is 8 kN. Assume the material at A is rigid.

Eal = 70 GPa, Emg = 45 GPa.

30 mm

Normal Stress:

P 8(103)

sb = = p 2

= 159.15 MPa

4 (0.008 )

Ab

P 8(103)

ss = = 2

= 39.79 MPa

As p

4 (0.02 - 0.0122)

Normal Strain: Applying Hooke’s Law

sb 159.15(106)

eb = = = 0.00227 mm>mm Ans.

Eal 70(109)

ss 39.79(106)

es = = = 0.000884 mm>mm Ans.

Emg 45(109)

120

533

SM_CH08.indd 533 4/11/11 9:54:44 AM

© 2011

© 2010 Pearson

Pearson Education,

Education, Inc.,

Inc., Upper

Upper Saddle

Saddle River,

River, NJ.NJ.

AllAll rights

rights reserved.

reserved. This

This material

material is is protected

protected under

under allall copyright

copyright laws

laws asas they

they currently

currently

exist.

exist. NoNo portion

portion of of this

this material

material maymay

bebe reproduced,

reproduced, in in

anyany form

form or or

byby

anyany means,

means, without

without permission

permission in in writing

writing from

from thethe publisher.

publisher.

*3–44.

*8–40. The A-36 steel wire AB has a cross-sectional area

of 10 mm2 and is unstretched when u = 45.0°. Determine A

the applied load P needed to cause u = 44.9°.

400 mm

u

400 m

m B

P

¿

LAB 400

=

sin 90.2° sin 44.9°

¿

LAB = 566.67 mm

400

LAB = = 565.69

sin 45°

¿

LAB - LAB 566.67 - 565.69

e = = = 0.001744

LAB 565.69

s = Ee = 200(109) (0.001744) = 348.76 MPa

a + ©MA = 0

P(400 cos 0.2°) - FAB sin 44.9° (400) = 0 (1)

However,

FAB = sA = 348.76(106)(10)(10 - 6) = 3.488 kN

From Eq. (1),

P = 2.46 kN Ans.

121

534

SM_CH08.indd 534 4/11/11 9:54:44 AM

You might also like

- Emotional Barometer PDFDocument5 pagesEmotional Barometer PDFGilbert Sanko100% (1)

- Hibbeler 10e CH05Document49 pagesHibbeler 10e CH05Eugene ChandNo ratings yet

- Introduction To Microsoft OfficeDocument28 pagesIntroduction To Microsoft OfficeTimes RideNo ratings yet

- Ebook PDF Calculus For Biology and Medicine 4th Edition PDFDocument41 pagesEbook PDF Calculus For Biology and Medicine 4th Edition PDFkelly.thomas740100% (30)

- 1094HW-S.M Chapter 03Document5 pages1094HW-S.M Chapter 03吳至永No ratings yet

- SM CH05 PDFDocument84 pagesSM CH05 PDFtuyaNo ratings yet

- 1094HW-S.M Chapter 04Document5 pages1094HW-S.M Chapter 04吳至永No ratings yet

- SM CH07Document72 pagesSM CH07Frisco GabrielNo ratings yet

- 1094HW-S.M Chapter 06Document6 pages1094HW-S.M Chapter 06吳至永No ratings yet

- Untitled PDFDocument87 pagesUntitled PDFasadNo ratings yet

- Filedate 5270Document36 pagesFiledate 5270rose.gang768No ratings yet

- Solution Manual For Mechanics of Materials 10th Edition Hibbeler 0134319656 9780134319650Document16 pagesSolution Manual For Mechanics of Materials 10th Edition Hibbeler 0134319656 9780134319650jessicabendergripebtsom100% (20)

- Solution Manual For Engineering Mechanics Statics 14Th Edition by Hibbeler Isbn 0133918920 978013391892 Full Chapter PDFDocument36 pagesSolution Manual For Engineering Mechanics Statics 14Th Edition by Hibbeler Isbn 0133918920 978013391892 Full Chapter PDFruby.kinkel639100% (11)

- PDF Business Ethics q4 Mod3 The Business Responsibilities and Accountabilities2 - Compress PDFDocument40 pagesPDF Business Ethics q4 Mod3 The Business Responsibilities and Accountabilities2 - Compress PDFHejarah AmpuanNo ratings yet

- Full Download Managerial Economics and Business Strategy 8th Edition Baye Test Bank PDF Full ChapterDocument36 pagesFull Download Managerial Economics and Business Strategy 8th Edition Baye Test Bank PDF Full Chapterkempenoilsjuvbu100% (18)

- Managerial Economics and Business Strategy 8th Edition Baye Test BankDocument36 pagesManagerial Economics and Business Strategy 8th Edition Baye Test Bankangelot.ayriejrbkqb100% (36)

- Duka Hand OutDocument7 pagesDuka Hand OutDannah KrystaNo ratings yet

- RCCPDocument10 pagesRCCPEunice Lyafe PanilagNo ratings yet

- Biology (Purple)Document10 pagesBiology (Purple)F4AC1 (31) WONG CHI KEI, ALICENo ratings yet

- Intrasexual Competition and Canine Dimorphism in Anthropoid PrimatesDocument9 pagesIntrasexual Competition and Canine Dimorphism in Anthropoid PrimatesCarlos PlazasNo ratings yet

- Carlos Guastavino The InterseDocument21 pagesCarlos Guastavino The InterseMaria DiazNo ratings yet

- 20th-Century GuitarDocument2 pages20th-Century GuitarSergio Calero FernándezNo ratings yet

- IFC - ODS CompletoDocument44 pagesIFC - ODS CompletoByron AndradeNo ratings yet

- Edoc - Pub EdtgdDocument262 pagesEdoc - Pub EdtgdutpalNo ratings yet

- Awesome Biology RecapDocument2 pagesAwesome Biology Recapcarolinebrongelcopti24No ratings yet

- Either,... Etc. (Explanation and Exercise)Document1 pageEither,... Etc. (Explanation and Exercise)Nudiya SalwaNo ratings yet

- British Opera in RetrospectDocument4 pagesBritish Opera in RetrospectOlimpia CristeaNo ratings yet

- Generative AI in Banking and Financial Services by Accubits CompressedDocument34 pagesGenerative AI in Banking and Financial Services by Accubits CompresseddivyanshuNo ratings yet

- Basic Qur'aanic Arabic Grammar ChartDocument1 pageBasic Qur'aanic Arabic Grammar Chartlalukhan0% (1)

- Tech Time: Helpful Tips For The Avionics TechnicianDocument2 pagesTech Time: Helpful Tips For The Avionics TechnicianJoão AlmeidaNo ratings yet

- 964491Document5 pages964491MatejaNo ratings yet

- Artera Tibială AnterioarăDocument3 pagesArtera Tibială AnterioarăMariaNo ratings yet

- Lifelinespecsheet PDFDocument2 pagesLifelinespecsheet PDFRoberto Carlos Lozano PlacenciaNo ratings yet

- Woost - Review of KapfererDocument4 pagesWoost - Review of KapfererAyon MukherjiNo ratings yet

- Mediterranean 4BR Type A Villa-Min - 2Document2 pagesMediterranean 4BR Type A Villa-Min - 2TUẤN CƯƠNG NGUYỄNNo ratings yet

- MOSP G5 Final PresentationDocument11 pagesMOSP G5 Final PresentationrakeshNo ratings yet

- Writing Skill OneDocument1 pageWriting Skill OneSylvia CHENNo ratings yet

- TQL 2012 Web PDFDocument78 pagesTQL 2012 Web PDFHaroldNo ratings yet

- Słowotwórstwo - Ćwiczenia Repetytorium Express PublishingDocument34 pagesSłowotwórstwo - Ćwiczenia Repetytorium Express PublishingzuznixyzNo ratings yet

- CAT76A-AA Metric Accessories GDocument25 pagesCAT76A-AA Metric Accessories GM. GUNERNo ratings yet

- The Law of DemandDocument5 pagesThe Law of DemandVidushi salariaNo ratings yet

- 无标题的笔记本Document3 pages无标题的笔记本QingjuanNo ratings yet

- Moonbump Brochure SpanishDocument1 pageMoonbump Brochure SpanishPierinaCeciliaVillegasCotrinaNo ratings yet

- Ilide - Info Reviwer For Materials Engineer PRDocument41 pagesIlide - Info Reviwer For Materials Engineer PRMariya MariyaNo ratings yet

- Fowler (1995) - Improving Survey Questions. Design and Evaluation.Document4 pagesFowler (1995) - Improving Survey Questions. Design and Evaluation.Katia AvilesNo ratings yet

- HandyReadingStrategiesBookmarks 11Document2 pagesHandyReadingStrategiesBookmarks 11Shabnam SulimanNo ratings yet

- Full Download Test Bank For Managing Operations Across The Supply Chain 2nd Edition by Swink PDF Full ChapterDocument7 pagesFull Download Test Bank For Managing Operations Across The Supply Chain 2nd Edition by Swink PDF Full Chapterfozinesshimself.xuqvs100% (21)

- Test Bank For Lesikars Business Communication Connecting in A Digital World 13Th Edition Rentz Lentz 0073403210 978007340321 Full Chapter PDFDocument36 pagesTest Bank For Lesikars Business Communication Connecting in A Digital World 13Th Edition Rentz Lentz 0073403210 978007340321 Full Chapter PDFsally.begley155100% (15)

- Test Bank For Lesikars Business Communication Connecting in A Digital World 13th Edition Rentz Lentz 0073403210 9780073403212Document36 pagesTest Bank For Lesikars Business Communication Connecting in A Digital World 13th Edition Rentz Lentz 0073403210 9780073403212JasonBoydgdtj100% (26)

- Test Bank For Managing Operations Across The Supply Chain 2nd Edition by SwinkDocument36 pagesTest Bank For Managing Operations Across The Supply Chain 2nd Edition by Swinkfeodshippingqors98% (49)

- An Introduction To Microsoft OfficeDocument30 pagesAn Introduction To Microsoft Officemaazali0037No ratings yet

- Ap A4Document24 pagesAp A4فردوس سليمانNo ratings yet

- PostMine RehabDocument1 pagePostMine Rehabapi-19745097No ratings yet

- WhatMeTooMeans KeyFindings CTIDocument5 pagesWhatMeTooMeans KeyFindings CTIsofiabloemNo ratings yet